Your Premier Suppository Filling Machine

High Accurate Filling

Circulating Cooling System

Combination Triangle & Dot Line Knife

AIPAK Suppository Filling Machine

AIPAK suppository filling machines are suitable for the production of special shape such as bullet head shape, duck mouth shape and other shapes,satisfies the production of various suppositories.Its main series of machine include:Lab suppository packaging,middle speed (linear or U type) suppository packaging,high speed linear type suppository packaging line.With PLC control system,industry grade person-machine inerface operation,AIPAK suppository packaging line attaches feature with high degree automatization, convenience in adjustment, high precise thermo-control reliability in action and steady in running.

The Buyer's Guide

Suppository Filling Machine:the Ultimate Importing Guide in 2025

For suppositories, affected by the influence of traditional ideas,most people may have poor acceptance of such products.

However,according to the data analysis, the sales of suppositories are growing rapidly in recent years.

And with the continuous development of the market,the improvement of consumers' knowledge level, and the increase of clinical largely promotion,doctors and consumers have gradually accepted such suppository and affirmed its efficacy.

Some of the suppositories have even rushed out of fog that achieved some well-known enterprises.

Today I am going to take advantage of this suppository filling machine ultimate buying guide to introduce the low competition rapidly growing suppository filling machine.

It will cover everything you need to know from the basic definition,specification,working principle,benefits and FAQ about this machinery.

You will choose the most suitable suppository filling machine by reading through this article.

Let’s go to the topic directly.

1.What is Suppository?

A suppository is a different form of drug delivery where medication is introduced into the body through the rectum or the vagina or even the urethra.

This method of delivery is used for medication that is difficult to swallow, or is not well absorbed through the stomach.

And it is a kind of solid preparation formed by medication and suitable matrix to be certain shapes and administered in the cavity.

Suppository

Normally,we use conventional drugs through injection, orally,apply and drops while

suppository administration is an entirely different way.

They are solid at room temperature, while being plugged into the lumen, they can soften, melt or dissolve in the secretion rapidly at body temperature, and release the drugs gradually, resulting in partial or systemic effects.

In the early days, it was thought that the suppository only had local effects such as lubrication, astringency, antibacterial, insecticidal and local anesthesia.

Later, it was found that the suppository could still play a systemic role through rectal absorption and avoid the first pass effect of liver.

2.What shapes of Suppository are there?

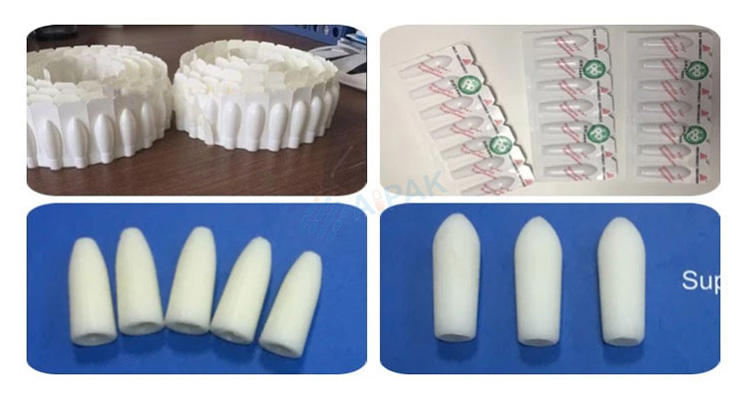

Suppositories usually come in cone shapes, cylindrical shapes,torpedo shapes and mostly small in size.

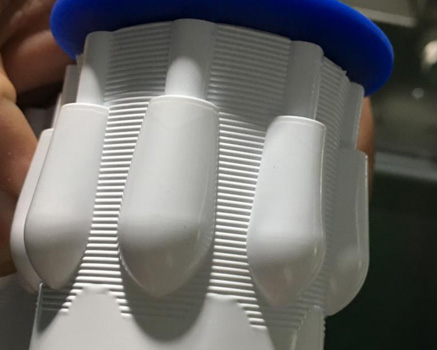

Various shapes of suppositories-Photo credits:Trademanufacturing

While there are also other special shapes,such as bullet shapes,duck billed shapes.

3.How many types of Suppositories are there?

Suppositories can be classified into various types as below two ways:

.Route of administration

It can be divided into rectal, vaginal and urethral suppositories, such as anal suppositories, vaginal suppositories, urethral suppositories, dental suppositories, etc.

The most commonly used ones are anal suppositories and vaginal suppositories.

In order to adapt to the application site of the body, the properties and weight of the suppository are different, which are generally clearly defined.

1.Anal suppositories

The anal suppositories have cone shapes, cylinder shapes and torpedo shapes.

Each one weighs about 2g, 3-4cm long and 1g for children.

Anal suppositories

Among them, the shape of torpedo is better.

As after being inserted into the anus, it is easy to press into rectum due to contraction of sphincter.

However,the drugs in anal suppository can only play the role of partial treatment.

2.Vaginal suppositories

The weight of each vaginal suppository is about 2-5g and the diameter is 1.5-2.5cm.

3.Urethral suppositories

There are two kinds of urethra suppository: the weight of male is about 4g, the length is 1-1.5cm.

The weight of female is about 2g, the length is 0.60-0.75cm.

Besides,you need also know that the weight of the suppositories mentioned above is made of cocoa butter as the matrix.

If the specific gravity of the matrix is different, the weight of the suppository is also different.

.Preparation process and drug release

1.Double layer suppository

One is that the inner and outer layers contain different drugs.

The other is that the upper and lower layers use water-soluble or fat soluble matrix respectively to separate different drugs in different layers,to control the dissolution of each layer, so that the drug has different release speed.

2.Hollow suppository

It can release drug quickly.

The hollow part is filled with various solid or liquid drugs, and the dissolution rate is faster than the ordinary suppository.

3.Controlled-release, slow-release suppository

Such as the microcapsule type, skeleton type, osmotic pump type and gel slow release type.

4.What are the advantages of Suppository?

You will find many advantages of suppository,such as:

1.Suppository will make one avoid the situations,the drugs damaged by gastrointestinal pH value or enzyme.

2.Suppository will avoid the irritation of drugs to gastric mucosa.

3.The absorption of middle and lower rectal vein can avoid the first pass of liver.

4.Suppository will be suitable for patients who are unable or unwilling to take orally.

5.Suppository can be used for lubrication, antibacterial, insecticidal, astringent, analgesic and antipruritic

6.Suppository are absorbed in the retum that will eliminate some of the interference factors than oral administration.

7.Suppository can be an effective treatment way for patients with vomiting.

5.Are there any disadvantages of Suppository?

Just like everything has two sides,suppository administration also has its disadvantages.

1.Suppository is not as convenient as oral administration.

2.Suppository may have higher production cost than that of tablet and capsule.

3.The production efficiency of suppository may also lower than that of tablet and capsule.

6.How to use Suppository correctly?

You may have to pay attention to the following aspects when using a suppository:

1.You must clean your hands before using the suppository, and put on the disposable gloves.

2.Let the child lie on his side and bend his legs up, gently push the suppository into the anus about 2-3 cm deep with your fingers, and continue lying for a few minutes.

3.You must avoid storing suppositories in places with high temperature.It is better to put them in the refrigerator in summer.

4.When using antipyretic suppository, you can only use it alternately with other dosage forms of antipyretic drugs, but can’t at the same time.

In case of continuous pain or fever, you can repeat the medication every 4-6 hours, but no more than 4 times in 24 hours.

5.Suppository belongs to external dosage form.

Before using, pay attention to identify the label on the drug packaging box.

Remember not to take suppository orally.

7.What is a Suppository Filling Machine?

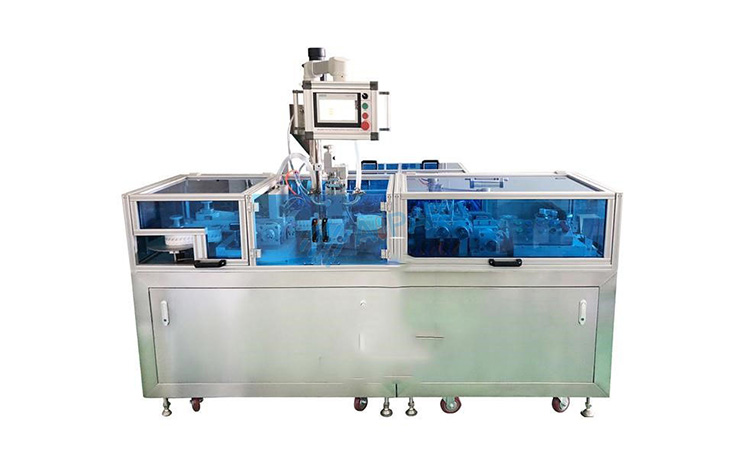

A Suppository filling machine is a line of production machine that made to automatically form the base material, fill in the active ingredient and seal for further batching and distribution.

AIPAK Suppository Filling Machine

While form the base material is to prepares the shell for the suppositories by using the PVC, PVC + PVDC, PE or PVC + PE material.

And fill in the active ingredient refers to fill the medicinal value into the suppository shell.

8.Where to use a Suppository Filling Machine?

The suppository filling machine is a technical machine but also very sturdy in its process.

It has a wide rang of applications including:

1.Pharmaceutical industry

Pharmaceutical industry is the main area that suppository filling machine is regularly of value.

The continuously growing and increasingly active medical fields have facilitated the continuous release in suppositories to cater to these new trends.

AIPAK Suppository Filling Machine for pharnaceutical use

So,pharmaceutical industries all over the world are fast accept the using of suppositories as a way of administering vital drugs.

2.Food industry

Suppositories in food industry provide more concentrated nutrients which you will not take through the mouth.

It may out of your worthing appreciating that suppository filling machine also has a healthy life value other it has a meant for medicinal industry.

The application of suppository filling machine in food industry is very convenient.

Ingredients in suppository include food nutrients, herbal values and nutrients.

So the use of suppository instead of pharmaceuticals drugs will eliminate the effects related with them.

Caffeine Suppository-Photo Credits:Farward

Besides,rectal suppositories filled with nutrient will be absorbed the same way as medicinal suppositories.

And through the help of various blood vessels in the rectum,all the nutrients in the suppositories will enter the body's central bloodstream directly.

Moreover,rectal suppositories is a nontoxic and effectively way of importing.

3.Cosmetic industry

Suppository filling machine is also used in cosmetic industry to make beauty suppositories though some products are still controversial.

The most commonly seen cosmetical suppositories are vaginal suppositories and rectal suppositories.

While the vaginal suppositories are used for cleaning,deodorizing and moisturizing of the body.

And rectal suppositories are used for preventing occasional constipation.

9.What are the benefits of using a Suppository Filling Machine?

Using a suppository filling machine you will benefit not only from the production of the suppositories,but also some procedural advantages you will get from the machine.

As some advancements are continuously prompted to this machine by the manufacturers.

The application and working mechanism are gradually improved over time that make the machine suitable for your use.

Below you will find the benefits of using a suppository filling machine.

1.High production efficiency

The suppository filling machine is fully automatic,that makes the complete automation of the fabrication.

That is,it has very high speed production rate,which you can even have 18,000 to 23,000 pcs of suppositories every hour.

| SP-15 Suppository Filling Machine Specifications | |||

|

|

Capacity | pcs/h | 18,000-23,000 |

| Volume | ml | 0.5-5g | |

| Filling Accuracy | % | <±2 | |

|

|

Film | thickness | PVCPE (0.15mm) |

| Tank volume | liter | 50 | |

| Working air pressure | Mpa | ≥0.6 | |

|

|

Air consumption/minute | m3 | 1.5 |

| Water Consumption/H | kgs | 50 (Recycling) | |

| Total power | KW | 9.7 | |

AIPAK Suppository Filling Machine Technical Parameters

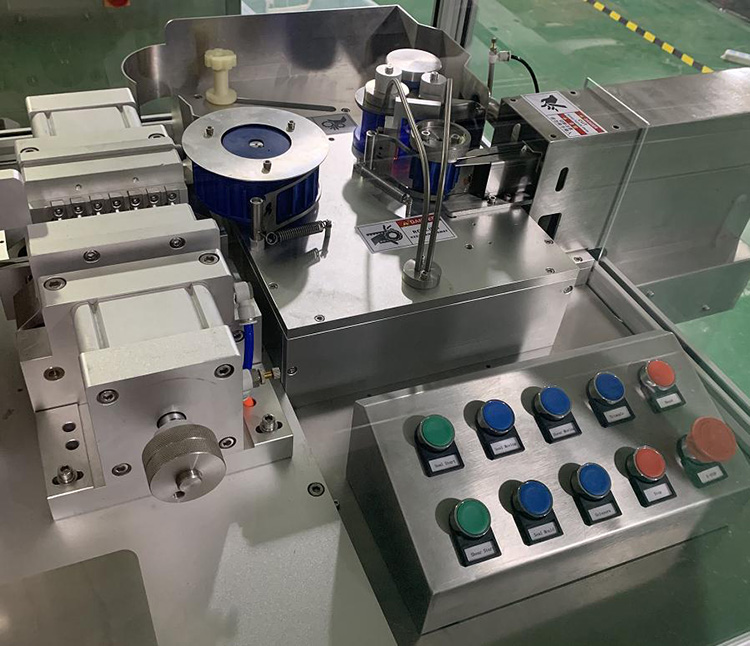

2.Easy operation

You will be easy to operate the machine and make it run as it will not involve too much human labor.

You will only need to correctly install the machine as the instruction manual.

In addition,there are touch screen and control box for your easy operating of the machine or adjust the production parameters.

3.Accurate and precise filling

You will accurate and precise filling of your suppository shells with drug content.

As there is a volumetric filling pump with the nozzles to make the drug content filled and firmly suit with the mold cavity opening.

That is,you can set the capacity in the machine control interface through the PLC before the production.

So,the machine will make your drug contents have no chance to be spilled or leaked.

What’s the most important,the machine will also eliminate the unqualified products with filling deviation.

4.Enough fluid reservation capacity

Most of these machines have large capacity storage tank for the fluids.

THe larger storage tank will save your energy and time to refill the tank regularly when the drug content is exhausted.

5.Less supervision required

You may need less supervision as all the production procedures are automatic.

And by the help of PLC,all the processes are programmed,you only need to key the required parameters then the make the machine running.

6.Automated PLC programming

From the above you have gotten that the machine fully automatic and whole production process will be completed automatically as the procedures are programmed.

In fact,apart from that,you will be easily monitor the whole manufacturing process through the PLC.

Besides,you will also have alarm sounds if any faults occur and the issue displayed automatically for your timely correct.

7.Flexible cooling system

As different drugs need different cooling speed.

Some drugs may need long time to solidify some may need short.

So with the flexible cooling system,you will be able to adjust the cooling speed to regulate the cooling time.

Then the temperature regulator in the cooling system will guarantee the uniformly and appropriately solidify of the drug contents.

Actually,apart from the above various benefits you will get from the suppository filling machine,there are other advantages that related with the system you may get,they are:

The suppository filling machine is compatible to use different types of materials like PVC,PE,PVC+PE to make the suppositories.

The machine is made of stainless steel that reduces any chance of corrosion or rusting.

10.How many types of Suppository Filling Machine are there?

There are many shapes and designs suppository filling machine in the market now.

And depending on the different applications requirements,the designs vary.

But you need to note that these machines are not different from each other in terms of operation, structure and modification.

You will find the three types of suppository filling machine are:

1.Rectal suppository filling machine

Rectal suppository filling machine an elite machine that used only for the constructing rectal suppositories.

Its operation is very simple and flexible and will produce round shape or bullet shape suppositories.

The sizes of the rectal suppositories are 1 inch long.

Rectal suppository filling machines are important due to rectal suppositories have the following functions:

.It can relieve pain, inflammation, repair mucous membrane and relieve the discomfort of anal distention.

.It can promote the repair of intestinal mucosa.

.Relieve the discomfort of anal distension

2.Vaginal suppository filling machine

AIPAK Vaginal suppository filling machine

Vaginal suppository filling machine is used to produce vaginal oval shape suppositories.

When they are used,they will melt to liquid when they are enter into the vagina as the warm temperature from the body.

The use of vaginal suppositories is to treat some vaginal related disorders,inflammation and infections.

In addition,they will also help to cure the fungal infections like the vaginal candidiasis that is a common vaginal illness .

3.Urethral suppository filling machine

Just like the vaginal suppository filling machine,the job of the urethral suppository filling machine is to produce urethral suppositories to cure urethral related illness.

The traditional urethral suppository is used to treat the urethra block and urinary incontinence.

They are small in szie like a grain.

11.What are the main parts of a Suppository Filling Machine?

A suppository filling machine consist of the following parts:

1.Feeding Part

The feeding part is the initial entry point for the film forming the required components of the mold.

It is made by the transfer fixture and the film release plate.

And the transfer fixture will act as a transport car for the films,the film release plate is the initial section that you will place your films.

The films you will use here can be chosen from three types like PVC, PE, PVC + PE according to your different production requirements.

2.Thermoforming Part

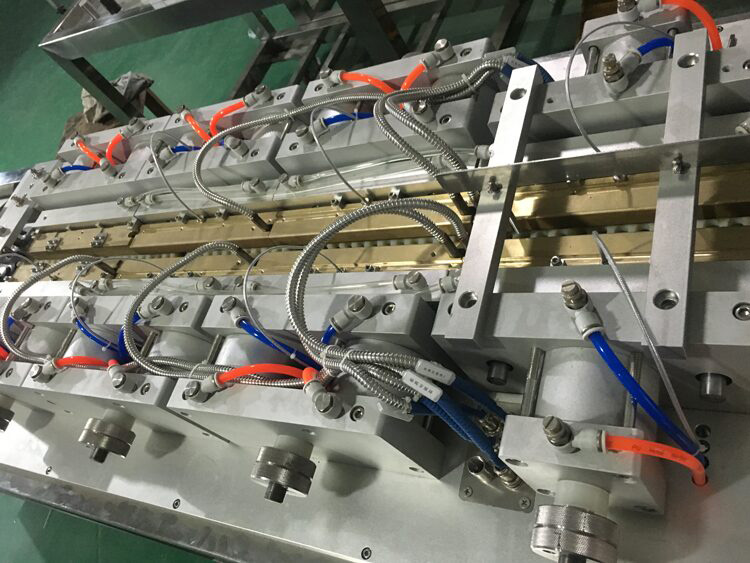

This is the critical part as it’s the area where the suppository shell are formed and molded here.

And there is a guide wheel in this part that is to roll the packaging compound to the thermoforming area.

It will be rolled up (PVC, PVC/PE) into the forming area by the preheated mold, the heating die, the mold, the blow molding and the bubble forming.

All these molds are used to make the shells of the suppositories through the shaping process.

Besides,this part also has the triangle-knife cutting edge (cutting edge) and the dotted line that help in the shaping and cutting of the shells.

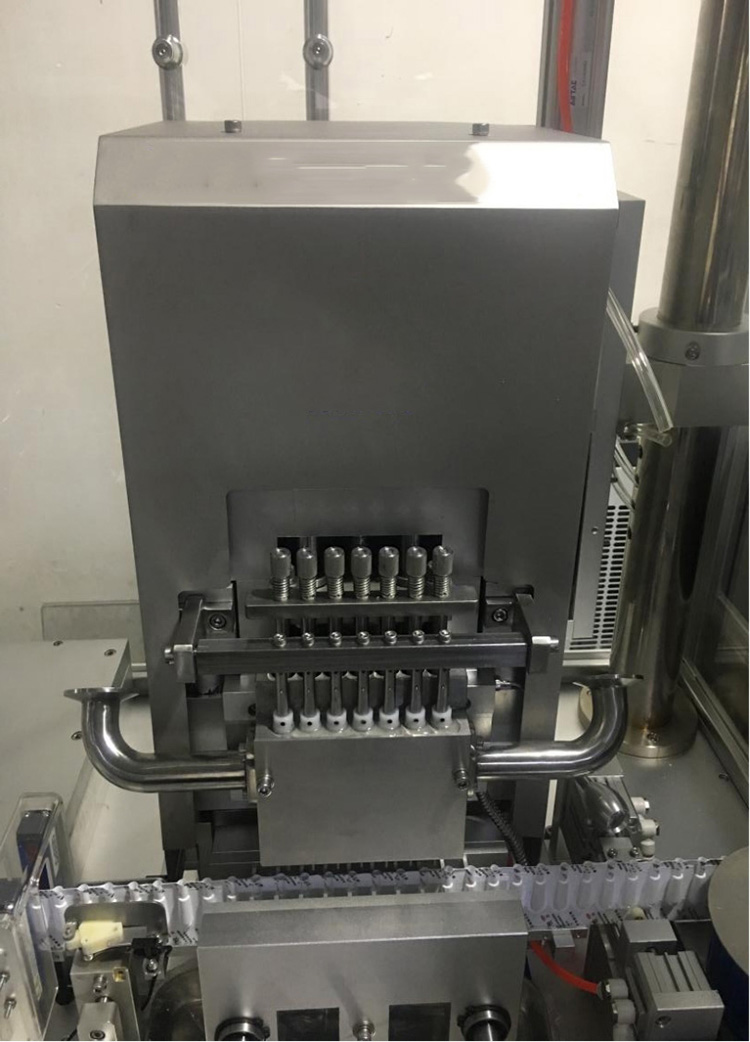

3.Filling part

The filling part is the section where the molds get filled with the materials.

The one-time molding suppository is embedded type filling, and the filling accuracy is ± 2%.

Somes devices are included in the filling part ,they are the filling pump,material bucket,circulating pump,agitator and stirrer.

Filling mold

The filling pump is to drive the materials mechanically by some force into the material bucket.

The material bucket serves as a temporary storage facility for the material to be evenly mixed.

The circulation pump helps in maintaining the continuous circulation and supply of the materials between the filling pump and the material barrel.

The agitators in the bucket are equipped with variable speed mixer and driven by the motor driven.

4.Cooling parts

The cooling parts are made by the cooling tunnels,the air cooling fans and the water chillers.

The cooling tunnels,who have a large surface area, are used for the sufficient cooling of the suppositories trips.

It will also ensure long and enough cooling time .

The cooling fans is used to distribute the low temperature provided by the water chillers.

In a word,all these segments will work together to make sure the temperature at the colling part keep at about 8 °C to 16 °C.

5.Sealing and Shearing Part

The cooled solid suppository will go to the preheating mold for another preheating process.

Then the suppositories tails will be sealed by the sealing mold.

6.Marking Part

Here there is the code mold will mark four lines on each strip of the suppositories.

And the marking is customized according to your suppository requirements.

The most commonly marks are the batch number,the expiry date,the manufacturing date,the batch number or the manufacturer name..

7.Trimming and Cutting Part

The suppository strip will pass to the triangle-knife to make their top edges trimmed.

Then finally,the sharp blades will cut the suppository.

8.Electrical control system and cabinet

The electrical control system is the place where to regulate the the power and electronic supply.

While there are some parts included in the section,they are:

.PLC

It is main to synchronize all the programmable information and data of the machine to make the normal operation of the machine.

.Human computer interface

It is made by various input and output electrical devices.

.Sensors

The sensors here you will find are temperature, piezoelectric and pressure transducers.

12.How does a Suppository Filling Machine works?

Have known each part of the suppository filling machine,you may follow the functions of them to get to know how the machine works:

1.Film unwinding

After selecting the film material,you can make the machine running.

Then the film material will move from the unwinding in the plate and will be pushed to pass through the transfer by the clamp.

Here the clamp will relay the film material into the molding section.

2.Thermoforming

The film strps will enter into the thermoforming section through the guide wheels.

And during the forming process,the materials will go through a few formation molds,the preheating mold,heating mold,forming mold,blowing mold.

Then after that,the formed shapes will be precisely cut by the triangle knife and dotted line to cut its blades.

3.Filling

When the evenly heated materials are at about the temperature of 80 °C,it will be ready for filling the shells.

The suppositories strips will be loaded and then relay to move forward.

From the above,you have known the acceptable filling accuracy is about ±0.2.

At the same time,the rest of the raw material will be continuously heated by the electrical heater.

And it is also kept to be evenly mixed by the mixing motor .

Afterwards,the raw material from the injector carrier will enter into the filling terminal through the circulator.

4.Cooling

Then all the suppository strips will go into the cooling tunnel.

Here they will be cooled by all the cooling devices,like the cooling fans and the water chillers.

The cooling tunnel makes the sufficient cooling of the suppository strip.

And remember to make appropriately cooling and solid forming,the temperature must be between 8 to 16 °C.

5.Sealing

Then all the cooled suppositories tails will be sealed.

That is ,the machine will replay the suppositories into the preheating mold for another reheating.

6.Printing

After sealing,the sealed suppositories will be transferred by the relay strips through the ink jet printer for printing.

You can print the codes on the suppository that include:the batch number,the manufacturing date,the manufacturer name.

7.Cutting

The ready products now must pass through a pair of sharp blades to be cutted.

Normally,six suppositories will be a in group to be cutted from the strip.

In fact,you can set the cutting number in the control panel to adjust the number of suppository you want to cut.

8.Packaging

Here you need a caroning machine to package the well cutted row drops.

13.What environment conditions do Suppository Filling Machine need?

To make the suppository filling machine function well,you must below requirements are meet:

1.Room temperature and humidity

The temperature needs to be between 18°C and 28 °C.

The relative humidity should be 30% to 60%.

2.Space

You must make sure no less than 1 meter of space all round the machine is kept for the conveniently maintenance by the operators in the later time.

3.Ground

You shall guarantee the ground shall not have too much vibration.

14.How to install the Suppository Filling Machine?

Have known the physical conditions for the machine,you may begin to wonder what is it to install the machine.

Though you may get the answer from the instruction manual ,I have still collected them in details for your easy reference.

First,you have to fix the framework using suitable hand tools.

And you must tighten the bolts to make all the parts are connected appropriately.

Then we will go to the installtion procedures:

1.Connect the filling part with the single end of the cooling tunnel.

2.Connect the sealing part with the other opposite site of the cooling part.

3.Install the material barrel.

4.Connect the chiller with the coolig part.

Then you wil go install the power connections.

6.Find out the electrical box.

7.Table the electrical cable and connect it with the aviation plug,who is at the back of the electrical box.

8.Adjust the power supply voltage and the working frequency as regulated on the instruction manual.

9.Open the door,fix the air connector located in the frame and the compressed air connector together .

Here,please be noted that the diameter of the connecting pipe should be at least 14 mm.

10.Adjust the pressure gauge to get your desired air pressure value.

11.Connect the chiller with the cooling shaft via the circulation pipes.

While one pipe is to cool water and another one is to heat water.

12.Make the outlet pipe and inlet pipe of the chiller and the cooling shaft connect respectively.

13.Connect the inlet pipe of the cooling shaft and the return pipe and the chiller respectively.

That is the whole assembling procedures.

15.What should you consider when using the Suppository Filling Machine?

For the correctly using the machine and longlife service of the machine,you must pay attention to the following points when using:

- When the equipment is working, there shall be no sundries in the machine.

- Suppositories exceeding the percentage of water content and serious corrosive suppositories shall not be used to avoid damage to the equipment.

- The electronic scale shall not be operated in damp, vibrating and swinging places. In order to avoid damage to the original electronic scale and accuracy.

- Water and sundries are not allowed to flow into electrical components and displays of suppository filling machine to prevent leakage and damage of electrical components.

- You shall check whether the filter is damaged or blocked every 5000 hours.

- After each operation,you should close the suction valve and turn the button switch to the cleaning position.

And clean the filter repeatedly, remove the residual substances in the filter assembly, and then open the valve of the filter assembly.

- You have to check the oil level in the vacuum pump.

- When the pump is running, the oil level should be in the middle of the two oil markings of the sight glass.

- After working for 3-6 months, the vacuum oil shall be replaced once.

- If the pollution is serious. The oil change time should be shortened according to the specific situation.

16.How to troubleshoot common problems of Suppository Filling Machine?

Errors are common problems for any electrical devices.

It is indeed very reasonable for the occurs of any faults for any other machines.

However,the suppository filling machine is not an excepion though they are fully automatic.

In fact,the most commonly meet problems are system errors and mechanical errors,while most effective and rapid way of solving these problems is troubleshooting.

Now,let’s talk about the common problems and their respectively solutions.

1.Machine not start

Solutions:

i.You shall confirm if all the components of the machine are appropriately connected.

ii.You may check if the emergency stop switch is lose,if yes,you may need to screw it firmly.

iii.You shall check if the electrical and gas connect are correct.

iv.You may check if there is any irrelevant information show,if there is,you may consult with a technical expert.

2.The automatic mode not start

Solutions:

i.You can reset the machine.

ii.You may check if the emergency stop switch is loose,that you must make sure it is always tightly screwed.

iii.You may check if all the sensors have the right signals and are working normally.

iv.You may check if there displaying any valuable information ,if you can’t understand them,you may seek the help of a technician.

3.Shell can’t be heaten

If the shell can’t be heaten,it also means that the temperature doesn’t rise.

Solutions:

i.You may have to see if the thermostat is set correctly or if it is running well.

ii.You shall check if the terminals of the heater is in contact with the mold.

iii.You may check if the heating wire is broken ,if yes,you may need to replace it.

iv.You should check if there is short-circuited on the electric heater.

4.Machine slows down/production speed declines

Solutions:

i.You may check if there is sufficient air pressure.

ii.You shall check if the pneumatic pipe is blocked or there is any leakages.

iii.You should check if the seal ring on the piston is damaged or not on it.

5.Monitor malfunctions

Solutions:

i.You may check if the communicator appriately attached to the power control.

ii.You shall check if there is anything wrong with power cables.

6.Can’t reset the machine

Solutions:

i.You may press the emergency stop button and then make it start again.

ii.You need to check if the sensor is working well and shows anything wrong.

17.What are the Quality Assessment of Suppository?

A qualified suppository must pass the quality assessment to ensure the safety for using.

First,you must make sure they are stored under 30 ℃ in an airtight manner to prevent deformation, mildew and deterioration due to heat and moisture.

Then ,suppository must pass the below quality assessment :

1.Weight difference

The weight difference limit inspection shall conform to the relevant provisions of Pharmaceutical Pharmacopoeia.

2.Melting time limit

It referring to the softening, melting or dissolving time of suppository under the temperature (37 ℃ ± 1 ℃).

You can by ways of :

Take 3 suppositories and put them at room temperature for 1 hour.

According to the regulation of pharmacopoeia, suppository of fat matrix should be melted or softened completely or without hard core within 30 minutes.

Suppository of water-soluble matrix should be dissolved completely within 60 minutes.

3.Microbial limit

Suppository shall meet the requirements in the Pharmaceutical Pharmacopoeia through the "microbial limit inspection method" .

18.Is there any new technological advancement in Suppository Filling Machine?

With the development of medical science and the widely use of suppository filling machine ,people are trying every ways to facilitate the technology innovation to this machine.

First you will get the new advancement of touch screen instead of the traditional operation interface ,that you no need to press continuously,it will respond at the touch of command.

While,you will still input various commands such the pressure,temperature parameter setting,and it will display all the information the screen automatically.

Besides,with the use of touch sensitive induction switch,you will have many free operation on the machine.

For example,you can freely set the production speed , do some changes to the setting parameters.

Another technological advancement is the application of thermostat.

That is to regulating the temperature when the machine is running.

You can set relevant thermostat parameter through the touch screen,that it will alarm when the temperature of the operation varies from the setting one.

19.What are the types of Suppository Filling Machine in AIPAK ?

Hubei AIPAK pharmaceutical machinery is a well-known company with several years of experience in various pharmaceutical equipment.

The machinery it provides are integrated with new technology both domestic and abroad.

Now ,let’s take a look at them.

1.SP-2 2 Nuzzles Lab Supository Filling Machine

The SJ-2 automatic suppository filling machine is suitable for the production of suppositories with special shapes such as bullet head, torpedo shape and duck bill, which can meet the production of various suppositories. (mold specifications can be opened according to the specific requirements of customers)

PLC programmable control and man-machine interface operation, easy operation, convenient adjustment, accurate temperature control, smooth operation.

Temperature sensor and microcomputer control system are used to achieve high precision temperature control.

The liquid storage tank is made of 316L stainless steel with proper volume, heat preservation, heating function and accurate temperature control.

The tank is equipped with a stirring device to ensure the homogeneity of the liquid in the barrel at any time.

The liquid storage tank is connected with the filling mechanism through the pipe, and the medicine liquid is insulated and circulated to ensure the fluidity of the liquid and satisfy the need of filling.

With the insertion type linear perfusion mechanism, the location is accurate, no medicine, no wall; Single grain measurement 0.5-5ml, filling error plus or minus 2%.

Continuous cooling design, after infusion, the suppository shell can be fully cooled, and the liquid solid transformation can be achieved.

Continuous strip, continuous sealing, sealing process batch number self-printing;

Seal should be well sealed, with neat appearance, with a good rate of not less than 98%.

Click here to learn more about this machine.

2.SP- 7L Linear type Medium Speed Suppository Filling Machine

SP-7L Linear type medium speed suppository filling machine is suitable for the production of special shape such as bullet head, duck mouth shape and other shapes, which satisfies the production of various suppositories. (according to the specifications of the mould according to the requirements of the customer).

The equipment adopts PLC programmable control and man-machine interface operation, simple operation, convenient adjustment, accurate temperature control and smooth operation.

The temperature sensor and microcomputer control system are used to achieve high precision thermostatic control.

The storage tanks are made of 316L stainless steel, which is suitable for heat preservation, heating and accurate temperature control.

The tank is equipped with a mixing device to ensure the uniformity of the liquid at any time. The reservoir can be connected to the bottling organ through the pipe, and the liquid can be kept in circulation, ensuring the liquid of the liquid and satisfying the filling demand.

Adopting the insertion type line filling mechanism, the position is accurate, no drops, no wall. A single dose of 0.5 to 5ml, the filling error plus or minus 2%.

Continuous cooling pattern, the suppository casing can be fully cooled and the liquid solid conversion is achieved.

Continuous tape, continuous sealing, sealing process batch number self-printing; The sealing should be well sealed, with neat appearance and no less than 98% good quality.

3.SP- 7L U Type Middle Speed Suppository Filling Machine

SP - 7L type full automatic suppository filling machine has a stable and efficient suppositories preheating mold, heated mold, molding, belting, canned, frozen, sealing bolt all production processes such as complete system process, grain production capacity of 8,000-12,000 / hour.

Click the following link for more information.

4.SP-15L Linear Type High Speed Suppository Filling Machine

SP-15L type automatic suppository filling machine is suitable for the production of special shape such as bullet head shape, duck mouth shape and other shapes, which satisfies the production of various suppositories. (according to the specifications of the mould according to the requirements of the customer).

Suppository Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586