How To Make Sugar Free Gummy Bears: The Complete FAQ Guide in 2025

Sugar-free gummy bears do not have sweet ingredients. Rather they are sweet in a different way with a different ingredient.

Health is wealth and every one of us is concerned about health these days.

A proper diet is a must to keep the balance and keep you fit. Without adjusted sustenance, your body is prone to diseases and sickness.

You don’t want to live an unhealthy life. Most people are dieting these days and don’t want to eat products with sugar.

These Sugar-free gummy bears are a perfect match for your diet with no loss for your health. You can have them with no problem at all.

I’ll be explaining each and every bit of this topic. By the end of this, you will know about Sugar-Free Gummy Making, Pros/cons, how they are made, what is kept in mind when they are made and much like this.

Let me drive you through.

1.What is the Sugar-Free Gummy Bear?

Sugar free gummy bears

Sugar free or sugarless gummy bears are the jellies or gummies like haribo that does not offer sugar ingredient in them.

Other than that, they use maltitol which is makes them sugarless.

It is more like diet pepsi and you can use them even though you’re diabetics.

2.What Are The Sugar-Free Gummy Bear Ingredients?

How are these sugar-free gummies made? If you are thinking that the lack of sugar will make it boring and tasteless then you are wrong. The sugar-free gummies are as tasty as the sweet ones, the only difference between both is that the health hazardous effects of sugar are replaced by healthy natural sweeteners.

To make a gummy is easy, because all you need is an active ingredient, a jelly agent which most of the time is gelatine, and a sweetener along with food colouring since the fantastic rainbow of gummies is loves by everyone. With time people are getting more health-conscious, and that is not a bad thing at all. Because the use of only healthy ingredients under such a scenario eventually builds up the base for popular sugar-free gummies!

Active ingredients

The active ingredient is the main ingredient in your product. And when it comes to gummy bear candies, the most common active ingredients are vitamins and minerals. If your gummies are healthy, they are more likely to be famous not only among children but also adults. That is the main reason why bodybuilders and other people focusing on their diets prefer sugar free gummies.

Gelling ingredients

Gelling Ingredients-Photo Credit: Veganz

Okay, now that you are done understanding the active ingredients and how to incorporate them carefully, it’s time to jump to another most important element. It wouldn’t be wrong to say that the real ingredients behind the success of these gummies are their giggly agents.

But do you know that the giggly quality is not the only reason why gelatine is added to these bear candies? You would be surprised to know that without the addition of gelatine, it wouldn’t be possible for you to achieve the perfect shape of the gummy.

The reason behind why gelatine is a must ingredient when it comes to gummy candy is because it has the thickening power to keep the candy in its shape even when exposed to harsh environmental elements. The gummy candy has a jelly type structure which is achieved only through the gelling nature of gelatine.

Sugar-free ingredients

The very first thing to know about a gummy candy is that taste values above everything. Yes, the health-conscious teams are always in search of harmful elements, but here the point to notice is that the taste of your gummy should be as important as the other wholesome constituents.

That is why it is crucial to look for a natural ingredient to make your gummies tasty because in the absence of sugar in a competitive environment, handling the sweetener alone can be a lot trickier.

Gelatine

Since these are the basic elements to make a sugar free gummy bear candy, the nutritional benefits hold second place. Think of it as a recipe where you add multiple ingredients to cook something. In the same way, the main constituent of a basic gummy candy is gelatine. As the name suggests, it has a jelly-like structure that is stretchy, bouncy and makes the gummies giggly.

The gelatine is mixed with other ingredients that include colourants, flavours, and at time nutrients to form candy. Water is also added as a helping agent to enhance the elasticity of gummy. Not only gelatine helps the gummy get a chewable texture, but also enable the candy to sustain its shape after formulation. Therefore, the right quantity of gelatine is important in achieving the desired texture of the final product.

Water

Water is another most important ingredient in the formulation of sugarless gummies, thanks to nature for such a valuable constituent. This universal ingredient is used to blend all the elements to make a smooth texture with which then gummies are made.

Now the main thing to remember here is the quantity of water you will use in your manufacturing process because it can either make or break the final product. Also, when trying for the first time, make sure to add the water little by little to see what quantity goes best with the procedure.

Not only water maintains a harmonic relation between all the ingredients with which they are kept intact to form a final gummy candy, but it also plays a significant role to make the candy tender and soft. In other words, water goes side by side with gelatine to help the gummy achieve its giggly texture.

Corn Syrup

Corn syrup is another essential element when it comes to giggly gummies. Now you may ask why the addition of this ingredient? The answer is simple. The gelatine works with water to form a smooth paste, but the task of corn syrup here is to retain the moisture as all the ingredients are mixed thoroughly.

Not just that, even after the gummy has made, it is the corn syrup that preserves the candy’s overall moisture to keep it intact and soft at the same time. It wouldn’t be wrong to say that without such an ingredient, the gummy may become hard as the gelatine is prone to stiffness in the harsh atmospheric elements.

Colours

Colours are an essential ingredient in gummies, with or without sugar. They have many roles to play and the top of them is the most superficial one: to attract customers. Children mostly are attracted to multiple colours of candy and like to play with it. But the rise in demand for gummies has shown that it is not the children only who are captivated by various colours as the adults find themselves equally addicted to these gummies.

Starch

Kinds Of Starch-Photo Credit: andritz

Now, this is another ingredient that you can add to your sugarless gummy candy, and though it doesn’t come under the ‘basic ingredients’ list, it still can play a great role in the formula. The reason behind it is that starch is not suitable for every ingredient and may create a chemical reaction within the candy if not handled properly.

However, the use of starch in precise quantity can surely enhance your gummy as it can add to their volumes. The job is much like the corn syrup except that the taste of starch is not sweet, rather it has a tasteless, odourless texture when in pure form. Thus adding it to your formula will not have a direct effect on the taste of gummies.

Other than that, in a sugar-free gummy bear candy, you can add starch to enhance the nutritional level as it is rich in iron, calcium, fibre, and vitamins. Moreover, unlike the famous myth, they are not fatty at all but have calories even half than the fat sources.

3.What is the Sugar-Free Gummy Bear Making Machine?

AIPAK sugar-free gummy bears

Sugar-Free Bear Making Machine is used for making the different types of the gummies, candies and related products in the different shape and sizes.

The preparing line is a high-level and ceaseless plant for making various sizes of confections.

4. What Are The Parts Of Sugar-Free Gummy Bear Manufacturing Machines?

Simply stated, a gummy bear machine is made of all those parts that play their role to process one step of gummy formulation at one time.

This can include mixing, blending, moulding, cooling, and drying the gummies. But before moving one, you should know that the Sugar free gummy making machines are either semi-automatic or fully automatic. You can choose any depending on your comfort and budget, however, they all have the following necessary parts:

Mixing and Melting system

AIPAK Gummy Making Machine Mixing System

This is the chamber/unit where the ingredients are mixed to form a homogenous mixture. First, the gelatin is added and melted properly. When it reaches the required state, other ingredients are added.

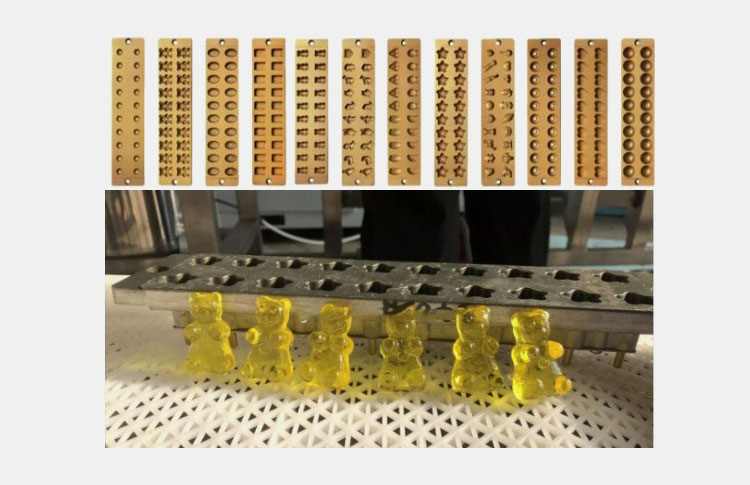

Molding system

This is the unit that comes into working after the mixing tank as here the prepared mixture is put into the molds to form the bear shape. You can have many types of molds to make different gummy shapes and sizes. The machine pours the mixture in them through the dosage pump and then they are taken to the freezing unit.

Freezing system

Cooling Tunnel Of Gummy making machine-Photo Credit: isweetech

When the melted mixture is poured into the molds to form gummy bears, the freezing unit takes charge and cools the temperature to solidify the bears. Even before that, the melting of ingredients is done through it as it increases the temperature to soften them. It is designed in such a way that its chilling system provides cooling and warmth at a steady pace to successfully carry the process.

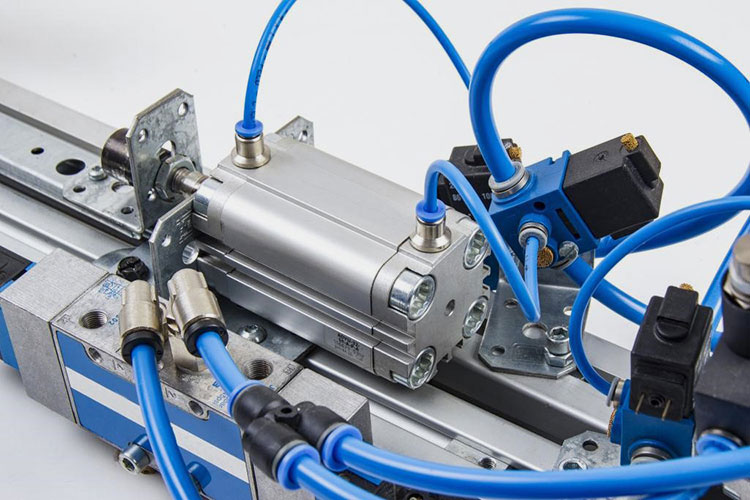

Pneumatic system

Pneumatic System-Photo Credit: Medium

Like temperature, pressure also plays its role in the manufacturing of gummy bears. And this pressure consumption of air is done through the pneumatic unit where different subunits work together to provide steady pressure to the mixture during the processing.

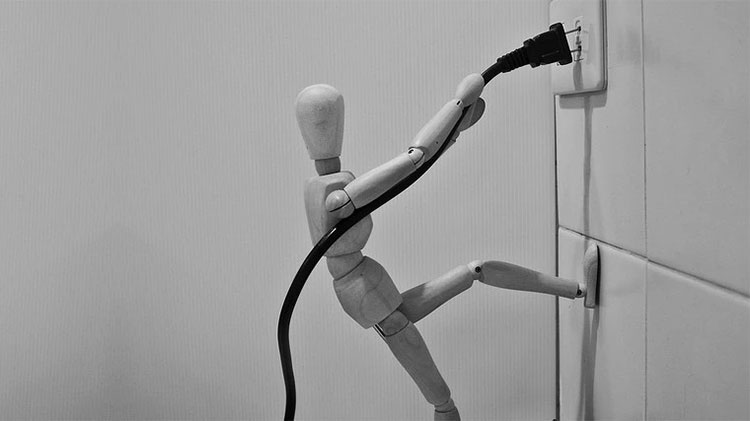

Electrical system

Electrical System-Photo Credit: isweetech

Equipment like gummy bear manufacturing machines use mechanical energy and for that they have to first convert electrical energy into it. All this is done through an electrical system which not only keeps the balance in the energies but also maintains an overall control on all the operations taking within the machine.

Transport system

Deposit or transferring part of Gummy Making Machine-Photo Credit: isweetech

This serves as the main connection between all the activities as they take one step forward to the next. As implied by the name, this unit is responsible for taking the mixture/molds from one unit to another and such as from mixing chamber to the molding unit, and then to the freezing system.

Control system

Control System-Photo Credit: automation development

Modern gummy bear machines are designed with a built-in control system. This includes a display panel that recognizes the human touch and takes input in the form on graphics, voicing, and data. Then the information is processed through the programmed software to take the action. You can do anything with it as you set all the parameters here. All the systems are human friendly and allow you to work without any hectic.

Greasing system

After the gummies are frozen into their solid form, it is necessary to dip them into oil to retain their soft chewy side. This is done through the greasing system since it takes in all the gummies and helps them become giggly. Moreover, it is designed to keep them safe at the same time.

Greased Gummy Bears-Photo Credit: onegreebplanet

Other parts

Aside from the main units, there are also some other parts that serve their minor role in making the gummies. They are as follows:

Sieve

This part is responsible for keeping the gummies starch free and it is very good at its job. It comes with various parts made of metal that help remove the excessive starch over the surface of gummy candies by vibrating. Another significant feature of this part is that it doesn’t harm the gummies at all.

Sensors

Sensors are a wonderful gift of technology as they can save your machine from ruining. When you set the parameters on the display panel and the machine starts working on them, it is the sensors that make sure that nothing is going against the required guidelines. If they see any disturbance, they immediately ring and notify the user that something is going wrong. Not only that, they can also stop the machine from working if there is a bigger problem going on. Thus you can trust sensors because they help the units work accordingly to the set limitations.

Dust assortment part

This part helps in the maintenance and cleaning of the machine since it collects the excessive starch that is removed from the gummies. You can either reuse the starch or dispose of it, but for the former option, make sure it is not health contagious.

Oscillating brushes

How the bears are made starch free? With these brushes which are designed to eliminate the excessive starch through their to and fro movement, the working of the machine has been enhanced a lot. Furthermore, they work at a steady pace to ensure the production of excellent candies.

5. What Are The Manufacturing Process Of The Sugar-Free Gummy Bear Making Machine?

Now that you have learnt deeply all about the ingredients and different choices in them, you can now proceed to the real procedure and learn how to make gummies. As previously stated, there are different steps in making a gummy and for that different parts of the machine work together to make a final product.

So here are those crucial steps that ensure the success of gummy bear candies:

a.Mixing the Sugar-Free Gummy Bear Ingredients

Once you have decided which ingredients you will use in your gummies, it’s time to make one. And for that, the very first step of course is to add and mix well all those ingredients. Remember that the perfect gummy will obtained by trying different quantities of the gummies and thus you should be careful not only in what you choose but also how much you add.

The part of the machine that will begin the process is the tank where all the ingredients will be melted and mixed. This is done by first heating all the constituents to melt down a little and then a shear mixing takes place to blend each one in another. This will create a homogenous mixture necessary for the production of intact and solid yet giggly gummies.

Another important thing to note here is that the thorough process usually takes almost two or three hours, but the timings can vary depending on the amount of each ingredient. Once this process is over, you can test the prepared paste/mixture in the food laboratories to ensure quality, taste, and other factors.

b.Moulding Sugar-Free Gummy Bear Ingredients

Now that all the ingredients are thoroughly mixed and you have also ensured their perfect state, it is time to put them in the moulds to give them their shape. Now here’s the thing: you can have as many moulds you want and with that, you can manufacture gummies in lots of different shapes. The traditional bear shape is of the bear in a sitting position, but you can also incorporate any unique idea.

The dosing pump comes in handy here since all the mixture is poured into the moulds through it. The moulding machine makes sure all the moulds are filled properly and all the trays are packed with the material. If you have used starch, you can relax as it will keep the material from adhering to different parts of the machine as well as let the bears attain their shape properly by keeping them intact.

Most of the automated machines today come with a built-in cleaning system that cleanses and sanitize the silicone and stainless steel moulds and trays by just receiving instructions from the control panel. However, you need to check it specifically because of its semi-automated nature.

c.Cooling Sugar-Free Gummy Bear Ingredients

Gummy Bear After Cooled-Photo Credit:isweet

The fun part is here. Because this is the part where the mixture will become delicious giggly gummies. The filled moulds will be taken to the cooling segment through the transport system where they will be placed under a low temperature to reach their solid-state.

Nothing much happens in this part, since the machine takes the instructions and then puts the trays containing moulds in the cooling section. However, you should note that unlike the mixing process which took only two or three hours, the cooling process can be as long as a complete day. The reason behind this is that all the ingredients in the mixture need their time to blend into one gummy.

Thus, always make sure that your gummies are getting enough cooling time which in most cases varies somewhere between a twenty-four to twenty-six hour period. Moreover, the cooling time can differ in different Sugar-free gummy making machines.

d.De-moulding of Sugar-Free Gummy Bear

Now you may be confused about what does this ‘de-moulding means. This is fun to know because unlike the superficial meaning that gives the assumptions of remaking the gummies, it is extremely simple: de-moulding of gummies simply means to take out the cooled gummies from their moulds. Sounds peculiar, right?

But caution is required here since the gummies should be carefully removed from their moulds. In the case of a machine, all is set because they are programmed to do the job with extreme care. Then, all the formed gummies are put into a large drum, and no, this won’t harm them as the next step is more interesting to keep them safe.

e.Oil Coating of Sugar-Free Gummy Bear

Lots of questions arise here. Why are gummies being coated in oil? Won’t it affect their overall taste? Is it to give them their giggly texture? Keep calm as the answer to each question is the same. First of all, you should understand that the gummies are made of gelatine. Since it is their main ingredient, they will retain its characteristics too which is the stretchy quality.

But being bouncy is not the only gelatine incorporates in the gummies. Instead, it also makes them a bit sticky. And when the gummies are coming out of a freezer with extremely low temperature, it is more likely that most of the moisture would have gone. So the oil coating is used to protect the moisture in the gummy as well as to make them giggly, fresh, and soft for a much longer time.

Lastly, if you have used starch as an ingredient in the formulation of your gummies, then the coating of food oil will also serve another purpose: to keep the surplus starch away from the gummy candy.

f.Drying of Sugar-Free Gummy Bear

Drying Gummy Bears-Photo Credit: studiokatie

Of course, the drying process is a must in a Sugar-free gummy making machine when the candies are being coated with oil. Notice that this drying method doesn’t involve blowing the excessive oil from the gummies because that will ‘dry’ the candies in real terms: it will also blow off all their moisture, thus destroying the whole idea of oil coating.

So how do you dry your gummies? The transport machine will take the coated gummies to the drying section where they will be dried under specific temperatures. The thing to note here is that the main job is to let the gummies remove excess oil while keeping their oily layer on them. So all this can take up to 72 hours as a whole.

Why is moisture so important? Because it is the moisture that makes the giggly and chewy. Otherwise, they will become pure solid. Also, keep in mind that you would need to change the gummy position which is of course automatic in an automatic machine. The typical changing time is 48 hours.

g.Sorting of Sugar-Free Gummy Bear

As previously mentioned, you can make different types of gummy bear candies depending on their colour, taste, and also the shape of size. So all of them at this step are separated from each other to sort them into their respective batch mates.

Some factories also add different colours and flavours to make the packets more fun. You can also mix and match and bring innovative ideas. A popular way is to keep all the gummies in two sections. One involves all the gummies separated from others depending on their colours, shapes, and flavours, while the other section mixed them all and creates new packages.

Packaging of Sugar-Free Gummy Bear

Here comes the packaging part. You can go for different packages as per your need and requirement, but the most common are single pillows, plastic bottles, and pouch bags. Whatever the type, make sure the covering is not boring at all. Makes it attractive by incorporating shapes, colors, and even text where necessary.

Next comes the sealing. The package should be tightly sealed since it will keep the moisture in the gummy bear candies intact and fresh. All these points are highly important in the packaging of gummies since they play a significant role in the longevity of candies.

h. Storage of Sugar-Free Gummy Bear

This is the last step where after packaging and sealing the gummies, they are stored in places safe from harsh environmental elements. And the best place for that is the one that has a cool and normal temperature. Also, the gummies should be kept in a dry place to help them retain their moisture. The next noteworthy things are to keep the packets no longer than a year since after twelve months the gummies can begin to deteriorate. Other than that, you should keeps the packets in a systemic order for ease and comfort.

6. What Are The Types Of Gummy Bear Machines In The Market?

The simplest answer to this question is: there are two. One is automatic and the other semi-automatic. It is extremely hard to formulate gummies all by yourself since all the factors require precise calculation which can only be obtained through a:

a.Automatic machine

AIPAK Gummy Bear Making Machine

The automatic machines need no human labour since they are designed to meet the modern requirements which are to prepare more in less time. It comes with a human-friendly control panel to let you give all the instructions and the rest will be handled by the machine itself.

b.Semi-automatic machine

AIPAK Semi-Automatic gummy Bear Making Machine

As the name implies, the semi-automatic gummy bear machine is half automated and half labour operated. You would need to hire people to help in the formulation process. While some of the steps are also done by the machine but again, they would require human help.

There are no manual Sugar-free gummy making machines because they belonged to the earliest generations of gummies.

7. What Are The Possible Challenges In Manufacturing Sugar-Free Gummy Bear?

You have learnt all the process of making a gummy bear candy. However, it is not as easy as it seems, since a lot of game is handled by different factors that, if not addressed carefully, risk your gummy business. The first one is gummy safety, which is on the top because it also relates to the health of consumers.

However, when it comes to gummies, and their manufacturing, the problems occur when they are unable to get the proper shape. This mostly happens in the mixing state when the ingredients aren’t mixed properly, thus later in the moulding state they do not attain their accurate shape.

The gummies are also prone to melting, and that is why care is highly needed in all the processing. This is most likely in the drying process when the oil coating is not properly removed, thus leaving the candy prone to harsh elements.

As time is changing, consumers are also expecting more from the gummies and this not only refers to the shape and size but also colours and flavours. Since gummies are in demand for more than many decades, the world is bored of eating the same flavours which creates a huge challenge in the marketing of gummy bear candies.

8. How to Quality Control Sugar-free Gummy Bear Manufacturing Process?

All the ingredients that you will use in making your gummies will require proper authentication from different organizations and bodies. The testing of the labs will ensure that your gummy candies are not health hazardous and thus don’t pose a threat to the health of consumers.

The best way to keep all this in check is to show a caring attitude from the beginning. If you don’t have much knowledge about an ingredient or whether it will cause what reactions, you should always get the proper understanding before incorporating the constituent in your gummy formula.

Another great method is to get the ingredients from suppliers who are worthy of your trust but still, in that case, I would suggest you test your gummies first. Furthermore, it is not only the quality of the gummy but the way it is packed and delivered also matters. So focus on that too.

Other than that, you can look for CGMP (Current Good Manufacturing Practices) to ensure the quality of your gummy. Some other bodies include ISO (International Standards Organization) as well as FDA (Food and Drug Administration). Lastly, make sure to go for CE (*) too because it would ensure your machine as highly productive and protected.

9. How does Sugar Gummy Making Equipment compare To Candy Maker Machine?

Here’s the main thing: the gummy bear machines and candy maker machines are both so much alike that it feels natural to be confused in both. However, they have certain similarities as well as differences that must be kept in mind when addressing any.

First of all, both the machines lack in manual mode, and that is a good thing relying only on human labur to form the candies can often result in complete ruin of the final product. That is why both the machines come in automatic and semi-automatic modes to formulate candies.

Now if I talk about the differences, the top of the list has the difference in their nature. As suggested by the name, the candy maker machines make candies, and the Sugar-free gummy making machines make gummies. But is there more to it?3

Yes. The difference lies in the texture. Gummies are giggly, bouncy and stretchy, while the candies are solid. Furthermore, the giggly gummies are chewable while the candies are sucked to enjoy their flavours. This makes both a complete opposite to each other.

Sugarfree Chewable Gummy Candies-Photo Credit: lelong

Not to mention the size of the machine, the candy making machine is often smaller. While on the other hand, the gummy bear machine includes lots of steps and thus has a bigger size. So these were some of the differences between both the machines and should be kept in mind.

10. What Quality Standards You Must Verify in Gummy Production Equipment?

You should look for the following when considering the quality standards of gummy bear machine:

- CGMP quality standards: This body ensures that the machinery and the products are safe to use.

- FDA quality standards: It also ensures that the manufactured product is safe for public health and doesn't contain any harmful ingredients.

- ISO quality standards: This organization makes sure that the machinery is efficient, safe, and meets the quality requirements.

- CE quality standards: Another body to verify the sound, robust machine and its quality performance.

11. How To Choose A Perfect Sugar-Free Gummy Bears Machine?

Whenever looking for a gummy machine in the market, make sure to focus on the following factors:

- The capacity of the machine: the bigger the size of the tank, the more ingredients can be mixed.

- The dimensions of the machine: this includes the height and width of the machine

- The pressure specifications: is the machine capable of providing enough pressure for the processing?

- The power specifications: the machine should provide sufficient power rate for the thorough mixing as well as other formulation process of the ingredients.

- The pneumatic specifications: This includes steam consumption and the consumption of compressed air by the machine.

- The floor space: the machine will take how much space of the room and does it go well with your manufacturing place?

- The temperature specifications: is the machine capable of providing enough temperature for the processing?

12. What Are The Common Troubleshooting Of Sugar-Free Gummy Bear Machines?

Following are the three main problems that can arise when working with a gummy machine and how you can solve them on your own:

Problem 1: Ingredients are not blending properly

No doubt you need a homogenous mixture for the formulation of gummies which can only be achieved by thorough mixing. But it can happen that the machine is failing in achieving that level of homogeneity. What can you do in such a situation?

Homogeneous Mixture-Photo Credit: Mental Floss

Often the issue happens because the mixing speed is not matching the rate at which the ingredients should be mixed. Thus, make sure there is a balance in both. Secondly, if the machine is used many times, and is not cleansed properly, then it is likely that the parts of the machine mixing are clogged. Thus try cleaning them first.

Problem 2: The final product is too stiff or too giggly

All this is caused due to ineffective planning. You may have added any ingredient in your mixture that has caused reactions in the processing, or it can also because the blending, moulding, or drying processes are done ineffectively.

Whatever the cause, you should understand that the balance between each ingredient in the key to a successful gummy. Also, if the quantities of the ingredients are not fully set, or any constituent is added more or less can also affect the final product. Thus you should carefully observe where the problem is coming from and then try to solve it.

Problem 3: The final product cannot retain its shape

This is one of the most common problems. It differs from the above problem in the way that here the gummy is neither giggly not stiff, but it often melts down to lose its shape. The problem, again, lies in the unbalanced ingredient quantities, or the addition or exclusion of any constituent that can fix the problem. As stated previously, the perfect balance will be obtained by the trial and experience method, so it is suggested to try multiple times till the perfect shape is attained.

13. How To Maintain Sugar-Free Gummy Bears Machine?

After investing in a sugar-free gummy making machine, the thing most essential is maintenance. The modern machines are designed with a built-in cleansing system in them which doesn’t require any effort, but the maintenance of the machine is more than that. Such a heavy investment shouldn’t be destroyed within months, and for that reason, pay attention to the following:

Unplug your machine: It may seem useless but in the long run, you would realize the importance of it. Never touch your machine with bare hands when it’s working because it is extremely hot at that time and may cause you harm. Thus, wait for a while to let it cool down.

Disassemble the machine: After the machine is cooled enough to touch safely, carefully start separating different parts of the machine using tools. Take help from the manual that was provided to you when purchasing the machine.

Cleanse the machine: Now once the machine is fully separated, it’s time to clean it thoroughly. You can use multiple tools for this job such as narrow brushes that go deep into the machine, and clothe pieces that won’t harm the delicate parts. Also, you can use cleanings detergents but make sure they are recommended by the manufacturer and don’t cause any harm to the machine.

Watch out and replace: While cleansing, carefully observes for any part which seems worn-out. If you find any, replace them with fresh pieces. This is highly crucial because it promises the long term use of the gummy bear machine.

Reassemble the machine: Lastly, join all the parts again by seeking help from the manual.

14. What Are The New Technological Advancements In Sugar-Free Gummy Manufacturing?

Technology has changed the world and is still changing it each day. In one second innovation is introduces and in the next, some other advancement outdates the previous one. All this happens so quickly that it is mandatory to keep up with the change. And the same goes for the modern gummy bear machines.

One of the famous shift in the manufacturing of gummy machines is caused by the addition of SiMoGel. Now, what does it do? The job of this technology is to make sure that the work is done in as little time as possible. Thus, it brings a rise in the normal speed of the mixing and blending and helps in the successful formulation at a faster pace.

The next thing that the modern Sugar-free gummy making machines are capable of doing is to sort different types, shapes, sizes, flavours, and colours of gummies much quickly that the previous sorters. Not only that, but they are also built with the technology to verify whether the gummy formulation was polluted with any unfamiliar constituent. This makes them a must to have in your gummy machine.

Gummy Making Machine Related Products

Gummy Making Machine Related Posts

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine