High Efficient Tablet Coating Machine

Meeting GMP requirements

High Energy Conservation

Good Safety

AIPAK Tablet Coating Machine

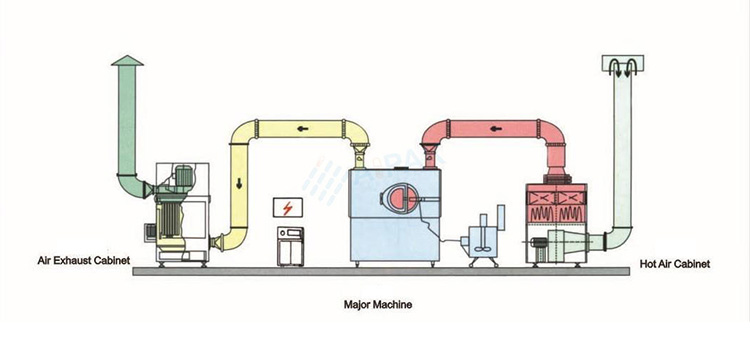

AIPAK BG series Tablet Coating Machine can be used for coating various tablets, pills, and sweets with organic film, water-soluble film sugar film, etc. Has high efficiency, low energy consumption, and a small floor area occupation. Widely used in pharmaceutical, chemical, and food research institutes for coating and polishing tablets and pills. Also used in the food industry for making candy pills or coated and polished sugar-coated tablets.

AIPAK BG series Tablet Coating Machine is made of high-quality stainless steel and meets the GMP requirements.

The tablets make complicated and constant track movement with easy and smooth turning and frequent exchanging in the clean and closed rotational cylinder of the film coating machine. It can automatically spray coating medium according to the process flow and reasonable process parameters. The hot air exhausts through the bottom of the tablets under the effect of air exhaust and negative pressure to make the coating medium dry quickly on the surfaces of the tablets and form a firm, fine close, and smooth surface film.

The Buyer's Guide

Tablet Coating Machine:the Ultimate Buying Guide in 2025

"Is the medicine no longer sugar-coated?" Someone is questioning the pills when buying cold medicine in a drugstore.

After a talk with the shop assistant, she learned that sugar-coated tablets refer to pharmaceutical-coated tablets whose coating layer is mainly sucrose, which are very widely used in the early times.

Sugar coating has certain moisture-proof and air isolation functions, can cover up the bad smell of drugs,can improve the appearance and make the patients easy to swallow, has little effect on tablet disintegration.

But now the pharmaceutical factory basically no longer uses it,tablets nowadays are basically coated with film.

Because after polishing, the color of the film coating is bright and the integrated consolidated coating produced by the sugar crystallization on the surface can not only prevent the pills from oxidation, deterioration, moisture or volatilization, but also cover the uncomfortable taste of the pills when it is taken.

So,when it comes to this,you may naturally think of the tablet coating machine.

Today,I am going to use this tablet coating machine ultimate buying guide to introduce all vital aspects covering features,benefits,classifications,working principle and FAQ about this machinery.

You are going to learn how to buy a high quality tablet coating machine by sparing a few minutes reading this article.

1. What is a Tablet Coating Machine?

A tablet coating machine is equipment that applies a thin film or layer to the external surface of a pharmaceutical fully compressed tablet.

Tablet coating machine

It is widely used in pharmaceutical, chemical, and food research institutes for coating and polishing tablets and pills.

It is also used in the food industry for making candy pills or coated and polished sugar-coated tablets.

2. Where are Tablet Coating Machines used?

The most common areas that tablet coating machines are:

1. Pharmaceutical Industry

You will always see tablet coating machines used for pharmaceutical drug manufacturing.

Tablet coating machines will aid in increasing the appeal, improving their colors, covering up bad taste, or releasing drug speed thus facilitating drug function.

The coated drugs will be easier for the patients to take due to their coating features.

2. Food Industry

Another most commonly seen industry that uses coating machines is confectionery.

Some food will have a good taste and beautiful appearance after being coated.

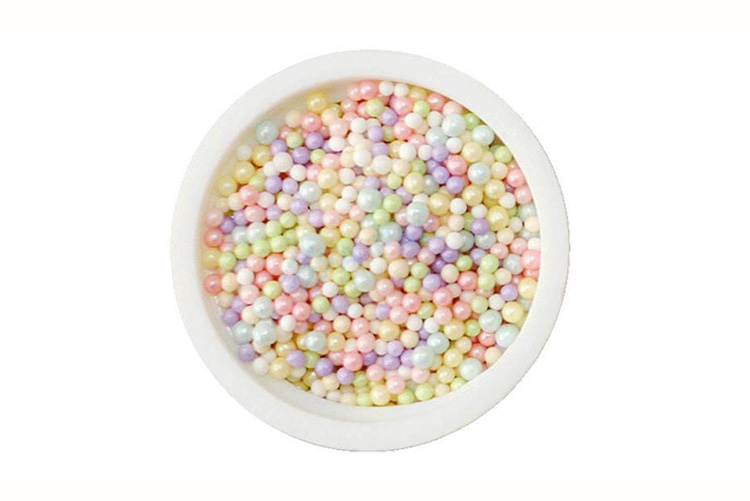

Coated candies

Some dried fruits will become tasteless as their sugar content was lost through drying, but with the help of a tablet coating machine, they will be sugar added, which will be more attractive and have better taste.

3. Cosmetic Industry

The cosmetic industry uses a tablet coater machine for the manufacturing of certain cosmetic products.

Coated Make-up pills

With color and stability properties added to the cosmetic products, they will become more eye-catching and, hence for the final purpose, increase their sales.

4. Agriculture Industry

Seed coating is a new and high technology developed in the mid-1980s to promote agricultural production and harvest.

Coated seeds

Seeds coated with seed coating agent can rapidly absorb water and expand after sowing. With the gradual development of the embryo and the growth of seedlings, the effective components contained in the seed coating agent are released slowly and absorbed into the body by the seedlings.

To achieve the purpose of preventing and controlling diseases and insect pests, promoting growth and development, and increasing crop yield.

Seed coating has been listed as a key agricultural technology project in China.

Besides, seed coating may cause negative effects on ecology, such as the decline of the bee population.

3. Why do you need your tablets coated?

Some tablets need to be coated, they are:

- Have a bad smell.

- Need to control the drug release position.

- Necessary to reduce the stimulation to the stomach.

- Necessary to control the release rate of drugs to achieve the purpose of sustained release and long-term effect.

So the reasons why you need your tablets coated are:

It will cover up the bad taste of drugs for your easy swallow.

It will enhance the appearance of your tablets to make them more attractive and easy for your identification.

It will be moistureproof, lightproof, and air-isolated to increase the stability of your tablets.

It will control the release rate of your tablets as the coated tablets will reduce your daily taken times, or otherwise, a large number of tablets released in a short time is likely to cause side effects.

It will be convenient for your tablets to form, allowing your tablets to enter a specific position (such as stomach and intestine), then disintegrate, and control the tablet's release speed.

It will guarantee your tablet efficacy within the validity date as the coating will stay the same with your tablets.

It will allow you to place two or more kinds of drug ingredients with compatibility to the core and coating layer respectively to avoid the drug property change.

It will make you avoid the situation that drugs are damaged in gastric juice by acid or gastric enzymes, and then stimulate the stomach, causing vomiting.

4. What are the advantages of using a Tablet Coating Machine?

You will have below advantages of using a tablet coating machine:

1. Your tablet stability enhanced

Through the coating process, your tablets will become water-resistant, and will not react with the outside environment.

This will not only enhance your tablet's stability but also increase its lifespan and usability.

2. Your tablet's chemical incompatibility prevented

Using a tablet coating machine will reduce the chances of chemical contamination when your tablets are mixed with other tablets.

Hence, this also increases the safety of the tablets.

3. Your tablets for easy identification

Some tablets may look the same and sometimes will be wrongly taken by the users.

While using a tablet coating machine, you can print various logos or patterns written on your tablets, which will make them easier to identify.

4. Your tablet's appealing enhanced

Through colorful coating, the appearance of your tablets will be enhanced, thus making them more attractive.

But also increase your tablet usage rate as they are more acceptable.

5. Your tablet lifespan prolonged

The temperature and humidity will affect your store time and the quality of your tablets.

So using a tablet coating machine to coat your tablets will minimize the external environmental interference to them.

5. Are there any disadvantages of coating your tablet?

Yes, just like everything is double-sided, the disadvantage is using a tablet press machine to coat your tablets.

They are:

Cost increasing

It will add to your costs as coating tablets is an expensive process.

You will have to spend a large sum of money on purchasing the coating machine, buying the coating materials, energy running or maintaining the machine.

Space occupying

You need to have a large space to make the effective running of the tablet coating equipment as it is a connected line made by some devices.

Tablet properties changing

To some extent, coating tablets may change certain properties, such as the smooth, which is especially obvious when the tablets are unevenly coated.

Some pharmacodynamic properties of the tablets may also be changed, thus making the tablets difficult for you to swallow.

Solvent Toxicity

The mixture of solvent is a complex process, requiring a proper amount at a certain time, or the change of the solvent properties will result in hazardous and toxic.

Besides, you may also encounter defects such as chipping, capping, or bridging due to the tablet coating process.

6. Which material can you use for Tablet Coating?

The main materials that you can to coat your tablets include:

1. Polymers

Polymers are materials with relative thousands and millions of molar weights.

A large number of molecules will form a chain that binds together during the chemical reaction, which makes the polymers the ideal material for tablet coating.

Now, the most commonly used polymers are Carbohydrates, glycols, vinyl polymer, acrylic acid, and cellulose.

Polymer

The polymers also can dissolve in various types of solvents.

And when meeting with light, oxygen, moisture, heat, or tablets such factors, they are still stable.

The polymers are highly compatible with different additives used for the tablet coating.

Last but not least, polymers are non-toxic as they are free of any pharmacological activity.

So, tablets coated with polymers are in good appeal which are attractive to the customers.

2. Plasticizers

Plasticizers have light molecular weight.

They are used together with polymers to change the physical properties.

The most commonly used plasticizers for tablet coating now are glycerol, diethyl phthalate, and fractionated coconut oil.

They are critical in weakening the polymer chain attraction and important in attracting the dispersed solvent polymer spheres together in the coating process.

Different plasticizers may have different coat permeability due to their different physicochemical properties.

Its using is to decrease the elastic modulus and the tensile strength and then increase the coating adhesion during the coating process in different conditions.

3. Colourants

Colorants are pigments in the coating process that increase the appearance of the tablets and then make the tablets more eye-appealing.

They also play an important role in making the variation of tablets in various industries.

The main types of colorants used nowadays include FD and C lakes, D and C lakes, and water-soluble dyes.

Besides, colorants are key to shading the tablets since they increase their opaqueness.

You will also find the colorants have good moisture barrier properties.

4. Solvent

Use the solvents but not water due to solvents have poor drying properties.

The most commonly used solvents include ethyl acetate, ethyl lactate, chloroform, and methylene chloride.

In addition, you can also use other materials like flavors or sweeteners to coat your tablets.

Because the flavors or sweeteners will cover the bad odor from the tablets and make them more delicious.

7. How many types of Tablet Coating methods are there?

Depending on different coating materials, there are many types of tablet coating.

You can see these include:

Sugar coating

Sugar coating machine-Photo Credits: Food processing

Sugar coating has been used widely in the confectionary and pharmaceutical industry in the past but now have been replaced by film coating.

You can use sugar coating to produce a variety of foods such as dried fruits, seeds, nuts, toffees, chewing gums, caramels, biscuits, chewy candies, and extruded products.

They are more appealing to young children as sugar-coated products are more shiny, and colorful and have a sweet taste.

Sugar-coated products

You can apply syrup, sucrose, dextrose, polyol, and icing sugar to cover the tablets using a sugar coating machine, and the sweet water will evaporate in the hot hair, thus, leaving a thin sugar layer around the tablets.

Sugar-coated tablets will become smooth, rounded, and glossy.

Surely, tablets with sugar coating will taste sweet as the sugar has hidden the bitter taste, so you can also use sugar coating to cover drugs with bad smells.

Film coating

Nowadays, as traditional sugar coating not only takes time but also not labor-saving and can’t guarantee quality, so with the rapid development of the pharmaceutical industry, film coating has become a trend, and efficiency is also much faster.

AIPAK Film coating machine

Film coating is spraying a layer of a relatively stable solution of polymer, plasticizers, solvent, and colorant on the core surface by a sprayer, and forming one or several layers of continuous, dense, durable, and functional coating film.

The sprayed tablets are dried in the rotating plan immediately, so, you can see the main advantage of film coating is the entire covering time is quite short.

It is suitable for coating, polishing, and rolling round pills on the surface of Chinese and Western medicine tablet cores in the pharmaceutical, medical, food, and healthcare industries.

A high-quality coating agent for color film should have: no stratification, no precipitation; no nozzle plugging; consistent color; fast film formation; strong adhesion; flexible film; smooth and even.

Film coating is a little bit expensive but you may be also faced with some challenges.

As the film coating agent is not just a mixture of several subsidiaries, the whole process is still quite complex, because each subsidiary will interact with each other, whose physical state and physical relationship will change a lot, such as phase transition, and molecular fusion.

Products by film coating

In addition, generally speaking, there are types of film coating, they are oral dissolution, slow-release, and controlled release.

The material used for film coating can be divided into enteric and non-enteric.

While enteric material cellulose acetate and so on, and non-enteric material include hydroxypropyl cellulose and hydroxypropyl methylcellulose.

Enteric coating

It refers to a tablet that bypasses the stomach and releases the drug into the small intestine.

It is a common tablet that is coated with an enteric coating on the surface.

Is enteric-coating Aspirin safer?_photo credits: Berkeley Wellness

Aspirin enteric coated tablet is the most typical enteric one.

Enteric coating assists in making the tablets go through the stomach into the small intestine without being dissolved and slowly released in the small intestine.

So for this reason, you can not crush or chew an enteric coating tablet.

It may result in destroying the gastric mucosal barrier and blocking the blood flow of gastric, thus, affecting the drug curative effect.

Gelatin coating

This type of coating is to cover the tablets with a gelatin layer.

You will find the tablets become capsule-shaped after compression.

Gelatin is a natural binding, coating, and disintegration agent that meets the requirements of those consumers concerned about the use of chemically modified ingredients.

Gelatin coating tablets-Photo credits: Yasin Gelatin

You can also make your branding on the tablets, thus, preventing counterfeiting.

Surely, the gelatin coating also helps in covering up the bad odor and smell, providing a delayed release of the medication, maintaining the shape of the tablet, thus, improving the stability of tablets,

Apart from that, the contents of tablets are protected from stomach acids.

8. What is the difference between Film Coating tablets and Enteric Coating tablets?

You will get the difference between film coating and enteric coating tablets are:

1. Enteric-coating tablets will not dissolve in a gastric environment while film-coating tablets will be easily absorbed within a gastric environment.

2. Enteric coating tablets can be taken orally and dissolve in the upper digestive tract such as the intestines while film coating tablets are used for the lower digestive tract.

3. You will have an advanced enteric coating tablet for drug absorption studies.

4. Film coating tablets and enteric coating tablets are all the main formulation components, such as the Polymer, Plasticizer, Colourant, Opacifier, and Solvent.

9. How many types of Tablet Coating Machine are there?

There are several types of tablet coating machines in the market now.

The three principal types are:

1. Standard Coating Pan

It is the most commonly used tablet coating machine in the pharmaceutical industry.

Coating Pan Machine-Photo Credits: Indiamart

It consists of a circular metal pan between about 15 and 200 cm that is 6 to 80 inches in diameter which is tilted on a benchtop stand.

The pan will be rotated with an electric motor.

When you put a batch of tablets into the pan that has been set to rotate, the rotating motion will make the tablets tumble within the pan.

Then you will apply the coating solution to the rotating tablet bed by spraying in atomized form, which will produce much faster and make a more even distribution than simply using it as a liquid.

At this point, you need to do the drying now.

While there are three ways for you to acquire the effective drying :

1. You can also use a baffled pan and diffuser, which will allow the uniform distribution of drying air over the surface of the tablets.

2. An immersion sword, that is the drying air is distributed through a perforated metal sword that is immersed in the bed.

3. An immersion tube system, that is the tube is immersed in the bed where the tube delivers heated air through the spray nozzle.

2. Perforated Coating Pan

This equipment is made by a partial or full perforated drum that rotates on its horizontal axis, the whole system being enclosed in a sealed housing.

Perforated Coating Machine

The drying air is directed to the drum, passing through the tablet bed, and is released through the perforations in the drum.

During the drying process, you will find the drum rotates the dip into the tablet bed and dry air passes up through and fluidized bed with the air exhausting through the back of the pan.

The main feature of this machine is that it uses fully perforated drums which combines maximum spray rates and extremely short process times.

The horizontal process airflow minimizes turbulence in the nozzle area and therefore also contributes to a perfect coating result.

The design of the drum will not only protect your tablets but also guarantee a very even and exceptionally high-quality coating.

Besides, the coating solution in all of the perforated pan systems is applied through spraying nozzles which are positioned inside the drum.

3. Fluidized bed coater

Fluidized bed coater-Photo credits: Indiamart

Fluid bed coater is used in food processing to granulate and/or coat solid particulate ingredients.

It originated in the early times to manufacture oral pharmaceutical products.

You will find there are three ways of coating methods in this machine, including:

- Bottom spray

- Top spray

- Tangential spray

When using this machine, you will achieve a variety of goals including the following:

(1)It will reduce the fine particles or dust;

(2)It will improve your handling properties;

(3)It will make homogeneity products for you;

(4)It helps add color or flavor to your products;

(5)It will reduce the undesired flavors or bad taste of your products;

(6)It is a protective barrier coat applications to shield from oxygen, moisture, or other reactive ingredients;

(7)It will introduce the properties of sustained, delayed, burst, or enteric release.

10 . What are the main components of a Tablet Coating Machine?

A tablet coating machine is made of many parts and components,and as the size, functionality, and model vary,the number of parts may vary.

You may need to read through the manual or brochure before you think of buying a tablet coating machine.

Now, let’s explore the basic parts and components of a tablet coating machine:

1. Automated control system

This is the part where you can automatically control the various functions of a tablet coating machine, such as

I. You can select the running/operation state of the machine

ii.You can set various parameters of the machine like the speed,temperature and negative pressure.

iii. You can record or print the working state of the machine.

iv.You can make it display all data during the production process.

ix.You can control the spraying gun or the atomization process.

So, whenever you decide to buy a tablet coating machine, you need to consider the type of technology.

With this, it will be easier for you to optimize all operations of the machine, and at the same time ensure the safety standards.

2. Electric motor

Electric motors perform various operations such as creating negative pressure, blowing air, mixing tablets, etc.

A tablet coating machine may have different types and sizes of electric motors.

For example, in a film coating machine, you may have electric motors in the peristalsis pump, hot air equipment, air exhaust section, and the coating drum.

But remember, they are not the only sections.

In addition,you need to know that a single tablet coating machine will have more than three motors, depending on its complexity and design. You also need to know the rating of the motor, which will determine the energy consumption and cost of coating your tablets.

Tablet coating chamber

3.Touch Screen Operation Panel

This part is the product of technologies advancements in the modern tablet coating machine.

It adopts a user-friendly human machine interface(HMI) for your easy operation.

And the HMI is fully enclosed that allow for your seamless operation of the tablet coating machine.

4. Guide Plate

The tablet coating system features an agitator of streamline guide plate

Its function is to allow all tablets to tumble smoothly.

It is essential when blowing hot air through the tablets during the drying process.

As when the tablets collide with the solvent from the spraying nozzle,the guide plate will prevent possible breakage or chipping.

Moreover, the narrow surface of the guide plate will also help to prevent possible adhesion of the coating material.

5.Peristaltic Pump

You will find many modern tablet coating systems have peristaltic pumps.

As these pumps will help to guarantee the following unique features:

1.It will help to stabilize the atomization by making the spray system simple and easy to be automated.

2.It also aids in making constant pressure variable thereby eliminating the use of return pipes

6.Spraying System

The spray system is made of a tank, nozzle, and pumps and has a simple design.

With the spray system,you will be easier to conduct the following:

1.Stabilize the atomization

2.Clean and maintain the spraying gun

3.Save tablet coating solution

4.Prevent plugging-up of the spraying gun

5.Universally adjusting the head to make easy adaptability

6.Efficient and even atomization with a large coverage of spraying

Besides,you will also need to remember that the spraying system is the heart of a tablet coating machine.

If without proper control, it may lead to wastage of the coating substrate.

7.Exhaust

Hot air that dries the coated powder leaves the system though this section.

So, the exhaust sytem plays an significant role on the temperature dropping.

8.Coating preparation tank

This is the part where you will prepare the coating substrate.

The system pump will then instruct it to the spraying nozzle in the tablet coating machine.

9.Clean air circulation

The clean air circulation is to receive air from the external environment.

It will induce an appropriate amount of heat into the air, before blowing it over the coated tablets.

11. How does the Tablet Coating Machine work?

Fristly,you will have to select approiate coating materials for the coating process.

While this also dependent on the kind of tablets that you want to coat and your desired coating process.

Of course, there are criteria for your selection.

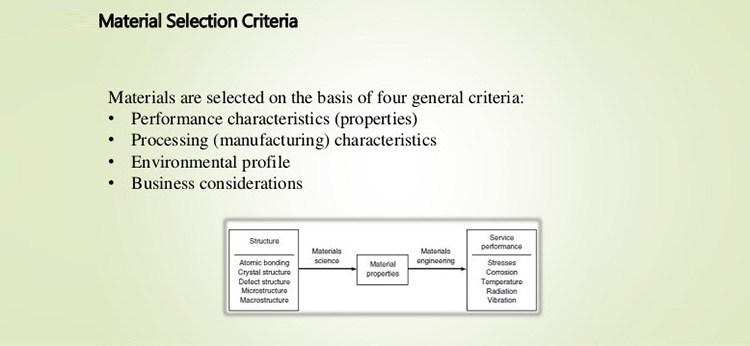

Coating materials selection criteria-Photo creditsSlidesharee

Secondly,you need to do the tablet spinning.

That is, you will put your tablets in a drum and make it rotate.

During this continuous process,the streamlined plate will control most of the operations.

At the same time, when the drum is spinning, the nozzle will spray the coating solution onto the tablets.

In fact,you will use the controlling system to control this process that make it running automatically and guarantee the accurate and even spraying of the tablets.

In addition, the angled baffles in the drum will turn the tablets sideways to aid the even spraying of the tablets.

The third step is the hot air accessing and coating spraying beginning.

That is, when the spraying and rotation process continues, the tablet coating machine will pump hot air into the drum.

Then your tablets will be coated by the solution quickly.

Surely, during the process,the machine will automatically control the temperature of the hot air that flows in,because the excess temperature of the hot air may affect the chemical properties of your tablets.

And the automated control system of the machine will also manage the pressure within the drum to make it aligned with the outside environment.

The fourth step is the drying process.

When all the tablets are evenly coated, the spinning and spraying system will be stopped, and all the tablets will be moved to the drying part.

The air will flow over your tablet to dry them.

Of course, here, there is controlling system to regulate the volume of air that flows over the tablets to make sure there is no interference to the tablets.

The final step is you can packaging your tablets when all these processes are over.

12.What is a Film Coating Machine?

A film coating machine is a new type of equipment that transformed from the original sugar coating machine.

AIPAK BG series Film Coating Machine

It integrates strong electricity, weak electricity, hydraulic pressure, and pneumatic power to apply a thin cover around a tablet.

The coated film is a polymer-based coating material.

Most of the times,you can use either organic solvents or water,which depends on the specific properties you want tablets to possess.

13 . What are the Parameters for the BG series Film Coating Machine?

BG series film coating machine meets the GMP requirements and, is a kind of mechanically and electrically integrated coating equipment.

It has high efficiency, energy conservation, good safety,y, and good cleanliness for organic film coating water-soluble coating, dripping pill coating, sugar coating, chocolate and candy coating of tablets, pills,s, and candies

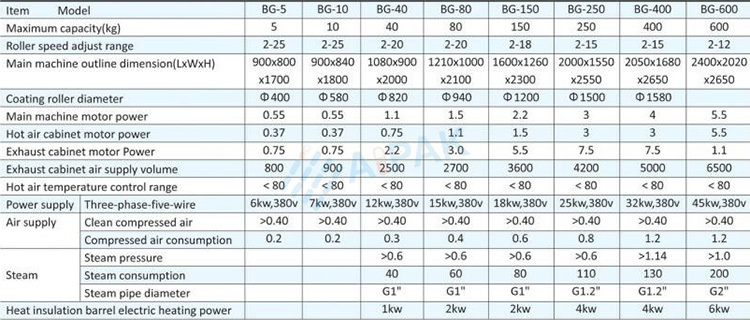

So I would like to share the parameters of the BG series film coating machine with you.

14 . What are the advantages of using a Film Coating Machine?

The traditional sugar coating largely increase the size of the tablets while using a film coating machine,it will not only increase your production and shipping cost but will also bring below benefits to you:

1.Film coating is thin,so it will only add just between 2-3% to its weight,that it will not increase the tablet size .

2. The film-coated tablets are safe for your customer to take.

3. Film-coated tablets will have a better taste as the thin layer will protect the flavor content of the medicine.

4 . The film will protect your tablets from moisture and light that may interfere with the efficacy of your medicine.

5 . Through film coating your drug will become inactive in the stomach.

6 . Using a film coating will help to improve your drug's effectiveness and prolong its dosing interval.

7 . Your tablets will become easier to identify as the film coating will enhance their appearance and make them more acceptable to your customers.

8.Using a film coating machine will facilitate your drug absorption in the body as the film coated tablets will break down in agitation while there is large amount of moisture in the saliva or stomach acid.

15 . What should be considered when choosing a Tablet Coating Machine for pharmaceutical use?

When you are going to choose tablet coating machines for your pharmaceutical manufacturing ,you can select from the following aspects to choose the most suitable one.

1.GMP compliant design

That is, all tablet coating machines used in pharmaceutical must meet with the requirements of Current Good Manufacturing Practice standards.

A tablet coating machine with a compliant design will ensure the safe and quality for you to use.

2. Material type

You must choose a tablet coating machine with corrosion-resistant material for your pharmaceutical use. That refers to the materials that must adhere to AISI 316 for the coating drums, spraying device, and coating substrate container, which are the inner parts.

And AISI 304 for the electrical panel, wheel joints, and the outer casing, which are the outside parts.

3 . Ergonomic Design

It is the tablet coating machine should have a wheel for easy movement, which will also help to reduce the happening of accidents and prevent breakdowns.

In addition,tablet coating machine with ergonomic design will help to enhance the reliability and performance of the machine.

Thus, ensuring the continuous tablet coating of your manufacturing.

16.How to choose solvent for your tablet coating?

A good solvent will affect either your manufacturing process or your tablet's quality.

So you need to consider the following aspects to choosing a solvent to coat your tablets:

1.Environment affection

A good solvent should not react with the environment or have any environment affection. Any reaction with the environment may lead to a change in the chemical properties of the tablets which can result in a hazard of your tablets.

2.Physical properties

You would consider the physical property of the solvent, like the colourless, odourless, inert, and non-toxic as an ideal solvent should have qualified ones.

Organic solvent

3 . Drying rate

An ideal solvent must be able to dry quickly and effectively, to reduce the defect formation of your tablet.

4 .DispersionTheA best solvent should be able to dissolve the polymer system and easily disperse the coating solutions.

17 .Which factors will affect the Tablet Coating Efficiency?

There are things you need to consider in a tablet coating machine as they will affect your tablet coating efficiency.

Here,you will find a list of them.

Air capacity

It refers to the amount of air flowing through the be.

The air capacity will determine the amount of water or solvent that can be removed during the coating process.

It is vital in the drying process of your tablets coating as effective drying will prevent the occurrence of certain defects.

So, to improve your tablet coating efficiency, you must make sure the machine is supplied with sufficient air.

Coating composition

The coating composition includes the ingredients that are applied to the surface as well as to the solvent that acts as a carrier for the ingredients.

The solvent is removed during the coating process by the flow of air through the coating machine.

To speed up this process ,you can heat the incoming air.

However,you must make sure there is a fine balance between the rate at which solvent can be evaporated and the rate at which the coating liquid can be introduced.

Tablet surface area

It is easy to weigh a batch of tablets that are to be coated, to give an idea of the amount of coating solution that needs to be applied.

However, it is the surface area of the tablets that determines the total amount of coating solution required.

The size of the tablets and the nature of their surface can significantly affect the coating conditions and quantities of solution required.

The total area/weight ratio decreases significantly from a smaller to a larger tablet.

So you make sure the size meets the standards of the machine.

An appropriate size will not only affect the efficiency but also lead to tablet defects.

Efficiency of equipment

The conventional sugar coating efficiency is not very efficient but 60% is deemed to be acceptable.

The efficiency of the tablet coating machine will determine the whole coating efficiency.

So you must make sure all components of the machine are in good condition.

18 . How do you protect your drugs from dampness by film coating?

To be clear, the general film coating does not have the moisture-proof effect in a strict sense unless it is used as a sealing layer, the moisture-proof effect can be achieved under special circumstances.

Because the strict moisture-proof effect is likely to cause disintegration or even not collapse within a certain period of time.

Therefore, the so-called film coating moisture-proof mainly refers to delaying the chip cor's damping time.

It is very common to use hydrophobic materials to delay dampness.

But in consideration of economy and safety, the mainstream coating products now are coating agents that take water as a solvent and have the function of delaying the dampness time of chip core, such as all water dampproof coating agents.

Its main principle is to use special polymer materials to fully open the swelling in a large number of good solvents (water), and it will be expanded in a small number of solvents.

The coating agent fully swells in a large amount of water in a certain proportion and forms a dry and continuous film on the surface of the chip core through manipulation.

In the later storage time, due to the change of external conditions, the film may have the opportunity to contact a small amount of water molecules in the air.

At this time, the specific polymer materials in the film will expand due to the presence of a small amount of solvent.

Of course, some other corresponding materials such as adhesion, modulus of elasticity, tensile strength, h, and other film performance indicators will change to some extent, but the basic effect is not significant.

With the expansion of specific polymer materials one by one, the probability of contact between water molecules and the chip core covered by the film is greatly reduced.

At the same time, due to the expansion of the polymer, the pore diameter of water gas migration becomes smaller and the migration path becomes longer, which increases the difficulty of contact between water molecules and the chip core, thus protecting the chip core.

However, when almost all specific polymer materials are expanded, the sacrificial stage of delaying moisture is over, so the long-term stored chip core will still be affected by moisture.

In conclusion, the film coating can only play a role in delaying moisture.

19 . What is the difference between Aqueous Film coating and Non-Aqueous Film Coating?

The aqueous film coating refers to the use of water as the solvent agent during the tablet coating, while the non-aqueous film coating uses organic solvents during that.

The evaporation time for aqueous film coating is longer than that of non-aqueous tablet coating.

So aqueous film coating may lead to tablet defects due to the long evaporation time.

Aqueous film coating tablets

Non-aqueous tablet coating will produce a toxic substance in the environment while aqueous tablet coating is environment friendly and safe.

So when you choose the types of solvents to coat your tablets, you must consider the possible environmental impact.

You can use non-aqueous tablet coating to coat tablets that are sensitive to moisture and use aqueous tablet coating to coat tablets that have a high chemical reactivity.

You need enough ventilation for the non-aqueous tablet coating while the aqueous tablet coating no need.

20. How to troubleshoot common problems of Film Coating Machines?

You may encounter some problems when using a film coating machine, the solutions are:

1. Gluing

This issue is mainly due to too fast spraying, which violates the principle of solvent evaporation balance that makes the tablets adhere to each other.

So, in this case, you will need to reduce the spraying amount of the coating liquid and increase the temperature of hot air and the rotating speed of the boiler.

2.” orange peel" film

This is mainly due to improper drying and low spray pressure of the coating liquid, which makes the uneven heat concentration of the ejected liquid droplets, thus resulting in the corrugation of the film.

Then you will need to increase the spraying pressure and control the evaporation rate immediately.

3."Bridge construction"

This problem refers to the blurring of the mark caused by the coating film on the lettering piece.

The solution is you have to slow down the coating spraying speed, reduce the drying temperature, and pay attention to control the hot air temperature.

4. Appearance of color spots

This situation is caused by uneven mixing or insufficient fineness of the solids when preparing the coating solution.

The solution is you have to mix the coating solution well.

5. Crack, fracture, peeling, or abrasion of the coating film on the surface or edge of the tablet

All these problems are caused by improper selection of coating liquid-solid content, the rotating speed of the coating machine is too fast, and the spraying amount is too small.

So you may have to select the appropriate coating liquid-solid content, and the rotating speed and spraying amount shall be properly adjusted.

If the hardness of the tablet core is too poor, the formula and process of the tablet core shall be improved.

6."Frost spray" appears on the coating film

This situation is caused by too high humidity of hot air, too long spraying process, and poor atomization effect.

At this time, you need to reduce the temperature, shorten the spray range, and improve the atomization effect.

7. There is a color difference between tablets

This problem is caused by the uneven fan surface when spraying liquid, excessive solid content of coating liquid, or slow rotation speed of the coating machine.

At this time, you must adjust the spray angle of the spray gun, reduce the solid content of the coating liquid, and properly increase the rotating speed of the coating machine.

8. There are pinholes on the surface of the coating film

It is caused by too much air involved in the preparation of the coating solution. Therefore, you will have to avoid too much air when dispensing.

21. What are the common problems of the Tablet Coating Machine and how to solve them?

Common problems and solutions of tablet coating machines are:

1. Excessive humidity

The reason for wetting is that the spray speed is too fast compared with the drying efficiency, and there is no balance between spray and drying.

In the process of water-soluble coating, this phenomenon is easy to appear, because water is more difficult to dry than organic solvent.

Because it is too wet, the tablets will stick to the wall of the pot, or they will stick to each other.

This will cause damage and uneven film.

To avoid excessive humidity, you need to carefully control the spray speed and increase the air inlet temperature.

In addition, adding talcum powder or magnesium stearate into the coating solution may reduce the happening of this phenomenon.

2. Tablets surface rough, not smooth

In most cases, spray drying causes the droplets to be unable to spread because of too fast drying.

In addition, the dried polymer particles adhere to the surface of the chip core, which makes the coating film rough.

You can increase the spraying speed, by reducing the air inlet temperature or shortening the distance between the spray gun and the tablet bed.

3. Orange peel phenomenon

This is a case of Coarseness on the surface of the coating film.

The droplet spread on the surface of the chip core is not complete, and the dry polymer particles are irregularly distributed on the surface of the chip core.

That is to say, it is mainly caused by improper drying, so you can avoid it by controlling the evaporation rate, increasing the spraying rate, or shortening the distance between the spraying gun and the tablet bed.

4. Bridging and filling

When the outer surface of the tablet is irregular and engraved with the marking letters, these marks on the surface will disappear and be filled by the coating liquid. This is usually due to the viscosity of the coating solution is too large.

You shall increase the amount of solvent or plasticizer, and then this bridging or filling phenomenon will disappear.

5. Film color difference

In many prescriptions, some pigments or dyes are suspended in polymer coating solutions.

If the mixing is too slow, it will cause precipitation, resulting in color differences between batches of tablets.

If the temperature is too high, the pigment is easy to diffuse and the color of the coating film becomes lighter.

You can reduce this by reducing the amount of plasticizer and stirring the coating solution.

6. Rupture of film

This is one of the common problems in coating.

When the problem occurs, it may occur several hours after the coating.

It is caused by the prescription.

Adding polymer with a larger molecular weight or increasing the amount of plasticizer in the coating solution will avoid this situation.

22. How to maintain the Tablet Coating Machine?

The following steps will help you maintain your tablet coating machine:

- You shall replace the lubricating oil in the gearbox and the lubricating grease in the inner cavity of the rolling bearing regularly, generally for no more than six months.

- If the coating pot is not used for a long time, you should clean it and make it lubricated.

- You shall pressurize the spraying gun and rinse with clear water after using each shift to prevent the mouth from being blocked.

If the mouth of the bottle is blocked, you will have to disassemble the spray nozzle according to the instructions of the spray gun and remove the residue at the mouth with a fine needle.

- To ensure that the worm gear in the gearbox meets the lubrication conditions of the transmission, the temperature rise of the gearbox in operation shall not exceed 50 ℃.

- You should inspect the oil-proof sealing ring at the worm shaft end and replace it regularly, no more than six months.

- The machine must be reliably grounded, and its grounding resistance value shall be ≤ 4 Ω.

- Do not remove electrical appliances at will.

23. How to clean the Tablet Coating Machine?

The cleaning is good maintenance work for the tablet coating machine, which can be more conducive to improving its working efficiency and extending its life.

You will need to note that when cleaning the tablet coating machine, you need to cut off the power supply, remove the dust and waste outside the equipment, connect the drain pipe, and then start cleaning the equipment.

The cleaning of the mixing drum, peristaltic pump, spray gun, and silicone tube should be done:

- Drain the heat preservation water in the mixing drum, then wash the drum with drinking water, and drain the water.

- Add a certain amount of drinking water and cleaning agent into the inner insulation barrel, use a soft brush with a handle to clean the inner wall, remove the sewage, and wash it with drinking water once.

- Then add a certain amount of drinking water and cleaning agent, start stirring, discharge port to a peristaltic pump and spray gun, start the peristaltic pump, open the spray gun, spray and clean the silicon rubber pipe, peristaltic pump, spray gun and spray pipe,

- Change to drinking water and repeatedly rinse and clean.

- Lastly, replace the purified water, then use 75% ethanol to clean and disinfect the whole spray device.

- Close the drain pipe to clean the main engine, connect the drinking water inlet pipe, open the valve, and add the water into the coating roll.

24. How to choose the most suitable Tablet Coating Machine?

When purchasing the tablet coating machine, you should not only blindly pursue the price, appearance, and other surface factors, but also comprehensively consider all the coating costs of the equipment in the production process of product coating. Below are the aspects you need to consider to purchase the ideal tablet coating machine.

1. The position of the spraying gun

That is the position of the atomizing spray gun in the coating drum.

Generally, there are two positions:

The spraying gun facing the lower position in the drum or the spraying gun facing a certain position on the inner wall of the drum.

It is very important for the final coating quality, so you will need to consider it for the final determination.

2. The spraying speed

That is, the amount of atomization, and the total amount of coating liquid (suspension) ejected in a unit time.

3. Atomization pressure

There are two points for the atomization pressure, namely:

The pressure of the atomization gas at the nozzle and the mist generated by the suspension.

The pressure of atomization gas itself.

4. Air inlet temperature

You need to take the temperature of hot air used to dry coated tablets in the inlet drum into consideration.

5. The total air intake

That is, the air volume used for drying and penetrating the tablet bed in the inlet drum, is generally adjusted to be slightly larger than the air intake, to cause a slight negative pressure in the coating drum, so that the coating liquid can enter the tablets bed smoothly.

6. The pressure inside the coating drum

It is the pressure difference between the coating drum and the chamber.

If the pressure difference is insufficient, the coating liquid can not be inhaled into the bed.

It will adhere to the surface of the tablet, the entrance, the inner wall of the drum, or the spraying system.

If the pressure difference is too high, it will bring into the overlay of the film bed.

7. The speed of the coating roller

There is a theory that the speed of the coating roller should be set as constant according to experience.

25. What is the prospect of a Tablet Coating Machine?

With the development of the times, intelligence has entered all walks of life.

Many pharmaceutical machinery enterprises have taken the initiative, learned advanced technology, supplemented equipment deficiencies, and developed intelligent coating machines.

Compared with the conventional coating machine, all the process parameters of the intelligent coating machine are digitized, more controllable, and easy to analyze the production data and optimize the production process.

AIPAK BG-80 Film coating machine

Including the incoming wind temperature, humidity, air volume, wind speed, coating spraying pressure, flow rate, bed temperature, and so on.

Moreover, the modular conversion between various batches is particularly convenient, only a few minutes.

It is more to improve the production efficiency, increase the stability of drugs, and meet the needs of modern energy conservation and environmental protection.

In conclusion, the future tablet coating machine will be centralized to develop towards intelligence and energy saving.

Tablet Coating Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586