Tablet Inspection Machine: The Ultimate Buying Guide In 2025

Have you ever noticed that every tablet has an accurate appearance? For instance, colors, texture, size, shapes, etc. In the medicinal industry, it is very important to ensure that there is not a single defect in tablets or capsules. However, it’s challenging to examine when you deal with a large production scale. Because a huge amount of time, energy, and strict vigilance is required for tablet inspection.

The tablet inspection machine is of great value for inspecting tablets thoroughly before being released on the market. Read on the Tablet Inspection Machine review blog to learn important key points before purchasing the system.

1.What is a tablet inspection machine?

A sleek designed tablet inspection machine is one of the sophisticated technique that rapidly detect external defects of tablets.

Tablet Inspection Machine

It is a highly efficient machine that ensures easy and precise monitoring of various shapes, colors, sizes of pills only with simple settings. It gives you the same inspection quality as that detecting via applying algorithm method without complicated ways. It performs an excellent inspection job with effortless parameter setting. For instance, no blind spot, allowing various tablet formats, and conformed to cGMP requirements. In a nutshell, the machine has ‘No Room for Error’.

2.What are various types of tablet inspection machines?

Types of tablet inspection machines are described below:

Manual Tablet Inspection Machine

Traditionally, tablets were inspected via handheld method. Manufactured tablets were manually introduced onto the inspecting tray. With the help of light, reflective mirrors, and magnifying glass tablets were inspected by operators.

Semi-Automatic Tablet Inspection Machine

Semi-Automatic Tablet Inspection Machine

This machine involves tablet inspection before packaging. The operator sits in front of the conveyor belt to check tablets. Some machines are designed in such a way that two operators are required to work on each side. Automatic feeding of a tablet onto the conveyor belt is passed to the first operator. The faulty tablets are removed by the operator and then passed onto the next conveyor for the second operator. Suitable tablets are collected in a collecting box. This machine is not suitable for large production sizes, as the operator needs to sit for hours in the same posture (which causes shoulder and back discomfort).

Automatic Tablet Inspection Machine

Automatic Tablet Inspection Machine

This is a standalone machine for tablet inspection. This is a compact machine with excellent inspecting cameras, lights, and mirrors to ensure 99.99% accurate throughput. Unlike manual or semi-automatic machines, here you don’t require technicians or operators. Just feed the protocol and allow the machine to perform the rest of the job. Capturing multiple photos from various sides ensures a safe and quality detection of broken, misprints issues, or related tablet issues e.g., discoloration, chipping, fissures, measurements, etc.

3.What are the industrial applications of tablet inspection machines?

Due to excessive production of pills, tablets, capsules, and beans, many industrial firms are taking the help of tablet inspection machines for better evaluation of their goods in terms of quality and quantity.

Some of them are as follows:

| Pharmaceutical Industry

|

Tablet inspection machine is the core tool of the pharmaceutical industry. The reason behind this is the accuracy, hygiene, and safety of millions of tablets that are produced every day. For this, a tablet inspection machine is a suitable device with an efficient inspection ratio. |

| Nutraceutical Industry

|

Nutraceuticals are medical food for health to boost your health. All essential nutrients (phytochemicals, nutrients, trace elements) are gathered in the form of tablets, capsules, or pills. The entire finished product is perfectly examined by a tablet inspection machine, which also maintains the integrity of the tablets and their brand. |

| Veterinary Industry

|

Similar to human beings, animals also require proper medical treatment. For their medication, different types of therapeutic agents are prepared in the form of tablets in the veterinary industry. Therefore, tablet inspection machine is in higher demand in this sector. |

| Chemical Industry

|

Another manufacturing firm that demands a tablet inspection machine is the chemical industry. Here, several types of tablets are formulated under strict limits. For example: pH tablets, buffer pellets, salt tablets. |

| Food Industry

|

A tablet inspection machine plays a crucial role in the food industry, where enormous products including gummies, chewing gums, coffee beans, and candies need to be well identified before packaging. For such bulk production analysis, a tablet inspection machine is recommended. |

| Cosmetic Industry

|

The rapid advancement in an industrial area has also gripped the cosmetic industry. Many tablets or capsules are made for glowing skin and removing dark circles or wrinkles. A tablet inspection machine is a significant device to perform tablet estimation activity. |

4.Importance of tablet inspection machine in pharmaceutical manufacturing?

There are some major reasons why tablet inspection machine is important for the pharmaceutical industry:

Consistent and Accurate

In pharmaceuticals, there is no compromise when it comes to the accuracy and consistency of manufactured products. A tablet inspection machine ensures tablets with no defects.

Storing Batch Reports

When you store the data or run a protocol, machine saves it till you remove the file deliberately. This machine is helpful to store long-run data and provides batch records with date and timings.

Mountable Conveyor Belt

The machine ensures fast tablet inspection via scalable conveyor belt. The pharmaceutical production line is associated with bulk production. So, you cannot ignore when it comes to deal tablets in a huge quantity.

Durability

The tablet inspection machine is made up of stainless steel. The machine is long-lasting, durable, and not susceptible to physical damage.

Long-Run Production

An automatic tablet inspection machine is popular in the pharmaceutical sector for long-run production (day and night) where you cannot afford operators all the time.

5.What are the advantages of a tablet inspection machine?

The advantages of the tablet inspection machine are described below:

Smooth Operation

The machine ensures smooth and firm transferring of tablet product onto the inspecting belt for the inspecting procedure.

No-Risk of Contamination

There is no risk of contamination during the procedure by friction belts or chains. Moreover, the machine is designed with a simple structure hence minimizing the chances of cross-contamination.

Easy Replacement of Tools

The machines takes only a few minutes for disassembly or replacement of inspecting rollers.

User-Friendly and Environmental-Friendly Machine

It is easy to operate and creates less noise. Moreover, an external vacuum-cleaning takes place by use of a suction system. Hence it avoids dust formation in the environment.

Less Laborious

The machine reduces the fatigue of technicians by offering ergonomic designs.

HMI- Smart Control

The machine does not require high vigilance of operator as the entire procedure is performed by the machine itself.

6.What are the structural components of a tablet inspection machine?

Feeding Hopper

A feeding hopper stores the tablets and facilitates to vibratory feeding chute.

Vibratory Feeding Chut

It moves tablets in vibratory motion to eliminate dust, dirt, or chip particles over its surface.

Wing Door

Semi-automatic tablet inspection machine has opened structure. While some automatic machines are available with enclosed housing and wing doors. Purpose of wing door is to assures a safe working condition.

Jam Free Sorter

It helps in preventing the jamming of tablets via providing a linear pathway.

Smart HMI

The machine is facilitated with a smart HMI that not only works for controlling software functions but also controls the mechanical setting and fine-tuning.

Collecting Container

Each tablet is categorized and collected into separated containers e.g., defected or rejected and good ones.

Inspection Belt

Feeders allow evenly spaced tablets onto the inspection belt. They are transported in a stable condition for a camera inspection.

Suction Belt Conveyor Unit

It is a simple design with air suction that enable non-stop inspection for a long time.

Camera Unit Mechanism

This unit involves taking images of pills from different directions such as various face, edges, and sides. There are two types of cameras commonly installed in the machine.

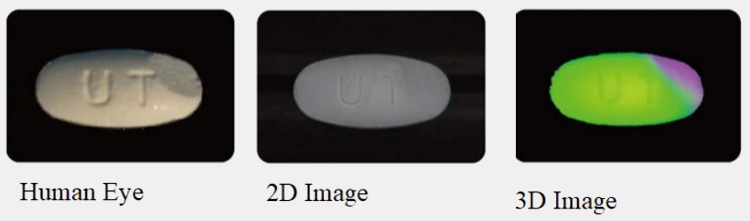

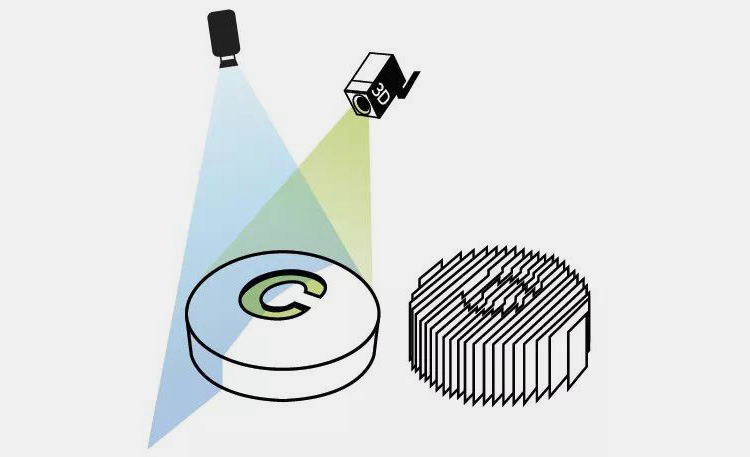

2D Camera

This device is unmatched in its ability to inspect and identify minor fluctuations. It ensures the best performance, and can easily scan the colors, surface, logos, and other relevant characters.

3D Camera

It is an essential unit for enhancing the tablet inspection process. It is of extreme importance when it comes to detecting in-depth problems, such as engraving chips or broken surface flaws. A 2D unit is somehow uncleared, but 3D image gives you 100% cleared identification of defects.

Transfer Disc

It is utilized to reverse the tablet onto the inspection belt and run parallel direction. Tablets are sent to inspect the rear face. They are inspected by a camera identical to that used for the front face. The same inspection unit is used for the front and rear face.

Sorting Unit

It is specially designed where a defective product is distinguished from non-defective. This unit ensures that defective and non-defective tablets are not mixed. The entire process takes place under a constant surveillance.

Rejected Tablet Container

It is provided to separate unwanted or rejected tablets.

Defective Path

Defective tablets are sent to this path for re-inspection.

Inspecting Mirrors

Some machines are provided with mirrors to monitor tablets from the reverse side.

Electrical Cabinet

The electrical cabinet facilitates electrical supply to whole unit.

Top Illuminating Lamp

It allows illuminating light on the top of tablets for ease of inspection.

Bottom Illuminating Lamp

It illuminates the tablet from bottom surface for easy inspection.

Castor

The machine is mounted on a castor to ease the movement of tablets from one place to another.

Air Pressure Reducer

It is used to eliminate rejected tablets from the tablet belt.

Compressed Air Connector

It facilitates compressed air as per the tablet’s weight. It ensures a stable movement of the product for easy inspection.

Vacuum Generator

It creates a vacuum required for tablet handling tasks. The device generates a vacuum via compressed air or electrically using a displacement pump.

7.What is the working principle of a tablet inspection machine?

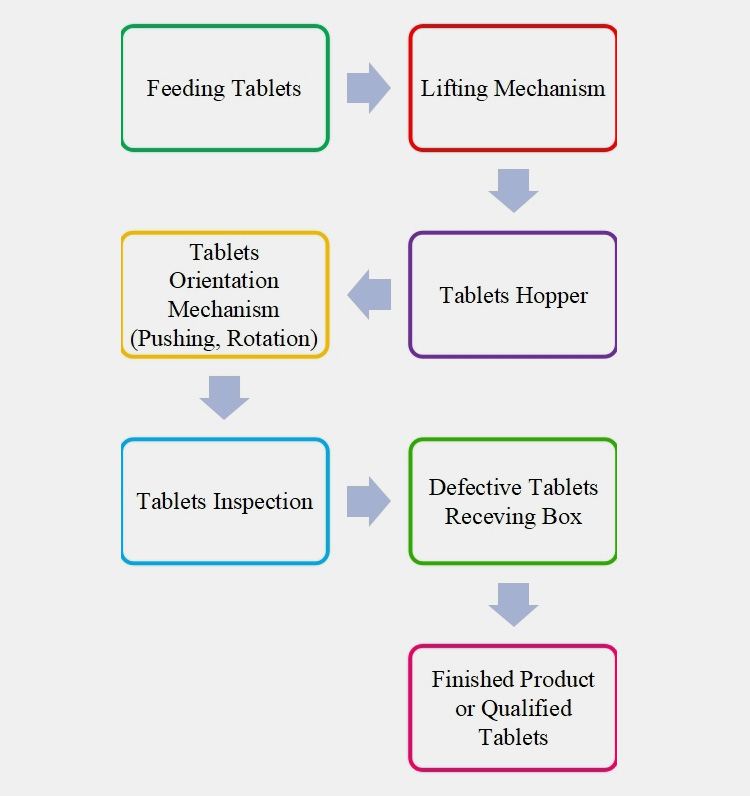

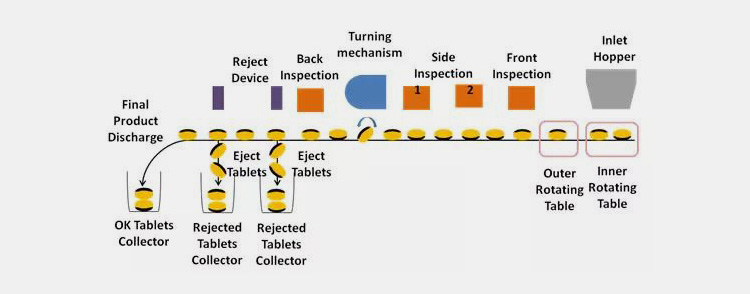

Feeding Tablets

The tablets are entered into the feeding hopper via an automatic lifting mechanism or are introduced manually.

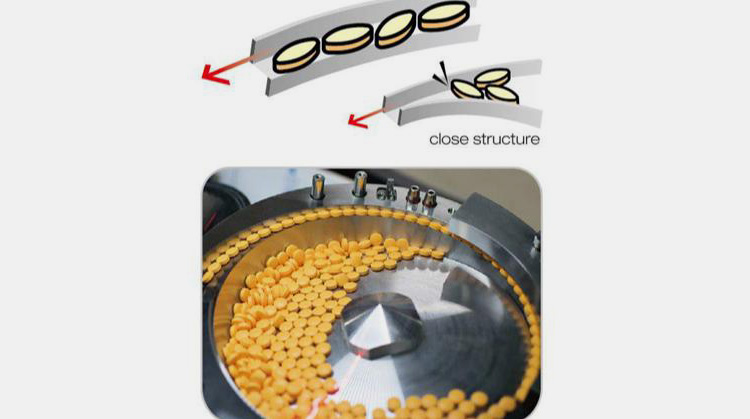

Tablets Orientation

This mechanism arranges tablets vertically and releases them at one time. Then push horizontally to enter the tablet rotating mechanism. It allows the tablets to rotate circumferentially.

Tablets Inspection

This is the fundamental process of tablet inspection. Through multiple optical reflectors, illuminating lamps, and cameras tablets are inspected visually in all directions.

Discharging Mechanism

The inspected tablets are sent to a collector by discharging mechanism where a side-by-side visual inspection process takes place. Finally, the defective tablets are collected into the rejection device, while qualified tablets are sent to the final product barrel.

8.What defects can be analysed by a tablet inspection machine?

Following tablet defects can be assessed by tablet inspection machine:

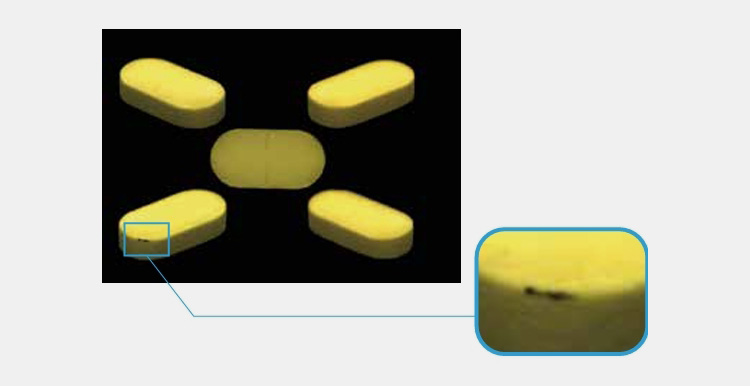

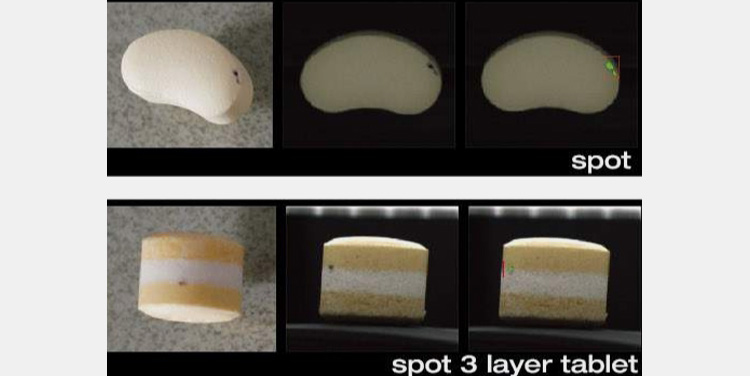

Spots

A tablet inspection machine helps you in identifying the spots on tablets. This is accompanied by discoloration or black speckles over the surface. There are many reasons, such as contamination of raw products, manufacturing fault or particle-particle interaction.

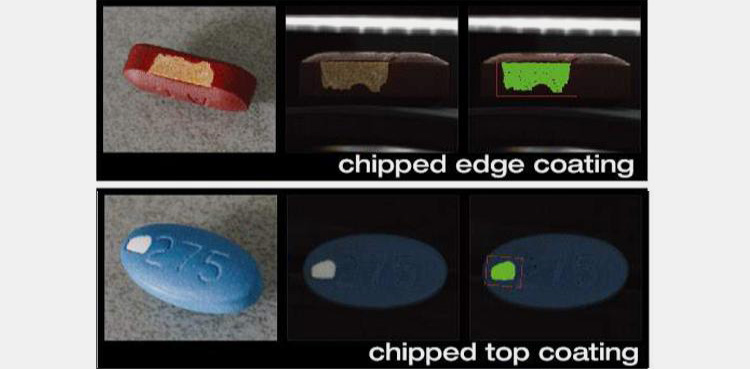

Chipped Edges Coating

It is the breakage of tablet edges during the handling or coating procedure of tablet manufacturing. This could be occur due to certain reasons such as less lubricant or inadequate drying time during coating. The tablet inspection machine is of great value to detect the problem.

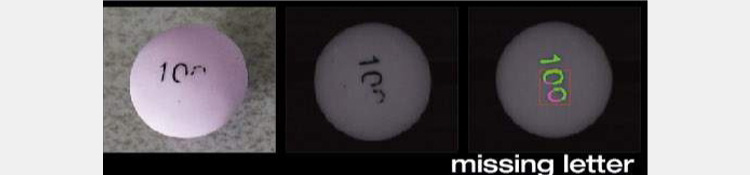

Missing Logos

To have a logo on tablet assures a good branding. Sometimes it is missing during the manufacturing process. It is necessary to identify it via using inspection machine.

Spots in Engraving

Spots in engraving present a poor quality of the manufactured tablet. It may occur due to reduced drying time, improper binders, or addition of coloring agents, etc. Tablet inspection machines accurately catch this problem via efficient detecting cameras and illuminating lights.

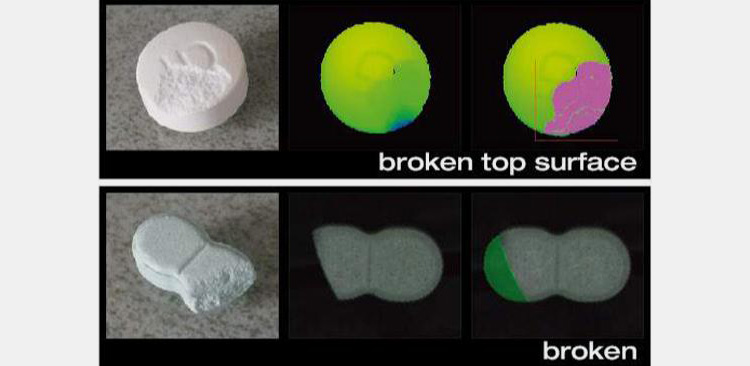

Broken Top Surface

Breaking the top or side surface during compression process is a very common problem. It may disturb the integrity of tablet and patient compliance. The machine ensures finished product is free from broken tablets.

Tablet Cracked

Inadequate lubricant, solvent, binders, or tablet compression results in cracking. Tablet inspection machine immediately catch the problem and transfer the tablets into rejection box.

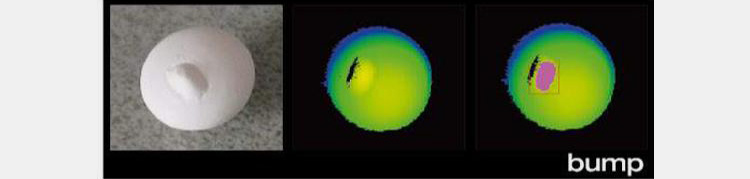

Bump

Due to bad lamination or coating, a bump is formed on the tablet’s surface. The machine has ability to detect the problem via illuminating properties.

9.What different sizes and shapes of tablets are inspected on the tablet inspection machine?

Discussed below are categories of tablets that can be easily analyzed by a machine:

| Name | Diameter | Length | Width | Height | Image |

| Large Tablet | 12.5mm | - | - | 6.3mm |  |

| Thin Tablet | 9mm | - | - | 2.2mm |  |

| Deep Convex | 6mm | - | - | 3.6mm |  |

| Small Size | 4.3mm | 2.6mm |  |

||

| Large Oblong | - | 22.4mm | 9.5mm | 6.2mm |  |

| Large Thick, Deep Convex | - | 14.2mm | 7.0mm | 6.3mm |  |

| Oval With Sharp Edges | 14.1mm | - | - | 6.7mm |  |

| Small Size Oblong | - | 9.1mm | - | 4.5mm |  |

| Water Drop Shape | - | 15.1mm | - | - |  |

| Octagon Shape Uncoated | - | 10.0mm | - | - |  |

| Half-Round Shape | - | 9.5mm | - | - |  |

| Pentagon Shape | - | 9.0mm | - | - |  |

| Triangle Shape | - | 11mm | - | - |  |

| Peanut Shape Uncoated | - | 10mm | - | - |  |

| Heart Shape Uncoated | - | 7.0mm | - | - |  |

| Sugar Coated | 10.5mm | - | - | 5.7mm |  |

10.What are the technical problems and troubleshooting of tablet inspection machine?

A Tablet inspection machine is an advanced technique where an actual defect can be displayed on a touch screen to alarm the operator. You must know the common technical problems and their solutions when operating a machine. Such as:

| PROBLEM | SOLUTION |

| Conveyor Belts Produce Noise |

|

| Incorrect Tablet Inspection |

|

| Less Sensitive to Display Contrast Defects |

|

| The machine cannot Power ‘ON’ |

|

| The machine does not detect faulty tablets |

|

| Cameras give uncleared images |

|

11.How to select the most suitable tablet inspection machine?

To declare that a tablet meets quality standards, you must pass through it a tablet inspection machine to assure its potency and consumer safety. It displays all relevant parameters that every production line looks for. Selecting the most suitable machine is equally important as other manufacturing equipment. You must consider the following significant points when choosing the right one.

What is your production material? For e.g., multi-layer tablets, micro-tablets, uncoated, coated, or effervescent.

What tablet inspection machine do you need? For e.g., visual inspection of pharmaceuticals or healthcare products or assessing the chemical composition.

High Visual Inspection Machine

Are you looking for a high-speed inspection unit for tablets?

What are your production goals? How many tablets do you want to inspect via inspection machine? For e.g., tablets/hour or tablets/day.

What is your financial budget? You can discuss these factors with your supply vendor also. According to our analysis, asking for consultation or technical support will help you to achieve the right machine.

What camera system do you require for the tablet inspection machine? 2D or 3D?

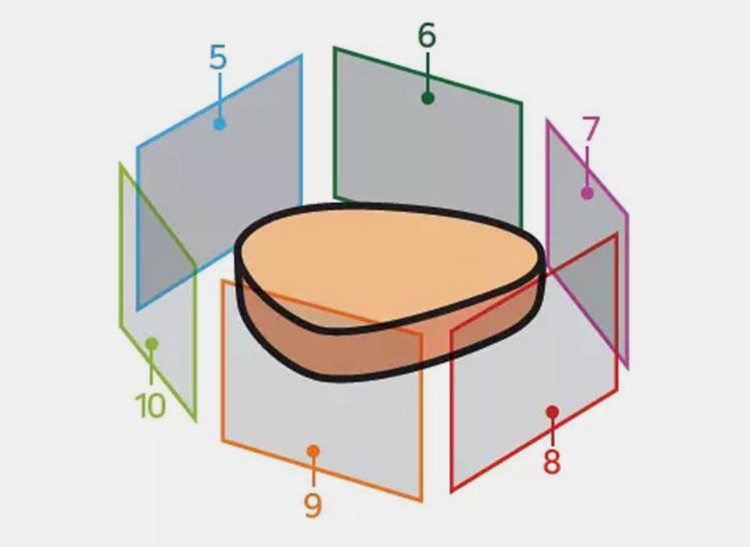

Pharmaceutical and health sectors are strictly confined to automatic versions. This is because each tablet is inspected from 8 different directions by 2D cameras (2 cameras capture images from the top and bottom, remaining 6 cameras take images from surroundings). Similarly, 3D cameras help in monitoring engraves and broken tablet surfaces.

CONCLUSION

With the automation of tablet inspection machines, the pharmaceutical industries are capable enough to offer quality products. The machine is capable meet the criteria assigned by the consumers. Aipak Pharmaceutical is a leading manufacturer of pharmaceutical equipment that strictly conforms to international quality standards. If you have more queries about Tablet Inspection Machine or require technical support. Please feel free to contact us 24/7/365.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine