AIPAK Supercritical CO2 Extraction Machine

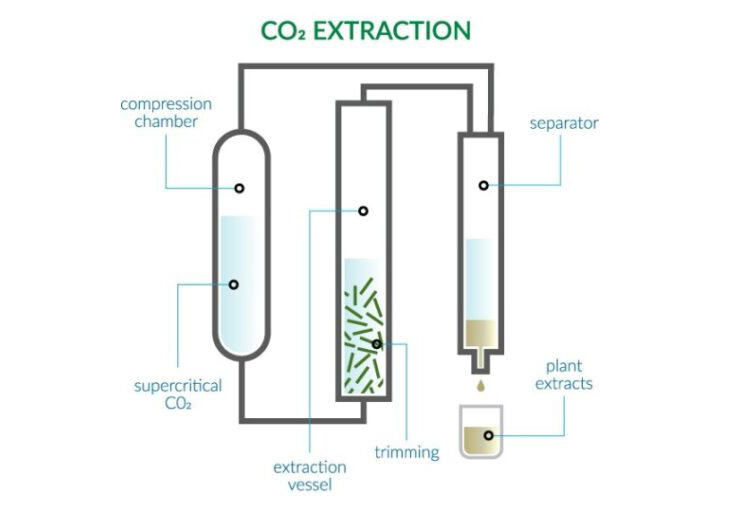

Supercritical fluid extraction technology is a new type of separation technology that emerges in modern engineering analysis and food purification. Supercritical CO2 extraction machine uses CO2 as a solvent. The density and dielectric constant of CO2 fluid in supercritical state are large, and the solubility of substances is very high. It is large and changes rapidly with changes in pressure and temperature. Therefore, it is not only selective for the solubility of certain substances but also the solvent and the extract are very easy to separate. All AIPAK Supercritical CO2 extraction machines are particularly suitable for the extraction of fat-soluble, high-boiling, and heat-sensitive substances, and they are also suitable for the fine separation of different components., that is, supercritical fine mixing. Supercritical CO2 is used as a solvent to extract and purify many products such as biology, food and medicine.

All AIPAK supercritical essential oil extraction machines are used for material extraction (solid or liquid) under high pressure and appropriate temperature. The conditions in the separator are changed so that the dissolved material can be resolved to achieve the purpose of separation.

Complete AIPAK Supercritical CO2 Extraction Machine System

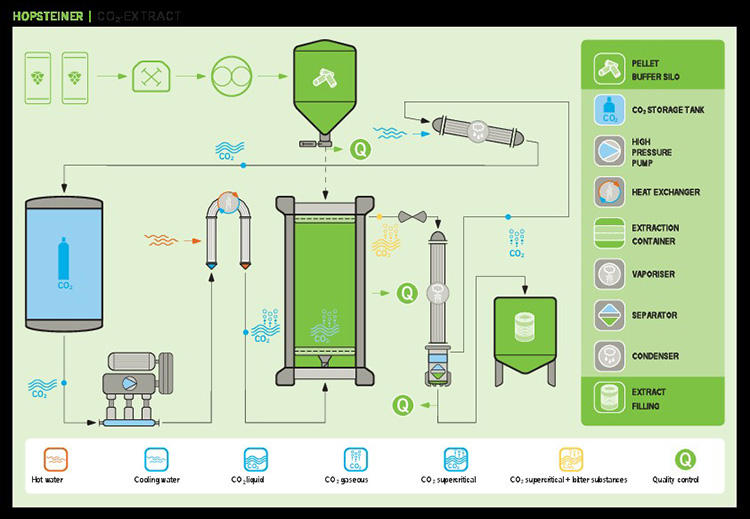

Whole set of AIPAK supercritical CO2 extraction equipment consists of four systems: CO2 gas system, hot water system, cold water system and electric control system.

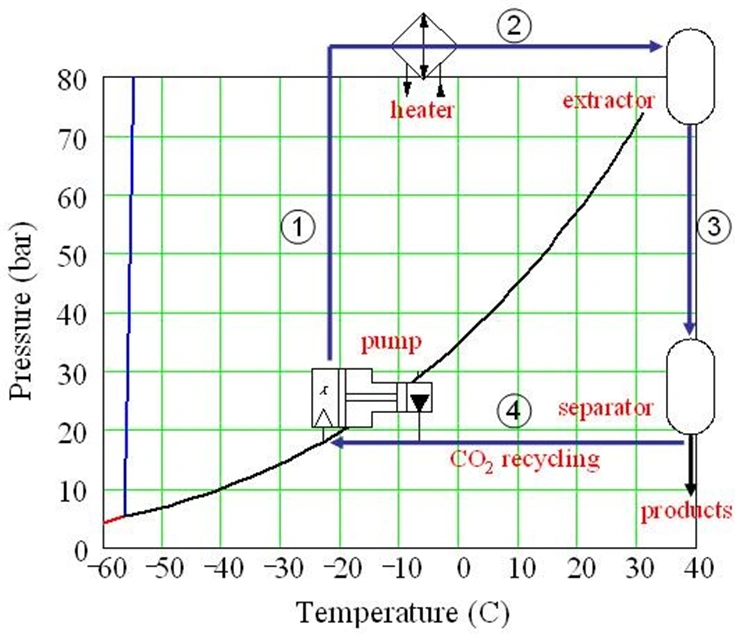

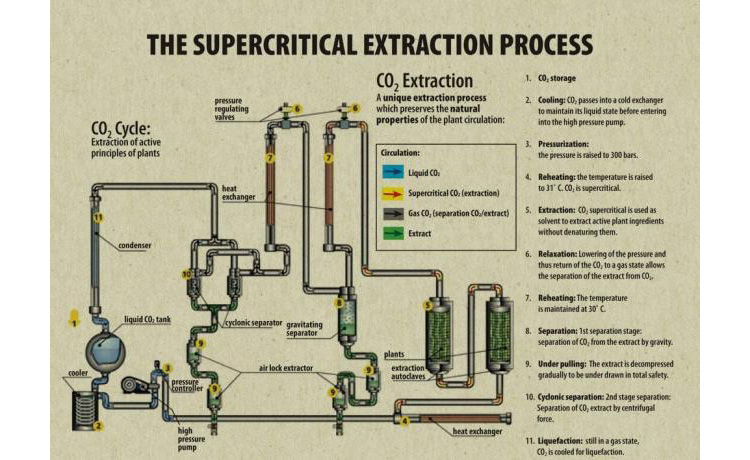

First, liquid CO2 is stored in the CO2 tank, pressurized by the pump, heated by the heater, become supercritical. SC enters the extractor to extract raw material. Then the SC and the extract flow into the separator and its pressure is reduced, the product stays in the separator, and the CO2 becomes gas and flows away. After cooling, it becomes the liquid and returns to the CO2 tank.

AIPAK Supercritical CO2 Extraction Machines

HB121-50-0.5 Supercritical CO2 Extraction Machine

AIPAK Supercritical CO2 Extraction Machine is the latest discipline emerging in modern industrial separation, and it is one of the internationally emerging advanced separation processes.The so-called supercritical fluid means that the thermodynamic state is above the critical point (Pc, Tc). The critical point is the state point where the gas-liquid interface has just disappeared.

Wide operating range

Easy to adjust

Good selectivity

HB120-50-01 Supercritical CO2 Extraction Machine

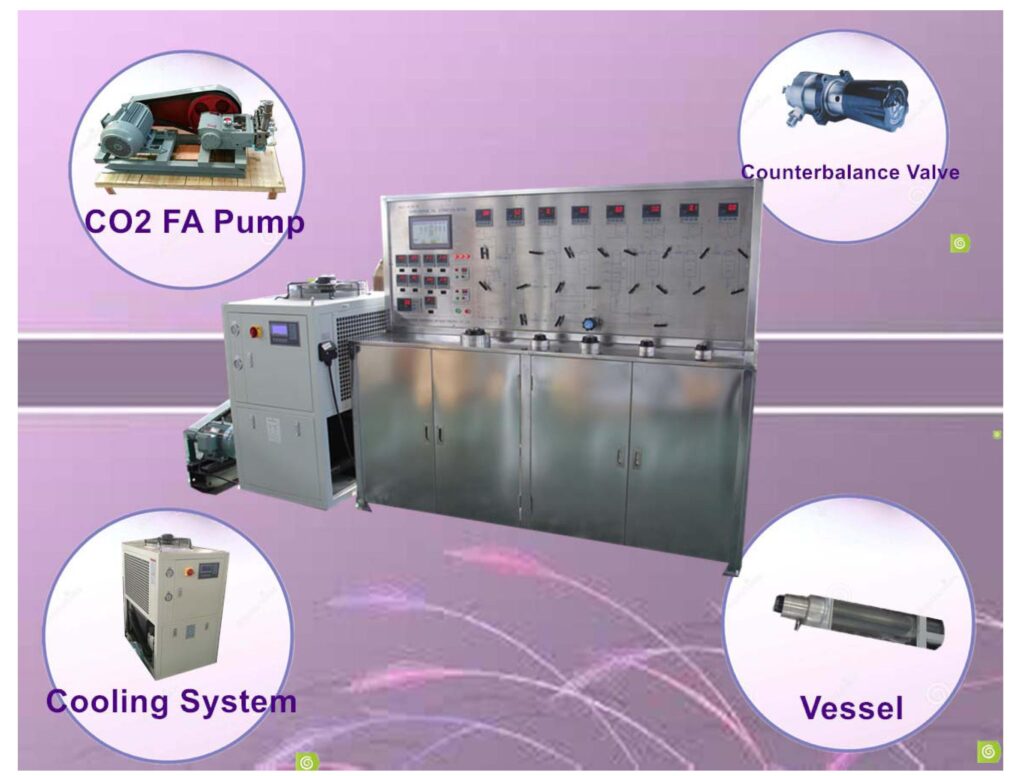

AIPAK Supercritical CO2 Extraction Machine (SCFE) is well designed for effective oil extraction and easily operation. It is a completely configured system consists of extraction vessels (extractors), separation vessels (separators), Operation front panel, High pressure CO2 Pump, Chilling system, heating system, Pressure regulator valve, Co-solvent pump, CO2 Storage tank, CO2 Recovery pump etc. You can run the machine to produce essential oils only need to provide with electricity and CO2.

Safety

Clean and Quick

Low Critical temperature

HB121-50-1.5 Supercritical CO2 Extraction Machine

AIPAK Supercritical CO2 extraction machine is usually be used for material extraction under the high pressure and suitable temperature (solid or fluid), Changing conditions in the separator to parse out dissolved substances in order to achieve the purpose of separation. The supercritical CO2 extraction machine is mainly composed of : extractionkettle, Separate kettle, CO2 high-pressure pump, entrainer pump, cooling system, CO2 basin, exergy transfer system, purification system, flowmeter, temperature-controlled system, safety protection device and so on.

Convenient in operation

Can be used widely

Nontoxic, flavorless, noncombustible CO2

HB121-50-02 Supercritical CO2 Extraction Machine

AIPAK supercritical CO2 extraction machine is widely used in the extraction of plant essential oils (such as hemp CBD/THC oil, ginger oil, rose oil, etc.), preparation of new materials (Graphene, E-TPU foamed materials, aerogels), treatment of sewage sludge (high concentration COD sewage, crude oil contaminated soil remediation), removal of harmful substances in plant components (for example, removal of caffeine in tea,tobacco. Nicotine in leaves, pesticide residues in plant materials, etc.) The supercritical CO2 extraction machine has high extraction pressure and high automation. The special extraction process maximizes the production capacity,lowers the cost of use and maintenance. It can also customize the product and extraction process for customers' products.

Can be extracted near to the room temperature

CO2 is cheap and compound

CO2 can be recycle used

HB121-50-05 Supercritical CO2 Extraction Machine

AIPAK supercritical CO2 extraction machine is workable for high pressure and suitable temperature extraction material (solid & liquid), in separator change conditions to make the solvable material resolve the target product during extraction and separation.The whole system including extractor, separator, CO2 high pressure pump, Co-solvent pump, Cooling system, heat exchange system, CO2 storage tank, liquid level meter, purifying filter system, flow meter, temperature control system, security protection system, etc. All the main machinery and auxiliary equipment could satisfy supercritical extraction system and technical process requirement.

Low Critical temperature

No toxicity

Non-flammable

HB221-50-06 Supercritical CO2 Extraction Machine

AIPAK supercritical fluid extraction is a new subject from Modern Chemicals Industries, which is one of the advanced Separation Technology. As for SCF(Supercritical Fluid), it is was that fluid on Critical Point(Pc, Tc) under Thermodynamic State, the Critical Point is the state point when interface of Gas and Liquid disappear, which process very novel physical& chemical characters. It density degree close to liquid, viscosity degree close to gas, but bigger diffusion coefficient &dielectric constant, smaller viscosity etc. these characters have contributed to good separation effects.

No residue of solvent

No nitrate and ions of heavy metal

No pollution upon environment

HB220-40-10 Supercritical CO2 Extraction Machine

AIPAK supercritical CO2 extraction machine working process creates phase changes in carbon dioxide utilizing temperature and pressure. CO2 is known as a “tunable solvent” making it extremely versatile for creating a multitude of end products by controlling temperature and pressure. These phase changes create an environment to drop out differing weights of components in the plant material.The unique design of AIPAK supercritical co2 extraction Series systems allow for separation and collection of these constituents during a single extraction. This enables collection of light essential oils separately from other desirable constituents and heavier lipids.

Supercritical CO2 fluid extraction (SCFE) methodology delivers a clean, unaltered, consistent-yet-flexible product.

Safety

Clean and Quick

Nontoxic, flavorless CO2

HB221-40-20 Supercritical CO2 Extraction Machine

AIPAK supercritical fluid extraction machine is specially suitable for extraction of fat-soluble andheat sensitive substances with high boiling point mainly consists of extraction kettle,separation kettle,fine distillation column,CO2 high pressure pump,entrainer pump,refrigerating system,heat exchange system,purifying system,pressure stabilizing system of extraction kettle,CO2 tank,flow meter,temperature and pressure control(protection)system etc.The supercritical CO2 extraction machine is specially suitable for extraction of fat-soluble and heat sensitive substances with high boiling point and widely used in pharmaceutical,foodstuff,cosmestyics & perfumery,chemical and other industies.

Intermittent or continuous work

CO2 can be recovered and reused

Wide applicability

HB121-40-24 Supercritical CO2 Extraction Machine

AIPAK supercritical fluid extraction) is a new subject from rn mode chemicals Industries, which is one of the advanced Separation Technology. As for SCF(Supercritical Fluid), it is was that fluid on Critical Point(Pc, Tc) under Thermodynamic State, the Critical Point is the state point when interface of Gas and Liquid disappear, which process very novel physical& chemical characters. It density degree close to liquid, viscosity degree close to gas, but bigger diffusion coefficient &dielectric constant, smaller viscosity etc. these characters have contributed to good separation effects.

Easy to operate and adjust

Well selectivity

Low operating temperature

HB220-40-48 Supercritical CO2 Extraction Machine

AIPAK supercritical CO2 extraction machine is used under high pressure and suitable temperature suitable to extract valuable content from material (solid or liquid), it is to change the pressure and temperature conditions of the separator tanks to let the dissolved substances separated out to achieve the purpose of separation. This technology could be used to make extraction and purification on biological products, foodstuff and medicines, etc.

Quick extraction speed

Non-poisonous, tasteless, inflammable CO2

No residue of solvent

HB421-40-50 Supercritical CO2 Extraction Machine

AIPAK Supercritical CO2 extraction is a new-type separation technology in modern chemical seperation.The Super Critical extaction takes CO2 as the solvent.As CO2 fluid under Super Critical state has larger density and dielectric constant,large dissolvability against substances,which can change abruptly when pressure and temperature chnage therefore it has not only the selection of dissolvability against some substances,the separation of the solvent with the extracted substances is also easily.The super critial CO2 extraction is specially suitable for extraction of fat-soluble and heat sensitive substances with high boiling point,and is suitable for fine separation of different components,i.e.Super Critical fine distillation.

Convenient in operation

Can be used widely

Excellent optional function

HB221-40-100 Supercritical CO2 Extraction Machine

Supercritical CO2 Extraction Machine is the latest discipline emerging in modern industrial separation, and it is one of the internationally emerging advanced separation processes.The so-called supercritical fluid means that the thermodynamic state is above the critical point (Pc, Tc). The critical point is the state point where the gas-liquid interface has just disappeared.

Wide operating range

Easy to adjust

Good selectivity

HB221-40-180 Supercritical CO2 Extraction Machine

AIPAK Supercritical CO2 extraction system is used under high pressure and suitable temperature suitable to extract valuable content from material (solid or liquid), it is to change the pressure and temperature conditions of the separator tanks to let the dissolved substances separated out to achieve the purpose of separation. This technology could be used to make extraction and purification on biological products, foodstuff and medicines, etc.

CO2 can be used in circulation

GMP standard

Automatic control system

HB220-40-200 Supercritical CO2 Extraction Machine

AIPAK supercritical CO2 extraction machine is used under high pressure and suitable temperature suitable to extract valuable content from material (solid or liquid), it is to change the pressure and temperature conditions of the separator tanks to let the dissolved substances separated out to achieve the purpose of separation. This technology could be used to make extraction and purification on biological products, foodstuff and medicines, etc.

CO2 can be used in circulation

GMP standard

Automatic control system

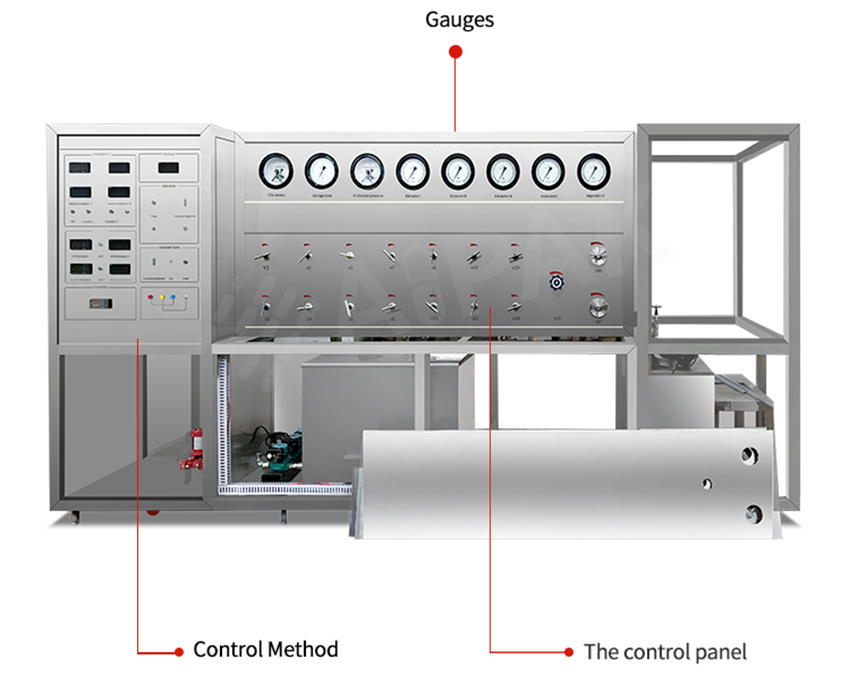

Supercritical CO2 Extraction Machine Details

Control Method

Convenient and reliable operation control method,can choose instrument semi- automatic,PLC automatic control of two modes.

Safety Protection

Automatic pressure relief of overpressure,when the pressure temperature exceeds the protection pressure ,the alam light will give an alam to ensure the safe operation of the equipment.

Product Materia

All stainless steel containers,pipe valves sanitary grade SS304 or SS316,Special requirements of the non-standard customized design and production to meet your special needs.

Gauges

Gases in fluid condition ( above the critical pressure and the critical tempera -ture) dissolve larger quantities of substances than the partial pressure of the substance in the solvent normally permits.

Internal Pipeline

Single Extraction Kettle

Internal Structure

10L Extraction Equipment

Why Use Supercritical CO2 Extraction ?

No organic solvent, no pollution

Efficient to extract & separate

Low temperature extraction

No exhaust gas, waste residue or waste water

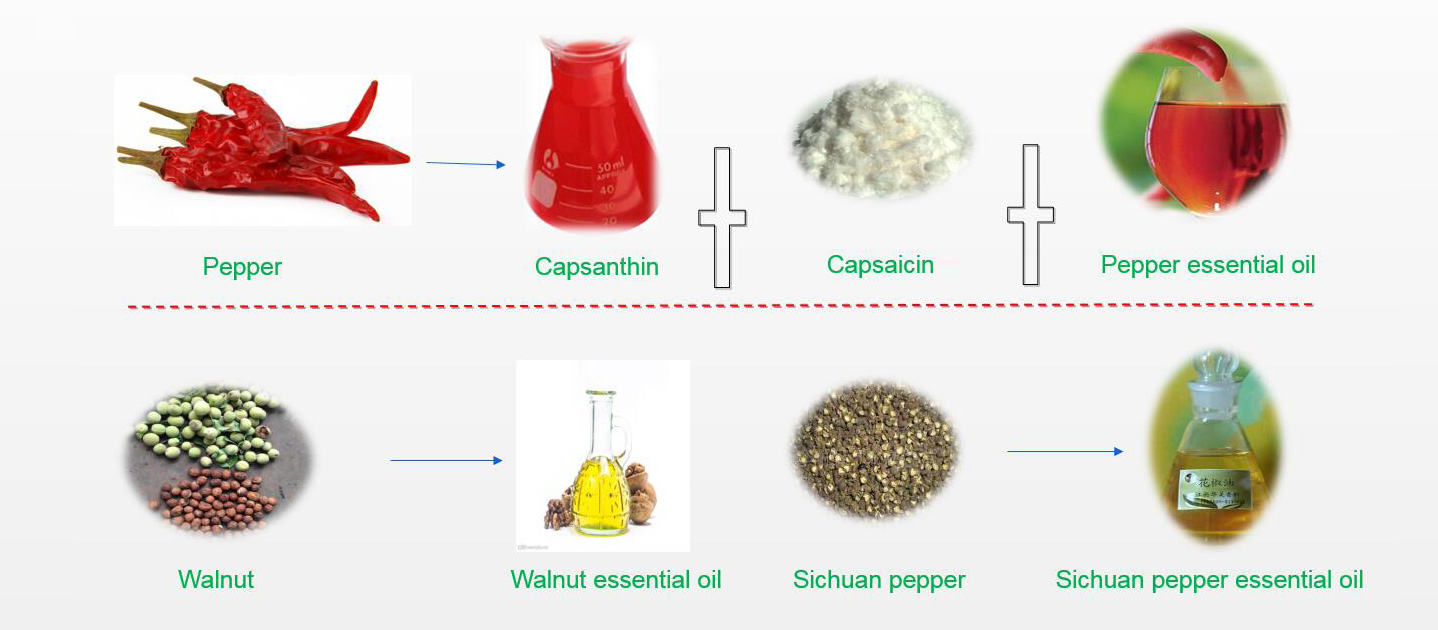

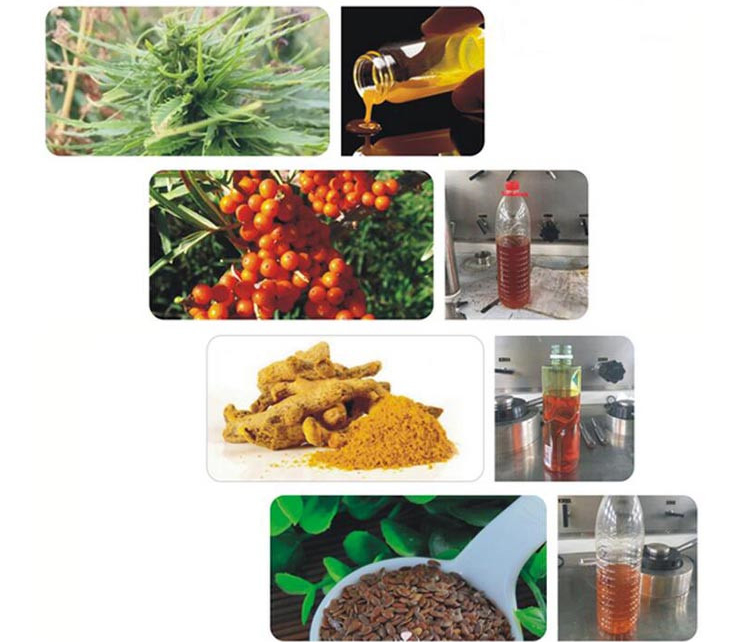

AIPAK Supercritical CO2 Extraction Applications

The Buyer's Guide

Supercritical CO2 Extraction Machine:The Complete Buying Guide in 2025

A machine which is used to extract the things by using the CO2 as main tool is called CO2 extraction machine or extractor as well. This guide will help you understand the every aspect of that machine.

Let's get started.

1.What is Supercritical CO2 extraction?

Supercritical CO2 extraction is another method of discussing CO2 extraction. Despite the fact that it's by all accounts not the only type of extraction, whenever you think about the most ordinarily utilized extraction, you are most of the time referring to supercritical CO2 extraction.

Supercritical CO2 extraction-Photo credits:vitalitycbd

Carbon dioxide typically presents as a gas at normal pressure and standard temperature. Notwithstanding, Supercritical CO2 points on CO2's liquid state, which happens over its normal pressure in pascals and basic temperature.

The supercritical CO2 extraction method is now an ordinary extraction technique in natural enhancement and food ventures.

Likewise, numerous individuals may not understand that supercritical CO2 extraction is utilized for the expulsion of caffeine from espresso beans with the goal for makers to deliver decaffeinated espresso beans.

Moreover, CO2 is utilized as an extraction dissolvable in the creation of basic oils.

The cannabis business also depends on supercritical CO2 extraction is currently an unbelievable fact.

A supercritical liquid has properties between a gas and a fluid. For example, a supercritical liquid can occupy a space just like a gas does in the normal properties; be that as it may, even now keep up its fluid-like thickness.

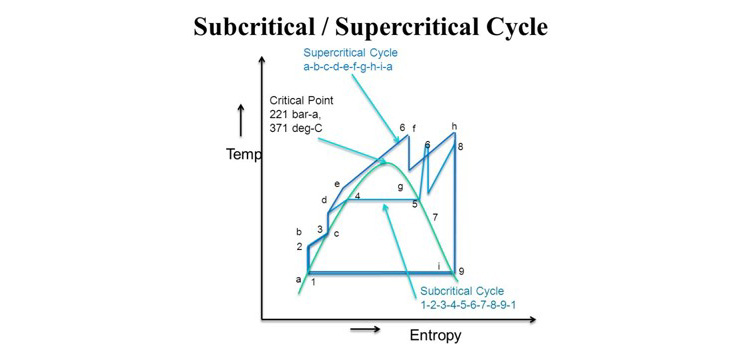

2.What is Sub-critical CO2 extraction?

Subcritical CO2 extractions (low temperature and low weight) aren't as normal as the supercritical CO2 extractions since they consume additional time and produce fewer items.

Strangely, CO2 extractions subcritical hold the terpenes, basic oils and other delicate synthetic substances inside the plant. Alternately, supercritical is high weight and high-temperature measure as compared to the super critical.

Subcritical vs Supercritical

3.What is Supercritical CO2 used for?

Since we have investigated supercritical CO2, It is a must to know where it is used? The universe of extraction is unmistakably not restricted to the cannabis and hemp industry.

Indeed, there are numerous ventures that have been using CO2 in their business a long time before it was even used to separate cannabis mixes:

Decaffeinated Coffee

Despite the fact that numerous individuals appreciate a solid mug of coffee to begin their day, a lot of others appreciate a cup without getting a bad case of nerves.

The regular extraction strategy used to eliminate the normally happening caffeine from the beans of the coffee is CO2 extrication.

This is among the most pervasive employment of CO2 and is a much more secure option in contrast to the solvents recently utilized for decaffeinate including ethyl acetic acid derivation, methylene chloride, trichloroethane and other possibly harmful solvents.

Comparable techniques are likewise used to decaffeinate different drinks and tea.

Extraction of Hops

Extraction of hops can be utilized for fermenting beer and supercritical CO2 is by a long shot the most secure strategy to get them. In view of its intensity, these concentrates are frequently utilized in high-bounced lagers like IPAs.

When the tars are separated from the jumps plant material, it is bundled and disseminated to brewers who can utilize it on a mechanical scale.

Cooking Extracts

While different solvents like food-grade ethanol are still prevalently utilized in this kind of item, cooking separates like vanilla, maple, and others are regularly removed utilizing supercritical CO2.

Even though different solvents are proficient in this type of extraction, there is little uncertainty that CO2 is the time tested "spotless and green" technique for removing consumable items like these.

Basic Oils

These items are clearing the worldwide markets and are utilized for an assortment of reasons including deodorizers, comprehensive cures, cooking items and many more.

Natural plant oils

Like cannabis and hemp extraction, basic oils are pulled from the plant material by immersion of liquid CO2 as a dissolvable.

When the plant oils have been taken from the excess material of the plant, the CO2 is vanished off and taken again in a similar cycle as CBD or THC extraction.

4.Is Supercritical CO2 extraction healthy?

Indeed, supercritical CO2 extraction is a solid and healthy process since it leaves no side-effects, but only if contamination is being removed from the source material.

Otherwise, that contamination will go through to the concentrate, and not just that, it will be concentrated as well.

Before and after the extraction the material to be extracted can be a great help for sure.

Previously, to guarantee that there are no toxins in the plants, and after on the grounds that there may have been imperceptible measures of foreign substances in the source material which are presently focused and perceivable.

Shockingly, there is no oversight in the hemp and cannabis ventures, makers can make a wide range of claims about the substance of the container, without demonstrating it.

It is consistently a decent practice to demand a research center confirmation to guarantee the neatness of the item and furthermore to guarantee that what will be marked on the label as well as what is inside the bottle.

5.What are the benefits of Supercritical CO2 extraction?

Considering one of the most important advantages of utilizing cannabis separate from CO2 extraction is 'green solvent.' Whether it is THC extraction or CBD extraction, the utilization of carbon dioxide gives a cleaner and more advantageous item.

We produce CO2 normally as a feature of the breathing cycle when we breathe out.

Supercritical CO2 extraction has special properties.

- It is non-combustible, inactive, and non-poisonous.

- It is a process with moderate basic constants.

- By changing the fluid's thickness, You can tweak the solvation quality.

- As carbon dioxide departs a low degree of leftovers contrasted with different solvents, you should discover huge amounts in the form of purity.

- The basic temperature of CO2 is more like according to the environment, which implies it is an ideal dissolvable for temperature-delicate materials.

Benefits of CO2 extraction

Why is this a priority?

I don’t think it is quite long when we were just ignoring the fact that CDB is only used for bad reasons. However, if i say you have been ignorant that long, it wouldn’t be wrong at all.

Presently, new laws have been introduced by the different countries and old laws have been abolished regarding the fact how we can profit by CBD in the clinical field.

The synthetic substances in the cannabis plant are proceeding to express exactly how significant they can be on the mind.

Understanding distinctive cannabinoids through the CO2 extraction measure is massively significant in proceeding to make clinical advances. Who knows where we will be in 5 or 10 years, yet it will probably be in enormous gratitude to a CO2 extraction strategy.

Supercritical CO2 extraction is so adaptable, however that is just where the advantages start.

Can be made at home

There are a couple of ways that you can make your own cannabis oil on a small scale or at home for example, putting decarboxylated Hemp blossoms into a moderate cooker and so forth however they are never entirely right and the degrees of cannabinoids are practically difficult to do the measurement.

It is fun testing however with regards to genuine CBD oils, it is in every case best to leave your prosperity in the possession of an expert.

No Toxins

Compounds that are combustible or oil-based solvents don't utilize in CO2 extraction.

It implies that when the cycle is finished, the dissolvable (being CO2) turns around into vapor and gas.

The end product remains pure and cleaner because it does not leave a residue.

More secure and Cleaner Products

As you can envision, a hemp plant that has been pulled out of the field may have spores of form, insect and residue living on the plant.

Regardless of how enthusiastically you attempt, this is simply an integral part of developing this plant.

The supercritical CO2 extraction measure guarantees that the entirety of the undesirable microbes, bugs or other undesirable nastiest are destroyed during the process.

More prominent control

You can either have as refined or as crude a plan as you want. For example, you can get more paste from a raw plant (like our own hemp raws) or distill the item down to a distillate which just contains cannabinoids.

By changing the pressure and temperature of the machines, you can have more control regarding how your item is being produced.

The other advantage indeed relates to a significant well-being feature. In other extraction measures, specialists use ethanol liquor to winterize and utilize butane to concentrate or de-wax the cannabis oils.

Because of the absence of synthetic compounds and safeguarding of terpene fragrances, CO2 removed oil is additionally much better tasting, making them ideal for cannabis concentrates.

6.What are the advantages and disadvantages of Supercritical CO2 extraction?

This is the activity of the low temperature: heat-delicate segments stay intact.

Avoidance of oxygen: oxidation-delicate segments stay intact.

Higher selectivity and higher mass exchange prompts better outcomes and a more drawn out time span of usability.

Cleaner measures both as far as ecological effect and the yield.

The longer time span of usability of the item contrasted with regular extraction techniques and a better flavor and aroma contrasted with regular items.

There are some minor disadvantages to SCF extraction:

Greater expenses and mechanical requirements contrasted with a traditional extraction of maceration.

Normally an extreme shade of the concentrate.

Supercritical CO2 extraction normally does cost a bit more than the normal same type of the process.

7.What is the principle of a Supercritical CO2 Extraction Machine?

This whole process can be defined as the: extraction, partition, and buildup or in other words condensation.

To start with, fluid CO2 is supercooled and taken care of into the pump. Because of very high pressure, with pressures up to 1,000 bar, the CO2 is warmed up and changed into the supercritical form.

Keeping these conditions, it has the properties of a gas and fluid and is portrayed essentially by its amazing dissolving limits.

The high smoothness of too supercritical CO2 permits it to enter into the littlest pores of food and concentrate the ideal substances from the crude material.

The excessively critical or another word super critical CO2 is then extended and warmed up.

It turns around into a gas and turns into the vapor suddenly and completely, leaving only the good extracts. As CO2 is latent, it neither responds with the concentrate nor contorts its properties.

Principle of CO2 extraction

8.What is the Extraction Equipment and Method of Supercritical CO2 extraction machine?

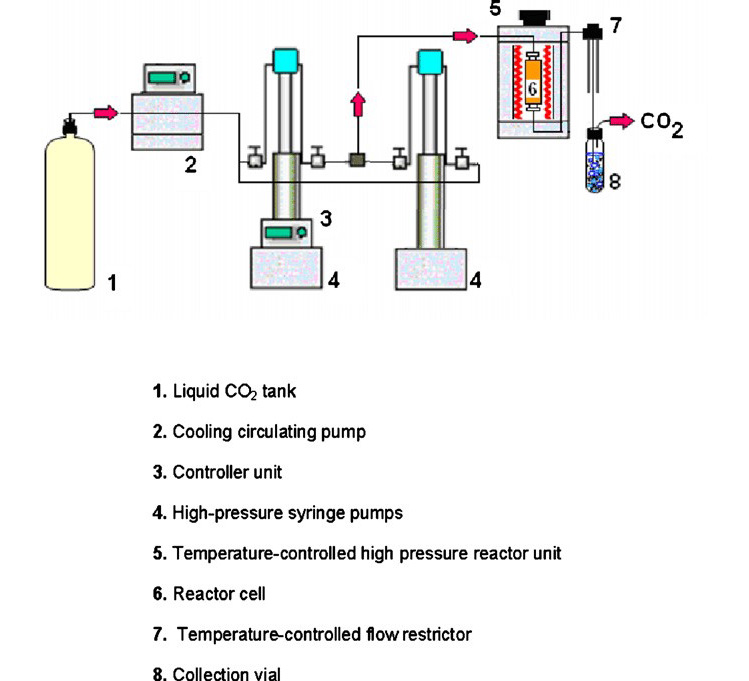

The size of the extraction framework will shift and it depends upon the batch size as well. On the same note, sample size can also differ from like a hundred kilo to ten grams.

A few frameworks have the choice to be robotized, so the maker shouldn't be available during the running process.

- Supercritical CO2 extraction takes more time to finish than different techniques, because of the ceaseless variances in pressure and temperature.

- For instance, The time can be taken as 4 to 6 hours for the extraction of 20 lbs. of plant material.

- To run an extraction, the plant material must be ground and set into an extraction vessel to run the process. CO2 gas goes through high pressure and and temperature.

- A pump at that point powers supercritical CO2 into the extraction vessel where it comes across the plant and breaks the trichomes permitting it to disintegrate part of the plant material.

- The valve is opened at that by applying the pressure at that point permits the material to stream into a different vessel, where an interior blower and warmer are utilized to change weight and temperature.

- By varying the pressure and temperature just as stream rate, certain particles will attach to CO2, permitting them to be isolated from the plant.

- Numerous frameworks will reroute CO2 back into the tank to be utilized during the following cluster. The concentrate is then moved to an assortment container.

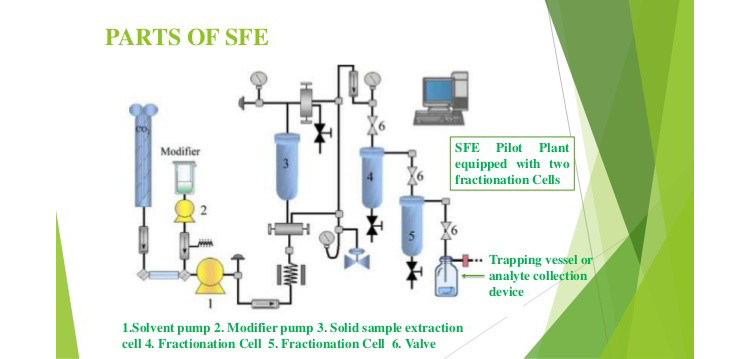

9.What are the main parts of the Supercritical CO2 extraction machine?

Just like any other machine, the supercritical CO2 extraction machine also has many parts together which run the functions together.

Parts of Supercritical extraction machine

CO2 pump

CO2 extraction machine high pressuring carbon dioxide infusion pumps are less speed responding high pressuring pumps, utilizing zirconia three unclogger structure, as the vital system of Supercritical CO2 CBD extraction framework, can be generally utilized in natural, drug, food and different fields.

Has the attributes of stable weight, little volume, high productivity, wonderful appearance, helpful activity and upkeep, versatile and adaptable.

Cooling system

Cooling framework coordinates blower,flowing framework heat exchanger and cooler. It has a compact plan, decreases consumed space, diminishes energy misfortune, improves cooling productivity and guarantees stable fluid carbon dioxide flexibly.

The cooling limit is multiple times that of the others, keep the machine running regularly.

Part of supercritical CO2 extraction machine

Energy storage sealing structure

Extraction pot holds spring energy stockpiling fixing structure, which is solid, simple to introduce, no plasticizer adjusts to GMP standard, and you can use it again for more than 3 to 4 months.

Energy stockpiling seal is a sort of spring pressure, framing an outward strain, which makes the fixing lip near the fixing channel.

Since the spring gives flexible power to the fixing lip forever, it can make up for we are of the fixing shell and the erraticism of the coordinating parts, accordingly framing a seal from the vacuum.

Furthermore, the pressure of the framework will help the spring energy stockpiling, the more the pressure the more completely the fixing lip and groove fit, resulting in a high-pressure seal.

High precision measuring system

The choice of high exactness sensors guarantees the precision of estimation information and establishes a framework for the investigation of the supercritical CO2 extraction process.

A CO2 extraction machine high-exactness pressure sensor gotten from other countries is utilized to analyze the inward weight of the framework.

Direct correspondence convention is utilized to send it to the control framework to minimize the loss of precision of electrical transformation. The precision of the sensor of pressure is 0.1%.

PT100 temperature test is utilized to set, control and measure temperature with a temperature regulator.

With oneself tuning capacity of PID, the temperature dormancy subsequent to arriving at the objective set worth is survived. Temperature show range: 100 C; Accuracy: 0.5% of the full reach.

High precision pressure regulator

The back weight valve of TESCOM 26-1700 arrangement is used. The valve has high weight control accuracy and long working life.

Control system

The control framework is made out of a low voltage switch box, Cabinet of PLC control, control PC, cooling unit control bureau and so forth.

At the point when the framework works, the cooling water refrigerator unit pump, condenser and CO2 transitional capacity tank are begun simultaneously, the carbon dioxide middle of the tank of storage and the temperature of the condenser are controlled to be completely melted with the goal that the carbon dioxide siphon can work.

The temperature of the condenser and the carbon dioxide halfway capacity tank is watched and recorded by the upper PC.

Pressure should be kept at extraction necessity when at setting pressure by a high weight programmed change valve, simultaneously, the pressure separator will ship off PLC by the transducer, after a change to PC and record, keep division pressure and accomplish CO2 circle back.

This video explains the equipment of supercritical CO2 extraction:

10.Why is a Supercritical CO2 extraction machine a better option?

Supercritical liquids are progressively taking place instead of the natural solvents that are utilized in mechanical cleaning and re doing the crystallization activities in view of administrative and ecological pressure on hydrocarbons and on the emission of ozone depletion.

A supercritical liquid is described by its properties of physicality thermal and that are in the middle of gas and liquid.

The liquid thickness is a solid capacity of the pressure and temperature.

The diffusivity of supercritical fluid is a lot higher than for a fluid and promptly infiltrates permeable and solids.

So that can offer great reactant action.

The fundamental preferences of utilizing supercritical liquids for extractions is that they are quite reasonable, extracting that more fastly and environment friendly than natural dissolvable.

Thus supercritical liquid CO2 is the reagent broadly utilized as the supercritical dissolvable.

With the SFE procedure, the separation and fractionation is carried out in a continuous counter-current operation.

The SFE process offers a new alternative to the conventional methods, eliminating both the thermal degradation of the active ingredients caused by high processing temperatures and high operating costs.

The strength of supercritical CO2 additionally permits most mixes to be removed with little harm or denaturing.

With the Supercritical extraction system, the partition or separation is completed in a persistent counter-current activity.

- Due to the elimination of dissolved oxygen and co-extraction of antioxidants.

- Reduced pesticides

- Flawless process

- Operation cost is less

- Rapid diffusion of CO2 through condensed phases

- Similar to liquid organic solvents solvating powers

11.What are some of the technical details of the machine?

There you find some technical details of the supercritical extraction machine.

| What is SC liquid in that? | CO2 |

| Separation kettle | 0.3L, 30MPa, 2 sets |

| Extraction kettle | 0.5L, 50MPa |

| What is the pressure? | 50MPa |

| What is the temperature? | normal temperature ~ 85 ℃ |

| What about flow? | 0 ~ 50L / h adjustable |

| Power supply | 380V 50Hz |

| Instantaneous maximum power | 16KW |

| It may vary from machine to machine and size to size as well. | |

For more technical details please visit our website for further details:

https://www.icapsulepack.com/p/hb220-40-48-supercritical-co2-extraction-machine/

12.How to operate a Supercritical CO2 extraction machine?

At the point when utilized at high temperature as well as pressure, a powerful solvent is considered CO2. In a super critical extraction machine it works in the four steps which are like this:

An amazing video to watch the process:

Step 1: Dried, ground up plant material is loaded upon the vessel by an operator and guarantees that all seals are accurately fixed. The individual in question will start the activity (in an automatic frameworks are completely mechanized so once the boundaries are set, the framework will run without anyone else), and filling will start in the extraction vessel.

Step 2: Once fixed, the framework starts to put the pressure. It will put the pressure up to the PSI set by the administrator at the framework beginning. On most systems CO2 flow pushes through system by a compressor.

Step 3: The stream of CO2 goes over the material of the plant while it's squeezing and pulls the oil from the cannabis. At that point it goes through to the Separate vessel where it courses through a hole that depressurizes the stream and makes the oil exit the CO2 stream.

Step 4: The running of CO2 in the CO2 extraction proceeds in the shut circle framework until the run is finished (boundaries, temperature, pressure and time are set by the administrator toward the beginning so the framework runs until it accomplishes those numbers) before it goes into the recuperation stage.

The CO2 running (short the oil, which is given up in the assortment cup) is recouped once more into the CO2 chambers.

13.How Long will the Supercritical CO2 Extraction Run?

Here is an overall guideline while doing supercritical CO2 extractions that almost 70 to 80% of the oil from the plant will turn out in a given time span which actually relies upon some factors like the gear utilized, the extraction is done from the plant material and of course the most important factor to be known is pressure and temperature used.

To get the leftover 20-30%, you should run the extractor twice as long. So, you ask yourself if you want to achieve the full yield or you want to save time.

There are two things here that also affect the decision:

If you are doing the extraction process for yourself or it is your requirement or you are doing your customers order.

If you have a restricted amount of extravagant plants, full yield is more significant.

On the other way around, In the event that you have plentiful flexibility of economical plant, 70-80% is most likely a decent halting point dependent on the standard of consistent losses versus overhead.

When looking for a CO2 framework, the more significant inquiry is, what number of grams every hour does it put out? The majority of the producers in this market have frameworks that create 15-30 grams for every hour.

The gas booster frameworks are more like 15 gm/hour while there are a few liquid pumping frameworks that are more like 30 grams per hour.

14.Which type of Supercritical CO2 Extraction System is Best?

With regards to supercritical CO2 extraction there is a reasonable contrast in the normal yields between two sorts of CO2 extraction machines available. CO2 extraction machine can be separated into two essential types

Gas booster system operation

Liquid pumping system

Though, there are two systems but, still liquid pumping system is considered as the premium choice and priorities has given to it.

These are some of the possible circumstances why this system has always given the superiority.

- Energy reserve. With a fluid pumping framework a similar measure of energy input is used to move more CO2 in its fluid stage than its gas stage.

- Run times are pretty much shorter.

- Liquid frameworks are undeniably more accurate with regards to fractionating different mixes like terpenes and oleoresins. Mixtures can be gathered separately and a more extensive determination of items can be acquired.

- Yields are in every case better with full fluid frameworks.

15.SUBCRITICAL AND SUPERCRITICAL: What is the difference?

| SUBCRITICAL | SUPERCRITICAL |

| Subcritical CO2 extraction takes additional time.

Subcritical CO2 extraction delivers a more lesser yield.

Subcritical CO2 extraction is better ready to hold a considerable lot of the significant oils, terpenes, and other delicate synthetic compounds inside the plant. |

Supercritical extraction, then again, is a high-pressure, high-heat strategy that hurts a large portion of the plant's terpenes and warmth touchy synthetic compounds.

The benefit of supercritical extraction is its capacity to remove a lot greater atoms.

Supercritical however takes less time.

Supercritical extraction has greater yield. |

16.Why Are Yields Better with Liquid Pumping Systems?

Vapors are being created by the gas booster pumping frameworks. At the point when a framework is pumping CO2 fume (in the gaseous form), the CO2 neither goes into the supercritical stage nor into the liquid state until it really goes through and came out from the outlet of the pump of the CO2 extraction machine and starts to enter the vessel used for the extraction.

This part is considered as an important part of the CO2 extraction machine inefficiency as the weight measure may not precisely calculate that fluid is surely filling the extraction vessel.

In the event that fluid isn't filling the vessel according to the need, at that point proper saturation doesn't happen for a full extraction which can be a problem .

Whereas when we see the same thing in the liquid pumping frameworks turn the fume to fluid well before arriving at the extraction vessel by gathering the fume in the condensing tower and gathering before it arrives at the pumping channel.

With this cycle, the gas is as of now in a state where it can start on solubilizing plant mixture before it arrives at the pump of the CO2 extraction machine. Accordingly, fluid frameworks are basically more dependable at getting reliably exceptional results or in other words better yield.

The other thing about this system is they do have a comparatively long life time.

liquid pumping frameworks

17.What is the Yield on Your Supercritical CO2 Extraction Machines?

This inquiry can be especially angering when the inquirer is under the feeling that the yield is dependent on the extraction framework.

This is a nuanced answer that envelops various segments - the framework, the dissolvable, the plant material and the cycle created to make a specific item. All significantly affect yield.

AIPAK Supercritical CO2 Extraction machine

The basic answer is that whatever level of oil is in the plant material will be considered as the last yield if the extractor is enhanced for that material and is run by the cycle created for material and wanted item.

A model would be a terpene rich item. Running the framework at subcritical (under 87F and more than 1100 PSI) will expand the running time and lessen absolute yield as the cycle isn't pulling the parts that turn out in the critical stage.

18.What is the Entourage Effect of a Supercritical CO2 extraction machine?

Entourage effect is a proposed mechanism by which cannabis compounds other than tetrahydrocannabinol act synergistically.

While a spotless item is fundamental, maybe the greatest advantage of CO2 extraction is its ability to extricate a lot of terpenes and cannabinoids.

The pot plant has more than 110 recognized cannabinoids and many terpenes and flavonoids.

Despite the fact that CBD and THC both have a variety of indicated benefits, an expanding number of specialists currently accept that weed and hemp's genuine 'wizardry' includes a mix of its cannabinoids and terpenes.

Cannabinoids, for example, cannabinol (CBN) and cannabigerol (CBG) are not as plentiful as CBD and THC, but rather conceivably have medical advantages of their own.

For instance, CBG could have neuroprotective properties. In the interim, CBN has a connection with a critical diminishing in torment levels.

At that point there is the little matter of terpenes. For instance, alpha-pinene could neutralize cognitive decline related with THC.

Myrcene may diminish opposition in the blood-mind obstruction and lead to a more agreeable entry of supportive synthetic substances in the body.

The rundown continues endlessly. The entourage effect recommends that cannabinoids and terpenes work preferred together over in isolation. While a top notch CBD or THC seclude has its usages, a full-range item is possibly a superior choice.

In spite of the fact that 'CO2 oil' is one of the best oils, don't be stunned to discover that the ease cannabis you want doesn't include CO2 extraction.

19.Why Supercritical CO2 is the Superior Extraction Method?

We've covered topics like; what CO2 is, the means by which it is utilized in its supercritical state, and how CO2 extractors work. Presently, for what reason is this extraction strategy the most ideal alternative?

Green and Spotless

Clean is Green-Photo credits:papaandbarkley

These frameworks of CO2 extraction are regularly the cleanest extraction choice in general.

Since CO2 is viewed as a characteristic dissolvable, processors can all the more effectively become a confirmed natural producer and purchasers can relax realizing that substance residuals are not an issue to be considered.

CO2 additionally doesn't add to any polluted impacts into the climate when reused appropriately making it the "green and perfect" extraction choice.

Handling Costs

When we talk about CO2 extraction it is a way less expensive extraction technique contrasted with other same types of CO2 extraction.

For instance, Ethanol which can be generally $4 per pound contrasted with CO2 is 4 pennies a pound. The solution which goes into the waste additionally adds to the general expense.

For instance, 1-ton-per-day ethanol extraction frameworks would see an expected $1,260,000.

Most secure Products for Consumers

Since there are no compound denaturants or unstable solvents leftover in a CO2 separated item, there is little uncertainty that it is the most secure extraction measure for customers.

An organic and natural dissolvable like CO2 implies client confirmation without let go of item strength settling on CO2 extraction frameworks the most ideal decision for unadulterated items that are unquestionably alright for ordinary utilization.

20.Does Supercritical CO2 Extraction Kill Mold?

CO2 (Carbon Dioxide) has been having multiple usages, starting from the extraction of cannabis to the cleaning, and so forth. All the while, it likewise mitigates some sure problem with the plant material, similar to mold.

Nonetheless, it is critical to take note that handling rotten material isn't suggested, at any conditions!

The microscopic organisms found alongside mold can be unsafe, even though in a very small sum. Utilizing the CO2 strategy for extraction should not be utilized as a shape moderation strategy.

Good products can only be created with healthy material.

Mold is only one risk right now we are looking at. Plant material can contain weighty metals are taken out from the soil when plants are being removed (particularly in hemp, which keeps an eye on "cleaning" space at a planned space), pesticides, and other microbes.

21.How much is a Supercritical CO2 extraction Machine?

Among the types of machines, prices can vary for the CO2 extraction machine. It may go from the less to higher prices.

Everything appears to be very straightforward, yet the machine included is over the top expensive; costing from a huge number of dollars for little units and running into thousands of dollars for a front line arrangement with a 60-liter extraction limit.

While expensive, supercritical extraction machines contrast well with the expense of other dissolvable based methodologies when considering the security of equipment and exceptional offices lawful needs in certain nations for working with combustible solvents.

Supercritical CO2 extraction might be more secure, yet given the pressure in question and the requirement for exactness; it's not such a machine you'd need to buy off an online bazaar or use without a lot of preparation.

The nature of supercritical CO2 machines is certainly not something worth compromising on.

AIPAK Supercritical CO2 Extraction Machine

This is the activity of the low temperature: heat-delicate segments stay intact.

Avoidance of oxygen: oxidation-delicate segments stay intact.

Higher selectivity and higher mass exchange which prompts better outcomes and a more drawn out time span of usability.

Cleaner measures both as far as ecological effect and the yield.

Longer time span of usability of the item contrasted with regular extraction techniques and a better flavor and aroma contrasted with regular items.

Greater expenses and mechanical requirements contrasted with a traditional extraction of maceration.

Normally an extreme shade of the concentrate.

CO2 extraction normally does cost a bit more than the normal same type of the process.

22. What is the difference between Supercritical solvent extraction and Solvent Extraction methods?

| Supercritical solvent extraction | Solvent Extraction |

|

Is absolutely liberated from solvents and henceforth exceptionally sheer.

Absolutely liberated from substantial metals since they are not extricated regardless of whether they are available in the crude material. The whole equipment is free from any kind of heavy metals.

Thoroughly liberated from inorganic salts utilizing a similar clarification as above.

No such chance since there is exceptionally high selectivity of CO2 and zero chance of polar substances shaping polymers. What's more, the working temperature is just 40-50 degree Celsius.

Just nonpolar tones get removed.

No additional unit tasks required and yield of helpful material is high. |

Dissolvable presence can't be dodged. The lingering ppm level of the dissolvable relies upon the kind of dissolvable utilized.

Weighty metal substance is likewise unavoidable and relies upon the dissolvable, the reuse strategy for the dissolvable, the resource of the crude material, and the material for development of the contact portions of the CO2 extraction machine.

Inorganic salt substances can't be stayed away from, utilizing a similar idea as above .

Polar substances get broken down alongside the lipophilic substances from the crude material because of helpless selectivity of the dissolvable .

Dissolvable evacuation requires additional unit activities and thus the cost and recovery of helpful material is lower. |

23.What is the future of Supercritical CO2 extraction machines?

The Removal process is must to get the CBD out of cannabis. While there are quite a few approaches to extricate elements like CBD out of the cannabis plant, CO2 extraction is one of the well known and widely accepted in the ever-growing industry of cannabis.

This is top of the line, cutting edge extraction procedure (a supercritical CO2 extraction machine can begin at $40,000) is an industry chief which is as it should be.

It is better when the extraction process of cannabinoids is talked about. CO2 is now utilized broadly in food creation and has been endorsed by the FDA.

For what reason isn't each organization utilizing CO2 extraction techniques? First of all, CO2 extraction machines cause more money. For another, this costly machine is huge and requires much room. The individuals who make the speculation, nonetheless, will discover the re-visitation to be certainly justified regardless of the underlying expense.

Why?

CO2 extraction ensures the highest caliber, cleanest removes accessible available. The extraction of CO2 is one reason that can certainly offer a safer way, high-caliber, predictable items.

CONCLUSIONS

In the end, the unique advantages which are written up in the article of this supercritical CO2 extraction machine make it a unique product to be used. AIPAK has always been known in the world for making high-effectiveness supercritical CO2 extraction machines with a wide range and extraordinary qualities.

Further Reading:

1> Cannabis Oil Extraction Machine:The Complete Buying Guide in 2025

2>Supercritical Fluid Extraction-Source: Wikipedia

3>CO2 Extraction Process-Source: Endenlabs

4>Supercritical CO2 Technology For Biomass Extraction: Review