The Influence Of Pharmaceutical Equipment To Medicine Quality

As we all know, medicine is closely related to human’s life and health, so the relevant workers need to strictly follow the production quality management specification of medicine in the process of medicine production.

Because medicine has various types, its production modes are also slightly different, so choosing the appropriate pharmaceutical equipment is of great significance for medicine production.

Only by selecting a suitable pharmaceutical equipment, can you make sure of the quality and safety of medicine production. So this article is mainly to talk about the influence of pharmaceutical equipment on medicine quality.

First, the function of pharmaceutical equipment influence the quality of medicine production

A pharmaceutical equipment’s fabrication depends on the pharmaceutical technology, so the function needs to be consistent with the technology. If the pharmaceutical equipment can achieve a function much higher than the technical requirements, which may cause a situation of higher cost of production.

Take the actual situation of oral liquid preparation pharmaceutical equipment as an example, the clean air preparation is higher than the technical requirements in most cases in a sterilization drying oven. The procedure of sterilization drying is more complicated that will lead to the cost moving up and easily bring some risks to product’s quality.

But if the function is lower than technical requirements, which will also bring some hidden danger to production quality. For example, in the actual production of eye drops, due to the lack of a unified model for the production of plastic bottle eye drops in China, a series of different eye drops technology and equipment configurations have been produced.

At present, the function of Chinese production equipment of plastic bottle eye drops is still lower than the corresponding technological requirements, which is easy to bring hidden dangers to product quality.

According to the industry professionals reflection, at present in the medicine machine market, there are also some cases where the function of some products does not coincide with the pharmaceutical technical requirements so that the equipment has many problems in the process of medicine production.

In recent years, with the pharmaceutical industry facing higher and higher quality requirements, upgrading preparation technology and improving pharmaceutical equipment has become a trend.

Pharmaceutical equipment manufacturers need to continue to optimize the product structure and configuration according to the new pharmaceutical process requirements of customers.

Only by continuously practicing the integration and innovation concept of pharmaceutical equipment and pharmaceutical process can we ensure the quality of products to be safe, effective and uniform, and promote the improvement of pharmaceutical production level.

Secondly, the cleanliness of pharmaceutical equipment has a certain impact on the quality of drug production.

When dust or microorganisms exist in pharmaceutical equipment, it often brings the risk of contamination and cross-contamination to drugs, and brings uncertainty to the production quality of drugs.

In order to reduce the risk of contamination and cross-contamination in the drug production process, operators need to check and clean the pharmaceutical equipment regularly. They should clean the equipment regularly according to relevant regulations and requirements, such as dust cleaning and aseptic treatment.

It is understood that different pharmaceutical equipment needs to take different cleaning methods, operators should be based on the specific situation of the equipment, determine the operational cleaning method, to ensure the quality and safety of drug production.

Third, the production structure of pharmaceutical equipment will also affect the quality of drug production.

The production structure of pharmaceutical equipment includes the overall equipment work and the production line of work.

It is understood that a production structure, if complete, will help to improve the quality and speed of production of drugs, but if the production line and production structure are defective, the production efficiency will be low, and the quality of drugs will also be affected.

After talking about the impact of pharmaceutical equipment on drugs, with the increasingly stringent requirements for equipment in tablet production, how should the pharmaceutical equipment itself improve or enhance the structural design required for pharmaceutical production? Specifically, it can be carried out from the following aspects:

Facilitate material flow, displacement and cleaning

Almost all pharmaceutical equipment has direct and indirect contact with drugs, and the powder, liquid, particle, paste and so on. Therefore, in medicine preparation, the structure of the pharmaceutical equipment should be conducive to the flow, displacement, reaction, exchange and cleaning of the above-mentioned materials.

Practice has proved that we must remove and clean unfavorable materials such as convex and concave, grooves, and corners in the pharmaceutical equipment. Therefore, it is required that the structural elements of these parts should be as large as possible with rounded slopes, taper angles, etc., so as to avoid hanging belts and blocking materials.

In addition, it is extremely important to have good self-unloading and easy-to-clean properties for fixed, rotating containers and the material holding and conveying mechanisms on pharmaceutical machinery.

Attach importance to non-major component structures

The design of some non-major parts of the structure of pharmaceutical equipment is easy to ignore, which is exactly the link that needs attention. For example, the components of the parts in contact with medicine should have a high finish without attaching materials.

Among them, polishing treatment is an effective technological method. Many parts and components in pharmaceutical equipment are processed by polishing. With the application of single-sided and double-sided stainless steel polishing plate, the polishing objects are mainly stainless steel plate, casting, welding parts, etc.

The problem of insufficient polishing in manufacturing often occurs, so the external contour structure is required to be simple, so that the continuous rotating body can be easily polished in place.

Lubrication is also necessary for mechanical movement, and a considerable part of pharmaceutical equipment belongs to the table movement mode. The moving rod and moving shaft are concentrated and complex in structure, and they are all related to the production of medicines, and the equipment also has specific requirements for cleaning.

The industry professionals point out that in any case, lubricants and cleaning agents must not come into contact with the drug, including falling, infiltration, etc.

There are two solutions: one is to use the barrier of medicine, the other way is to block the lubricating part to ensure that the oil and cleaning water during lubrication and cleaning do not come into contact with pharmaceutical raw materials, intermediates, and finished pharmaceutical products.

Different pharmaceutical equipment has different structural requirements

According to industry professionals, there will be different levels of dust, heat, waste gas, water, steam, etc. generated by pharmaceutical equipment in use, which is likely to pose a threat to drug production. To solve the hidden dangers, it is mainly necessary to start from the equipment itself.

As each kind of pharmaceutical equipment produced by the pollution situation is different, the treatment scheme and structure requirements are also different.

For example, dust is more common in powder machinery, such as crushing, mixing, granulation, tablet pressing, coating, screening, drying and other processes. The dust equipment should have a dust trapping mechanism.

The dehumidifying equipment should have an exhaust ventilation device; the heat dissipation equipment should have an insulation structure.

When the pharmaceutical equipment has dustproof, water, steam, heat, oil, noise, vibration and vibration and other functions, whether single operation or movement, combination, linkage can meet the requirements of utilizing.

Don't forget to share this post!

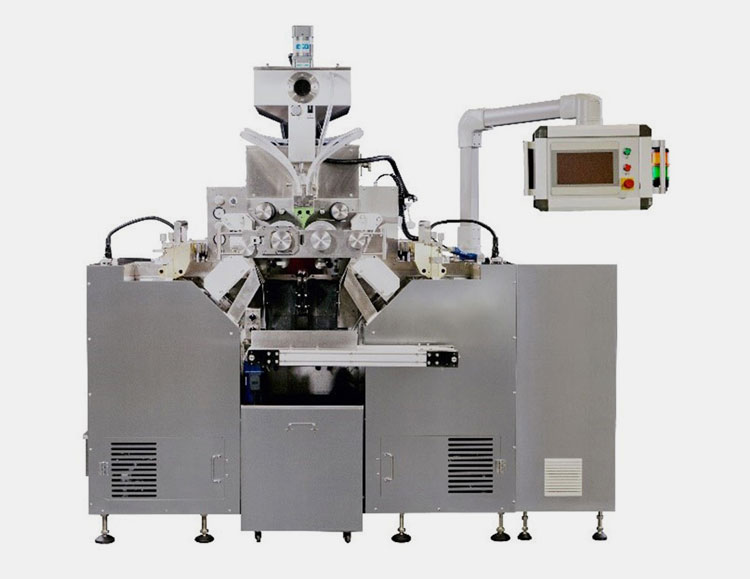

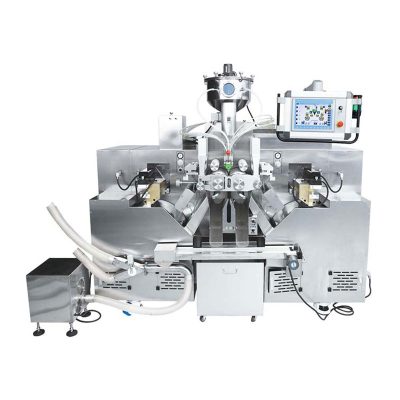

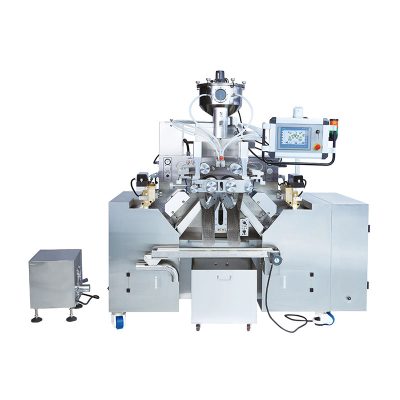

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine