Spice Filling Machine: The Complete Buying Guide In 2025

Spices are essential ingredients for cooking delicious food. As people around the world change towards healthy living, the pursuit of spices by different ethnic groups continues to grow. Therefore, the spice packaging industry faces considerable challenges.

Spice Filling-sourced: spicejungle

Do you understand the current general trends and development directions in spice filling and packaging? In line with the changing trends in modern packaging, this complete buying guide of spice filling machine can take you through the different related information of spice filling machine. Let us try it out!

1. What Is Spice?

What Is Spice-sourced: pharmeasy

Spice is the powder that ground from the dried herbs that can be used as a flavoring and garnish for food. They usually come from the herb which is a plant or part of a plant. In daily life, they are often used in cooking to add flavor to food. Even a small amount of spice can go a long way.

2. What Is The Spice Filling Machine?

What Is The Spice Filling Machine-sourced: AIPAK

The spice filling machine is specially designed for filling and sealing different spices and powder into containers with high efficiency and quality. It can fill powder products into different bottles or bag containers. According to different powder products, the types of filling machines are also different.

3. What Are The Applications Of Spice Filling Machine?

The spice filling machine is now widely used in all aspects of our lives, including:

Food Industry

Food Industry-sourced: suhana

The spice filling machine can fill various food granules or powder products for you, such as spices, salt, milk powder, flour, cake mix, pancake mix, chili powder, coffee powder, cocoa powder, plant food, tobacco, curry powder, turmeric powder, cereals, seeds, grass and fennel seeds, rice products etc.

Pharmaceutical Industry

Pharmaceutical Industry-sourced: goldenmonk

Various pharmaceutical powders can also be filled using spice filling machines. These pharmaceutical powders include but are not limited to capsule powder, tablet powder, granular powder granules, various excipients, additives, etc., vitamin powder, protein powder, etc.

Chemical Industry

Chemical Industry-sourced: palminc

Many chemical and industrial raw materials can also be filled using spice filling machines. These raw materials include metal powder, cement, concrete, clay, kaolin, magnesium carbonate, talc, pigment powder, washing powder, etc.

Cosmetics Industry

Cosmetics Industry-sourced: seventeen

For women who love beauty, there are countless opportunities to use powder. Therefore, spice filling machines are also frequently used in the female cosmetics industry. For example, setting powder, blush, eye shadow, eyebrow powder, talcum powder, bath salt, etc.

4. How Do You Package Spices By Spice Filling Machine?

How to package the spices after they are filled? The spice filling machine usually fills spices into different containers to protect the product from moisture, light and other influences that may affect the quality and shelf life of the spices. The following are several packaging methods for spice filling machines:

Jars

Powder In Jars-sourced: byjamiejune

Manufacturers often use glass or plastic jars and seal them with lids. By using transparent jars, consumers can easily see the color and type of spices inside the jar.

Cans

Powder In Cans-sourced: mymexicancandy

Spices or other powder products can be filled using cans. Most cans are made of metal or plastic and then sealed with a lid or tab for easy opening. This packaging method is more environmentally friendly and healthy.

Tins

Powder In Tins-sourced: arla

Tins are often used for filling large-capacity milk powder, protein powder, soy milk powder and other food powders. It can well protect products from deterioration caused by external temperature, humidity and light.

Bags

Powder In Bags-sourced: medallionmilk

Plastic bags are often used for filling large volumes of industrial powders. Such as cement, concrete, pigments, metal powders, etc. Because bags can facilitate storage, transportation and use.

However, no matter which packaging method is used, there is a possibility that the product will be exposed to moisture, light and other factors that may affect its quality.

5. What Are The Benefits Of Spice Filling Machine?

As a widely used machine, the spice filling machine can help you fill various products, thereby improving your production efficiency. The benefits of spice filling machine are:

Versatility and Wide Application

Versality and Wide Application-sourced: southernliving

The spice filling machine can be used in various fields of life, including food, chemical, pharmaceutical, cosmetics and other industries. It can be basically used in all powder filling. From bottles to bags, it can adapt to various packaging forms.

Save Costs

Save Costs-sourced: fastcapital360

Compared with labor costs, the spice filling machine can not only improve your production efficiency and production volume, but also save your production costs, including labor costs. By saving on labor costs, you can invest money in other industries to improve your competitiveness.

High Quality and Durability

High Quality and Durability-sourced: AIPAK

Most of the spice filling machine is made of high-quality food-grade stainless steel material. High quality and durable.

Sealing and Filling Integration

Sealing and Filling Integration-sourced: AIPAK

The spice filling machine can integrate filling and sealing processes to optimize the machine's work efficiency. Minimize downtime and increase machine productivity.

6. What Are The Types Of Spice Filling Machine?

How to understand the types of spice filling machines? In fact, there are many types of spice filling machines. Let's get to know them according to the following machine classifications!

According to the degree of automation, it can be divided into:

Semi-automatic Spice Filling Machine

Semi-automatic Spice Filling Machine-sourced: AIPAK

The semi-automatic spice filling machine mainly uses the screw electronic weighing method and is combined with a micro-controller to weigh and fill powder materials. It requires manual loading and unloading. According to your needs, automatic feeders, conveyors, sealing machines and other equipment can be configured.

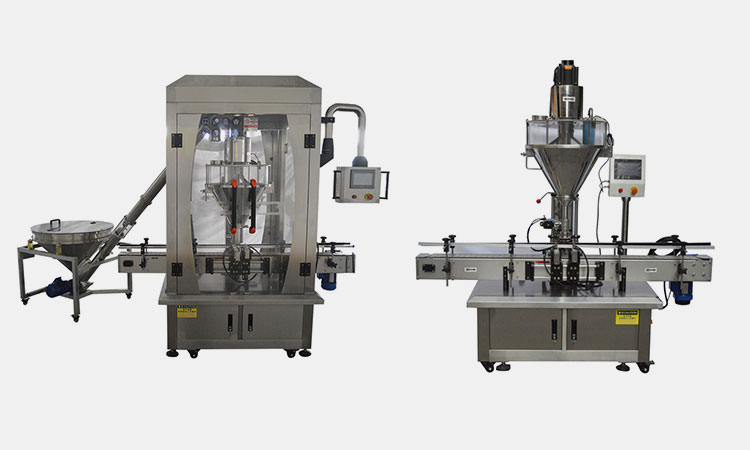

Automatic Spice Filling Machine

Automatic Spice Filling Machine-sourced: AIPAK

The automatic spice filling machine is able to provide high speed and high efficiency spice powder filling. It is integrated with a multi-stage filling, check-weighing and rejecting system to provide you with accurate powder weighing and filling. With high output and high precision, this machine can also be widely used in various powder filling production lines.

Depending on the machine's filling method, it includes:

Auger Spice Filling Machine

Auger Spice Filling Machine-sourced: AIPAK

The auger spice filling machine is suitable for filling liquid powder products. It mainly uses screw electronic weighing and measuring method to fill powder into bottles, cans and bags. The filling port can be adjusted according to different containers. This kind of machine mainly uses a servo motor to drive the screw for powder filling.

Screw Blanking Spice Filling Machine

Screw Blanking Spice Filling Machine-sourced: ALLPACK

The screw blanking spice filling machine mainly uses automatic screw blanking filling and screw filling for powder or free-flowing solid filling. It is suitable for filling powdery materials in the fields of food, daily chemicals, medicine and other fields.

Volumetric Cup Spice Filling Machine

Volumetric Cup Spice Filling Machine-sourced: all-fill

The volumetric cup spice filling machine is a piece of equipment commonly used for filling powdered products. It ensures that each container is filled with an accurate dose of product. This machine is equipped with a stirrer to ensure that the products in the cup are evenly mixed and prevent them from settling.

Depending on the amount of filling nozzle, it includes:

Single-head Automatic Spice Filling Machine

Single-head Automatic Spice Filling Machine-AIPAK

The single-head automatic spice filling machine is specially designed for filling spices and powder into different containers and bottles. Introduced through a conveyor belt combined with a pouring system and equipped with a photoelectric eye sensor detection system, this machine is capable of fully automatic powder filling of bottles. .

Double-head Automatic Spice Filling Machine

Double-head Automatic Spice Filling Machine-AIPAK

Equipped with double-head filling nozzles, the double-head automatic spice filling machine is suitable for powder packaging in food, medicine, medical equipment, hardware, electronics and other industries. Adopting an imported control system, this equipment can efficiently complete the filling work of various powder products.

7.What Are The Main Parts Of Spice Filling Machine?

Different types of spice filling machines may have different components. According to automation standards, the main parts of spice filling machine are:

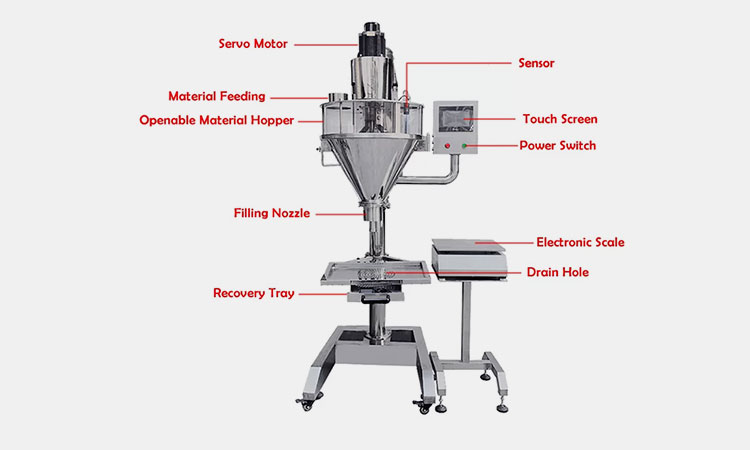

Main Parts Of Semi-automatic Spice Filling Machine

Main Parts Of Semi-automatic Spice Filling Machine-sourced: vkpak

- Servo Motor

The servo motor is connected to the sensor and is mainly used to control the filling speed of the filling machine. Servo motor can control the speed and torque of machine operation very accurately.

- Material Feeding

The material feeding is used for uploading powder that need to be filled and sealed. It is usually connected to an automatic feeding system to increase your powder feeding speed.

- Sensor

The sensor is connected to the servo motor. It can control the powder feeding speed. Through the parameters you set, the sensor can accurately control the feeding speed and frequency of your powder.

- Openable Material Hopper

The openable material hopper can be opened to increase your loading speed and capacity. At the same time, it also facilitates subsequent cleaning and maintenance.

- Touch Screen

The touch screen is specially used for you to manually set your own loading parameters and set up your own loading program. Depending on the efficiency you need, you can manually adjust the feeding speed.

- Power Switch

Through the power switch, you can start or shut down the machine. When the machine stops loading, or when you need to clean or repair, you need to turn off the power switch.

- Filling Nozzle

Prevent filling containers below the filling nozzle, thus starting the machine, you can complete powder filling of different containers.

- Electronic Scale

The electronic scale can be used to measure and weigh your filled products. It can accurately check the weight of filled products.

- Drain Hole

The drain hole is used to filter materials leaked during the powder filling process. This avoids the accumulation of powder on the filling table.

- Recovery Tray

You can manually clean the recovery tray by collecting spilled powder material.

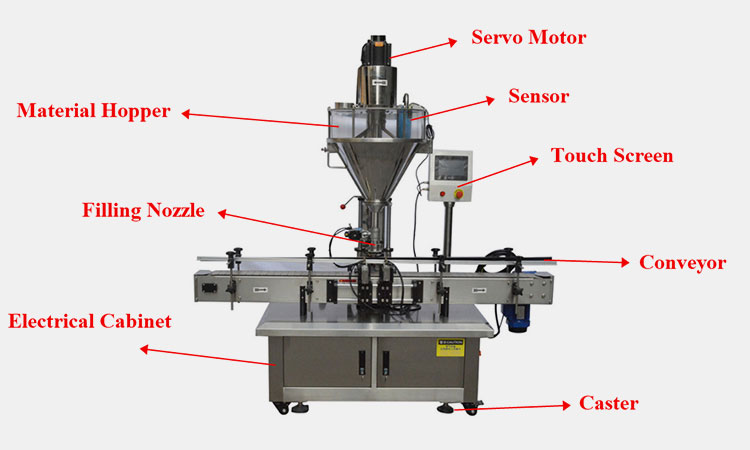

Main Parts Of Automatic Spice Filling Machine

Main Parts Of Automatic Spice Filling Machine-sourced: AIPAK

- Servo Motor

The servo motor is connected to the sensor and is mainly used to control the filling speed of the filling machine. Servo motor can control the speed and torque of machine operation very accurately.

- Material Hopper

The material hopper can design different feeding ports for different materials. It can easily help you with feeding.

- Sensor

The sensor is used to detect filling materials. When the material is insufficiently filled, the sensor will send a signal to the system to control the feeder for feeding.

- Touch Screen

Equipped with touch screen, this allows you to adjust working parameters such as charging weight and conveying speed at any time during the debugging process. It can be customized in different languages to facilitate your use.

- Filling Nozzle

The filling nozzle is determined based on the material you are filling. It is dust-proof and ensures cleanliness in production.

- Conveyor

The size of the conveyor needs to be customized. It is customized according to the type of material your machine needs to fill and the shape and size of the filling container.

- Electrical Cabinet

The electrical cabinet can provide you with the power support you need. All circuits are inside this cabinet.

- Caster

The caster makes it easier for you to move the machine and integrate the spice filling machine into the entire line later.

8. What Machines Can Be Integrated Into A Line With Spice Filling Machine ?

To integrate the spice filling machine into a filling line, you can choose the machine below:

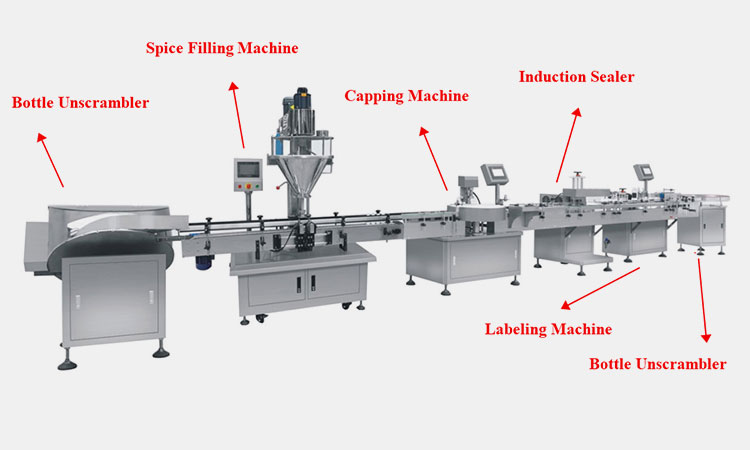

Fully Automatic Spice Filling Line

Fully Automatic Spice Filling Line-sourced: AIPAK

The fully automatic spice filling line consists of bottle unscramblers, powder filling machines, capping machines, aluminum foil sealing machines, labeling machines (coding machines) and other equipment.

It is suitable for filling various powdery materials such as milk powder, glucose, protein powder, cocoa powder, coffee powder, rice powder, etc. This filling line can be used for metering and filling of round cans and special-shaped cans of different specifications.

Machines can be integrated into the spice filling line that are:

Main Parts Of Spice Filling Line-sourced: AIPAK

- Bottle Unscrambler

Bottle Unscrambler-sourced: AIPAK

The bottle unscrambler uses variable frequency speed regulation and gear drive rotation. It can help empty bottles or cans to automatically enter the conveyor channel sequentially under the action of rotational tangential force, thereby facilitating subsequent powder filling.

- Automatic Spice Filling Machine

Automatic Spice Filling Machine-sourced: AIPAK

The automatic spice filling machine has strong compatibility. It can adjust the positioning device to adapt to the powder metering and filling of round cans and special-shaped cans of different specifications.

- Capping Machine

Capping Machine-sourced: AIPAK

The capping machine is capable of fastening a variety of caps with internal threads. After completing the powder filling, the capping machine can independently seal the bottle cap tightly to facilitate subsequent induction sealing.

- Induction Sealer

Induction Sealer-sourced: AIPAK

The induction sealer uses the principle of electromagnetic induction to cause the aluminum foil in the bottle to generate heat under the high-frequency action of electromagnetic induction, thereby firmly fixing the insulation film on the bottle mouth.

- Labeling Machine

Labeling Machine-sourced: ALLPACK

The labeling machine is suitable for automatic labeling of various plastic bottles, glass bottles, and metal bottles. The operation is simple and the labeling is beautiful and neat. And optional printers and inkjet printers are available.

9. What Is The Working Principle Of Spice Filling Machine?

As one of the most popular filling machines, the working principle of the automatic spice filling machine is very simple:

Working Principle Of Automatic Spice Filling Machine-sourced:AIPAK

- When the material enters the hopper, the auger driver causes the auger to start rotating at a constant speed to move the material down to the hopper;

- The mixer blades and auger rotate in opposite directions. Its function is to remove air from the powder and make the powder mix more evenly;

- The mixer blades are designed to extend all the way to the funnel. This prevents cavitation from occurring and ensures the auger blades are always filled with product;

- The auger plates are equally spaced, which ensures that each pitch is filled with ingredients of the same packing density and particle size;

- As the auger rotates, it enables precise dosing and filling.

10. What Are The Different Filling Parts For Your Spice Filling Machine?

By understanding the different filling parts, you can find the perfect powder filling solution for your business. The different filling parts are:

Volumetric Cup Filling

Volumetric Cup Filling-sourced:packaging-labelling

The volumetric cup filling is a common filling part of spice and powder filling. It is ideal for handling the filling of large, irregular granules and powders without causing any clogging and spillage.

Auger Filling

Auger Filling-sourced:spackmachine

The auger filling is suitable for filling various dry powder raw materials. An auger, usually powered by a motor or compressed air, moves powdered material into a container and then fills it into different containers. It is a reliable and efficient spice and powder filling solution.

Net Weight Filling

Net Weight Filling-sourced: busch

The net weight filling refers to a filling method in which the product raw materials are actually weighed before filling the spice and powder into the container. It is suitable for counting and filling products of various regular and irregular sizes, as well as dry or slightly moist products.

11. Are There Auxiliary Equipment For Spice Filling Machine?

What auxiliary equipment can help you complete powder filling more efficiently and easily? They are:

Screw Elevator

Screw Elevator-sourced: prepac

The screw elevator can transport powder and granular raw materials to the powder filling machine quickly and efficiently. It consists of a motor, a large drive nut, a threaded steel bar and an electrical supply.

Weight Checker

Weight Checker-sourced: mkpackagingmachine

The weight checker can weigh and count the filled materials. It can automatically eliminate substandard products. You can choose a suitable weight detector based on the weighing range of your product.

Metal Detector

Metal Detector-sourced: AIPAK

The metal detector can detect or eliminate metal contaminants in powder filling raw materials based on its different responses to the magnetic field of metal objects.

12. How To Maintain Your Spice Filling Machine?

There are several ways that you can maintain your spice filling machine. They are:

Test Run Before Working

Test Run Before Working-sourced: github

Before each official use, remember to power on the machine for inspection and trial operation. In addition to checking whether there is a problem with the power supply, you should also check whether the outer insulation layer of the power supply is damaged, whether the cable plug has fallen off, etc. After confirming that there are no problems, start running the device.

Daily Oil Lubrication

Daily Oil Lubrication-sourced: iselinc

After each use, the equipment's gear joints, seated bearing oil filling holes and moving parts should be regularly lubricated with oil. This extends the life of the equipment.

Daily Cleaning

Daily Cleaning-sourced: moravek

It is very important to do a good job of sanitation of the equipment every day and ensure that the parts in contact with materials are clean. Before commissioning, observe whether the equipment has been cleaned. After using the equipment, clean the heat sealing body, metering part, material inlet and outlet, etc. regularly.

13. How To Troubleshoot Your Spice Filling Machine?

The most common problems encountered during the operation of the Spice filling machine are:

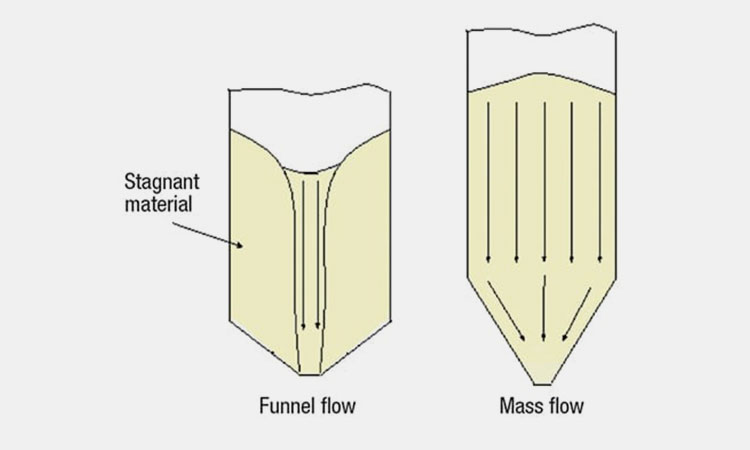

Flow-less In Hoppers

Flow-less In Hoppers-sourced: chemengonline

The fluidity problem of powder fillers is very important to the filling system of the machine. If the filled powder is sticky and not very fluid, the flow in the hopper above the filling head must be good, otherwise it will cause a deviation in the actual filling weight.

Weight Control

Spice and powder filling is actually large volume filling. Therefore, weight control for each filling is very important. Therefore, in addition to being equipped with a good filling head, it is also necessary to adjust the formula of the filling product.

Packaging Leakage

Packaging Leakage-sourced: uson

Whether bottling or filling, container leakage may occur during final inspection. At this time, it is necessary to check whether there is a problem with the weigher of the filling system. At the same time, check whether the sealed equipment is working properly.

Conclusion:

Through this complete buying guide of spice filling machine in 2024, you can get the most detailed information about the spice filling and packaging and know how to choose the best type spice filling machine for your group and business. After learning all these, are there more you want to know about? If you have any problems, do not wait to come to us!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine