Tablet Film Coating Machine: the Complete FAQ Guide In 2025

Have you noticed that there are various colors and flavors on the surface of the tablets when you are taking them? In fact, there is a thin film coating on the outside. Film coating can protect drug ingredients from oxidation and decomposition, increase drug stability, and have functions such as moisture resistance, light avoidance, and air isolation. Therefore, film coating is an indispensable process in the production of drugs, especially tablets.

Do you know the something about tablet film coating machine? Next, let’s take a look at the complete FAQ guide of tablet film coating machine!

1.What Is the Definition of Tablet Film Coating?

AIPAK Tablet Film Coating Machine

The tablet film coating machine is to evenly spray a relatively stable layer of high molecular polymer coating material on the surface of the tablet through spray, forming a plastic film layer several microns thick, so as to achieve certain expected results. Tablet film coating machine has multiple uses, such as making tablets easy to identify and swallow, controlling the drug release curve of tablets, etc.

Usually, tablet film coating is the most commonly used type of coated tablet. The film coating process technology is advanced and very complex, sometimes requiring the use of computational modeling and multiple coating techniques to achieve the expected results.

2.What Is the Benefits of Tablet Film Coating?

Why do tablets need film coating? In fact, there are many benefits to tablet film coating.

Protecting drugs

Protecting Drugs - Sourced: The Telegraph

The stability of drugs is poor, and the film coating of tablets can protect the drug core from external environmental influences such as humidity, light, etc., ensuring drug stability.

Control drug release rate

The main function of the release rate regulator in film coating technology is to control the release rate of drugs within a given time, thereby making the drugs more effective. By controlling the release rate, it is possible to avoid excessive drug release in a short period of time, achieve sustained or controlled release effects, and allow the drug to last longer in the body.

Covering up the smell of drugs

Covering Up the Smell of Drugs - Sourced: Thomas Processing

Most medicines have a bitter taste, which can cause consumer aversion due to its strong unpleasant odor. The film coating can mask unpleasant odors or flavors, improve the taste and smell of drugs, making pills easier to take.

Extending the shelf life of drugs

Film coating technology can extend the shelf life of drugs, allowing the active ingredients of drugs to remain active for a longer period of time.

3.What Are the Material Used in Tablet Film Coating Machine?

Film coating is a commonly used technique in the pharmaceutical industry to improve the appearance, stability, and ease of use of drugs. There are various materials can be used in tablet film coating machine, and the following will provide a detailed introduction to these materials and their functions.

Polymer

Polymer - Sourced: RSP Inc.

Polymer is the main component of film coating, which determines the basic properties and characteristics of the coating film. Commonly used polymers include cellulose derivatives, polyacrylic esters, polyvinylpyrrolidone, etc. These polymers have good film-forming properties, stability, and water resistance, which can protect drugs from external environmental influences.

Plasticizer

Plasticizer - Sourced: Dai A Industry

Plasticizers are materials used to increase the flexibility and extensibility of film coatings. Common plasticizers include glycerol, polyethylene glycol, etc. They are compatible with polymers, reducing the glass transition temperature of the coating film, thereby improving its flexibility and cold resistance. The selection of plasticizers should be determined based on the type of polymer and the performance requirements of the coating film.

Pigment

Pigment - Sourced: Accent Permanent Makeup

Pigments are materials used to impart specific colors to film coatings. In the pharmaceutical industry, the use of pigments can not only improve the appearance of drugs, but also play a role in distinguishing different drugs. Commonly used pigments include iron oxide red, iron oxide yellow, titanium dioxide, etc. These pigments have good covering power and stability, and can meet the coloring requirements of film coatings.

In addition to the above materials, other auxiliary ingredients such as light blocking agents, antioxidants, etc. may also be used in the tablet film coating machine to improve the specific properties of the coating film. The selection of these auxiliary components should be determined based on specific needs.

4.What Is the Manufacturing Process of Tablet Film CoatingMachine?

Do you have any understanding of the manufacturing process of tablet film coating machine? For the coating production process, there are three stages: charging, spraying, and discharging.

The Manufacturing Process of Tablet Film Coating Machine

Charging

Pressed tablets (plain tablets) are usually temporarily stored in stainless steel containers such as IBCs. Workers use tools such as shovels and ramps to slowly insert the tablets into the coating machine through the circular window in front of the machine. During the process, attention must be paid to the drop to avoid damaging the tablets and producing defective ones.

Spraying

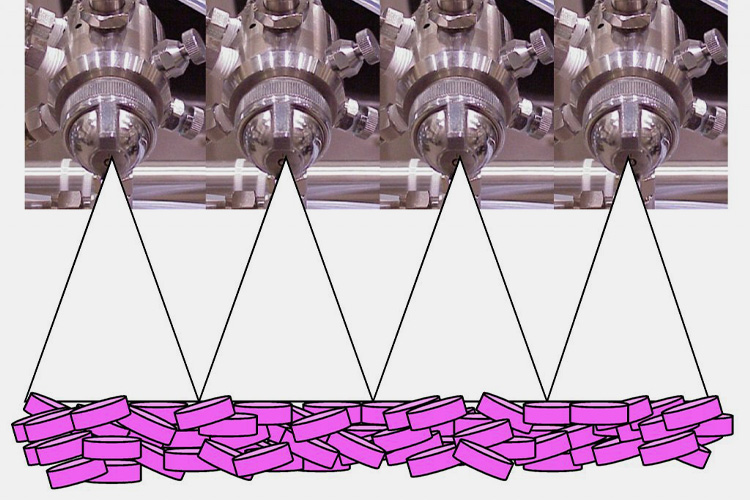

Spraying - Sourced: Freund Global

Operators slowly inject the prepared coating material slurry (mainly composed of easily film-forming polymer materials) into the nozzle position through a peristaltic pump.

Under the action of high-pressure gas, the slurry is sprayed as scattered droplets on the surface of the tablets. At the same time, a certain temperature and air volume are used to quickly dry it. The coating pot keeps rotating to ensure that all surfaces of the tablets are uniformly coated with a thin film formed by the polymer material.

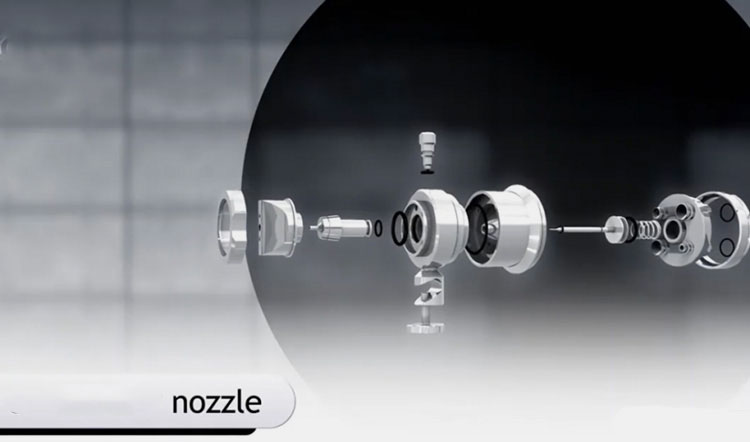

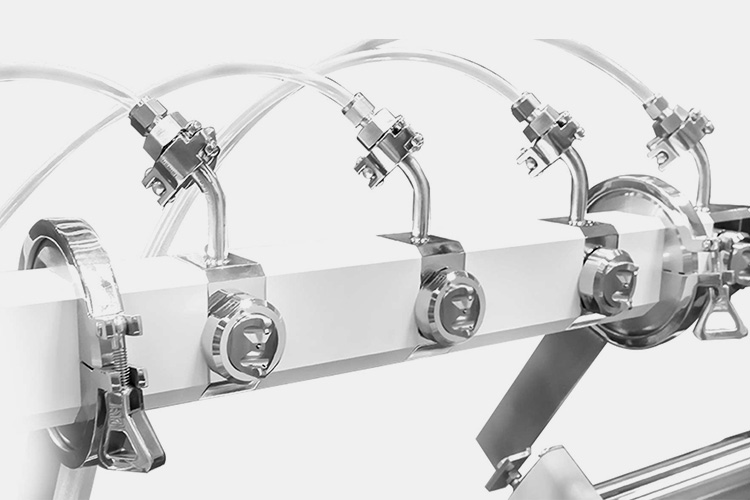

Nozzle

Here, there are several key points in the hardware of tablet coating film machine.

First, the structure, performance and anti blocking design of the nozzle, as well as the convenience of adjusting the spray angle, affect the quality of the spray sector;

The second is the aperture ratio of the coating pot (about 3mm per aperture), which affects the drying efficiency of the coating;

Third, the position of the air outlet shoe matches with the height of the tablet bed, the spray angle and the wind direction angle, which affects the utilization efficiency of the coating materials and the coating effect.

The fourth is the design of the stirring blade, which affects the rolling efficiency of the film. Some coating machines are designed to be replaceable.

Discharging

Discharging

After the weight gain and appearance of the tablets meet the requirements, stop spraying and thoroughly dry them. Then sprinkle an appropriate amount of polishing agent (such as talcum powder) and continue rolling for a few more circles to complete the coating.

The next step is to take out the tablets, usually in two ways: one is to install a dedicated tablet guide slot, and use the continued rotation of the coating machine to gradually guide the tablets out and drop them into intermediate containers such as IBCs. The second is to rotate the coating pot in the opposite direction, using specially designed blades to export the pills out of the pot.

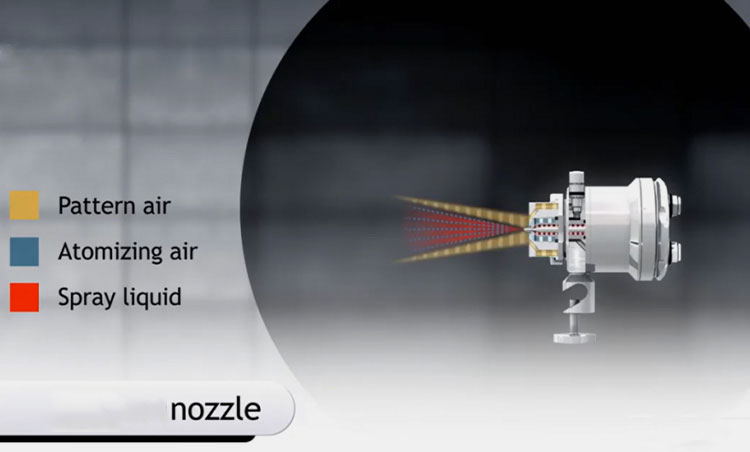

5.What Is the Special Design of the Nozzle in Tablet Film Coating Machine?

Special Design of Nozzle in Tablet Film Coating Machine

Especially for nozzles of tablet film coating machine, they are generally designed with three paths: spray liquid path, atomizing air path, and pattern air path. Under the action of atomizing air, the slurry droplets are conical and radiate. Through the flattening action of pattern air, a pattern shaped droplet spray is formed, which is evenly sprayed on the tablet bed.

6.Why Choose AIPAK Tablet Film Coating Machine?

In the modern pharmaceutical industry, the selection of tablet film coating machines plays a crucial role in the efficiency of the process and product quality. As one of the world’s leading pharmaceutical equipment, it is widely used in tablet film coating processes due to its efficient and reliable performance. The overall characteristics are summarized as follows.

Optimized airflow design

Adopting advanced airflow technology, AIPAK tablet film coating machine makes the airflow distribution more uniform during the coating process, ensuring the uniformity and high quality of the coating layer on the tablet surface. In addition, AIPAK’s equipment effectively reduces the waste of coating liquid and improves production efficiency through intelligent airflow control.

Accurate spray system

Accurate Spray System - Sourced: Flud Air

Equipped with a high-precision spray system, the coating machine can evenly and accurately spray the coating solution onto the tablet surface. Spray uniformity is the key to ensure the film quality. AIPAK’s equipment performs well in this respect, effectively avoiding uneven coating or excessively thick film.

Flexible design

AIPAK film coating machines offer different models and configurations to meet production needs of different scales. Whether it is small-scale laboratory production or large-scale industrial production, AIPAK can provide suitable solutions to meet customers’ personalized needs.

Intelligent control system

Intelligent Control System - Sourced: O’Hara Technologies

Equipped with an advanced control system, AIPAK film coating machine is easy to operate and can monitor key parameters during the coating process in real time, such as temperature, humidity, airflow rate, etc., to ensure that each batch of production meets regulatory requirements. In addition, its system supports data recording and tracking, which helps optimize the production process and quality control.

7.What Are theSolutions to Common Problems in the Production of Tablet Film Coating Machine?

The film coating technology has been widely used in solid preparations, but some technical problems have been encountered in trial production of tablet film coating machine. Now let’s take a look at the common problems and solutions.

Problem 1: Wear and cracking of tablet surface

Wear and Cracking of Tablet Surface

Solution1: Adjusting the prescription or production process of the tablets

The tablet core should be strong, wear-resistant, and have strong adhesion to the coating layer on one side. In addition, when selecting the tablet type, it is advisable to choose round, double convex tablets for coating to reduce the occurrence of coating defects.

Solution2: Adjusting the prescription of the coating solution

Increasing the solid content or viscosity of the coating solution, and improve the strength and adhesion of the coating film. The solid content in general water-based coating systems is 12%, while the solid content in organic solvent systems is 5% to 8%.

Solution3: Increasing the spray speed

The spray speed of tablet film coating machine should be increased, especially at the beginning of coating, the spray speed should be slightly faster, so that the core can be coated with a film in a short time to protect the core. Increasing the spray rate can also reduce the bed temperature, evaporation rate and film temperature, reduce the internal stress, and also reduce the incidence of film cracking.

Problem 2: Adhesion and blistering of the film

Adhesion and Blistering of the Film - Sourced: Tech-publish

Solution1: Adjusting spray and drying speed to achieve dynamic balance

The operators should reduce the spray speed of tablet film coating machine, increase the air inlet volume and temperature, and increase the bed temperature and drying speed.

Solution2: Adjusting the prescription of the coating solution

Increasing the solid content in the coating solution within the allowable viscosity range, reduce the amount of solvent or increase the ethanol concentration appropriately; Anti adhesive agents such as talcum powder, magnesium stearate, micro silica gel, or dipeptides can also be added appropriately.

Solution3: Choosing an appropriate tablet shaped coating

But for flat tablets, such as buflomedil hydrochloride tablets, efficient coating pots or baffles were later used in ordinary coating pots to promote the rolling of the tablet bed, successfully achieving coating.

Problem 3: Rough tablet surface

Rough Tablet Surface - Sourced: Colorcon

Solution1: Improve tablet core quality

On the premise of ensuring the quality of the tablet core, operators should adjust the coating solution prescription to reduce the viscosity (concentration) or solid content of the coating solution. Alcohol soluble or alcohol 2-water coating solutions can be selected.

Solution2: Increasing the atomizing pressure.

Operators should increase atomizing pressure of tablet film coating machine to accelerate the spray speed, and improving the atomizing degree and spray gas volume, so that the droplets are forced to spread on the surface of the film to form droplets with smaller average diameter to prevent the occurrence of large droplets, especially for coating solutions with higher viscosity.

Solution3: Adjusting the distance between the spray gun and the bed

Operators should choose a spray gun of tablet film coating machine with a smaller nozzle diameter (015 mm~1.2 mm) and a higher atomizing gas flow rate.

Problem 4: Color difference of film coating

Color Difference of Film Coating - Sourced: Paramount Wellness Retreat

Solution1: Increasing the amount of coating

In order to solve this problem, operators should choose a formula with strong covering power, or use a white coating material with strong covering power for pre coating (especially for colored tablet cores, especially traditional Chinese medicine tablet cores).

Solution2: Increasing the number of spray guns

You should ensure that the spray gun is in the correct position and adjust the atomizing effect and spray range of the spray gun. In addition, selecting high-quality, insoluble lake as the coloring agent, adjust the coating compatibility to ensure that the coloring agent can be evenly dispersed in the coating solution, and design an isolation layer for the tablet core to prevent uneven discoloration caused by the reaction between certain components of the tablet core and the coloring agent.

Conclusion

Do you have a deeper understanding of tablet film coating? Tablet film coating machine has many benefits and has become an indispensable process in tablet production. Do you have any questions about the tablet film coating machine? You can contact AIPAK at any time.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours

Tell us your material or budget,we'll reply you ASAP within 24 hours