Tablet Strip Packing Machine: The Complete Buying Guide In 2025

Did you see a tablet strip in the pharmacies or medical stores? Have you thought about its forming process? Packaging is not only meant for a good look and feel but has a pivotal role in product safeguarding. It provides a durable covering that shields the products from damage and also elements. In the pharmaceutical industry, it is directly attributed to the health of patients.

There are a multitude of packaging machines to seal pharmaceutical pills, such as tablets and capsules. The tablet strip packing machine is one of at work devices that has revolutionized tablet packaging. It is regarded as the magician of packaging because it generates tailored covering for each product. Furthermore, it helps manufacturers achieve success goals by exceeding their expectations in achieving higher product margins.

Whether you are a novice researcher or a professional manufacturer, this buying guide intends to equip you with all the facts about a tablet strip packing machine. So, let’s hit the hay while the sun is shining.

1.What is a tablet strip packing machine?

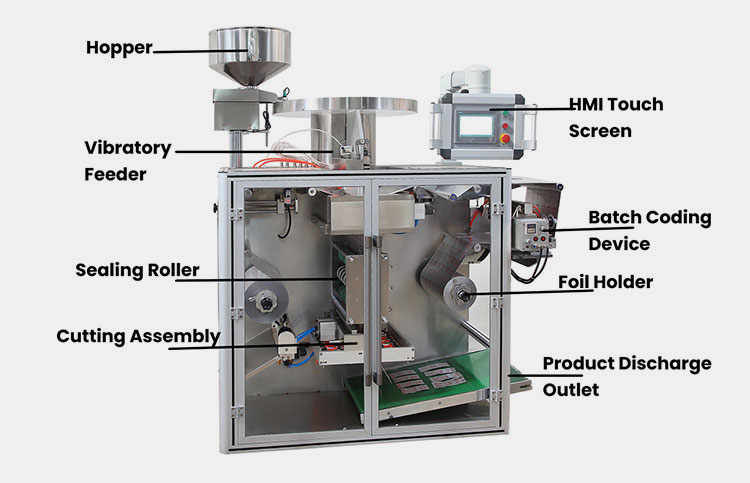

AIPAK Tablet Strip Packing Machine

Tablet strip packing is an intricate process having a series of diverse steps executed by a novel machine called a tablet strip packing machine.

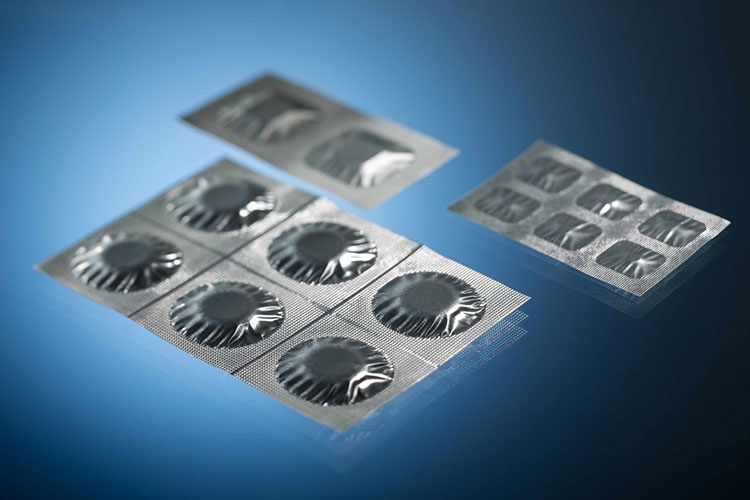

It is a high-speed and mechanical equipment that encloses different types of products (mostly tablets and capsules) in aluminum foil, paper, or plastic. It secures tablets between two web or layers of packaging foil by forming a tear-open pocket.

It manufactures opaque highly resistant packaging in which tablets are sandwiched between two sturdy layers. These products are wrapped separately in airtight and heat-sealed compartments. A single dose is separated from others by a perforation line.

2.What are the positive impacts of a tablet strip packing machine for businesses?

It is a wish for every businessman to grow and expand their business. So, they improve their production speeds by purchasing machines. A tablet strip packing machine belongs to a line of pharmaceutical machines that go beyond in impacting businesses in positive ways. For your information, here are various positive effects of this instrument:

More Product Protection

More Product Protection- Picture Courtesy: Romaco

Wrapping tablets is a failsafe way to increase their protection. Unopened products are usually at risk of degradation and contamination by the physical elements (air, moisture, and light) and biological agents. Hence, a tablet strip packing machine is utilized in the pharmaceutical sector to extend the shelf life of pills by sealing them in weather-proof barriers. You’ll also attain stability of the product by protecting it in strip packing.

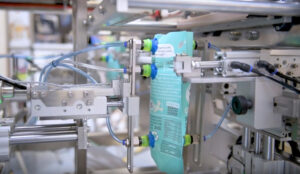

High Number of Products in the Market

High Number of Products in Market- Picture Courtesy: Romaco

You would certainly desire more and more tablets in the market. But what are ways to achieve this? One of the easiest ways to do so is by installing a tablet strip packing machine in facilities. This equipment is fabricated to increase the output capacity of the businesses through its automated loading, feeding, and offloading systems.

You can obtain more volume of packed tablets swiftly by using this device. As it operates with little human intervention, so decreases downtime.

Minimal Business Expense

Minimal Business Expense

This machine is highly favored in industrial sectors because it minimizes production expenses through diverse strategies. Above all, it reduces the need to hire a large number of workforce and by which cuts down labor expenses. Due to its consistent packaging quality, it reduces the film material wastage that is certainly caused when packed by human operators.

Finally, it is more economical for you to utilize a tablet strip packing machine than other complicated machinery because it exclusively uses aluminum foil materials. Hence, mitigating the necessity of buying more variety of materials.

Enhanced Brand Image

Enhanced Brand Image- Picture Courtesy: Romaco

If you would use the tablet strip packing machine in businesses then you’ll have highly polished and professional packing. And this is one approach to revitalizing brand image in the eyes of customers. Furthermore, the strip packs are tamper-proof, so customers can take their medication easily by knowing the safety and purity of their tablets.

More Market Reach

More Market Reach

By airtightly wrapping your tablets in the packaging, you can prolong their consumable life. In this way, tablets can be stored and distributed for longer periods. Hence, manufacturers widen their market reach by using a tablet strip packing machine. This equipment averts the likelihood of products being damaged when transported, which enables you to send your products to distinct or global markets.

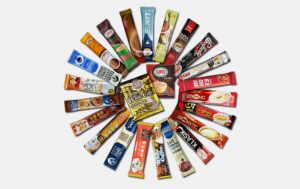

Meeting Varied Packaging Needs

Meeting Varied Packaging Needs

You would’ve noted the diversity in the packaging of popular brands. This is because they adapt their packaging formats for various festivities and demographics. This surely increases their standing in the market. A tablet strip packing machine has a pivotal role in meeting varied packaging requirements. You can customize this machine to manufacture diverse strip sizes, handle a variety of packaging films, and fill different numbers of doses per strip.

3.What is the principle behind the working of a tablet strip packing machine?

When you procure a tablet strip packing machine, the first question that arises in your mind is how this equipment works. Well, the working principle of a tablet strip packing machine is slightly complicated, involving the loading of tablets, their precise positioning, sealing of film, and ultimately cutting of strip packs. Now, let’s learn about the details of its every working step one by one:

Tablet Loading

Tablet Loading

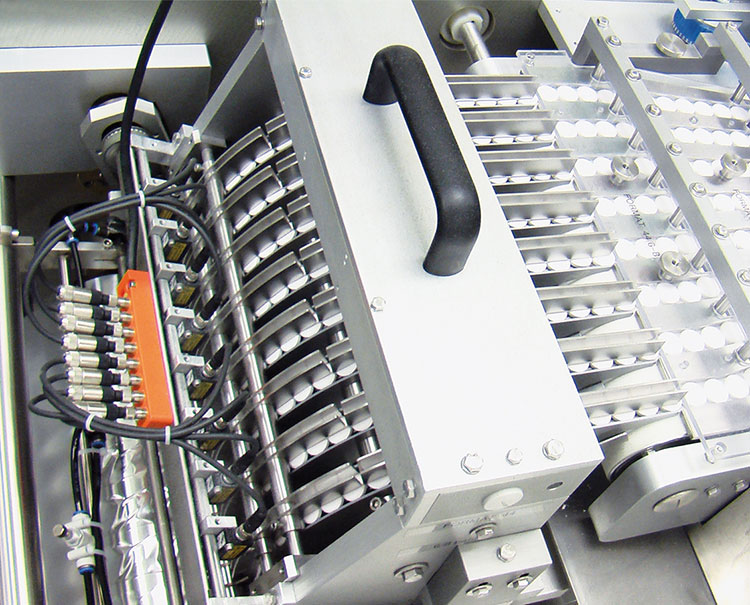

Before turning on the machine, the tablets (or capsules) are introduced into the machine hopper. Vibratory or rotary feeding systems are present in the equipment to take tablets from the hopper and align them in an orderly manner for packaging.

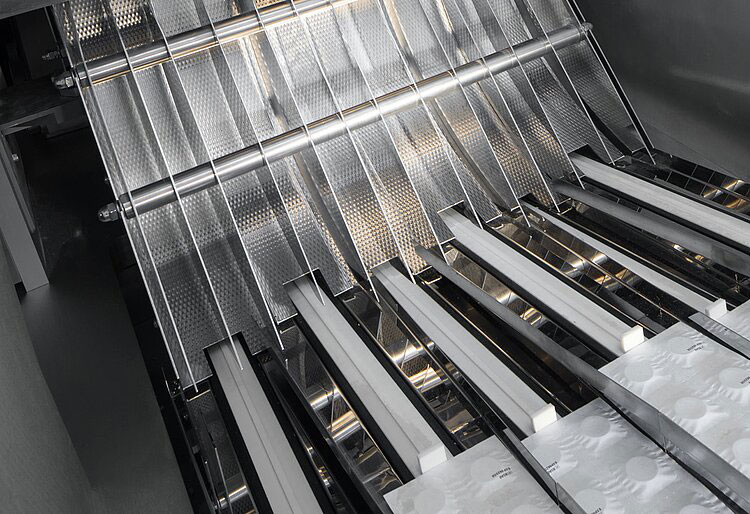

Film Uncoiling

Film Uncoiling- Picture Courtesy: Romaco

After tablet loading, two different rolls of packaging films are placed on separate unwinding disks for uncoiling. The rollers are responsible for moving as well as keeping the film on track and conveying the latter to the tablet positioning device.

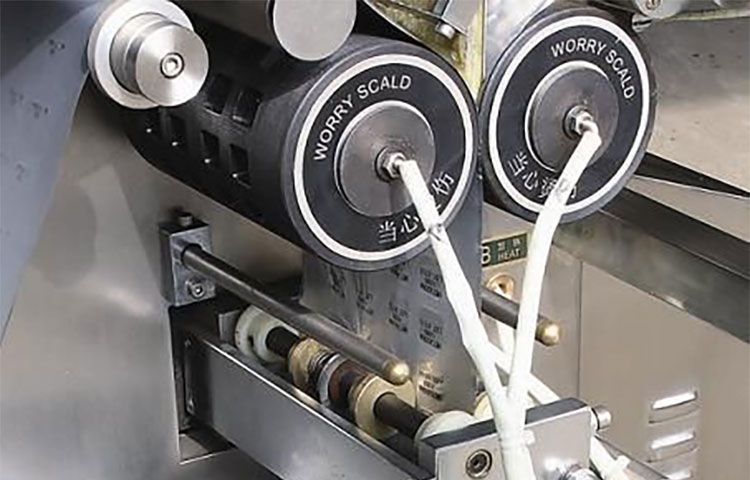

Tablet Positioning and Sealing

Tablet Positioning and Sealing

How tablets are sealed in strips? The tablets from the feeder are placed between two packaging layers. The sensors present in the device are integral in detecting the correct alignment of every tablet. By using sensors, the precise positioning of tablets is confirmed and then the sealing step is executed.

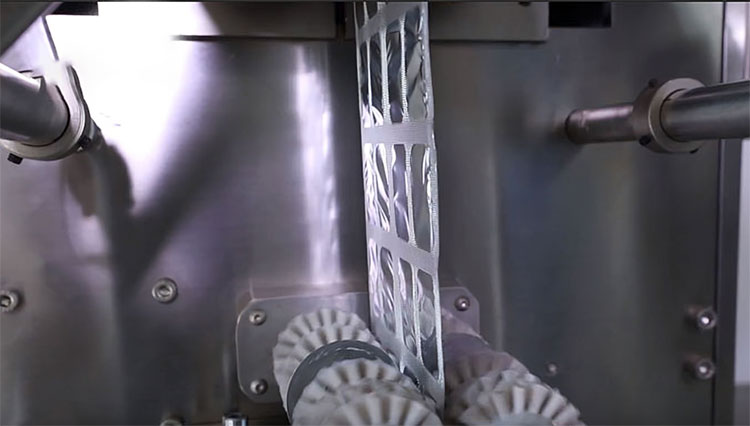

Heated rollers or platen are the main components to carry out the sealing of two layers of film. With thermal and pressure regulation, they form an airtight compartment around every dose.

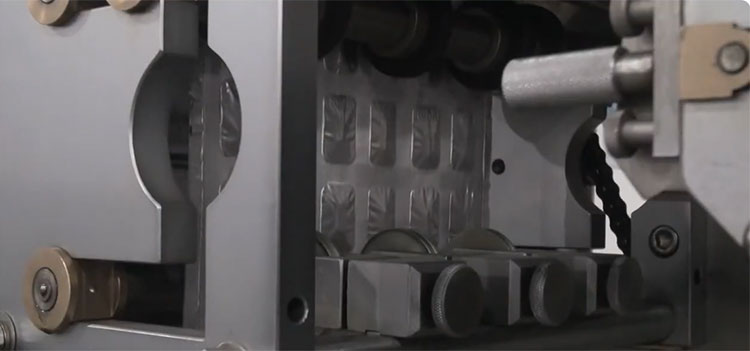

Cutting and Ejection

Cutting and Ejection- Picture Courtesy: Romaco

Have you seen perforations on strip packaging? After sealing, the tablet strip packing machine forms a perforated section between every tablet dose in the strip to provide patients ease of tearing a single packet.

Then, a cutter or blade- located at the bottom of the device- trims the large section of the strip into smaller fragments. These strip pieces have a particular number of tablets. Now the cut strips mechanically leave the equipment and go onto a conveyor belt for further cartoning. Or they are deposited on a collection tray after discharge from the machine.

4.In what industrial sector a tablet strip packing machine is often seen?

A tablet strip packing machine is frequently associated with the pharmaceutical sector. But you would be amazed to learn that this device has forged its path in other manufacturing sectors as well. Hence let’s learn about the wide-ranging applications of a tablet strip packing machine:

Pharmaceutical Sector

Pharmaceutical Strip Packing

The importance of a tablet strip packing machine in the pharmaceutical sector can’t be denied. It is the cornerstone of the pharmaceutical industry since it readily and precisely doses different kinds of pills, capsules, lozenges, suppositories, pessaries, and many more. Strip packaging made with durable and resistant material effectively combat a diverse range of contaminants.

Nutraceutical Sector

Nutraceutical Strip Packing- Picture Courtesy: Romaco

Are you concerned about the safety and appeal of your nutraceutical product packaging? Then, you can immediately switch to strip packing. A tablet strip packing machine is a perfect invention that enables nutraceutical brands to shield their merchandise, such as nutraceutical supplements, minerals, vitamins, herbal pills, and probiotics from water content and oxygen in the environment.

Veterinary Sector

Veterinary Strip Packing- Picture Courtesy: KBAALUFOILS

Everyone hopes their furry friends to be perfectly healthy and safe. To cater to the wish of animal-friendly customers, manufacturers have introduced their vet tablets in the strip packing. To accomplish this they heavily rely on the tablet strip packing machine. Certainly! You can retain their hygiene and potency throughout their efficacy period by precisely dosing them in hermetic pockets.

Chemical Industry

Chemical Pills- Picture Courtesy: Alpex Pharma

Yes, you got it right! Nowadays, the tablet strip packing machine has become a mainstay of the chemical and agriculture sector. How come? Because the tablet strip packing machine produces child-resistant and environmentally friendly packaging. Its high-activity packaging keeps chemical tablets, like mosquito repellent, camphor, naphthalene balls, and pH buffers tightly sealed to retain their effectiveness.

Food and Confectionery Industry

Confectionery Strips- Picture Courtesy: I Love 2 Bake

The specialty items, for instance, mint, lozenges, chocolates, and energy booster tablets are available in the strip packing. So, these goods have heightened safety from harsh conditions and biological pathogens. For this, you’ll regularly see the tablet strip packing machine in the food industry.

5.What are the fundamental parts of a tablet strip packing machine?

You would surely ask why it is important to know the parts of a tablet strip packing machine. To put it simply, if you want to properly operate and maintain your equipment then you must understand the jobs of its basic parts. Therefore, for your learning, we’re mentioning the definition of different components of a tablet strip packing machine:

Parts of the AIPAK Tablet Strip Packing Machine

| Hopper | It is the topmost part, generally identified with its characteristic cone or rectangular shape. You can store bulk quantities of tablets in the hopper for uninterpreted capsule feeding operations. It normally shakes to avert tablet blockage. |

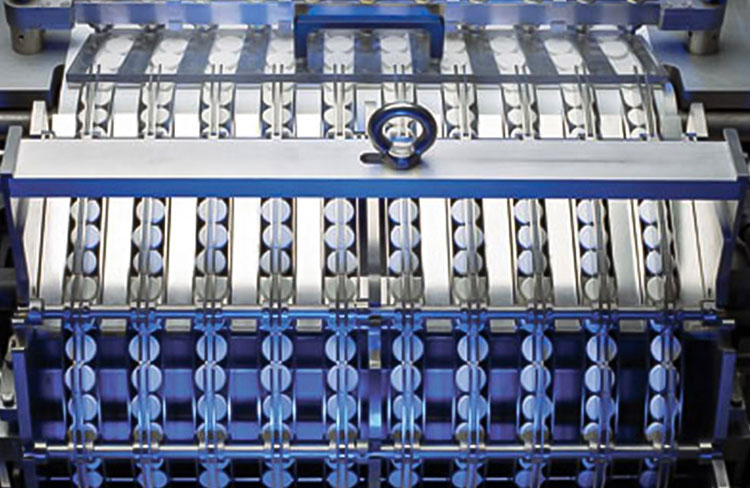

| Vibratory Feeder | As the name suggests, this part is responsible for tablet feeding in channels or tracks with its vibrations. It has a main role in the seamless alignment and orderly movement of tablets in the feeding tracks without any chance of overlaps or misalignment. |

| Sealing Rollers | Have you ever speculated which part carries out the sealing of strips? Sealing rollers join two films together to form a secure seal with locking tablets inside the strip pockets. These rollers are heated and apply pressure to airtightly bond the packing film. This seal is efficient in protecting products from dust, debris, moisture, oxygen, light, and microbes. |

| Cutting Assembly | Strips are available in the market in packs of 2, 4, 8, or 10 tablets. How is that possible? Although strip packing is manufactured as a continuous sheet, the cutter assembly- consisting of rotary knives or blades- is utilized for cutting the continuous strip in a clean and precise manner. They don’t destroy strip content and seal in any way. |

| HMI Touch Screen | Is it difficult to operate a tablet strip packing machine? Definitely not, with the assistance of an HMI touch screen, you can effortlessly operate this device. It enables you to adjust and program parameters, for instance, tablet count, feed speed, sealing temperature, and pressure. Furthermore, via the HMI touch screen, this equipment self-diagnoses problems in case of machine failure and offers you troubleshooting suggestions. It also provides real-time feedback information. |

| Batch Coding Device | This component consists of thermal or embossing printers to print diverse kinds of information, such as expiry date, manufacturing date, batch number, product name, etc. on the tablet strips. |

| Foil Holder | There are two foil holders in the tablet strip packing machine that hold the foil materials and slowly unwind them for their dispensing to the sealing rollers. You won’t spot any wrinkles or tears on the strip and it is because of the tension regulation mechanism in the foil holder assembly. |

| Product Discharge Outlet | You’ll normally see the product discharge outlet at the end of the machine. It is like a small conveyor through which packed strips depart from the device. It allows ease in the collection and is connected to large conveyor systems for immediate transport to the cartoning machine. |

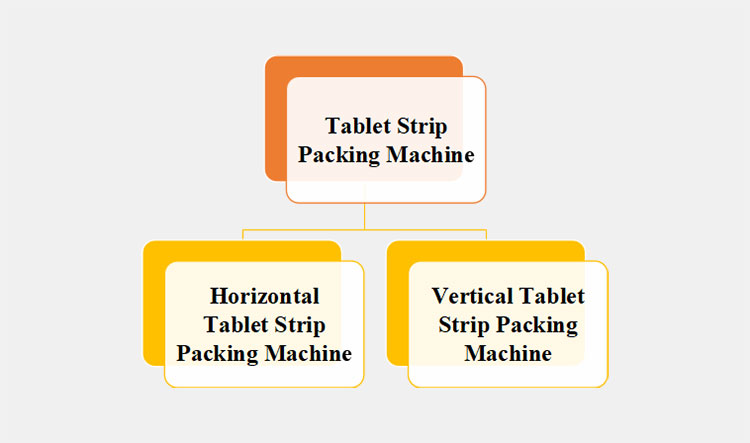

6.What is the classification of a tablet strip packing machine?

To understand the distinction between different models of a tablet strip packing machine, you must understand its different categories. Let’s read the classification of a strip packing machine:

Horizontal Tablet Strip Packing Machine

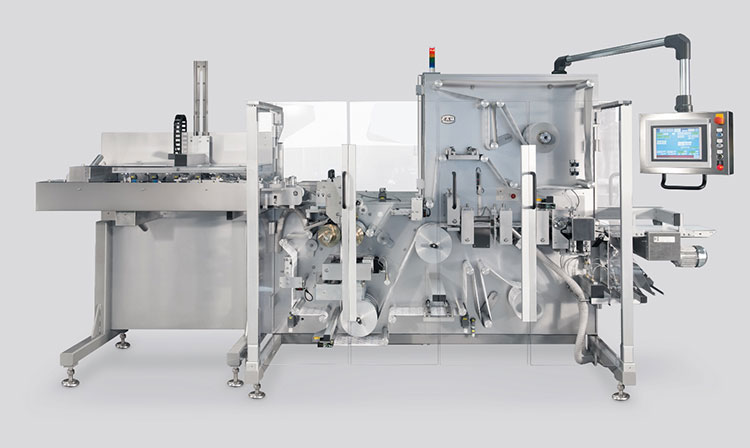

Horizontal Tablet Strip Packing Machine- Picture Courtesy: Campak Inc

This type of tablet strip packing machine is termed “horizontal” because of its horizontal exit. This product discharge system occupies more space; hence, this machine has a larger footprint. Consequently, it is more suitable for facilities with more production space.

Does it have more throughput than the vertical tablet strip packing machine? Absolutely, you get a greater number of packed tablets when you install this system in your firms. Because it habitually comes with multi-track for feeding, so, packs more tablets per cycle.

Vertical Tablet Strip Packing Machine

Vertical Tablet Strip Packing Machine- Picture Courtesy: Marchesini Group

If you have limited space in your facility then this type of tablet strip packing machine is the best match for you. Are you wondering why? As it has vertical configuration so needs minimal space for its placement. The strip packing is carried out in the vertical direction- with tablets going down from the hopper toward the sealing rollers.

Gravity has an integral role in tablet feeding and movement to tablet placement and sealing units. It is renowned for its versatility because it can produce strips of diverse lengths and varying tablet counts.

7.What materials are supported by a tablet strip packing machine?

There is a wide range of materials accommodated by a tablet strip packing machine to confer different levels of protection to tablets. The list of these materials is discussed below:

Aluminum Foil

Aluminum Foil Strip Packing- Picture Courtesy: LSKB Foils

It is one of the most widespread materials for strip packing. It offers a superior barrier against different environmental agents, particularly light. Therefore, it is highly recommended to pack light-sensitive tablets. Aluminum foil is known for its durability; thus, it extends the expiry period.

Paper-Aluminum Foil

Paper-Aluminum Foil- Picture Courtesy: Romaco

A combination of aluminum foil with paper presents a moderate level of moisture resilience, consequently, it encloses products that don’t require extreme barriers against oxygen and light. It has a lower price than Alu-Alu foil and can be eco-friendly due to its paper component.

Plastic-Aluminum Foil

Plastic-Aluminum Foil

This material is manufactured by combining aluminum foil with plastic polymers, for instance, PVC or PVDC. It is ideal for water resistance but provides less effective oxygen and light fortification. It is more malleable and offers product visibility. It packs vitamins and other common medications.

Polyethylene (PE) or Polypropylene (PP) Film

Polyethylene (PE) or Polypropylene (PP) Film- Picture Courtesy: Romaco

It is quite pliant, low-priced, and offers basic protection against moisture and oxygen. They are best for tablets with decreased sensitivity to physical agents.

Cellophane-Aluminum Foil

Cellophane-Aluminum Foil- Picture Courtesy: Romaco

It is considered green packaging because it uses a biodegradable cellophane film with aluminum. Cellophane-aluminum foil is handy in bestowing mild moisture and light protection.

8.What is the difference between a tablet strip packing machine and a blister packing machine?

Whether it is a tablet strip packing machine or a blister packing machine, both have their own distinct features and properties. We have summarized the basic differences just right below:

A Product Formed By A Tablet Strip Packing Machine & Tablet Blister Packing Machine- Picture Courtesy: Pharmaeducation

| Points | Tablet Strip Packing Machine | Tablet Blister Packing Machine |

| Description | This is the type of machine forming a series of products in a thermal sealing film via heat reciprocating platen. | This is a machine offering cavities or pockets for your product with a covering as a back lid and it takes place by thermoforming or cold forming procedure. |

| Productivity | Medium-to-high productivity is associated with tablet strip packing machines. | In the case of a tablet blister packing machine, it is observed to have greater productivity. |

| Challenging | The tablet strip packing machine provides lesser air entrapment to your tablets and deals with hygroscopic product packing. | There are greater chances of air entrapment when it comes to packing your product from a tablet blister packing machine. |

9.What are the recommended maintenance practices for a tablet strip packing machine?

Want to ensure that the tablet strip packing machine functions at its best continuously? Then you must maintain and clean the device regularly. A short maintenance guide is described below to assist you in your maintenance routine:

Maintenance of Tablet Strip Packing Machine- Picture Courtesy: Romaco

Cleaning After Every Batch

Begin each batch cycle by cleaning every part that is subjected to tablets, for instance, hoppers, feeders, and, sealing assemblies using soft clean cloth and food-grade cleaning solutions. This process is integral in clearing dust and tablet powders.

Component Examination

Machine parts are prone to damage as they are consistently working. So, first in the morning make sure to check evident wear on the vital parts, for example, sealing rollers, cutting knives, feeders, etc. This is beneficial in spotting early symptoms of deterioration before their performance is severely compromised.

Lubricating Mobile Parts

Certain moving components, such as bearings, screws, chains, etc. face extreme frictional forces with their movement, which wore them. Hence, keep in mind to lubricate these mobile components to avoid these issues.

Alignment of Components

Sensors are integral in detecting defects in tablets, inspecting sealing quality, and ensuring correct tablet placement in packaging. Therefore, you should routinely examine them for failure and properly level the feeder and sealing parts.

Calibration

Every control and sensor should be calibrated according to the standard specified in the machine manual. This guarantees seamless tablet loading, sealing, and, cutting.

Testing of Printing Devices

Printing components, like barcoding devices or printers, must be tested once a month. This will verify the clarity and legibility of printing. Also, don’t forget to reload ink or toner. Thoroughly clean the printer head to avert smudging possibilities.

10.What are the basic problems in the operation of a tablet strip packing machine? How to rectify them?

Manufacturers constantly worry about problems in the packing operation of their tablet strip packing machines because they negatively impact production performance and compromise the reliability of operations. Fortunately, these problems have an easy fix and don’t require costly repairs. Hence, for your ease, here are some basic problems along with their rectification guidelines:

Tablet Misalignment

Tablet Misalignment- Picture Courtesy: Campak Inc.

| Problem | Troubleshooting |

| Have you discovered tablet misalignment in the feeding channel? It is a frequent problem associated with defective packaging or broken tablets. It is attributed to improper programming of vibratory feeding devices, old alignment guides, or irregularities in feeding rates. | Here are a few approaches you should take to rectify this issue, for instance, altering the speed of the vibratory feeder to regulate the rate of tablet flow. Examining the alignment guide or feeding track for defects and replacing them if they exhibit serious damage. Locating blockage in the feeding system or hopper and unblocking them. |

Incomplete Sealing of Films

Incomplete Sealing of Films- Picture Courtesy: cnkingpack

| Problem | Troubleshooting |

| At some point, you would have observed that your strip packing has incomplete or weak bonding, causing the product to escape or be contaminated with environmental agents. Various factors, for example, improper inputs of temperature and pressure, damaged sealing rollers, or dirty sealing areas are the cause of this issue. | Here are some guidelines for you to rectify this problem:

First, check the settings of temperature and pressure and set them according to the recommended range mentioned in the machine manual. Examine sealing rollers for damage and switch them with new ones. Clean the whole sealing area after every batch and make sure to properly align rollers daily for uniform sealing pressure. |

Nonuniform Strip Cutting

Nonuniform Strip Cutting- Picture Courtesy: Jornen Machinery

| Problem | Troubleshooting |

| Are you having problems with the incomplete cutting of strip fragments? Is it having jagged cuts at the ends? Various reasons are linked with this error, such as a blunt or improperly positioned blade, wrong cut time, or strips moving too fast. | You can easily correct this malfunction by sharpening or replacing cutting knives periodically. Altering the speed of cutting assembly so that it’ll be in synchronization with the speed of the machine. You mustn’t overlook to inspect conveyor speed and machine vibrations to slow down the strip movement. |

Product Blockage on Product Outlet

Product Blockage on Product Outlet- Picture Courtesy: AIPAK Pharma

| Problem | Troubleshooting |

| Are you not satisfied with the movement of strip packing on product outlets? Is there any blockage? There are various explanations for this like decreased rate of packing exit from the equipment, obstruction on the outlet, or malfunctioning of the conveyor belt. | You must pay attention to product offloading speed. Adjust it to match the conveyor speed.

The outlet or product chute must be free of any hindrances. Fix the mechanical defects in the conveyor belt. |

Errors in Printing

Errors in Printing- Picture Courtesy: ANTAI

| Problem | Troubleshooting |

| Have you come across illegible information on strip packing? Is the barcode missing or is product data smeared? The decreased quantity of ink in the cartridge, incorrect leveling of the coding component, and mismatched coding speed might be contributing to this printing error. | It is suggested to refill the ink in the cartridge or substitute ink or cartridge to attain accurate printing outcomes. Properly level and position the batch coding unit. Match the printing speed with the equipment packing rate. |

Conclusion

The standing of a tablet packing machine is quite obvious in the pharmaceutical industry. This device is highly regarded for its accurate, uniform, durable, and protective packaging that plays a major role in boosting brand identity. Additionally, it also tremendously accelerates packing speed, leading to faster market deliveries. After reading this guide, you will surely be tempted to try your hand at the tablet strip packing machine. So, we invite you to transform your packaging operations with AIPAK's latest line of strip packing machines.

Don't forget to share this post!

Strip Packing Machine Related Posts

Strip Packing Machine Related Products

Strip Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours