Tablet Press Tooling: What Do You Know?

How tablets are formed? What components have a role in manufacturing? If you are linked to the pharmaceutical industry in any way or form, you certainly would’ve heard about the tablet press machine or have this machine in your facilities. You can view this equipment as the heart of the pharmaceutical sector. Because it executes the most important function such as, the compression of tablets from powders.

At this point, you would be guessing which part is regarded as the heart of the tablet press. Well, here is the right answer- a tablet press tooling. It is a core component that is involved in the transformation of tablets from powders. Tablet press tooling is comprised of two parts- punches and die. They work in harmony to create the most perfect tablets.

There would be many queries in your mind about tablet press tooling, for example, what is its function? What are its types? It is available in customized form? How does it work? The answers to all these questions and many more will be described in detail in this blog post: “Tablet Press Tooling: What Do You Know?”. So, let’s jump right into deep.

1.What is tablet press tooling?

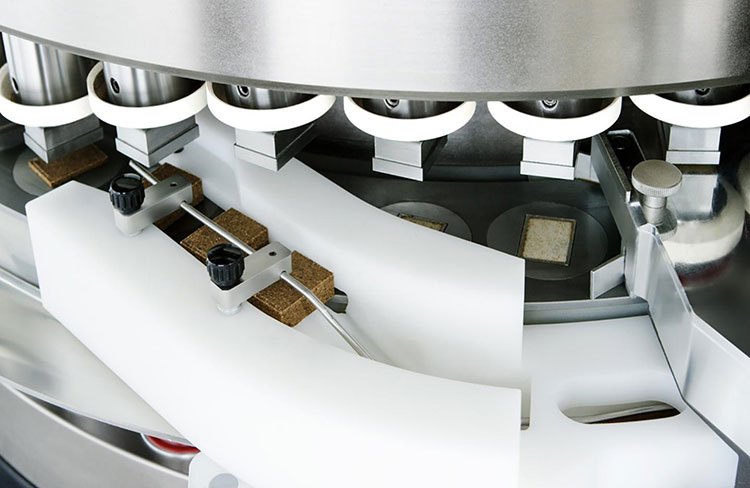

Tablet Press Tooling- Picture Courtesy: Elizabeth Companies

Tablet press tooling is a core part of the tablet press machine. This component holds the task of shaping, compressing, and ejecting tablets from the device. It has a decisive part in forming tablets of consistent shapes, sizes, hardness, weight, and appearance.

It has two important parts:

Punches

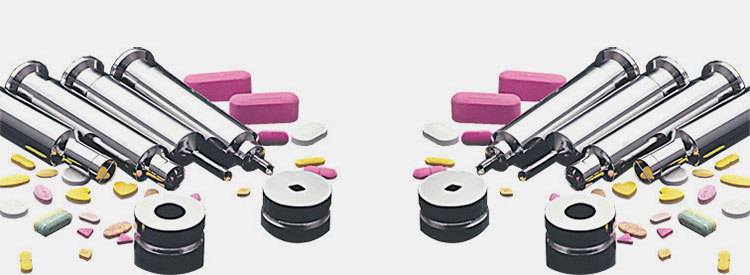

Upper and Lower Punch- Picture Courtesy: Vortexsg

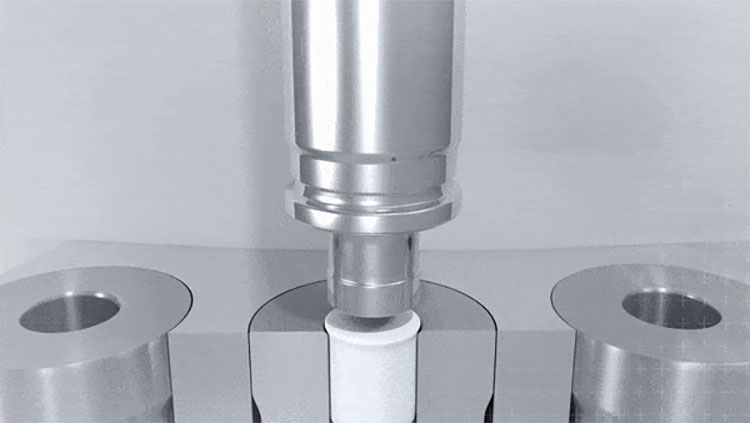

Is further subdivided into upper and lower punches. They are cylindrical in shape and are actually responsible for compressing the powders into tablets. Generally, in the case of a single-punch tablet press machine, only the upper punch is moved down to compress tablets. Conversely, in the rotary tablet press machine, both the upper and lower punch work together as a pair to successfully carry out the compression process.

The upper punch has the role of forcing air out of the powder. The lower punch is involved in retaining powder inside the die and also moves upward after compression to remove the tablets from the die cavity.

Die Cavity

Die Cavity- Picture Courtesy: HD PharmaTool

It is a hollow passageway that decides the shape and diameter of tablets. The powders are filled into internal space in the die cavity before compression. Also, the depth of the die is associated with the thickness of the tablets.

2.Why tablet press tooling is vital in tablet production?

Are you thinking about how tablet press tooling is useful? How does it impact production? It is indispensable in the pharmaceutical sector because the whole process of tableting revolves around it. We are explaining the useful benefits of tablet press tooling below:

Augmented Tablet Quality

Augmented Tablet Quality- Picture Courtesy: Romaco

Tablet press tooling dictates the physical attributes, for example, its shape, geometries, strength, embossing, and engraving. Perfectly aligned and compatible tablet press tooling forms tablets without any deviations of weight and dosage through its uniform filling in the die cavity.

Regulatory Compliance

Regulatory Compliance- Picture courtesy: The IMA

The FDA and EMA have defined strict regulations for dosage and marking on the tablets. Both these guidelines are easily achieved with the tablet press tooling. This part enables you to make tablets with precise dosages. Moreover, you can imprint certain information, such as medication names, scoring lines, or logos on tablets with tooling. This information display is attributed to product traceability and patient safety.

Increased Production Flow

Increased Production Flow- Picture Courtesy: The IMA

By using the tablet press tooling, you can run the tablet press machine at higher speeds. This device is assembled using high-quality materials, which improves durability and cuts down the need for recurrent tooling replacement. In this way, you’ll have a smooth and uninterrupted production flow without dire downtimes.

Decreased Material Wastage

Decreased Material Wastage- Picture Courtesy: Huda Pharma

Material wastage leads to financial difficulties for manufacturing firms since it increases the necessity of buying more materials. However, tablet press tooling significantly lowers the likelihood of defects in tablets. This saves the raw materials and decreases the chances of tablet rejections and recalls.

Custom-made Tablets

Custom-made Tablets- Picture Courtesy: Romaco

If you want to configure tablets with unique traits, then tablet press tooling helps you accomplish this goal. This component is tailored to create tablets with diverse geometries and dimensions. It is also manufactured to accommodate distinctive preparations with poor flowability and hardness problems.

3.What are the types of tablet press tooling?

You certainly would have seen different shapes of tablets in the market. Do you think about components that make them diverse? Well, here is an answer for you. There are diverse categories of tablet press tooling that are compatible with a multitude of tablet shapes and sizes. Let’s have an insight into types of tablet press tooling:

Types of Tablet Press Tooling- Picture Courtesy: Pharma Interview

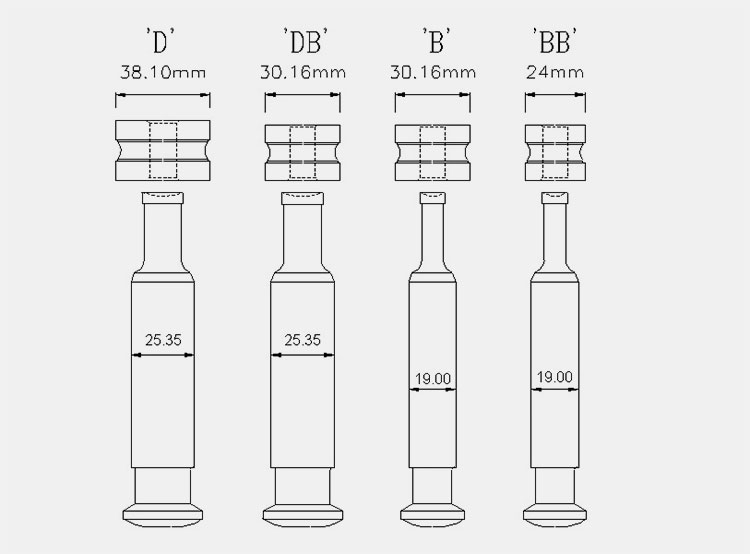

| D Tooling

|

It is more suitable if you are producing tablets with larger sizes, as it has a pouch diameter of 1 inch. Thus, it can apply larger compaction forces. Its die diameter is about 1.5 inches. D tooling is found in tablet presses that typically form chewable tablets or large tablets. It is also utilized to produce tablets with a high proportion of active ingredients.

|

| B Tooling

|

If you are involved in the manufacturing of smaller tablets, then B-type tooling is recommended for you. Its punch is about 0.75 inch or 19 mm. and the die diameter (0.945 inches) is also lower than the D tooling. Due to its smaller size, there are a higher number of B tooling units on the turret. It creates standard tablets and supplement pills. |

| DB Tooling

|

It is a variant of D tooling but with slight modifications. What are the differences in this tooling in contrast to D tooling? First, its die diameter (1.33 inches) is smaller than the D tooling. Secondly, there is a greater number of DB tooling on the tablet press machine than D tooling. Its punch diameter is similar to D tooling, which is about 1 inch. DB tooling is appropriate for forming medium to larger tablets having high density. |

| BB Tooling

|

It is a modified model of B tooling but comes with a reduced punch (barrel) and die diameter. The outer circumference of the punch and die is about 0.75 and 0.756 inches, respectively. Yes, you can install a higher number of BB tooling in the turret because of its decreased diameter. It is highly popular for making small-sized tablets, such as lozenges, mints, or minitablets. Its maximum tablet size is 13 mm. |

4.What are the designs of tablet press tooling?

Imagine an oval or square-shaped tablet. How it is produced? This is due to the diverse designs of tablet press tooling. Now, let’s have a deeper understanding of diverse designs of tablet press tooling:

Regular Shaped Tablet Press Tooling

Regular Shaped Tablet Press Tooling

With the help of this tablet press tooling, you form round-shaped tablets. It is a standard kind of tooling and is frequently utilized in the pharmaceutical and veterinary industries. Regular-shaped tablet press tooling is employed in manufacturing concave-shaped tablets with flat and bevel edges.

Oval Shaped Tablet Press Tooling

Oval Shaped Tablet Press Tooling

As the name suggests, this type of tablet press tooling is perfect for forming oval-shaped tablets. It is the second most common shape of tablet press tooling and is widespread in the pharmaceutical and herbal industries. It typically forms flat, deep, and concave tablets with bevel edges.

Capsule Shaped Tablet Press Tooling

Capsule-Shaped Tablet Press Tooling- Picture Courtesy: Morse-O-Tool

It is utilized in the pharmaceutical and ayurvedic sectors for producing tablets of long, oblong geometries with curved ends. These pills are identical in appearance to capsules. Capsule-shaped tablet press tooling increases the consumer appeal of tablets.

Geometric Shaped Tablet Press Tooling

Geometric Shaped Tablet Press Tooling

Its utility is not limited to the pharmaceutical industry but is also seen in the confectionery, chemical, and metallurgy industries. If you desire tablets with geometric shapes, for instance, triangle, benzene, square, rectangular, or rhombus, then you should make use of this tablet press tooling.

Irregular Shaped Tablet Press Tooling

Irregular Shaped Tablet Press Tooling

It is used to create tablets with diverse shapes like animals, fruits, stars, diamonds, and more. You’ll habitually see it in the confectionery industry.

Core Rod Shaped Tablet Press Tooling

Core Rod Shaped Tablet Press Tooling

This tablet press tooling is utilized for creating tablets with holes in the center. It is typically found in the pharmaceutical, confectionery, and ceramic industries. It compresses powders into two types of core rod tablets that are core rod tablets with concave ribs and core rod tablets with flat ribs.

Multi-tip Tablet Press Tooling

Multi-tip Tablet Press Tooling- Picture Courtesy: Elizabeth Companies

It is commonly used with a single tablet press machine to increase its efficiency. This means that you can produce a greater number of tablets per compression cycle using this tablet press tooling. The punches in multi-tip tablet press tooling have multitudes of compression tips. Whereas, the die plate is customized with numerous die holes to accommodate the punch tips.

Sealed Grove Tablet Press Tooling

Sealed Grove Tablet Press Tooling- Picture Courtesy: Holland

It is an innovative kind of tablet press tooling that is utilized for stopping powder escape during the compaction procedure. It encompasses a seal groove arrangement in punches or dies to seal the powders within the die cavity.

5.What are the standards of tablet press tooling?

These are the international standards that provide guidelines about the size and shape of the tablet press tooling. They have a central role in retaining uniformity across different tablet press machines and help manufacturers procure well-suited tablet press tooling from different vendors. For your information, we’re describing different types of international standards for tablet press tooling:

TSM (Tablet Specification Manual) Tooling Standard

TSM Standard

This manual guide was established by the American Pharmaceutical Association. It is a common standard for tablet press tooling in the United States. It has strict regulations for the length and diameters of punches and dies. It encompasses both B and D tooling and is also referred to as TSM-B and TSM-D.

How is the TSM tooling standard different from the EU tooling standard? Here are a few differences: the punches in TSM tooling have an angled head, which decreases the strain on punches at high speeds. The head of punches is larger in TSM tooling than in the EU tooling. This allows the tablet press tooling to create large-sized tablets, owing to its huge surface area for compression.

EU (European Union) Tooling Standard

EU Tooling Standard

This standard is customary in Europe and other regions of the world. It is based on the ISO 18084 standard. Are you wondering about the similarities between TSM and EU tablet press tooling? Is EU tooling compatible with TSM tablet press machines?

Well, to answer your question; yes, they both are quite identical but also have minute dissimilarities in sizes and diameters of punches and sizes. That’s why, it is not advised to use EU tooling with TSM tablet presses and vice versa.

The height of the head in EU tooling is less than in TSM tooling and also the former has a flat surface. This decreases the vibration rate in the equipment during fast-paced operations. And prolong its operating life.

RTP Tooling Standard (Rotary Tablet Press Tooling)

RTP Tooling Standard- Picture Courtesy: Karkhana

As the name specifies, this type of tablet press tooling standard exclusively provides guidelines for RTP tooling used in rotary tablet press machines. This standard regulates the dimensions of B and D-type tooling. In RTP tablet press tooling, the punches and dies are placed in the rotary turret and compact tablets with rotation of the turret.

This tooling executes processes continuously, so is routinely seen in high-throughput facilities. However, it has its set of cons, such as regular maintenance and leveling.

DP Tooling Standard

DP Tooling Standard- Picture Courtesy: Shanghai Chengxiang Machinery Co., Ltd.

You’ve guessed it right. This tablet press tooling standard specifies regulations for Die plate (DP) tooling. This tablet press tooling is tailored to work with the single-punch tablet press machine. In this tooling, die cavities are housed in a single die plate. How is it useful?

This tooling accelerates the operational speed by removing the need to insert dies one by one in the turret, thereby decreasing the time to prepare the tablet press equipment. In addition, it allows you to produce tablets with tailored configurations. However, it is not without limitations that include higher upfront expenses and complicated maintenance.

The below table briefly describes the summary of all these tooling standards (Table Courtesy: LFA Tablet Press).

| Tooling Standards | Tooling Types | Die Bore Height (mm) | Die Bore Diameter (mm) | Punch Complete Length (mm) | Punch Barrel Diameter (mm) |

| TSM | D | 23.81 | 38.1 | (133.35 - f) ±0.05 | 25.35 |

| B | 22.22 | 30.16 | (133.35 - f) ±0.05 | 19 | |

| DB | 23.22 | 30.16 | (133.35 - f) ±0.05 | 25.35 | |

| BB | 22.22 | 24 | (133.35 - f) ±0.05 | 19 | |

| EU | D | 23.81 | 38.1 | (133.6 - f) ±0.01 | 25.35 |

| B | 22.22 | 30.16 | (133.6 - f) ±0.01 | 19 | |

| DB | 23.22 | 30.16 | (133.6 - f) ±0.01 | 25.35 | |

| BB | 22.22 | 24 | (133.6 - f) ±0.01 | 19 | |

| RTP | 22 | 26 | 115 ±0.02 | 22 | |

| TDP | 22 | 37 | 42 | 10 | |

6.What problems are associated with tablet press tooling?

Inadequate performance of tablet press tooling is a significant cause of a wide array of problems in tableting outcomes, such as capping, laminating, picking, and others. These issues are easily reduced or completely eradicated by keeping this component in top-notch condition. Let’s review frequent problems and their solution associated with tablet press tooling:

Sticking and Picking

Sticking and Picking- Picture Courtesy: Manufacturing Chemist

Sticking happens when powders from the formulation adhere to punch and die walls, whereas, picking is due to embossed patterns in the tablet press tooling, leading to powder deposition on tooling. High moisture levels or stickiness in the formulation may be the reason for this problem.

Solutions

There is no need to worry because there are various solutions to this problem, such as you should always select high-grade stainless-steel material with high chromium content to prevent sticking and picking of powders from happening in the first place. Also, you must apply anti-stick coats like chromium or DLC to punch face and die walls. Try changing the recipe of preparation by adding lubricants to improve its fluidity.

Cracked or Chipped Tablets

Cracked or Chipped Tablets- Picture Courtesy: Sensum

At some point, you would’ve noticed cracked or chipped tablets in your facilities. Why is that? This problem is linked to the condition of tablet press tooling. For example, defective or old punches and die cause irregular compaction, leading to decreased bonding strength between particles.

Furthermore, misalignment of the tablet press tooling is associated with uneven compaction pressure, thus weakening some areas of the products. Besides this, poor lubrication of the tooling buildup friction. This exerts high stress on tablets, producing cracking and chipping.

Solutions

To solve this problem, you must regularly examine the wear of tablet press tooling and replace it if it experiences evident damage. Secondly, look for alignment errors in the tooling and appropriately calibrate and align them.

Finally, you should lubricate the dies and punches with suitable lubricants or food-grade oils to minimize stress on products.

Capping and Lamination

Capping and Lamination

Have you encountered tablet splitting after compression? Did your tablets break horizontally into two? The capping issue is caused by the entrapping of air in the formulation due to the design and shape of the punch face. On the other hand, the lamination is the result of high compression force, decreased powder fluidity, and weak adherence between formulation particles. The die contours can be the reason for the lamination.

Solutions

Capping and lamination defects can be conveniently resolved by changing the design of the punch and die. Because a well-designed tablet press tooling aids in the release of trapped air and improves the bonding strength between tablet layers. Also, it assists in the uniform application of compaction force, enhancing tablet quality.

Alterations in formulations boost powder flow traits. You can also alter compression force, residence time, and ejection velocity to improve the tableting outcomes.

Pitting or Rusting

Pitting or Rusting

Is your tablet press tooling rusted? Did you observe small depressions on punches and dies? There are many reasons for this, for instance, abrasive formulation components (active ingredients and excipients), increased compaction pressure, inconsistent lubrication, corrosive detergents, and a highly humid environment.

Solutions

Rest assured; this problem has an easy fix. You could modify the formulation by minimizing the ratio of abrasive excipients. Use sieves or mills to reduce the particle size of abrasive components. You can limit the amount of strain on tablet press tooling by optimizing the tableting parameters.

The deterioration of tooling can be reduced by lubricating and cleaning it using suitable lubricants and cleaning agents, respectively. Last but not least, storing the tablet press tooling in a controlled humid environment decreases the possibilities of rusting and pitting.

Tablet Contamination

Tablet Contamination- Picture Courtesy: The Sun

Are you wondering how tablet contamination is related to the tablet press tooling? Product sterility could be compromised by the escape of powders from the tooling components. A buildup of powders and granules on the punch tip, die bore, and walls of the die is also the reason for the tablet contamination. It leads to cross-contamination between batches.

Solutions

Here are some solutions to resolve this abnormality in tablets. Consider changing the design of the tooling and using sealed groove tablet press tooling to contain powder inside the die cavity. Also, you should implement a proper cleaning schedule between batches to avoid contamination.

Illegible Embossing Patterns

Illegible Embossing Patterns- Picture Courtesy: Daily Maverick

Do you have difficulty discerning embossing patterns on tablets? Poor embossing clarity certainly affects the brand image and could lead to incorrect dosing for patients. This problem is also correlated to mismatched punch design or aging of punches and dies. It could be because of the adhering of material into engraved regions of punches.

Solutions

You should customize your tablet press tooling according to tableting requirements. Replace punches and dies if they are damaged beyond repair. Anti-stick coating can improve embossing quality.

7.What are recent advancements in tablet press tooling?

Every form of technology is rapidly evolving and the same goes with tablet press tooling. This advancement is integral in augmenting throughput, life expediency, and accuracy and also addresses challenges related to tablet sticking, tooling damage, and compaction forces. Let’s have an overview of innovations in tablet press tooling:

Sophisticated Materials

Sophisticated Materials- Picture Courtesy: Karkhana

Novel materials and alloys like high-performance steel grades (M340 and 440C stainless steel) are introduced in the market to increase strength, rust resistance, and improved durability of tablet press tooling. With these materials, you surely have reduced the need for frequent replacements and repairs.

Improved Coated Tablet Press Tooling

Improved Coated Tablet Press Tooling- Picture Courtesy: Romaco

Today, pharmaceutical firms have a chance to install augmented-coated punches and die. They are often surface treated with the latest coating combinations, for instance, Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), titanium nitride (TiN), chromium nitride (CrN), and diamond-like carbon (DLC. These coatings certainly improve surface smoothness and punch longevity.

Enhanced Punch Design

Improved Punch Design- Picture Courtesy: Romaco

Engineers have started using Advanced computer-aided design (CAD) to precisely fabricate tablet press tooling. This allows developers to manufacture tailored tooling to accommodate unique geometries and components of tablet preparation.

Smart Tablet Press Tooling

Smart Tablet Press Tooling- Picture Courtesy: Romaco

Nowadays, there is an increase in the number of tablet press tooling with manufacturing execution systems (MES) and data management systems. This smart technology will facilitate users in monitoring operational data and analyzing patterns across different production runs. With the help of digital twining, virtual simulations are conducted to study the impact of various designs and materials of tablet press tooling on tablets.

Conclusion

The tablet press tooling is considered the soul of the tablet press machine. It is an engineering marvel where the magic of tablet compression occurs. It delivers consistent compaction pressure to turn loose powders and granules into flawless tablets. Choosing a well-suited tablet press tooling is pivotal to the tableting process because the well-designed tooling correlates impeccability in tablet hardness, thickness, size, shape, and appearance profile. So, experience the difference that quality tablet press tooling can make with AIPAK.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine