The Tube Filling Machine-Still Maintain High Growth

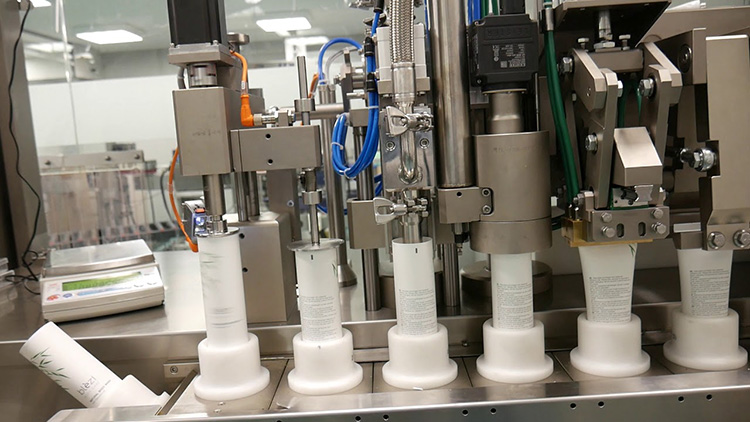

The tube filling machine is to inject various paste, viscosity fluids and other materials into the hose smoothly and accurately, and complete the work flow of hot air heating, sealing, batch number, production date, etc. in the tube.

At present, it is widely used in filling and sealing of large-diameter plastic pipes, composite pipes, and aluminum pipes in industries such as medicine, food, cosmetics, and daily chemical products.

Compared to the traditional filling, the tube filling machine adopts closed and semi-closed filling paste and liquid, the sealing has no leakage, the filling weight and capacity are consistent, and the filling, sealing and printing can be completed at one time, so the efficiency is very high.

It can be said that the filling and sealing machine is changing the action mode of the filling process and the processing method of the filling container and material under the automatic operation, which greatly improves the filling production.

Although the advantages of tube filling machines are prominent, with the fierce market competition, there is also a large gap in product quality, the product overlap rate is high, and even counterfeit and shoddy products are mixed into the market.

In order to meet the market demand, China's filling and sealing machine industry should actively get rid of the situation of product homogeneity and low technical content, and develop in the direction of multi-function, modularization, intelligent control and high precision.

In the field of the pharmaceutical industry, the overall requirements of pharmaceutical companies for this type of filling and sealing machine equipment are often high efficiency, filling, safety and stability. Therefore, the filling and sealing machines used by pharmaceutical companies have high requirements on the level of automation, and the companies have strong purchasing power for automation equipment.

With the improvement of the pharmaceutical environment, the pharmaceutical industry will usher in a good development space, and the filling and sealing machine market will maintain a stable and high growth trend.

The market competition is becoming more and more fierce, and filling and sealing machine manufacturers need to seize the market development. trend, highlighting its own advantages.

The professionals said that in the context of the changing pharmaceutical landscape, the demand and requirements of pharmaceutical companies for domestic tube filling machine equipment are constantly increasing, and the equipment should have a characteristic of flexibility.

The tube filling industry ought to take more responsibilities and solve more problems for pharmaceutical enterprises. It also needs to create more value with a set time period.

For example, to ensure that the production line of the filling and sealing machine is in good operation and that there will be no errors in the production process, so as to avoid the impact of errors and failures as much as possible, will create greater benefits for pharmaceutical companies and even patients.

At present, circular economy is expected to become the main pattern for the development of the packaging industry in the future. The recycling of packaging waste resources will be industrialized, green packaging materials will be vigorously developed and developed, and the basic packaging industry will also accelerate development.

Filling and sealing machine manufacturers consider factors such as "green", "environmental protection" and "energy saving" in the process of material selection, processing and structural design.

With the increase in the use of filling and sealing machines, the market competition has also increased, which has further stimulated the development of the equipment.

Many filling and sealing machine companies are scrambling to improve technology and develop more features about the tube filling machine , so as to enhance the performance of their own equipment, so as to gain an advantage in market competition.

In this way, it will form a good atmosphere for industry development and promote the development of the industry as a whole. The strength of an enterprise is not only related to its future survival and improvement, but also to whether the development of an enterprise can be verified.

From the mainstream perspective, due to the characteristics of economic rationality,the filling and sealing machines not only simplify the package form, structure, some related technology and equipment but also dramatically reduce the various consumption waste during the process of production and distribution.

In addition, the filling and sealing machine eliminates the occurrence of many unstable factors, thereby improving the overall efficiency, and finally reflecting the general direction of the development of the industry.

As a major polluter in the pharmaceutical industry and environmentally friendly pharmaceutical machinery has won the favor of many pharmaceutical companies.

With the country's emphasis on environmental protection issues and the gradual acceptance of the concept of environmental protection, recycled materials have become more and more popular.

Many companies also strive to carry out more research and development in this area, and have developed functional diversity, The pollution-free filling and sealing machine is well received by many customers.

Green and sustainable development is the goal of the filling and sealing machine industry, more functions will be set in the area, such as humidity, freshness, temperature, visualization, etc.

In the long run, the filling and sealing machine should meet the pursuit of developing green packaging and help more industries achieve the goals of green eating, antibacterial, sterilization, and deodorization.

Enterprises should provide timely and flexible production means for diversified products that are developing rapidly in the market. At the same time, they should continue to explore and accelerate their own technological innovation based on the actual needs of rationally simplifying packaging and advantageous packaging process methods.

In general, China's tube filling machine industry is constantly narrowing the gap with foreign products and technologies, and is developing towards high quality.

In the future, with the continuous improvement of industry requirements, it will also promote the continuous progress of filling machine technology.

Some experts predict that under the new situation, China's filling machinery manufacturing industry will accelerate its development in the four directions of high-speed production, rationalization of equipment structure, multi-functional equipment, and intelligent control.

And in technological development, it is moving towards functional diversification.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine