Talcum Powder Packaging: The Complete FAQ Guide in 2025

Talcum powder is the first cosmetic product that welcomes newborns. When you’re shopping, you’ll always look for the best product safe for the delicate skin of babies. This is talcum powder packaging that you observe and read first. Indeed, you won't grab any product with low quality packaging!

So, How to achieve good packaging, and more likely to know the process steps involved in it. We’ll help you with this article. Excited to know more? Start reading!

1.What is Talcum Powder Packaging?

Talcum powder is a common household and industrial product. Talcum powder packaging help to protect and preserve the potency, fragrance, and freshness of powder, which increases the product's life because the powder has the ability to absorb moisture.

Talcum Powder’s Packaging involves the filling and sealing of different types of containers by the use of various packaging materials in the form of plastic bottles, plastic bags, metal containers, glass, and more.

2.How is Talcum Powder Packaging Important?

Talcum powder packaging is important in every aspect of production and routine life. Let’s see how it benefits you!

Impact of Packaging on Consumer Behaviour

According to the finding of the research study, it has been observed that packaging is the most important factor. It revealed that packaging material has had the strongest effect on products' consumer purchasing behavior. If the packaging of talcum powder looks good, customers get attracted to it.

To Protect Active Ingredients

The precautions for the use of talcum powder are clearly indicated on the packaging of products. Because it can cause irritation when inhaled that’s why it should be necessary to pack it safely and tightly.

Puncture Proof Packaging

Talcum powder containers are manufactured by using advance techniques and high density plastic to ensure the structure of the container will remain strong and puncture proof. These containers are widely used for storing powder. The inner surface of this packaging is not sticky.

Packaging Can Boost your brand

It’s obvious that with the current competition in the marketplace, manufacturing companies need to find a way to promote their product which is done by artistically designed packaging of their product which results to boost their brand. They also need to make their brand more appealing and attractive on retail shelves. Good packaging ultimately helps in skyrocketing their brand.

Easy to Transport and Supply

The manufacturing companies need packaging of talcum powder to convey their product down the supply chain with safety and deliver it to end consumers with quality, hygiene and freshness.

Easy To Use

Packaging is very essential to hold the powder safely as well as for using it. Most of the people carry talcum powder with them as it gives a soothing and refreshing fragrance to them. Especially mothers keep the baby powder with them because it helps in preventing diaper rashes, and moisture, and keeps the baby fresh.

Extend the Shelf Life

The talcum powder packaging can preserve the freshness of powder which in turn increases product shelf life. Powder also has an expiry date which is also mentioned on the packaging.

3.What are the Types of Talcum Powder Packaging?

Talcum powder packaging options are continually updating with day to day innovative options. Let's see the flexible range of it.

| Pouches and Sachets

· Pouches and sachets are utilized for storing a limited amounts of talcum powder in small size beautiful packets. They are made up of plastic as an outer layer and aluminum as the inner layer, so as the content inside can be better protected from light and the external environment. |

|

| StickPacks

Stick packs are precise packets of shape like a narrow sticks. Like sachets and pouches, stick packs are also prepared from plastic and aluminum foil to better store the talcum powder and provide customers with an accessible amount of it. |

|

| Jars And Bottles

The most common type of talcum powder packaging you would ever find is jars and bottles. These bottles are created from flexible plastic or metal with easy and movable lids that can dispense powder when rotated by hand. |

|

| Stand Up Bags

Stand up bags are prepared from hard plastic with protective sheets and aluminum foil. These bags can stand alone with the help of a lower sheet that supports it to stand. Stand up bags can hold more amount of talcum powder than sachets and stick packs. |

|

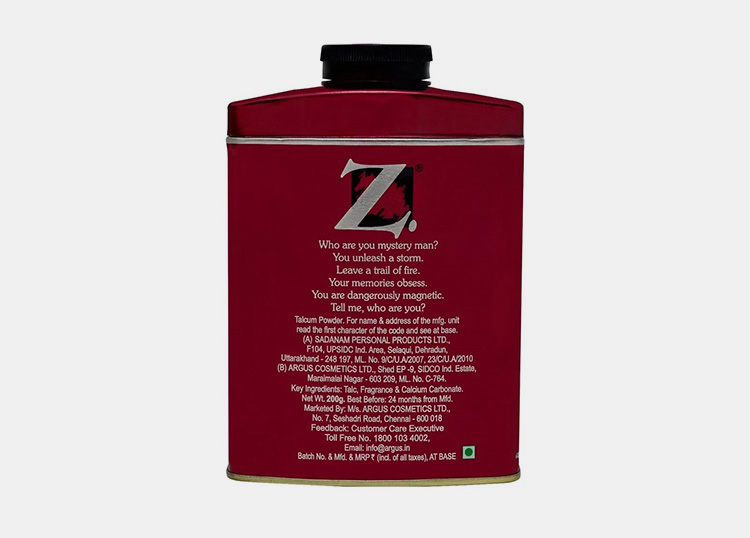

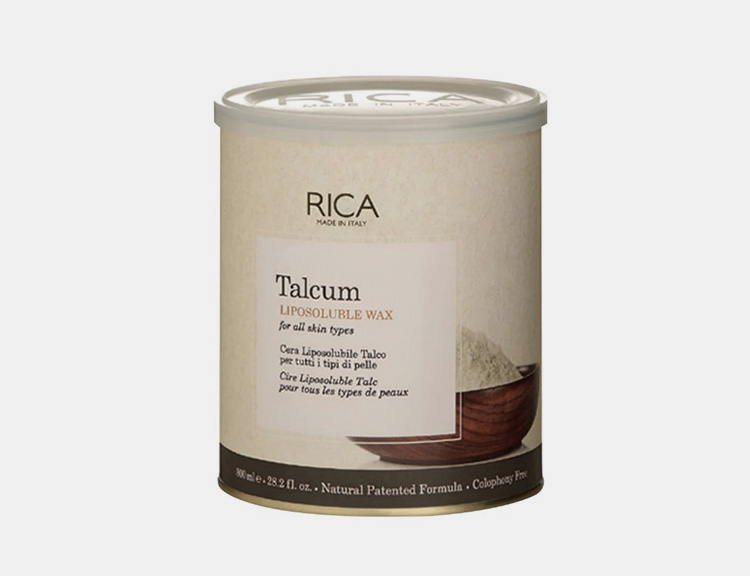

| Cans Or Canisters

Cans are hard containers with structure formed from aluminum, tin, or metal sheets. They are durable and compact which helps in the safe transportation of talcum powder. Most of reputable brands prefer using cans for delivering their goods. |

|

| A Super Sack or Bulk Bags

Sacks are large size bags with the capacity to hold a greater amount of talcum powder. The material used in preparing sacks or bulk bags varies. For instance, fabric, plastic, polymers or fiber. They are usually cheap in price while easy to carry and handle large volumes. |

|

| Bag In Box or Bulk Box

Bag in-box is a type of packaging where products are tightly sealed and packed in bags which are then placed in carton boxes for safe delivery. |

|

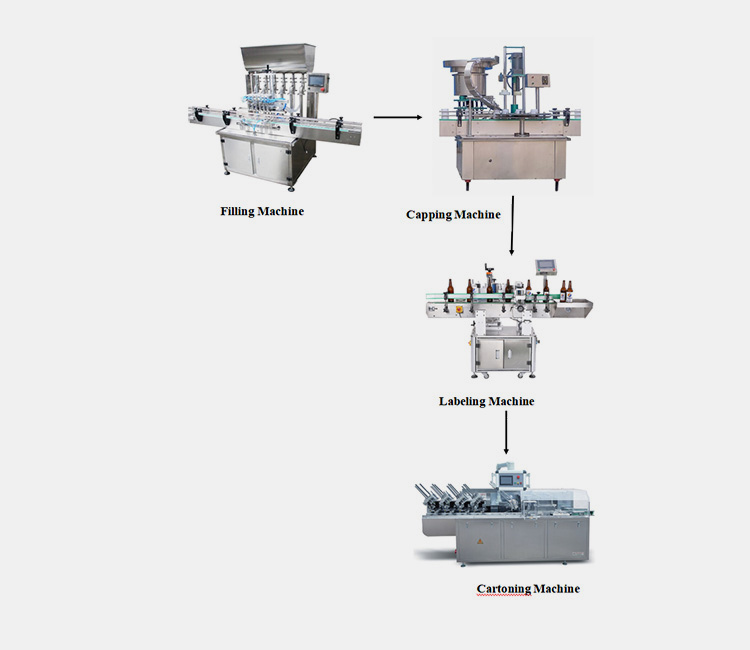

4.Which Devices Are Involved In The Talcum Powder Packaging Production Line?

Auger Filling Machine

An Auger filler machine is used for talcum powder packaging and consists of the Hopper, Auger screw, filling head, volume weight-based control system, and a drive unit.

The auger screw moves the powder from the hopper to the filling head, where it is dispensed into the container. The volumetric or weight-based control system regulates the amount of powder being dispensed to ensure accurate filling. The drive unit rotates the auger screw, moving the powder through the machine.

Capping Machine

Capping machines are commonly used in the packaging of talcum powder to secure the lid or cap on the container. These machines are designed to work with various types of caps, including screw caps, snap-on caps, and crimp-on caps.

Some common types of capping machines include chuck cappers, spindle cappers, and snap cappers. These machines can be equipped with features such as torque control, which helps to ensure consistent and secure cap application.

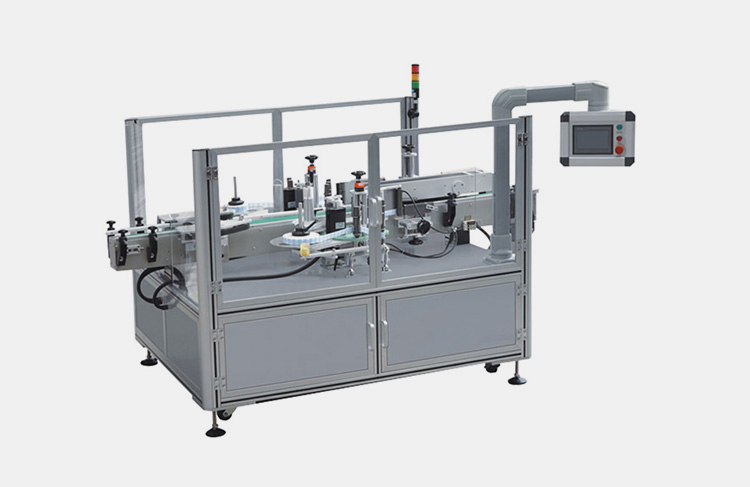

Labelling Machine

A labeling machine is used to apply product information, branding, and barcodes to the outside of the bag. There are several types of labeling machines, including pressure-sensitive, glue, and hot-stamp labeling machines.

Cartoning Machines

Cartoning machines are commonly used in the packaging of talcum powder to assemble and close cardboard boxes around the filled containers. These machines typically use a combination of mechanical and adhesive processes to form and seal the cartons.

The specific design and features of the cartoning machine will depend on factors such as the size and shape of the containers and the type of carton being used. These machines can be designed to run at high speeds and can be integrated with other packaging equipment, such as filling and capping machines, to create a complete, automated packaging line.

5.What are Different Talcum Powder Packaging Machines?

Talcum powder packaging can be achieved by using the following set of machines:

BOTTLE FILLING MACHINE

| Working Principle | Parts |

| The working principle of the machine is as follows:

Bottles are fed onto the conveyor belt and move through the various stages of the filling process. The powder filling system dispenses the talcum powder into the bottles. The capping system seals the bottles, ensuring that the powder stays inside the bottle. The labeling system applies labels to the bottles, providing product information and branding. The control panel allows the operator to set and monitor the filling parameters, ensuring that each bottle is filled with the correct amount of talcum powder. |

Powder Filling System: This component dispenses a precise amount of talcum powder into each bottle. It can be a volumetric filler, auger filler, or weigh filler.

Conveyor Belt: This component transports bottles to various stages of the filling process. Capping System: This component seals the bottles after they have been filled. Labeling System: This component applies labels to the filled bottles. Control Panel: This component allows the operator to set and monitor the filling parameters. |

POUCH PACKAGING MACHINES

| Working Principle | Parts |

| Talcum powder is poured into the supply hopper.

The auger filler measures and dispenses the powder into the pre-made pouch. The film unwinding unit supplies the film to the heating and sealing unit. The film is heated and sealed around the powder to form the pouch. The pouch is cut to the desired length by the pouch cutting unit. The sealed pouch is then conveyed to the end of the machine. The control panel monitors and adjusts the machine’s operations. |

The major components of a pouch packaging machine for talcum powder packaging are:

Supply hopper holds the talcum powder ready for dispensing. Auger filler: measures and dispenses the powder into the pouch. Film unwinding unit: supplies the film to the heating and sealing unit. Film heating and sealing unit: heats and seals the film around the powder. Pouch cutting unit: cuts the sealed pouch to the desired length. Conveying unit: transports the cut pouch to the end of the machine Control panel: monitors and controls the machine’s operations. |

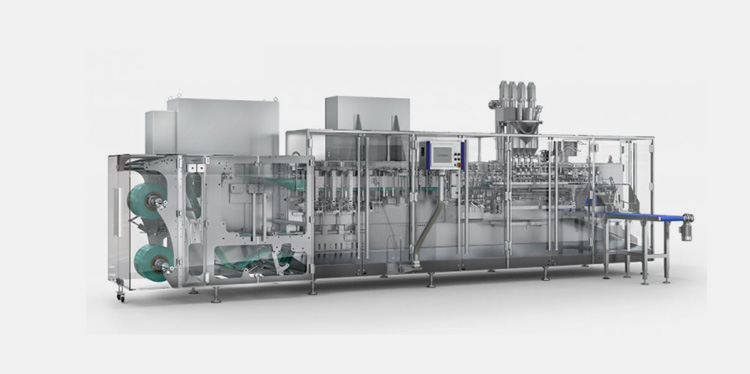

HFFS MACHINE

HFFS (Horizontal Form Fill Seal) machine is used for packaging talcum powder.

| Working Principle | Parts |

| The working principle of the HFFS machine is as followed:

The talcum powder is fed into the hopper and then transported to the forming unit through the feeding system. The forming unit forms the packaging film into a tube shape and seals the bottom end. The filled system then fills the talcum powder into the formed film pouch. The sealing unit seals the top end of the pouch, and the cutting unit cuts the pouches to the desired length. The final product is a packaged talcum powder pouch. |

The major components of an HFFS machine include: Feeding system: This consists of a hopper, screw feeder, and vibratory feeder that feed the talcum powder into the machine.Forming unit: This unit forms the packaging film into a tube shape and seals the bottom end.Filling system: This unit fills the talcum powder into the formed film pouch.Sealing unit: This unit seals the top end of the pouch and separates the filled pouches. Cutting unit: This unit cuts the pouches to the desired length. |

VFFS MACHINE

| Working Principle | Parts |

| The working principle of the VFFS machine is as followed:

The film is fed into the machine and forms a tube, which is sealed at the bottom to form a pouch. The talcum powder is then filled into the pouch and sealed at the top. The filled pouch is then cut and separated from the film roll, ready for further packaging. The entire process is controlled and managed by the controlling unit. |

Film Feeding System: Feeds the packaging film from the roll to the machine.

Sealing Unit: Consists of two heat sealing bars to make the vertical and horizontal seals of the pouch. Filling Unit: Fills the talcum powder into the pouch using a volumetric or a weigh-filling mechanism. Cutting Unit: Cuts the filled pouch from the film. Controlling Unit: Controls and manages the operations of the machine. |

6.What are the Features of the Talcum Powder Packaging Machine?

Underlying are a few characteristics that are helpful for the convenient operability of the machine:

- The machine utilizes electricity and lights to recognize the correct positioning of the bottle, powder’s filling, metering, bottle labeling, bottle capping, and then barcoding.

- Auger filling and measuring systems are used by this machine which ensures productive filling. The auger system can be replaced or modified according to the volume of fill required.

- Using alternative screw parts, this machine packs minute to ultra-fine powder particles. Different kinds of materials may be incorporated using negative vacuum pressure and the use of other devices.

- Talcum powder’s packaging machine adopts smart touch screen system which can be used to give directions and apply specifications to the process.

- Dust removal and the anti-leakage device can be installed on the machine to make sure of a hygienic environment.

7.What Materials are Used for Talcum Powder Packaging?

Various materials like plastic, glass, paper and metal containers might be employed for the packaging of talcum powder. However, these days the most common ones are as follows:

| HDPE: High Density Polyethylene It is a type of Plastic that is resistant to heat, has high tensile strength and is also recyclable. It is also impervious to moisture, insects, oil etc making it a suitable choice of plastic packaging for a wide range of products. And this is why it is used in the packaging of talcum powder’s plastic bottles, containers, and pouches. |

|

| LDPE:Low Density Polyethylene It is also utilized in packaging of talcum powder and other products as well. However, as compared to HDPE its tensile strength is low and is not regarded as sustainable as it produces greenhouse gases when exposed to sunlight. It has very good resistance against acids, alcohols and oils. |

|

| PET:Polyethylene Terephthalate It is a type of plastic packaging material that is 100% recyclable, lightweight and strong . However it is not often used for the packaging of talcum powder, but some uniquely styled bottles in the form of PET plastic powder spray bottles have been designed. |

|

| Metal This is one of the traditional packaging ways that is presented with good features, such as resistance to oils, moisture and many chemicals. Because of its excellent durability, it is a good choice for packaging. |

|

| Glass Glass bottles employed for packaging pharmaceutical powders like talcum powder or any other powder are usually composed of Borosilicate or soda-lime glass. It presents ideal properties like ideally for transportation in bulk amounts, inertness to chemicals, and resistance to light and moisture. |

|

8.What Characteristics of Powder Should be Consider for Talcum Powder Packaging?

There are few essential properties of Talcum powder that must be noted before carrying out efficient and reliable packaging.

Let’s see what those properties are:

| PHYSICAL PROPERTIES | CHEMICAL PROPERTIES | BIOLOGICAL PROPERTIES |

| The material of the packaging must not react with its product.

The product must not lose it’s integrity and efficacy owing to the type of packaging used. |

The powder should be impermeable to any sort of contaminant.

The packaging container must be able to bear enough heat if sterilization is required (might be in the case of medicated powders). The packaging container should be such that it does not allow light or moisture to pass through it. |

The product inside the container must be safe enough to be prevented from being attacked by any insects or microorganisms.

The packaging of the container must be such that it does not induce mold growth and spoil the product. |

9.What Is the Difference Between Talcum Powder Packaging And Granular Powder Packaging?

Some of the packaging variations between talcum and granular powder are as followed:

COMPOSITION

Talcum powder and granular powder are similar in terms of composition, they are separated due to their particle sizes. Talcum powder size is even less than 100 µm whereas granules are distinguished and easily visible that reach up to 1,000 µm or more. Hence talcum powder packaging requires a compact container to hold the product.

PACKAGING STYLES

Talcum powder is most often available in bottles with firm closures. Whereas granular powder has broad packaging options such as pouches, containers, bottles, jars, etc.,

PACKAGING MACHINES

Talcum powders and Granular powders are distinct in term of classes of the material although they’re the same. In particular reference talcum powders have finer sizes and easy to spread in the environment than granular ones; therefore it is highly recommended to use machines with compact and close structures. Although machines selection is the same as for granular powders.

PACKAGING SAFETY

An operator must use safety measures (PPIs) during talcum powder packaging as they are extremely finest and prone to inhale. Whereas, granular powder packaging is somewhat safer than talcum as its interaction is less significant and considered as dust-free.

10.What are the Problem and Solutions of Talcum Powder Packaging?

As other cosmetic products face some hurdles before finally being processed, manufactured and packaged so do challenges arise in talcum powder’s packaging.

| Problem | Solution |

| 1) Stability problems Talcum powder particles if exposed to moisture or degrade due to some stability issues , may form clumps together. The same goes for face powder, if it makes agglomerates it might pose difficulty in the formation of a face powder cake. |

Powders can be de-agglomerated by using processes like pulverization, milling, blending, and adding other powders or suitable liquid binders. |

| 2) Sifter Compatibility When the opening to the talcum powder bottle is not accurate according to the sifter, compatibility does not match. The size and number of orifices affect the powder’s dispensing. |

Changing the sifter in accordance with the compatibility of the product’s packaging will deliver the powder efficiently. The size and number of orifices in the cap’s opening must be accurate enough to allow the particles to pass through them smoothly. |

| 3) Selection of Applicator Providing an applicator along with talcum powder for face and for medicated powder ensures consistent application of powder on the skin surface. |

Choose the applicator for your talcum powder accordingly. It must be mentioned on the label of your packaging, that you’ve provided an applicator for customer’s satisfaction and ease. |

| 4) Stress Cracking Packaging carried out by using plastic like Low Density Polyethylene (LDPE) and materials employed for the formulation of talcum powder like some wetting agents or volatile oils may affect the plastic container by presenting a phenomenon called Stress Cracking. |

You can decide on a packaging container which is of High-Density Polyethylene (HDPE) or high quality plastic material resistant to any chemical or mechanical stress deteriorating the packing. |

Conclusion

There is no doubt, choosing the right talcum powder packaging is crucial for the production and consumer satisfaction. When making a decision for packaging, you must consider factors like product size, nature, flowability, etc., For more information and the right machine for talcum powder packaging; we suggest contacting our advisory team. AIPAK Pharmaceutical Equipment Promises to offer the right machine for your business. Message us for details Right Now.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine