Syrup Filling Machine:The Complete Buying Guide in 2025

Having the major issues in filling up syrup bottles right or you missing a syrup filling machine at your business for precise and accurate filling of the machine?

This is the place where you can find the best triumph to fill syrup in bottles Syrup filling machine will give you facile & effortless waya to get on with your production line.

Manual filling of syrup liquid in bottles is very intense it may harden your work rather than assisting you so, in this complete general guide about Syrup Liquid Filling Machine I am going to get you through all the working benefits, different scenarios, uses and applications of Syrup Filling Machine.

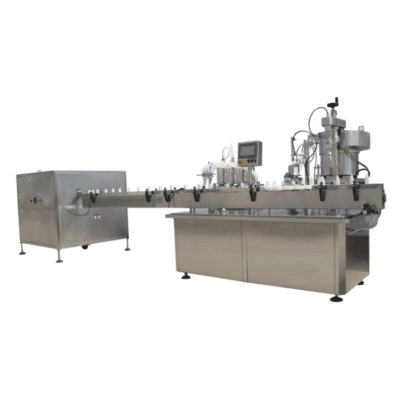

1.What is syrup filling machine?

AIPAK Syrup Filling Machine Production Line

Different kinds of liquids like syrups are one of them, can be filled and packed by AIPACK pharmaceutical equipment. To enhance each performance and profitability of your packaging system, we provide a collection of syrup filling machines and different kinds of other liquid packaging systems according to your need or demand. If you need filling machines, cappers or conveyors, labelers, we will assist you in deciding to put a high-quality system in your facility.

Through this type of machine, all kinds of syrups can be packed, filled, and labeled without any hurdle.

2.What are the different purposes of syrup filling machine?

In the present day commercial world, in which population explosion has significantly accelerated the need for goods, these machines are essential. A syrup filling machine gives you a chance for fast, accurate, secure product filling at a compelling price with minimal wastage of product.

Some types are completely automated; throughout the process, product contamination is low because of less human contact. Other than this, for maximum industries, the system has controlled to lessen the price of workers. Specifically, if it is an automatic one, the reason behind this is that it performed all of the tasks done previously by laborers.

Filling of products

There are many uses or purposes of syrup filling machines, which can help you have more efficient production. It is helpful in many of the industries, which are given below:

3.Explain different industries that use Syrup filling machine?

These machines are being used for different kind of operations and working in various kind of industries. Here we will cover the usage of those machines in the field of:

- Agricultural

- Pharmaceutical

- CarIndustries

- Cosmetics

- Construction

- FoodProcessing Industries

Now we will discuss each of them in detail.

Agricultural Industry

In filling different agricultural chemical compounds like herbicides, pesticides, and liquid fertilizers, syrup filling machine plays a vital role. It helps the industry to grow even more.

Pharmaceutical Industry

The use of this gadget, is likewise in pharmaceutical industries, the usage of this machine is even more relevant. These machines are being used to fill and pack different syrups like cough syrup, thick creamy medicines, dental gels, and anti-Bacterial soaps. In addition, by using an oral syrup filling machine, other Herbal supplements can be packaged.

Cosmetic industry

We have different objects in the cosmetic industry that can be packed or filled by using these syrup filling machines like gels, facial scrubbing lotions, thick lotions for facial cleansing, conditioners, frame lotions, shampoo, and shampoo, and glycerin.

Automotive Industry

Syrup filling machines play a crucial role in automotive industries as well. We have products that include lamps, Lubrication, and motor oils filled and sealed by using this system.

Bottled Water Companies

Water is filled and sealed in different sizes of packaging by using a syrup filling machine.

Food Industry

Food industries widely use this technology to fill and store their foodstuff in liquid form in different containers. Let us have an example of coffee flavoring, yogurt, wine, chocolate syrup, milk, sodas, sources, and juice are filled through this system. Also, honey, cooking oil, energy drinks, little one formula, and some other vital oils can be filled and packed with these machines.

Cooking Oil

Construction Industry

In the construction industry, we have extensive usage of this technology as well. These machines are being used to fill different products like silicone, paint, superglue, and sealants.

Paints

4.What are the different kinds of syrup filling machines?

At present, inside the market there are many kinds of syrup filling machines. Different fillers satisfy the filling needs of distinctive merchandise. The product viscosity is the main factor which decides which type of filling machine will be used for that kind of product filling. Type of container and filling rates also makes an impact that which type of machine should be used at which condition. The distinct kinds of syrup filling machine consist of:

- Fill to Level Syrup Filling Machine

- Net Weight Syrup Filling Machine

- Peristaltic Syrup Filling Machine

- Volumetric Syrup Filling Machine

- Time Gravity Liquid Syrup Filling Machine

- Piston Syrup Filling Machine

1.Fill to Level Syrup Filling Machine

In most of the cases, for the process of filling and capping of syrups this system is used. If you want to fill liquids with moderate or even low viscosity or you may call it thickness, these machines are being used. Besides, it could be used in order to fill drinks with stable substances much more minor than 1/16 inches. It may be used to fill containers small which are small in size.

This system can deal with different stages of thin, free-flowing, and different liquids with medium density.

This system has two sides. They include

- Deliver side

- Return side.

These sides have six distinctive components that carry out unique capabilities inside the whole filling process.

- Product feed overflow tank

- Process pump

- Main-fold

- Exchangeable switch stars

- Valve

- Plate Conveyor

Fill to Level Syrup Filling Machine

The syrups that typically use this technology consist of sauces, remedy syrups, water, mild gels, and shampoo.

2.Net Weight Syrup Filling Machine

In order to screen your products which is already filled into the packing containers, this system uses a weight scale. This system is applicable for merchandise that is offered; those are classified through weight. The machines can both be

- Automatic

- Semi-automatic.

Net Weight Syrup Filling Machine

This machine is more efficient or reasonable to fill containers with high filling capacity from gallons to even 20-liter containers. The system is more user-pleasant and might effortlessly be understand or learned through workers or labor present there.

Parts of Net Weight Syrup Filling Machine are given below:

- Bulk deliver Tank

- Product Tank

- Pneumatic Valve

3. Peristaltic Syrup Filling Machine

These machines are also utilized when you have small amount of filling material or substance but you want it at excessive speed. It is pretty endorsed for aqueous and fluids with mild viscosity. To reveal your product quantity that has been delivered, the system has a filler master pc. To make changeover even easier, this pc additionally stores all of the filling parameters. It can effortlessly be wiped clean therefore lowering cross-infection problems. The liquid direction may be disposed of, and any other installed place if there is any need of it.

Peristaltic Syrup Filling

Parts of Peristaltic Syrup Filling are given in below:

- Product deliver tank

- Peristaltic pumps

- Surgical/product tubing

- Computer controller

- Motor

- Digital rotation encoder

It is a choice by leading pharmaceutical companies.

4. Volumetric Syrup Filling Machine

This filler system fills through extent and not through a level or weight. It can fill different kind of products, starting from normal drinking water to highly viscous oils. There are two distinctive types of this type of syrup filler in the marketplace:

- Automatic volumetric filling device.

- Semi-automatic volumetric filling device.

High, medium, and low viscosity liquids can be filled through this type of filler. This device can function with any bottle, glass, or plastic.

When you look at different components of Volumetric Syrup Filling Machine, there you’ll find six distinctive elements, which are given below:

- Product tank

- PLC and Touch display screen

- Machine platform

- Nozzle

- Alarm

Volumetric Syrup Filling Machine

5. Time Gravity Liquid Syrup Filling Machine

Those liquids which don’t affect with surroundings temperature or variation of product batches and which have very less viscosity can be filled with this system. It is appropriate in liquids with thin thickness like water because those products fill at an utterly excessive speed or rate. When you talk about the costing and budgeting, you’ll find this one as most cost effective. This system is the maximum cost-effective of all syrup filling machines. This syrup filling system has five distinctive components. Each of those elements plays exceptional roles for the whole filling system to be successful. They consist of:

- Bulk supply tank

- A programmable touch screen panel

- Switch pump

- Electrically activated pneumatic valve

- Product tank

Time Gravity Liquid Syrup Filling Machine

This filling machine is widely used in industries like Food industries, Bottled water companies or detergent processing companies.

6. Piston Syrup Filling Machine

When you talk about syrup filling machines, you’ll find this system as most dependable. With the help of using many liquid packaging companies, it’s been using for a long time. This gadget could be best for products with higher viscosity. As compared to different syrup filling machines this system is much budget friendly. It has higher efficiency regardless it’s higher viscosity.

Parts of Piston Syrup Filling Machine are given in below:

- Cylinder

- Nozzle

- Rotary valve

- Piston

Piston Syrup Filling Machine

For heavy packaging sources, like in the cosmetic industry, Piston syrup filling machine is primarily used.

5.Define different benefits of syrup filling machine?

This system has grown to be very beneficial with inside the modern-day fast-developing monetary world. Still, there is a gap to cover. There were vast trends in automated liquid filling line machines. Following are many of the advantages of the syrup filling machine that you can ace if you have it.

syrup filling machine applicable lids

- It is cost-effective because human labor is decreased, especially for the automatic system, in which the filling is auto.

- This system could be very efficient, and therefore, industries are enabled to get their packaging accomplished faster.

- With big orders, the gadget can fill many boxes to satisfy the desired amount of merchandise on time. Moreover, most fillers may have a smooth changeover, which makes them perfect for packaging specific merchandise.

- By converting the head, you've got a brand new filler, and you could continue filling specific merchandise in specific portions.

- Multiple viscosity liquids can be used to fill by using this syrup filling machine.

- It can operate appropriately with many forms of box-like glass, plastic with spherical or squared backside shapes.

- The use of those machines ensures hygiene and protection of the goods and their operators. Due to decreased human touch with the goods, infection is minimal.

- The devices also are made so that injuries at some stage in the filling are reduced to an insignificant minimum.

- This gadget is simple to set, operate, smooth, and maintain.

- The automated and semi-automated device saves facts that may be retrieved for destiny use.

- It is simple to reveal the filling price of a product via the display screen because the filling system continues.

- This enables in figuring out the amount of the product that may be crammed inside a particular period.

- Therefore, the gadget operator can effortlessly plan to transport the orders they might have obtained from their customers.

- It is crafted from stainless steel.

- This makes it perfect for packaging much merchandise, together with foodstuffs.

6.Explain how Syrup filling machine works?

The working of syrup filling machine is quite easy and user-friendly.

https://youtube.com/watch?v=4xqIF3NnagU%3Flist%3DPLu1P45px_dPst0wdowz9oDDFGjWBOHCzr

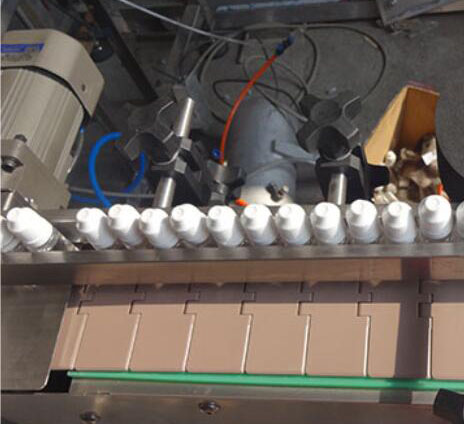

Bottles feed directly to the in-built infeed turntable, which is brought to the SS conveyor belt. Conveyor belt ships bottles to the filling station. There is a Pneumatic bottle stopper for actual bottleneck centering of bottles in the course of filling operation. From the lowest degree of the bottle, the nozzle is going upwards slowly in the direction of the neck in the system of filling to reduce forming adjustable nozzle is reciprocating in step with filling dose The dosing block with a hexagonal bolt, this indicates one of a kind fill length may be set without problems inside minimal use of time after liquid filling bottles are brought to capping/labeling system conveyor for more operations.

7.What are the different components of Syrup Filling Machine?

There are many types of syrup filling machine in market and every syrup machine has its own specific parts and components. Here, we’ll discuss the general parts of a syrup filling machine in below:

- Product feed overflow tank

At this point, for filling, this place is loaded with the material and later on it is pumped to the other parts of the machine according to the requirements.

- Process pump

So, once the material comes into the tank this part of the filling machine makes the movement of the material from tank.

- Main-fold

Through the valve, it keeps the product pour into the bottle. From the main-fold tank to the pneumatic valve, filling portions are predetermined then into the bottles via a valve.

- Changeable switch

It is the guiding part of the machine which guides the material in such a way so it can reach the valve and then later on can be filled by using this.

- Valve

The liquid comes into this part of the syrup filling machine and then, it fills the different type of the containers as per the requirements of the production.

- Plate Conveyor

The conveyor plate of the syrup filling machine is pretty much like conveyor belt of the machine which keeps the things rolling and moving in so they can be filled.

8.How accurate & precise filling can be done with Syrup filler?

Syrup filling machine filling accuracy depends on three major factors, which are described below:

The temperature due to mistakes. Oil, water, liquid milk, etc., at room temperature, has a buoyant density, temperature modifications after the density can even change, the identical extent of oil high-satisfactory will now no longer be similar. However, this distinction is in the allowable mistakes, must be indicated at the outer packaging might also additionally produce blunders range. The effect of flow meters in the filling control machine, flow detection is commonly carried out through lots of flow meters.

The primary blunders of the flow meter are received below the typical operating situations, with inside the actual use process, as the sphere use situations frequently deviate from the ordinary operating conditions, different mistakes could inevitably be generated, so the sphere use blunders of flow meter must be the synthesis of the flow meter primary error and other mistakes. Choose the flow meter, and we must attempt to select merchandise with minor blunders and excessive precision and try to keep away from the error because of that of the instrument.

The effect of the filling machine is now sensible improvement of filling machines, typically through the filling machine to manipulate the whole filling process, filling velocity and accuracy additionally relies upon to a significant volume at the evaluation and operation of the filling machine. More than is the small editor nowadays for anybody to arrange the information, it's tried that clients may be time after the repair, in operation to be careful, in spare time additionally need to do an excellent task of preservation work, an extended service existence of the system, so long as the heart to maintain, issues in a well-timed way repair, then its use period can also be infinitely extended.

9.What is the difference between?

- Syrup filling machine

Different kinds of liquids like syrups are one of them, can be filled and packed by AIPACK pharmaceutical equipment. To enhance each performance and profitability of your packaging system, we provide a collection of syrup filling machines and different kinds of other liquid packaging systems according to your need or demand. If you need filling machines, cappers or conveyors, labelers, we will assist you in deciding to put a high-quality system in your facility.

Through this type of machine all type of syrups can be packed, filled and labelled without any hurdle.

- Liquid filling machine

The liquid filling machine can only function under specific circumstances like while the stress is high. Since the liquid flows through the bottle primarily based totally on its weight, it can be may be labeled as fluid pressure filling. This system is even smoother to keep and to filling up the right amount.

Liquid filling machine

- Vial Filling Machine

The vial fillers can affect your budgeting cost, as it require lesser place and may be established in dense areas relying on the scale of regulators. It simply calls for the most influential one worker to operate the system. This machine offers and method of rejection improper filled vials and it also maintains a level of the weight as well for the vials.

Vial Filling Machine

- Bottle Filling Machine

Machines used for filling beverages or other particle substances into containers are known as bottle filling machines. It works at different business for packing the stuff with precision. However, the manual techniques of bottle filling can't be carried out in present-day industries with bulk filling necessities because the system can devour significant time and inflicting wastage. Therefore the unique gadgets known as bottle filling machines are hired in business packaging processes.

Bottle Filling Machine-Photo Credits: India Mart

10.What type of products can be filled with syrup filling machine?

These machines are being used for different kind of operations and working in various kind of industries. Here we will cover the usage of those machines in the field of:

- Agricultural:

Chemical compounds like herbicides, pesticides, and liquid fertilizers

- Pharmaceutical:

Cough syrup, thick creamy medicines, dental gels, and anti-Bacterial soaps

- CarIndustries:

Lamps, Lubrication, and motor oils

- Cosmetics:

Gels, facial scrubbing lotions, thick lotions for facial cleansing, conditioners, frame lotions, shampoo, and shampoo, and glycerin.

- Construction:

Silicone, paint, superglue, and sealants.

- FoodProcessing Industries:

Coffee flavoring, yogurt, wine, chocolate syrup, milk, sodas, sources, and juice

11.Define the importance of Syrup filling machine in pharmaceutical industry?

The use of this gadget, is likewise in pharmaceutical industries, the usage of this machine is even more relevant. These machines are being used to fill and pack different syrups like cough syrup, thick creamy medicines, dental gels, and anti-Bacterial soaps. In addition, by using an oral syrup filling machine, other Herbal supplements can be packaged.

Pharmaceutical and Syrup filler-Photo Credits: Kahan International

12.What is the Key points to consider while buying the syrup filling machine?

When you are going to buy the suitable machine for the liquid you're packing, few guidelines are explained below. Also, we can additionally study how the automated era affects the acquisition of devices.

The viscosity of Syrup

To recognize the basics of your product you're generating it may be vital to be in a function. This is as it will assist you in picking the proper filler machine which could package deal it correctly and accurately. Some merchandise is less dense, semi-viscous, or maybe heavy-viscous. The one-of-a-kind traits of drinks cause them to have wished for one-of-a-kind syrup filling machines. The viscosity of your product affects a lot of items in the pharmaceutical business.

Viscose Fluid-Photo Credits: India Mart

Therefore, in the industry there's a massive success in figuring out the product viscosity earlier than buying a syrup filling machine. For instance, piston filling gadget is extra best for thick merchandise. On the alternative hand, viscous merchandise is higher filled the usage of gravity syrup filling system.

Type of Filling Container

For the form of field you need to use, it’s far important to give attention to find the proper filling system for your products. You can choose out of many shapes. This is due to the fact this gadget will fill all packets to an equal stage. The field affects the selection of the system because a few pieces of merchandise can simplest be packaged into incredibly massive or small boxes. Containers with a distinctive cap can't stuff by a procedure that grasps the container from upper side.

Photo Credits: Alibaba

Similarly, boxes that might be too extensive might not paintings nicely with the filling system that receives keep of the field sides. Also, only aluminum cans are filled through these machines, they’re not designed to fill bottles.

Rate of Syrup Filling

This is the wide variety of boxes stuffed in step with minute, an hour, or step with manufacturing shift. Every syrup filling machine come up with the speed at which it will be filling the syrup. How much syrup is filled upon the rate of the dense syrup going on. Let’s say if it is dense of course, the rate will be slow and more if the liquid is not the dense. For instance, gadget like gravity syrup filling gadget is being used to fill up much less dense merchandise like water and soda.

Syrup Filling Technology

Currently, there are some of syrup filling system with inside the market. There is a guide, semi-automated and automated system. Some machines have field conveyors; the Computer manipulates structures with printers, PLC with a hint screen, and pneumatic valves. Technology is advancing with the every coming day and you as a business need to adopt it as soon as possible.

Automation Technology

This era imparts the possibility to perform nearly every responsibility effortlessly and with minimal time possible. The gadget has a programmable PLC manipulate device which stores the memory of information. It may be adjusted to one-of-a-kind volumes so that lots of liquid amount filling may be done. The machine can fill among 5mL-10L. due to which the output is likewise noticeably excessive, starting from 20-one hundred twenty bottles in step with min or 1200-7200 bottles in step with hour.

14.How to maintain the Syrup filling machine?

Machine should be made from stainless steel and it should be user friendly so that it can be maintained easily. Plus there are few quality standards; if you comply with those Standards your system would be maintained.

- Have Knowledge about your machine

The better you know the product its easy to implement your ideas on the machine and you will be able to handle it well.

- Complete Training of your employee

The way better option is training the people related to the machine or in most cases if they are working for a while a they can change it themselves if some minor part has any problem or the issues.

- Document your machine’s service history

Keeping the track of products does not help in that time, it keeps the things better for the future as well. You can see the history and take the major note what is going on with the syrup filling machine for a long time.

- Take a look at lubricants frequently

Lubricants lessen friction around any shifting part. A timetable of proper lubrication protection extends the lifestyles of massive equipment systems and elements.

- Keep huge machinery clean, and keep a clean environment

There are many seals and filters in the region on heavy equipment to maintain operating components easily and freed from contamination. Seals need to be inspected often to make sure they’re in the proper condition. Filters need to be examined and modified frequently. To keep away from developing a vacuum with inside the cab to suck contaminants into the cab , breathers need to be saved. The electronics with inside the cab are prone to breakdown if contaminated.

Syrup Filling Machine Related Products

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine