Standcap Pouch Vs Rigid Plastic

Compared with rigid plastic bottles, Standcap pouches use less plastic and significantly reduce fossil fuel consumption, greenhouse gas emissions, and water usage, according to a new report.

Rigid packaging such as plastic bottles, cups and containers are a popular method of packaging liquid materials. They’re strong, durable, and have been around for years. In fact, many major companies still use them today.

Some experts provide a life cycle assessment (LCA) report with descriptions on key environmental indicators based on comparing the premade standcap pouch with rigid plastic equivalent across a range of product categories including sauces, condiments, and personal care.

The premade standcap pouch has a number of sustainability benefits when compared to an HDPE bottle for packing and shipping chocolate syrup. These include lower fossil fuel and water use, GHG emissions, better product-to-package ratio and considerably less material discarded at end-of-life.

The LCA results show that the recycle-ready premade standcap pouch has lower environmental impacts including fossil fuel usage, GHG emissions, and water usage in this scenario than the inverted PET container.

The results of this scenario show that the premade standcap pouch results in lower impacts across a wide range of environmental metrics, including fossil fuel and water use, GHG emissions and discarded material.

This is driven by the efficient material usage of the flexible pouch, which uses less than half the amount of material needed to package the same amount of lotion.

The flexible premade standcap pouch has a number of positive sustainability attributes when compared to a rigid PET bottle for honey, which includes lower fossil fuel and water use, GHG emissions and discarded material; and a higher overall product-to-package ratio.

Don't forget to share this post!

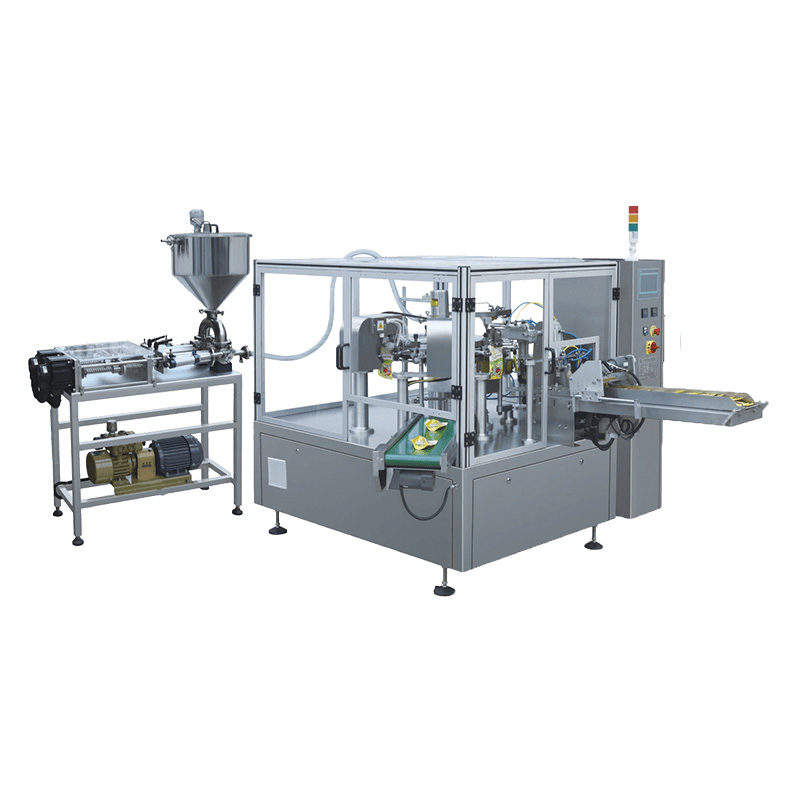

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine