The Remarkable Evolution Of Pharmaceutical Bottles

Pharmaceutical bottles are possibly the largest and most extensive way of drug delivery. It won’t be wrong in saying that medicinal bottles originated two centuries ago. Pharmaceutical bottles are ideal for prescription medicines. Their special closures, labeling, and easy dosing are among the popular features you find in a pharmacy.

This guide ‘The Remarkable Evolution of Pharmaceutical Bottles’ will highlight important aspects that you must know.

1.What Is Pharmaceutical Bottle?

The pharmaceutical bottle has been in use since ancient times for dispensing potions. These bottles are the type of containers that have small neck and flat base. These are used for packaging liquid solution and suspensions like cough syrups, pain relief medication for children, antibiotics powders, etc.

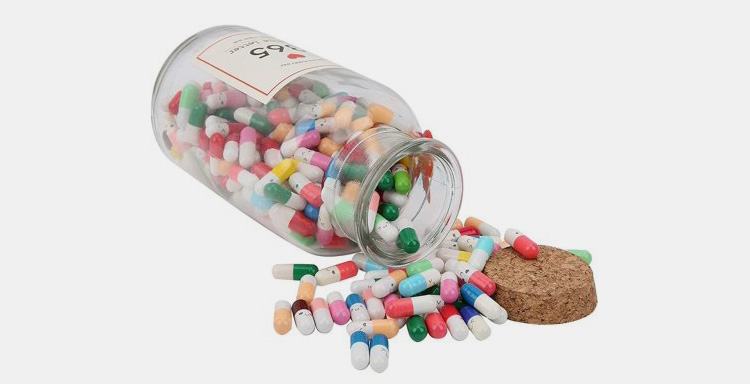

These are also utilized for delivering unit dosage like tablets and capsules all across the world but especially in North America.

There are numerous benefits of using pharmaceutical bottles for instance,

- These products guarantee the safety of the children as these bottles are design and packaged with special caps that make them child proof because these require high dexterousness and muscular strength to open.

- Accurate dosage can be administered to infants and children by using contrivances such as spoons, droppers, and measuring cups available with pharmaceutical bottle.

2.Remarkable Evolution of Pharmaceutical Bottles

The use of glass bottles for holding products has its origin in 1500 B.C. In early age, people use stone bottles for storing the medicine. But in 18th century, the glass replaced the stone as the storage material.

Design Styles

Old medicine bottles are long and cylindrical or rectangular in shape. These have short or straight necks and are 15 to 30 cm long. These have indentation for the surface of glass. Today, pharmaceutical bottles are usually short but have diverse shapes. These are labeled with paper presenting information about treatment characteristics.

From Corks to Plastic Closures

Corks were employed for the sealing of medicine bottles till 1930s. Initially, corks were cylindrical in shape and were un-tapered. These use a device called cork press for fitting the cork around the mouth of bottles. The metal screw caps with thread finishes were introduced around 1920s that ended the frequent use of cork. During 1960s, plastic replaced metals as the most popular manufacturing material for pharmaceutical bottle closures.

Hand Molding to Automatic Bottle Manufacturing Machine

Bottles were made with hand till 1880s and have “pontil” mark left behind by the glass blower. In 1830s, manufacturing of molded bottles began but these have molded joint on the side. Automatic bottle making was introduced in 1903 which revolutionized the production of pharmaceutical bottles.

3.Shapes of Pharmaceutical Bottles

There is wide variety in shapes of pharmaceutical bottle bottles. Some bottle shapes are discussed below:

Round

It has cylinder shape with round bottom.

Oblong

It is rectangular in shape but with unequal side angles.

Oval

These have elliptical shaped bodies.

Square

These have wider neck with square like body.

Triangle

The body of bottles is triangular in shape

Pinch Waist

This has broad neck about 53 mm and its body is waist shaped.

Unicorn

These have narrow opening and broad mouth for reducing leakage.

4.Material of Pharmaceutical Bottle

Many diverse kinds of material are used for the preparation of pharmaceutical bottles for instance:

Glass

It is widely employed for the purposes of manufacturing pharmaceutical bottles. About 50-60% of medicines are packed inside glass bottles.

Advantages

- Medications are easily visual in glass bottles

- This ensures the product stability by protecting them from moisture.

- These bottles can be easily cleaned and reused.

- Light sensitive drugs are enclosed inside tinted glass bottles like amber colored or green colored bottles.

- Chemical reaction between glass and inside drug does not take place consequently this lowers the production of toxic compounds.

- Glass has a high melting temperature meaning it maintains shelf life of drug even when placed at high or low temperature surrounding.

Plastic

These are organic polymers made synthetically by molding, casting or laminating. This material is commonly used in the packaging of disposable pharmaceutical containers.

Advantages

- The plastic bottles are unbreakable so prevents product spillage.

- These bottles are easy to carry because of their light weight capability.

- The plastic can be easily molded in different shape bottlers.

- These are fairly inexpensive.

- They are easily recycled.

Metal

Metal bottles are used for holding semi-solid dosage such as inhalers and aerosols. These are not suitable for storing liquid dosages as they can react with liquid drugs.

Advantages

- Metal can be molded in various designs for manufacturing of bottles.

- These bottles are impermeable to oxygen, water, and microbes.

- These bottles are printed directly on surface saving labeling cost.

5.Dimensions of Pharmaceutical Bottles

Pharmaceutical bottles available in market varying in dimensions and these usually depends upon the

- Volume of the Liquid

- Weight of Solid Dosage

Dimension, weight, and filling volume of some bottles are given in table.

| Nominal Volume (ml) | Height (mm) | Diameter (mm) |

| 1050 | 211 | 96.6 |

| 500 | 170 | 77 |

| 250 | 140 | 60 |

| 120 | 140 | 115 |

| 60 | 95 | 38 |

| 30 | 78 | 33 |

| 15 | 67.5 | 27 |

| 5 | 39.5 | 22 |

6.Color Of Pharmaceutical Bottles

The color of bottle has a significant impact on consumer sense of drug potency, its speed on action and price.

With the expansion of consumer to business market and online ordering, the color of packaging bottle has become a popular poor for identification of medication bottle.

The pharmaceutical bottles are available in several colors such as amber, red, white, green, yellow, black, blue, etc. These containers are also transparent.

If the medication is affected by light then interior of block is colored black while exterior can be of either color.

The bottle color also reflects on potency of drug. It has been thought that red and brown bottles have more potent medication than yellow and green ones. Furthermore, red and brown colored bottles are considered more expensive than green and blue ones.

Colors are associated with customer’s emotions. The visually appealing bottles are the major deciding factor in customer selection thus bringing more success to companies. This makes color an important branding element.

7.Closure of Pharmaceutical Bottles

Closure are the means by which bottle is sealed. It is important for maintaining the sterility of the products and also aid in prevention of product leakage and contamination. It keeps the bottle closed and perverse the shelf life of the drug.

There are various kinds of closures of the pharmaceutical bottles such as:

Continuous Thread closures

These closures have continuous threads that are twisted against the stem of bottle. These are most preferred kind of closures and are used in almost every pharmaceutical bottle from tablets to syrups.

Dispensing Closures

These are tightly fitted around the stem of bottle and increased the integrity of the products. They do not have usage inconvenience. Dispensing Closures are of various diameters depending upon the product and bottle size.

It is beneficial in pouring precise amount of product when the bottle is opened, consequently lowering the medication wastage.

Glass Dropper Closures

These come with plastic blub and pipette that goes inside the bottle. The medication is sucked when blub is pressed. These are used in essential oil and liquid medication bottles.

Disc top Caps

It has a much wider opening with sight indentation for opening and closing of the bottles when pushed down and up. This is used in lotion and cream bottles.

Twist top Closures

These are kinds of dispensing closures. When the caps are opened, there is a small opening inside called dropper tip and is used for pouring medicine drop by drop. These are used to seal eye drops and cream bottles.

Friction Fit Closures

Some bottles have movable lid for closure and friction is used to push open these closures.

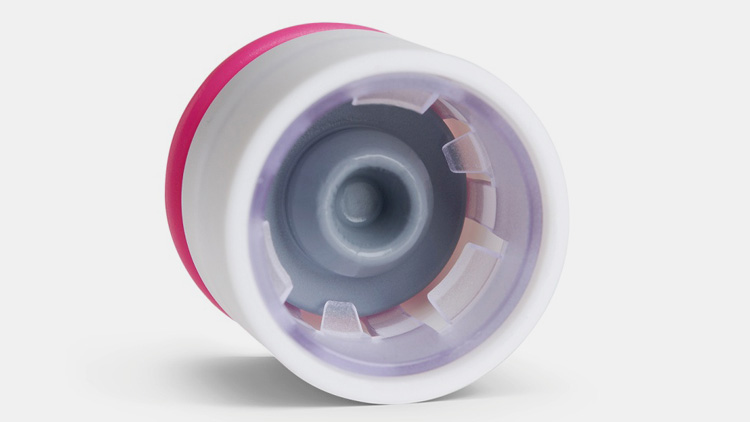

Child-resistant closures

These closures have one piece or two piece style and are closed by two different mechanisms, which prevent children from opening medication bottle. These closures stop children from consuming harmful drugs as kids are unable to open them.

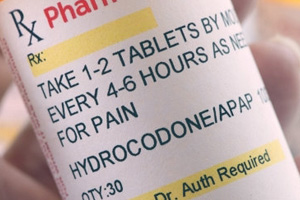

8.Labels Of Pharmaceutical Bottles

Label is written or graphical text glued around the pharmaceutical bottle. Labeling is of key importance in pharmaceutical industry as these guide the patients about usage of drugs and their warning. The drug regulatory authorities such as FDA have mandated that every pharmaceutical bottle should be labeled.

The labels on the bottles are called drug fact labels or manufacturing labels. Here are types of information displayed on label of pharmaceutical bottle.

| Generic Name of Formulation | This includes the name of drug recommended by WHO or by drug regulatory authority. |  |

| Brand Name | This is the marketing name of medication used by manufacturing companies. |  |

| Use

|

This tells patients or doctors about the quantity and frequency of medication to be taken per day. |  |

| Strength

|

It is the measure of active ingredient present in given drug |  |

| Quantity | Amount of medication in given bottle |  |

| Instruction

|

These are directions for proper storage of medication such as right temperature, humidity, and light for storing pharmaceutical bottle |  |

| Warning

|

This part tells about different conditions or diseases that makes the drug unsafe for consumption. |  |

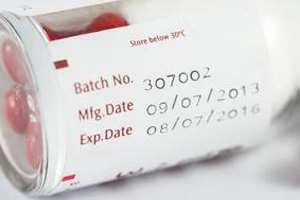

| Expiry Date | It informs about the date after which drug will lose its efficacy and potency. If expiry date of drug is passed then patient must not this that medication. |  |

| Manufacturer Information | This lists name and contacting address of manufacturing firm.

|

|

| Bar Code

|

This is represented by parallel lines of varying width and spaces. This is a means of entering drug inside computers. |  |

9.Types Of Dosage Form Stored in Pharmaceutical Bottles

Varying kind of dosages both liquids and solids are stored in pharmaceutical bottles such as:

Emulsion

These are the suspensions of fats and oils dissolved in water and are mixed with emulsifying agent. The example of suspension includes oil based vitamins and high fats supplements enterally administrated.

Magmas

These are suspension of bulky substances and are white in color. The particles settle down on bottle on standing because of their larger sizes.

Enemas

These are the rectal injection used for the treatment of chronic constipation. These liquids are inserted in rectum for cleaning the lower parts of digestive system.

Gargles

These are the aqueous alcoholic solution used for relieving sore throat. These liquid medications aid in soothing of throat thus reduce throat discomfort.

Syrup

These are viscous concentrated liquids with a sweet taste. These liquids might contain sugars.

Drops

These are liquid medication and are used with dropper for treating nasal, eye, and ear infections.

Sprays

It is a liquid solution having high vapor pressure and which is moved to nasal cavity via inhaled air.

Linctuses

It is sticky and viscous formulation having localized action for easing the throat congestion and dry cough.

Powders

These are finely divided particles mixed with water and orally taken. Antibiotics are supplied in powdered form for pediatric patients.

Capsules

Capsules encloses drug is in a gelatinous shell or natural plant polymers shell. These encapsulate pills, tablets, powders, liquids drugs inside them.

Tablets

These are the mixture of powdered active ingredients, excipients and binder. Compression is used to give tablets its compact shape. Tablets are covered with coating agents to create sleek and elegant appearance.

CONCLUSION

Pharmaceutical bottles are the diverse packaging forms. These occupy a central place for packaging bulk quantities of solid dosage and liquid medications. Old medication bottles were huge and were made with glass but today, these are made with materials like plastic and are available in diverse shapes, sizes, and colors. If you have any question in mind, Just drop us a message. Our technical staff is always there to welcome your queries 24/7/365.

Don't forget to share this post!

Automatic Labeling Machine Related Posts

Automatic Labeling Machine Related Products

Automatic Labeling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine