Your Best Spray Dryer Manufacturer

- Lab&Pilot To Industrial Scale

- Efficiently Dry Commodity Material

- Excellent Quality Control

AIPAK Spray Dryer

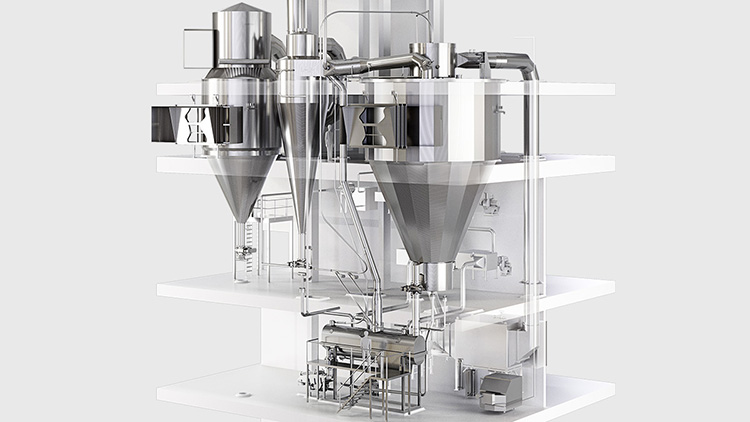

AIPAK spray dryer is applicable for the emulsion, suspension, paste and liquid solution. In polymers and resins, fuels, paints, ceramics, glass type, descaling agent, insecticide, carbohydrates, dairy products, detergents and surfactants, fertilizer,organic compounds and inorganic compounds of dry material ,the performance is particularly remarkable.This drier can be widely used into pharmaceutical, chemical , foodstuff and so on industries/field. AIPAK could provide you with either small spray dryer,which is used for small industrial production purpose or for doing experiment, or for lab; big type spray dryer , for mass industrial production of milk powder, protein, blood, chemical, herbal extract, etc.

AIPAK Spray Dryer Working Principle

The Buyer's Guide

Spray Dryer: A Buying Guide in 2025

After the advent of spray dryers in the 19th Century, these machines have gained immense popularity across the globe for their efficient drying. From manufacturing antibiotics to ceramics and PVC polymers, spray dryers are needed in every industry. These machines have a market size of US$ 5.1 billion in 2022. Constant innovation in spray dryers is increasing their demand.

In this blog, you will discover about uses, types, parts, working, and many more about these handy innovations.

Let’s read on!

1.What is Meant by Spray Dryer?

It is a machine used for removing moisture content from slurries or liquid pastes to produce dry powders. In a spray dryer, dry materials are produced from fluid suspension in a single processing step involving the spraying of liquid materials in hot gases. These liquid particles are evaporated through the exposure of heated gas and dry powder substances are left behind.

Spray dryers were first introduced in 1860 while in 1872, Samuel Percy in the USA patented an old version of spray dryers.

This machine is extremely popular in various industries, especially the pharmaceutical and food industries.

2.What are the Industrial Uses of Spray Dryers?

Spray dryers are one of the most commonly used dryers in different industrial fields. With the increase in demand for ready-made products, spray dryers are routinely employed for the production of dehydrated powders. Some common industrial applications of spray dryers include:

Pharmaceutical Industry

Spray dryers are used in the pharmaceutical industry for drying crystalline drugs to increase their bioavailability. Moreover, the latest innovations in spray dryers have found their use in the development of nasal drugs. These machines are often used in the encapsulation process of active pharmaceutical ingredients.

Nutraceutical Industry

Dry vitamins, protein, and, probiotics other supplement powders are prepared using spray dryers. These machines process nutrient materials in an inert environment to maintain the nutritional value and activity of powders.

Biological Industry

In the biological industry, spray dryers are used for desiccating microalgae and yeast extract. Furthermore, they are utilized in the preparation of enzymes, amino acids and, fodder antibiotics.

Food Industry

The largest market share of spray dryers is owned by the food industry. Readymade meals and powders in the food industry are attributed to spray dryers. The demand for processed food has led to the adoption of spray dryers in the food industry.

These systems are routinely employed in the food industry to dehydrate milk powders, spices, fresh vegetables, fruits, tea, and coffee.

Chemical Industry

Chemical processing is incomplete without spray dryers. These machines are part of productions where chemical solutions, emulsions, and suspensions are processed. Spray dryers are used for drying pigments, dyes, coloring, detergents, catalysts, etc.

Agriculture Industry

These machines are used for dehydrating different types of soils, organic feeds, humus, etc. in the agriculture industry. Additionally, these systems are widely employed in fertilizer production.

Plastic Industry

Processing and drying of plastic polymers, pellets, and resins are often performed by spray dryers. These machines are used to dehydrate suspension of plastic materials such as PP, PVC, etc.

3.What are the Advantages of Spray Dryers?

Spray dryers bring wide-ranging benefits to different processing lines. Some of these advantages include:

Fast Drying

Since atomization increases the surface area of liquid feedstock, therefore, evaporation occurs rapidly. Consequently, drying time is much shorter using spray dryers.

Good Quality Products

Spray dryers use atomizers to disperse liquid feeds and use cyclone separators to extract powders from hot air. Therefore, these machines are utilized in the formulation of excellent quality uniform-sized particles with high purity. Moreover, resultant particles have high stability and spherical morphology.

Control of Particle Size

The particle size of resulting powders can be easily controlled by customizing spray dryers in different designs. These machines can produce powders with particle sizes between 30-500 µm.

Simple Processing

The drying process is quite simple in spray dryers. About 40%-60% of moisture content is decreased in a single pass without using crushing and sieving. Moreover, drying parameters such as particle size and density of powders are easily adjusted in spray dryers.

Minimal Corrosion

There is a low chance of corrosion in spray dryers as inert materials are employed in the construction of spray dryers. Furthermore, dried products are exposed to the surface of a machine in anhydrous form.

Flexibility

These machines easily process different product types with varying moisture content, viscosities, particle characteristics, etc. They are versatile design configurations that aid in processing different products.

Reduced Energy Consumption

Spray dryers are energy-intensive machines because, in these machines, heating is applied for a short duration. There is minimal variation in temperature across the length of the drying chamber and also a significant amount of temperature is decreased by moving air outside.

Less Powder Buildup

These machines are designed in such a manner that minimizes the chance of powder sticking and accumulation at the base of the machine.

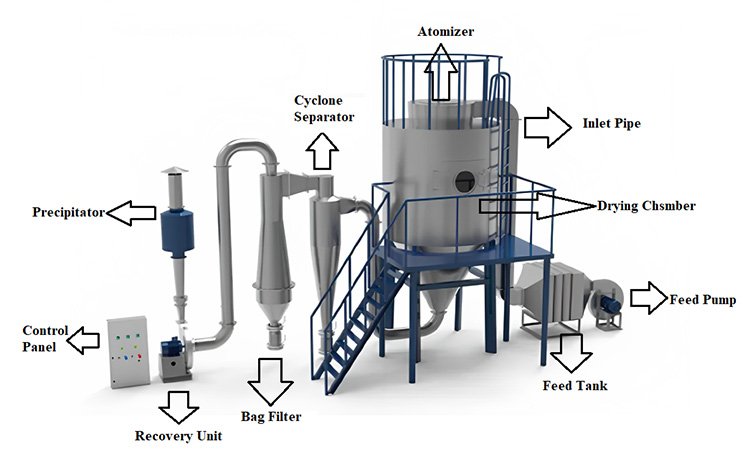

4.What are the Different Components of Spray Dryers?

Some components of spray dryers are detailed below:

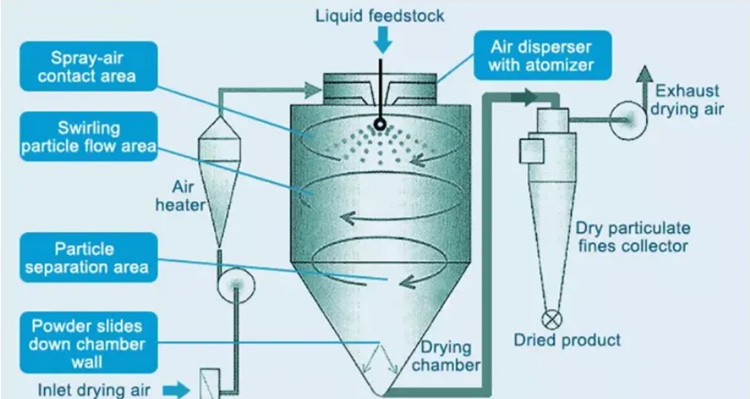

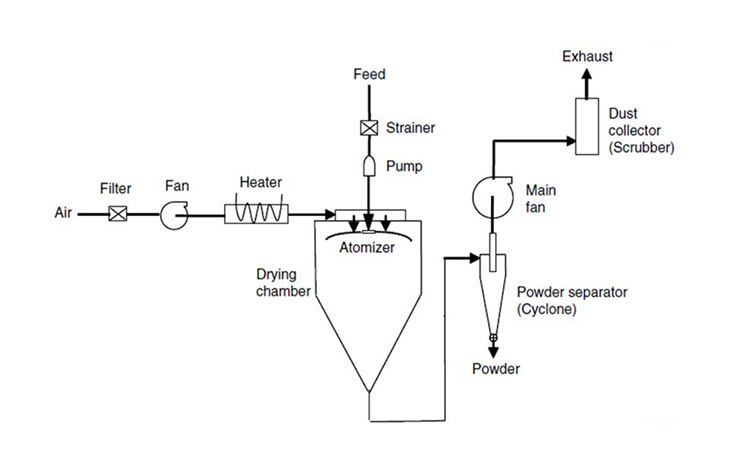

Drying Chamber

The main drying process is carried out in drying chambers. The liquid materials are introduced at a constant rate in the drying chamber and with the help of incoming hot gases, moisture is removed from the feed. The drying chamber can have vertical as well as horizontal configurations.

Atomizer

The part which disperses or scatters the liquid feedstock into tiny droplets is called atomizer. There are two main kinds of atomizers-rotary and nozzle pressure atomizers.

Cyclone Separator

It is the most common type of product separator in spray dryers. Product is introduced tangentially in the cyclone separator and powders and gas present in the impure product, rotate along the length of these devices. Powders are deposited at the bottom while air is drawn upward from the cyclone separator.

Bag Filter

Air or gas enters the filter with the aid of a fan. These filters are employed for extracting impurities and dust particles from the air which averts the chance of dry powder contamination. Moreover, these filters also separate inflammable particles from the air.

Exhaust Fan

There are about four to nine centrifugal fans present in spray dryers. These fans include supply, heating, cooling, nozzle, and exhaust fan. Heating and cooling fans are used for heating and cooling gaseous medium respectively. The supply fan draws the heated air into the drying chamber. The function of the exhaust fan is to move the gas and powders out of the machine

Feed Pump

It is used for transporting wet feedstock to the atomizer devices present at the top of machines. These pumps have a robust design to pump viscous and coarse materials.

Feed Tank

It is used for storing the wet feed. The materials enter the atomizer through the feed tank. An enclosed feed tank prevents the contamination of feed. Some feed tanks are jacketed to maintain the temperature of materials as well as to decrease their viscosity.

Heater

These parts are used for heating gases. Both indirect and direct heating methods are applied for heating the gaseous medium. In the direct method, the air is directly heated using an open heating source like a flame. Heat exchangers are used for the indirect heating of gas.

Precipitator

These devices use high voltage and collecting plates for the separation of powders from the drying medium. When air containing powder particles passed through a high voltage area, the particles get ionized and deposited on the collecting plates while air is discharged from outlet pipes.

Control System

These are electro-mechanical systems used for controlling the drying process inside the spray dryers. These devices regulate the temperature, atomization pressure, and flow rate of materials.

5.What are the Working Stages of Spray Dryers?

Spray dryers are efficient machines with each working step occurring in a precise sequence for efficient drying. Following are the steps involved in the spray dryer working.

Preparation of Feed Stock

The wet feedstock is usually concentrated before loading inside the spray dryers. The concentration step results in an increase of solid particles in slurries. This lowers the liquid content for vaporization.

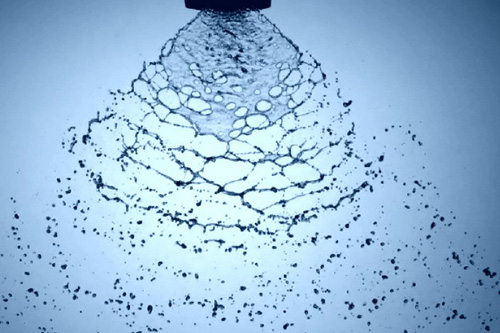

Atomization

It is a transformative process by which liquid feed is converted into minute droplets of spray. This stage occupies a central place in the working of spray dryers. Wet materials are disintegrated into smaller droplets by rotary atomizers or nozzles. This atomization increases the surface area of drying materials.

Spray-Gas Contact

Intimate contact between atomized spray and heated gas occurs inside the drying tower of the spray dryer. Drying gas or inert gas is heated before its introduction inside the drying chamber.

At this stage, droplets and gases flow in co-current and counter-current flow that is spray and air move in the same direction or can flow in opposite directions. This close contact between spray and heat air allows heat transfer for evaporation.

Evaporation

This stage began as soon as atomized spray is near the drying gas. In this step heat energy from gas is transferred to droplets and due to the pressure difference the moisture evaporates leaving behind dried powders.

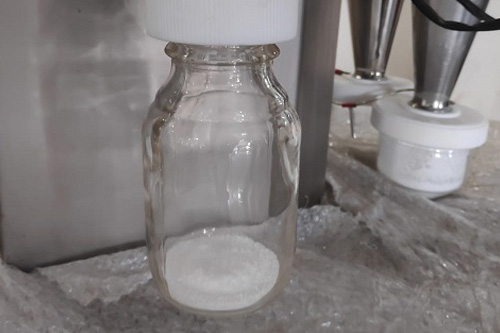

Separation

After the complete drying of powders, these are separated by drying air using two different techniques. In primary separation, powders are simply piled up from the bottom of conical drying towers and are removed from the base using screw conveyors or pneumatic systems.

In secondary separation, powders entrained in a drying medium are subjected to a cyclone separator, bag filter, and precipitators. These systems use centrifugal force, pressure, and, high voltage to completely separate powders and purify air respectively.

6.How is Spray Dryers Classified?

There are several ways in which spray dryers are classified for instance,

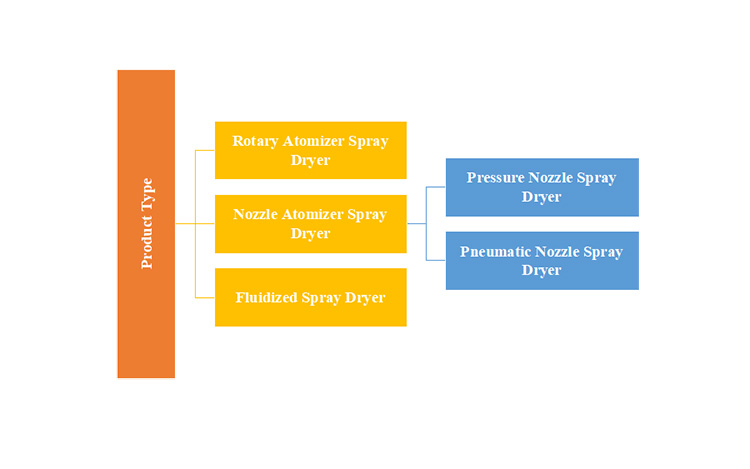

Classification on Basis of Product Type

Rotary Atomizer Spray Dryer

These are also known as centrifugal spray dryers because they use centrifugal force to scatter liquid particles. They have a horizontal disc and wet materials are loaded at the center, with the application of centrifugal force, the material solution moves toward the edges.

In these spray dryers, end material particle size is regulated by changing the speed of rotating discs. These spray dryers generate particle sizes of about 20-200 µm. These are suitable for processing large batches at speed.

Nozzle Atomizer Spray Dryer

There are two kinds of nozzle atomizer spray dryers including:

Pressure Nozzle Spray Dryer

These are also called one-nozzle spray dryers or hydraulic nozzle spray dryers. In pressure nozzle atomizer spray dryers, wet feed is pressurized via a pump and is pushed through the nozzle opening to disperse the liquids into tiny droplets. The nozzle orifice size in these machines is about 0.5-3 mm.

Pressure nozzle atomizer spray dryers have high-pressure pumps for spraying liquids and are often used for producing high-density coarse particles.

Pneumatic Nozzle Spray Dryers

These are known as two-nozzle spray dryers. Two processing materials-liquid slurries and compressed gas are discharged using different nozzles inside the drying tower. The compressed gas meets liquids outside of the nozzle and transfers its energy to the latter for atomization.

These machines are used for providing ultra-fine dry powders and are effective in atomizing highly viscous liquid solutions.

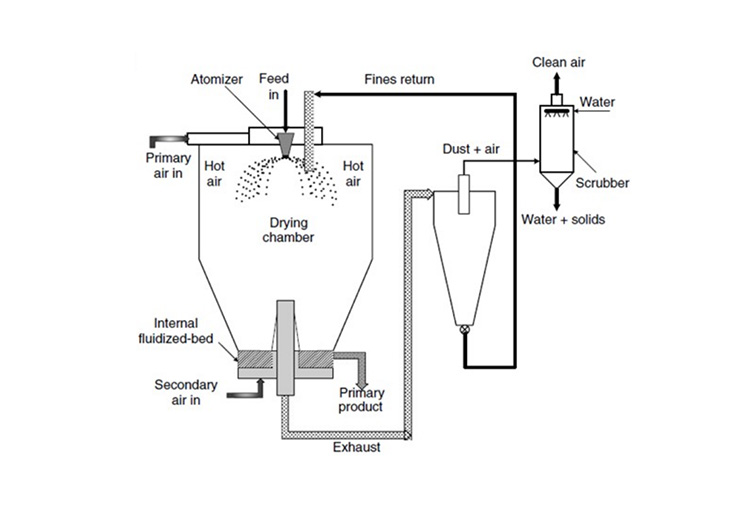

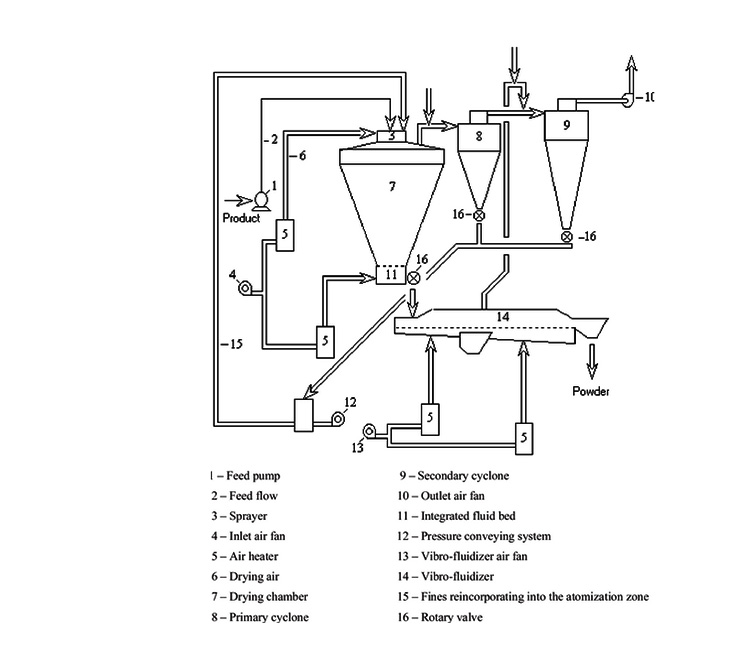

Fluidized Spray Dryer

In these machines, techniques of fluidization and spray drying are combined to offer high control over the size and structure of resultant particles. Fluidized spray dryers (FSM) are multi-stage spray dryers used for the production of dried powders in agglomerated or granulated form.

Additionally, these machines generate a minimal number of dustless particles. These systems are used for drying high moisture liquid content.

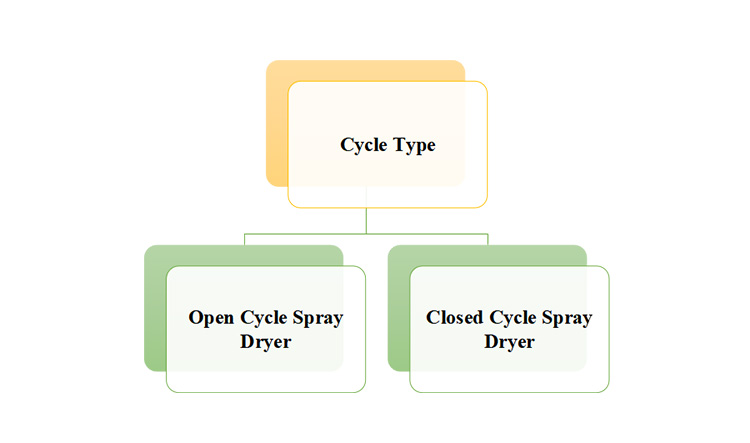

Classification on Basis of Cycle Type

These machines are divided into two types depending upon the type of cycle mechanism found in them.

Open Cycle Spray Dryer

In open-cycle spray dryers, the air for processing is sucked from the surrounding atmosphere, heated, and utilized for drying wet materials. After drying, this air is then released into the environment.

Close Cycle Spray Dryer

These spray dryers recycle and reuse processing air and do not draw air from the surrounding. They use an inert gas such as nitrogen for drying. The gas is filtered using HEPA filters in these spray dryers.

Close-cycle spray dryers are designed according to safety regulations and are used for processing flammable feeds containing explosive solvents like ethanol. Moreover, these systems are also used for drying powders that are prone to oxidation.

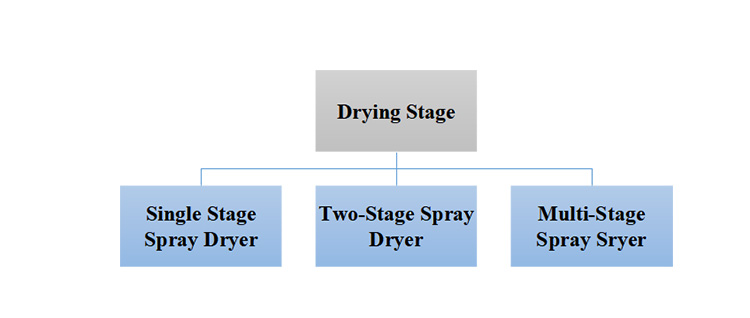

Classification on Basis of Drying Stage

There are three categories of spray dryers when classified on the type of drying stage.

Single Stage Spray Dryer

In this type of spray dryer, the moisture in liquid slurries is decreased to about 2%-5% in a single pass. Both feed and drying gas medium enter the drying chamber from the top and instant contact occur between atomized products and air resulting in evaporation of liquid.

This design configuration is used for producing spherical powders.

Two-Stage Spray Dryer

In a two-stage spray dryer, the drying of feed occurs in two steps. The feed leaving the drying chamber has high liquid content of about 5%-10% after the first drying step. Therefore, the moisture is reduced in the second stage. This stage is carried out in different dryers such as fluid bed dryers or vibratory bed dryers.

These spray dryers have low processing temperatures and therefore are ideal for drying heat-sensitive feeds.

Multi-Stage Spray Dryer

This type of spray dryer has a drying chamber as well as two fluid beds (integrated and external). Drying occurs at three different stages in three different drying chambers. First, the drying step occurs in the drying chamber of the spray dryer. Afterward, the feed with high moisture content is moved to an integrated fluid bed dryer.

Finally, at the third step feed is introduced into the external fluid bed dryer for ultimate drying. Multi-stage spray dryer has superior drying efficiency and consumes minimal energy than other spray dryers.

Classification on Basis of Flow Type

When spray dryers are categorized based on flow type, there exist three kinds of spray dryers.

Co-current Spray Dryer

In co-current spray dryers, both liquid droplets and gas move in the same direction in the drying container. Liquids and hot air enter usually from the top of the drying chamber.

The temperature of a gas is rapidly decreased due to fast liquid evaporation and thus drying time is must shorter. This design of a spray dryer is suitable for processing thermosensitive substances.

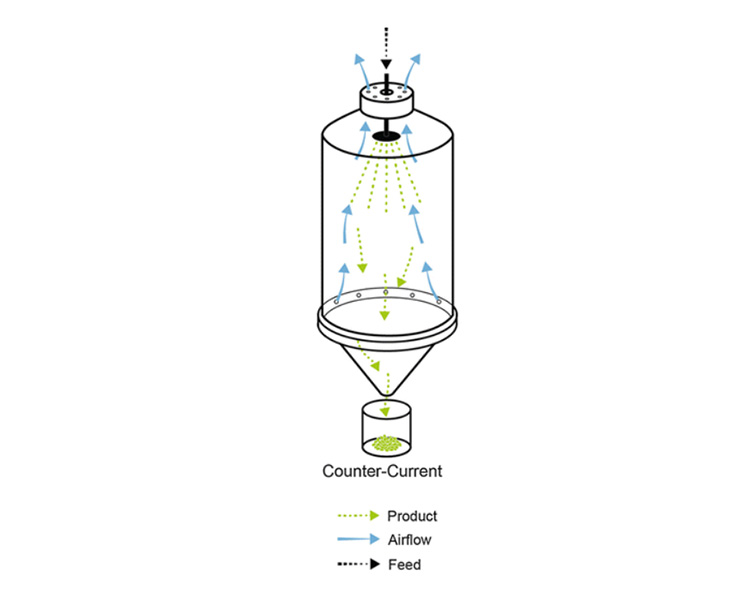

Counter Current Spray Dryer

Feed spray and hot gas are led inside the drying tower from opposite directions in these kinds of spray dryers. The atomizer nozzle disperses liquid droplets from the top while hot gas enters the chamber from the bottom.

They have a more rapid drying rate than their co-current counterparts. However, these are not appropriate for drying heat-sensitive substances since they may degrade later by overheating them. These systems are generally used for drying heat-resistant materials.

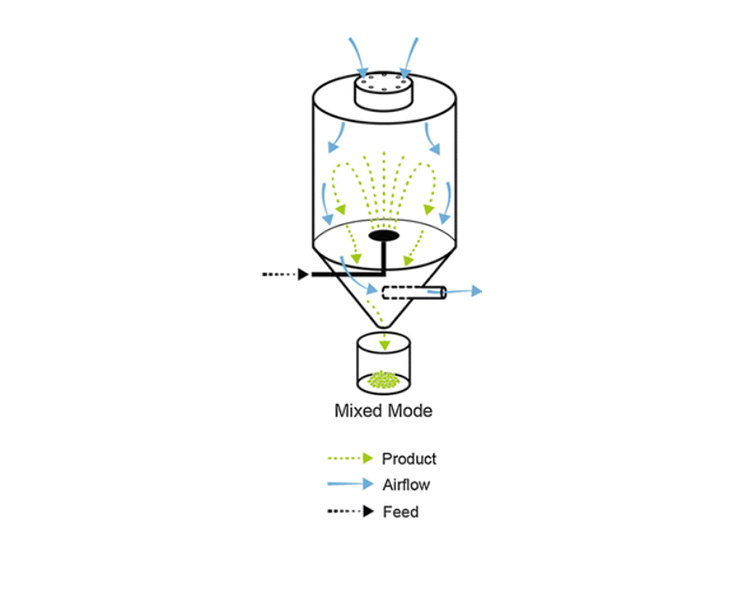

Mixed Spray Dryer

These types of spray dryers combine the working principle of both co-current and counter-current spray dryers. The atomizer is located at the bottom of the spray dryer thus liquids are sprayed inside the drying chamber from the bottom while air is introduced in the drying chamber from the top.

At first, particles travel in a counter-current manner but when they are carried by gas they move in a co-current manner. This design also exposes most dried powders to heated gas and thus is not suitable for processing heat-liable materials.

7.What is the Drying Temperature of Spray Dryers?

Usually spray dryers have huge variations in drying temperature. The temperature of hot gases entering in drying temperature is much higher than the temperature of exhaust gases.

The inlet temperature is about 400°F to 1000°F (200-500°). However, the selection of this temperature is usually influenced by the characteristics of end products. For drying inorganic salts mostly higher temperature is preferred while lower temperatures are generally for processing organic thermosensitive ingredients.

8.What are the Different Parameters of Spray Dryers?

The properties of dried materials are influenced by several processing parameters in spray dryers such as:

Atomization Pressure

The atomization step is performed using pressure especially when pressure nozzles are involved. This pressure influences the size of a droplet. Increasing pressure will reduce the size of droplets.

Surface Tension of Feed

For feed breakdown, the atomization force must reduce the surface tension of materials. Consequently, if materials have higher surface tension it will hamper atomization. For successful atomization, materials are normally emulsified and mixed before loading them in spray dryers.

Feed Viscosity

At higher material viscosity, more atomization pressure is required to overcome the viscosity of the feed solution. Thus, the amount of energy for droplet disintegration is decreased increasing droplet diameter.

Feed Flow Rate

An increase in droplet size is seen by boosting the rate of material flow. This is because more force is utilized to atomize the liquid, therefore droplet fission is reduced and is unable to lower the size of droplets.

Inlet Temperature

It is the temperature of heated gas measured before its flow into the drying chamber. If the drying medium has a higher temperature, it will evaporate solvents more quickly. However, higher temperatures will degrade the resulting products. Hence, inlet temperature should be selected according to wet material characteristics.

Flow Rate of Drying Medium

It is the rate at which drying medium-gas is introduced in the drying tower per unit of time. The increased flow rate will cause increased movement of feed particles inside towers and will decrease the exposure time of gas-spray. Airflow rare should be suitable to maintain drying efficiency.

Outlet Temperature

The temperature of exhaust air with dried particles just before its introduction into the collection unit is called outlet temperature. This temperature is usually the result of heat and mass transfer inside the spray dryer. The outlet temperature is affected by inlet temperature, material characteristics, and air flow rate.

Residence Time

It is the time duration of exposure of atomized spray in the drying tower. For complete drying residence time must be longer. But heat-sensitive materials must be taken into account before selecting residence time since longer exposure of thermosensitive feed inside the drying chamber may degrade them.

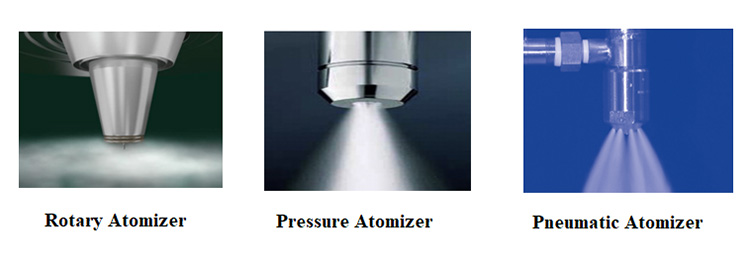

9.How are Different Types of Atomizers in Spray Dryer Compared?

There are three most common types of atomizers in spray dryers:

- Rotary Atomizer

- Pressure Atomizer

- Pneumatic Atomizer

Different comparison characteristics of each atomizer type are detailed below:

| Characteristics | Rotary Atomizer | Pressure Atomizer | Pneumatic Atomizer |

| Working | These are rotating discs and the liquid feedstock loaded at the center of the disc, is centrifugally accelerating liquid material. Feed moves towards the periphery and breakdown into tiny droplets. | These use pressure for the discharge of materials though through the nozzle opening. Pressure provides kinetic force to discharging liquids. Because of the high speed, the feed disintegrates into a spray. | High-speed air breaks down liquids into sprays upon contact with two nozzle atomizers. |

| Source of Atomization | The centrifugal force generated due to the rotation of a wheel | Pressure energy exerted by nozzle | The kinetic energy of gas and pressure exerted by the nozzle |

| Droplet Size | 30-120 micrometer | 120-250 micrometer | 30-150 micrometer |

| Spray Type | They produce fine, abrasive, or medium spray types. | Pressure atomizers produce an abrasive and less uniform spray. | They generate sprays having medium coarseness and poor uniformity |

| Atomization Pressure | Rotary atomizer uses lower pressures than their counterparts. | They have nozzle pressure of about 250-10,000 psi | These also have nozzle pressure of about 250-10,000 psi. |

| Feed Properties | They can process coarse liquids by use of brushings | They can process feeds of low viscosities. | They can process highly viscous liquids. |

| Particle Density | They produce medium-density particles. | Powdered materials have higher density. | Dry powders have a lower density |

| Clogging | Rotary atomizers do not have particle clogging | They also do not have much particle clogging. | These atomizers have a high clogging rate |

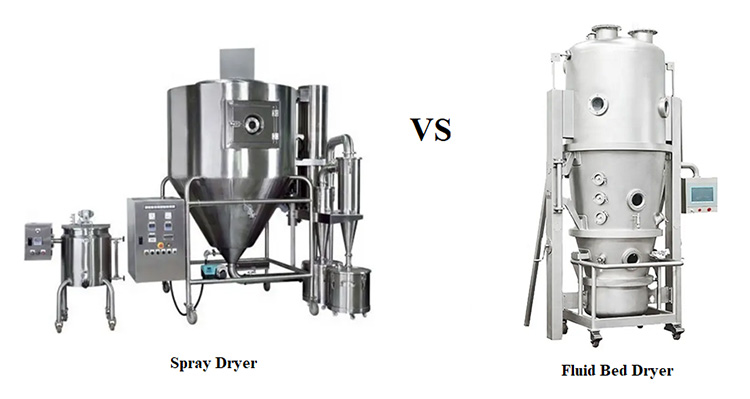

10.What is the Difference between Spray Dryer and Fluid Bed Dryer?

Although spray dryers and fluid bed dryers are commonly used in industries for drying wet feed, these machines could not be more different from one another. A few of these differences are:

| Spray Dryer | Fluid Bed Dryer |

| The fluid feed is sprayed using atomized nozzles through heated gas in spray dryers. | In these machines, heated gases are passed through perforated holes in a container having wet materials. |

| The first spray dryer machine was built in 1860. | The first fluid bed dryer was invented in 1942. |

| In spray dryers, liquid materials are processed. | In fluid bet dryer, solid materials are processed. |

| These machines have a shorter residence time about 5-100 seconds as compared to fluid bed dryers. | Fuild bed dryers have a longer residence time about 1-300 minutes. |

| The spray dryer processes smaller-sized materials particles with the size of particles of 10-150 µm. | These machines dry feed with a particle size of about 10-3000 µm. |

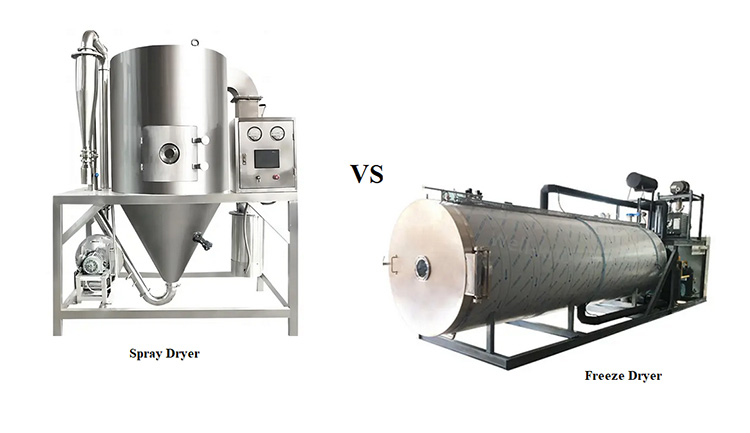

11.What are the Differences between Spray Dryer and Freeze Dryer?

Some differences between spray dryers and freeze dryers are:

| Spray Dryer | Freeze Dryer |

| In these machines, wet materials are atomized using different forces and evaporated by a hot gaseous medium to obtain dry materials. | In freeze dryers, the material suspension is frozen at low temperatures and directly changes into a gaseous form. |

| High temperature in these machines leads to the degradation of nutrients. | These machines are ideal for preserving the maximum nutritional content of the product. |

| Spray dryers are widely used in the food, chemical, and plastic industries. | Freeze dryers are suitable for drying biopharmaceutical products, injectable vaccines, proteins, etc. |

| Drying in these machines takes place at a temperature above 82°C (180°F) | In freeze dryers processing temperature is about -40°C to 30°C (-40-100°F). |

| They have a larger working capacity. | These have a smaller working capacity |

| These machines have shorter drying times. | Drying is slow in these machines and it takes longer to dry powders in freeze dryers |

| It is relatively inexpensive. | It has higher running expenses. |

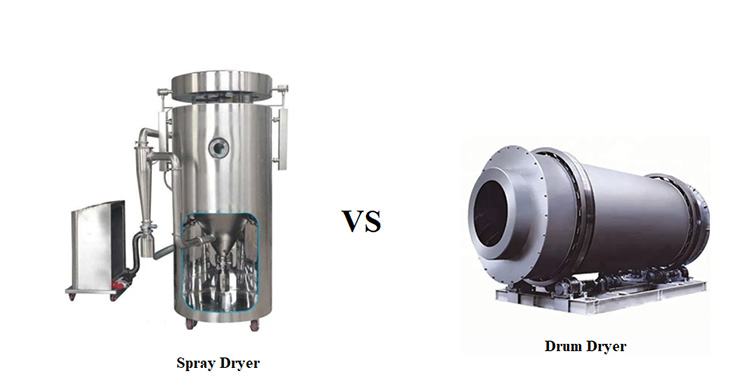

12.How Do You Differentiate between Spray Dryer and Drum Dryer?

There are some major differences between spray dryers and drum dryers including:

| Spray Dryer | Drum Dryer |

| The wet feed is sprayed with the help of nozzle atomizers or rotary atomizers in the drying towers and is heated by a hot gaseous medium in spray dryers. | The wet purees or slurries are dried in drum dryers by spraying them between rolling drums which are heated by steam. These machines are also called roller dryers. |

| They can process any type of feed. | It is limited to sticky and viscous materials. |

| Spray dryers are energy-intensive equipment. | Drum dryers are energy efficient as they use steam for drying. |

| Drying takes place in the presence of oxygen in these machines thus materials are prone to oxidation. | They use an oxygen-less environment for drying therefore feed does not get oxidized. |

| These machines have more operational expenses. | These machines are relatively cheap. |

| These instruments have a higher footprint. | Drum dryers need smaller spaces. |

| These machines do not result in scorched flavor and degraded products. | These machines have intense heat treatment therefore resultant products have scorched flavors, degraded and insoluble. |

13.What are the Problems and Their Troubleshooting in Spray Dryers?

Problems in spray dryers may decrease the productivity of spray dryers and result in high downtime expenses. Some common problems and their troubleshooting are spray dryers are:

| Problems | Reasons | Remedies |

| Sticking Powders in Drying Chamber or Other Parts

|

A large volume of feed

Poor heating of the drying chamber High rate of material flow |

Decrease amount of wet slurries in the drying chamber.

Increase inlet temperature of hot air Start with a small feed flow rate and then gradually increase it. |

| Poor Fluidity of Feed

|

Materials build up inside atomizers blocking their orifices

Highly viscous feed |

Clean atomizers thoroughly before atomization

Process materials of suitable viscosity as mentioned in the machine manual. |

| High Moisture Content in The Products

|

Poor exhaust or outlet temperature | Reduce feed quantity to increase outlet temperature |

| Poor Product Purity

|

Poor processing of air filtration devices

Worn-out filter components Inadequate purity of raw feed |

Clean the air filter systems before every use

Replace the defective filter components Filter raw feed before processing |

| Inadequate Separation in Cyclone Separator

|

Deformity in cyclone separator due to collisions

The inner wall as well as the discharge orifice of the cyclone separator are blocked due to material accumulation |

Replace or repair defective separator

Thoroughly clean the interior and discharge port of the cyclone separator |

| Lower Evaporation Rate of Solvents

|

Inadequate air volume in a drying chamber

A low temperature of hot air Entry of cold air inside the drying chamber due to air leakage |

Increase the volume of incoming hot air inside the drying chamber

Increase the inlet temperature Check the drying chamber for leakage and repair it

|

Conclusion

Spray dryers are the best drying machines because liquids in these machines are atomized and evaporated using hot air without using much energy. They widely utilized machines in wide-ranging industries because of their convenience, simplicity, flexibility, and product particle control. Spray dryers are available in various configurations depending on the type of atomizers, drying stages, cycle, and flow rate. Moreover, these machines can be customized according to product properties. If you require additional information regarding spray dryers you are welcome to contact our service helpline.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586