Soft Gel Capsule Machine: The Complete Buying Guide In 2025

With the innovation of soft gel capsule encapsulation technology in the early 20th century, more soft gel capsules are gradually replacing traditional tablets and are popular with the public. If you are a capsule pharmaceutical manufacturer, then having a suitable soft gel capsule machine can keep your business alive and competitive all the time!

If you do not have a soft gel capsule machine in your business now, you can first learn about this equipment. This guide of soft gel capsule machine may bring a comprehensive information for you. Finding a worthwhile soft gel capsule machine is a good investment for your business and let's start now!

1.What Is Soft Gel Capsule?

What Is Soft Gel Capsule-sourced: soft-gel

Soft gel capsule is an oral dosage form soft capsule made of gelatin or pectin. It is specially used to fill non-hydrophilic liquid, semi-solid or oil materials. If you fill hydrophilic materials into soft capsules, it will cause the capsule shell to absorb water. Therefore, most manufacturers may choose oil and fat-soluble content as the formula of soft gel capsules.

2.What Are The Benefits Of Soft Gel Capsules?

Now the market feedback of soft gel capsule is very good and the manufacturing technology is becoming more and more mature. Its benefits are:

Flexible shape and size

Flexible shape and size-sourced: rousselot

Unlike hard capsules, soft gel capsules are more flexible in shape and have various sizes. There are soft gel capsules of various shapes on the market, with various sizes and colors, which are easy to swallow. Compared with other dosage forms, it has more advantages.

Good sealing

Good sealing-sourced: rousselot

The soft capsule adopts heat sealing form, which has good sealing and can lock the ingredients in the capsule shell well, protecting them from light and oxygen.

Easy to store

Easy to store-sourced: renejix

The soft gel capsule shell has good heat and temperature resistance, which can protect sensitive ingredients from being affected and is more stable and easy to store. And it can help you transport better.

Improve bioavailability

Improve bioavailability-sourced: rousselot

The soft gel capsule material is special and can wrap various liquids and oil bodies inside. And it can improve the bioavailability of poor or soluble nutrients.

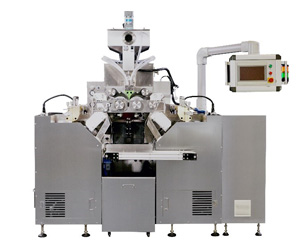

3.What Is Soft Gel Capsule Machine?

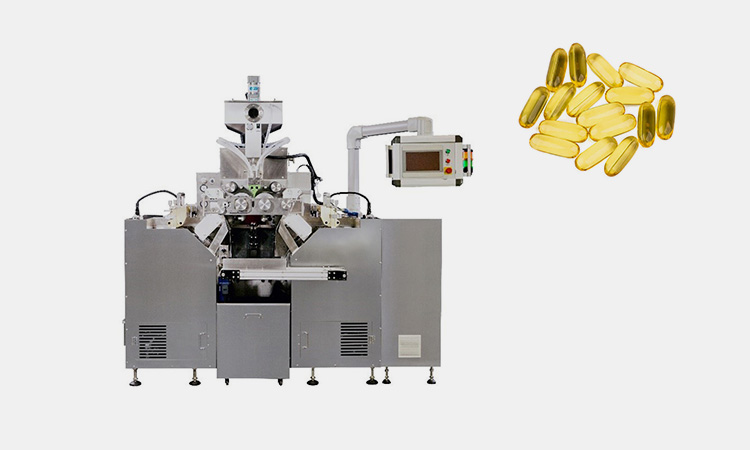

The soft gel capsule machine, also called as soft gel encapsulation machine, or soft gel capsule making machine, is a machine specially used to make soft gel capsules that are filled and encapsulated with different drug solutions and oils. It can be used to fill various liquid and oil body drug extraction forms, and then made into various shapes.

4.What Makes Soft Gel Capsule Machine So Important?

Why is the soft gel capsule machine always popular and the technology is always innovating? Because people have a huge demand for soft capsules. Basically, most industries may benefit from it. Reasons are:

Low cost and high efficiency

AIPAK Low cost and high efficiency

The soft gel capsule machine is basically based on automation or production lines, and is less dependent on manual labor, saving you a lot of labor work and cost. While being able to improve your production efficiency, it can also reduce your corresponding costs.

Dosage standardization

AIPAK Dosage standardization

The dosage of the contents filled in each soft capsule is fixed and accurate. The soft gel encapsulation machine can guarantee you a accurate and standard filling dosage.

Solutions for difficult drugs

Solutions for difficult drugs-sourced: asiangelatin

Powder or granular materials are suitable for filling and encapsulation of hard capsules. However, when designing sensitive liquids or oils, soft capsule shells are the best choice. The soft gel capsule making machine can provide you with packaging solutions for difficult and sensitive drugs.

5.What Are The Types Of Soft Gel Capsules That Soft Gel Capsule Machine Can Make?

There are many types of soft gel capsules on the market, and different soft gel capsule machines can provide different solutions. From the appearance, the soft gel capsules includes:

Transparent soft gel capsule

Transparent soft gel capsules-sourced: health.harvard

The shell of the transparent soft gel capsule is transparent and allows you to see the contents inside the capsule. This capsule shell is particularly suitable for filling oily substances that are stable in state.

Non-transparent soft gel capsules

Non-transparent soft gel capsules-sourced: renejix

Non-transparent soft capsules are mainly made of opaque materials and have a variety of colors for you to choose from. You cannot see the contents inside through the soft capsule shell. It is suitable for you filling and encapsulating sensitive drug formulas.

From the functional distinction, the soft gel capsule machine can make:

Enteric-coated soft gel capsules

Enteric-coated soft gel capsules-sourced: lfatabletpresses

A special drug coating is attached to the shell of the enteric-coated soft gel capsule. It can help protect the drug from the effects of stomach acid and ensure that the drug can be dissolved and absorbed in the alkaline environment of the intestine.

Double-layer soft gel capsules

Double-layer soft gel capsules-sourced: goodrx

The design of the double-layer soft capsule is very unique. It contains two separate layers or chambers. This design can accommodate two different formulas or ingredients for your needs.

Targeted release soft gel capsules

Targeted release soft gel capsules-sourced: nutraceuticalsworld

Targeted release soft gel capsules are soft capsules that are carefully designed to release at a specific location. It is mainly processed by making sensitive coating or bio-adhesive polymer on the capsule shell.

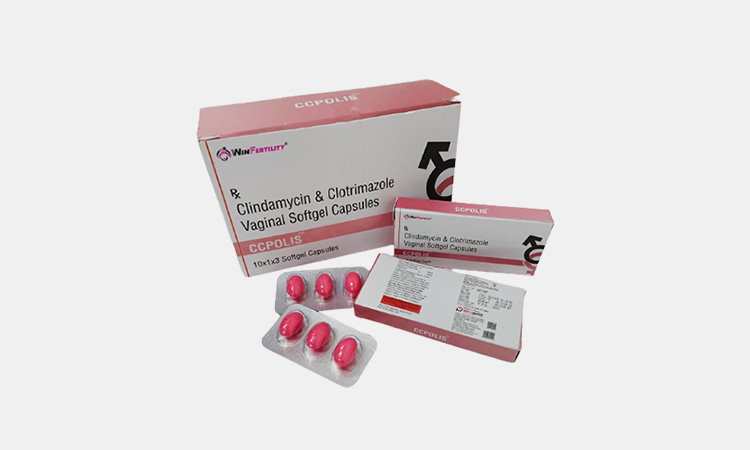

Suppository soft gel capsule

Suppository soft gel capsules-sourced: winfertility

Suppository soft capsule is mainly used to control the systemic efficacy by rectal insertion.

6.What Are The Shapes And Dimensions That Soft Gel Capsule Machine Can Make?

The shapes of soft gel capsules that are common on the market include:

Round soft gel capsules

Round soft gel capsules-sourced: winfertility

Round soft gel capsules are almost spherical and look cute. They can contain the active ingredients of the drug in the center and can contain a smaller dose.

Oval soft gel capsules

Oval soft gel capsules-sourced: sirio-europe

Oval soft gel capsules are very similar to the common hard capsules on the market, with a slightly bulging middle and flat sides. This increases the potential volume of the capsule and is easy to swallow.

Rectangular soft gel capsules

Rectangular soft gel capsules-sourced: lifevisionchandigarh

Rectangular soft gel capsules are like a cylinder, slender in the middle and rounded at both ends. They are similar to oval soft gel capsules.

Tube soft gel capsules

Tube soft gel capsules-sourced: sirio-europe

Tube soft gel capsules can hold a larger volume of contents. It is suitable for adults and other groups with strong swallowing functions.

Special shapes of soft gel capsules

Special shapes of soft gel capsules-sourced: wezhan

Many soft gel capsules can provide customized shape services. It can provide you with a complete set of soft gel capsule shape design, mold making, dosage design and packaging.

Common capsule sizes are:

| Round soft gel capsules | 1 microgram to 20 micrograms; |

| Oval soft gel capsules | 2 micrograms to 20 micrograms; |

| Rectangular soft gel capsules | 3 micrograms to 24 micrograms; |

| Tube soft gel capsules | 8 micrograms to 30 micrograms; |

7.What Are The Applications Of Soft Gel Capsule Machine?

Most of the soft gel capsule products on the market are mainly medicines and health products. The soft gel capsule machine is used in the following industries:

Pharmaceutical industry

Pharmaceutical industry-sourced: renejix

The pharmaceutical industry is a major user of soft gel capsule machine. It can produce various soft capsule products for patients, including cold soft capsules, pain relief soft capsules, antibiotic soft capsules, suppository capsules, etc. Now more and more herbal medicines with important value are using soft gel capsule packaging.

Health care products industry

Health care products industry-sourced: innovixlabs

Soft capsules can provide you with the nutrients you need for daily doses. The soft gel capsule machine can encapsulate various multivitamins, DHA, fish oil, minerals, etc. in soft gel capsules. In addition, various nutrients or sensitive drugs are encapsulated in soft capsule shells in different doses.

Cosmetics industry

Cosmetics industry-sourced: jdbmcosmetics

A variety of skin care products and cosmetics can now be encapsulated in soft capsules, including vitamin C essence, antioxidants, retinol essence or functional freckle essence. Not only the encapsulation effect is good, but also it is easy for you to carry and use.

8.What Are The Advantages Of Using Soft Gel Capsule Machine?

Compared with general capsule filling machines, the advantages of soft gel capsule machine are:

Easy to operate

Most of the soft gel capsule machines are designed with a high degree of automation. It is easy to operate, you only need to set up the program, and the maintenance cost is low, which can reduce your labor costs.

High flexibility

Compared with capsule filling machines, the soft gel capsule machine can produce soft capsules of various shapes and sizes, and can even provide you with customized capsule shell production and filling services. It can also be used in conjunction with capsule counting, printing and other equipment, with high flexibility.

Fast speed

The soft gel capsule machine has a fast speed and can provide you with more soft capsule production in a short time.

High precision

The soft gel encapsulation machine produces soft capsules with high dosage and precision, low loss and low cost.

9.What Are The Types Of Soft Gel Capsule Machine?

There are two main types of soft gel capsule machine for your choice, they are:

Table type soft gel capsule machine

AIPAK table type soft gel capsule machine

The table type soft gel capsule machine is small and compact, very suitable for small factories, laboratories or private small-scale production. It may require you to operate manually and has medium production capacity. And it is not equipped with corresponding gelatin boiling equipment and soft capsule drying equipment, which requires you to equip it separately according to your needs.

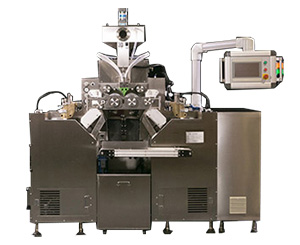

Industrial type soft gel capsule machine

Industrial type soft gel capsule machine-sourced: pharmacymachinery

The industrial type soft gel capsule machine is a complete production line. It comes with complete gelatin boiling equipment and soft capsule drying equipment at the back, which can provide you with the needs of mass production of soft gelatin capsules. The industrial type soft gel capsule machine is a fully automatic equipment, and does not require manual intervention, which can greatly reduce labor costs. This equipment can continuously provide efficient and stable soft gel capsule production.

10.What Is The Working Principle Of Soft Gel Capsule Machine?

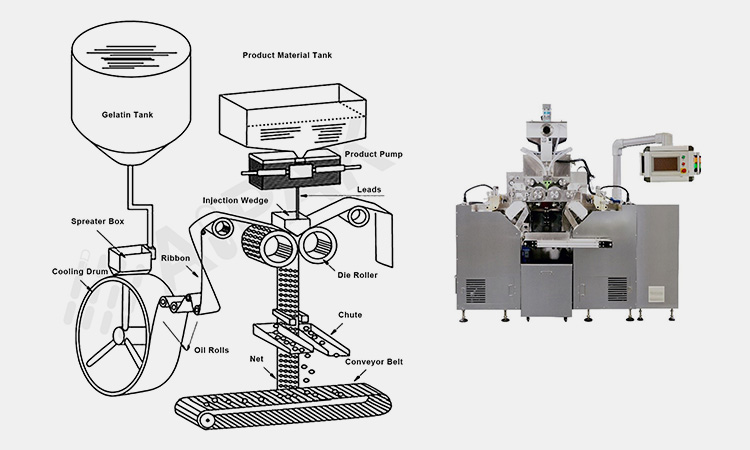

The working principle of soft gel capsule machine is:

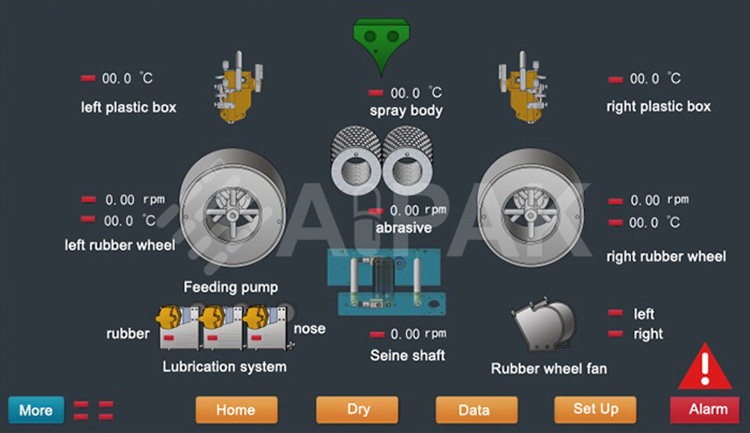

Working Principle Of AIPAK Soft Gel Capsule Machine

Step 1: Gelatin melting

At the first time, you may put the gelatin powder, water and glycerin into a melting pot, and then heat to 65 to 75 ℃ and stir. Then add various plasticizers, colorants, gelling agents, etc. and keep stirring until the particles are completely dissolved. When heated to a certain temperature and the mixture is completely dissolved, the mixture is allowed to stand and ready to be transferred to the soft gel capsule machine.

Step 2: Preparation of filling materials

Prepare the materials to be filled in the batching tank, colloid mill, emulsification tank and other equipment using your own formula and production method to facilitate the subsequent filling and packaging.

Step 3: Soft gel capsule encapsulation

Fill the prepared and de-bubbled solution into the forming plate of the soft gel capsule machine. When the solution is formed, the equipment will directly add the liquid or semi-solid drug to be filled into the soft capsule shell on the forming plate, and finally complete the encapsulation.

Step 4: Cooling and drying

The encapsulated soft capsules are wet and need to be immediately removed using a soft capsule drum dryer and thoroughly dried in the drying tunnel behind. Then place them on a PP drying tray to cool and stand for about 1-2 days.

Step 5: Inspection and classification

The completely dried soft capsules are manually screened and sorted to remove unqualified products for later packaging.

Step 6: Counting and packaging

The qualified soft capsules that have been screened out will be directly placed in a counting machine for counting and bottling. The purpose is to preserve freshness, extend the shelf life, and facilitate transportation and storage.

11.What Are The Main Components Of Soft Gel Capsule Machine?

There are some main components of soft gel capsule machine:

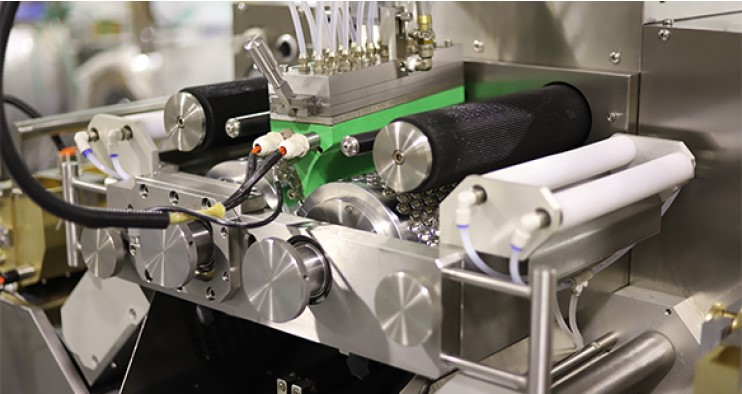

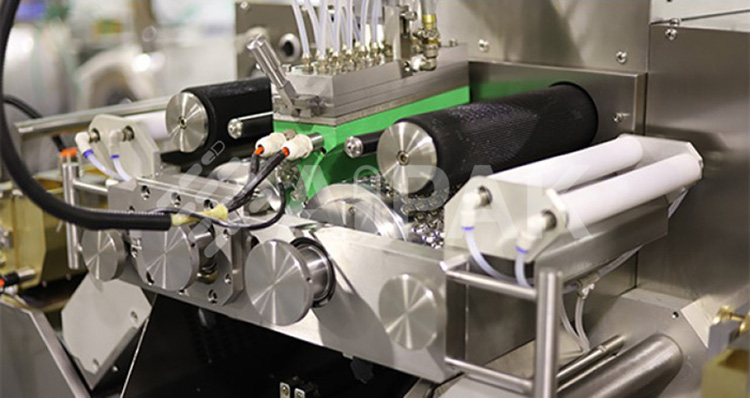

Main components AIPAK soft gel capsule machine

Gelatin tank

The gelatin tank is specially used to hold the processed gelatin solution. With heating and liquid volume detection functions, it can ensure you the volume and volume distribution of your gelatin solution.

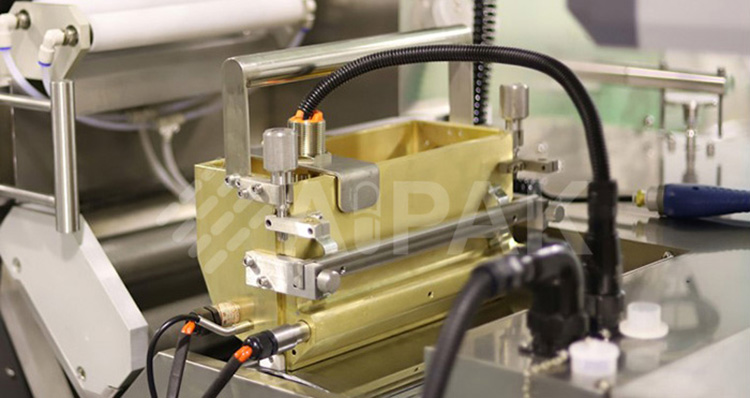

Product material tank

The product material tank, also called as drug or medicine hopper, is specially used to hold the drug or drug mixture that needs to be filled and encapsulated.

Product pump

The product pump is connected to the product material tank. It can accurately deliver the drug or drug solution to the filling pump. Equipped with an automation system, this part can automatically adjust the speed and pressure of drug delivery according to your needs.

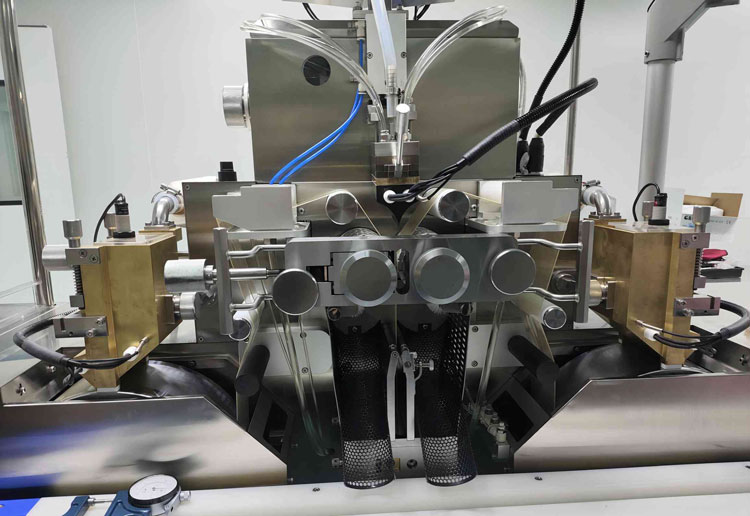

Injection wedge

The injection wedge is designed between the die rollers. It can easily inject drugs and drug solutions between the molds and ensure accurate dosage. The injection wedge can ensure that the content of each soft capsule is filled with accurate dosage without leakage.

Leads

The leads can guide the ribbons to move forward at a uniform and secure speed.

Spreater box

The spreater box is specially used to make spreater belts. It can evenly and accurately apply the prepared gelatin solution to the casting drum. The gelatin strip formed on the casting drum will form a uniform and complete soft capsule shell after cooling.

Cooling drum

The cooling drum can cool the gelatin strip on the drum to facilitate the filling and packaging of the medicine later.

Ribbon

The ribbon is also called the gelatin strip. When the gelatin solution is evenly applied to the casting drum, a ribbon is formed.

Oil rolls

The oil rolls are also called lubricating rollers. It is coated with thick lubricating oil. This can prevent the gelatin and the roller from sticking. And it is convenient for the demolding of the soft capsule after forming.

Die roller

Die roller, also known as stripping roller. It is mainly responsible for stripping the filled and sealed soft capsules from the ribbons and removing excess gelatin to improve your productivity.

Chute

The filled and sealed soft gel capsules stripped from the ribbon will be discharged from this chute.

Net

The net can help you weigh and check the weight of each soft gel capsule, which is convenient for your subsequent quality inspection.

Conveyor belt

The conveyor belt can help you transport the finished soft gel capsules to the drying area for the next step of dehydration and drying.

12.Should Soft Gel Capsule Machine Feature Fully Integrated Or Stand Alone Tumble Dryer?

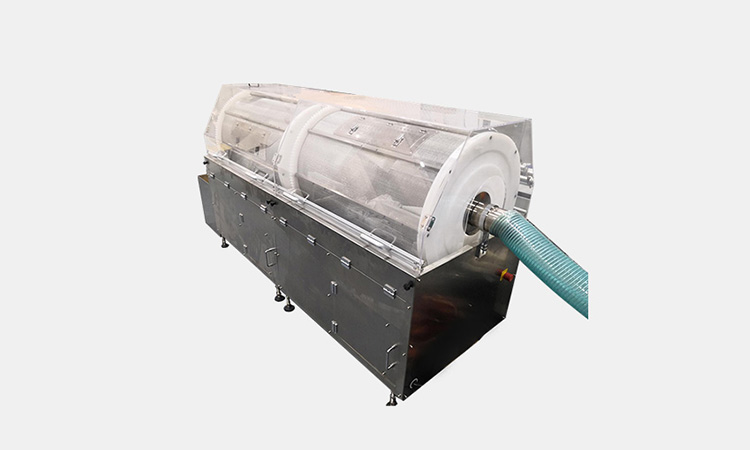

Tumble dryer of softgel encapsulation machine-sourced: cvctechnologies

The tumble dryer is an indispensable part of the soft gel capsule machine. It is separate from the main machine that stands alone and needs to be connected with a special pipeline. The model of the tumble dryer is different depending on the output of your soft gel capsules. If your output is average, you can choose a 1-2-section tumble dryer. If your output is high and you need to process more soft gel capsules, you can choose a double-layer tumble dryer with 2 sections or more.

13.How Do You Control Die Synchronization of Soft Gel Capsule Machine?

If you want to control the soft gel quality, then you need to control the die synchronization of soft gel capsule machine.

AIPAK Die Synchronization of Soft Gel Capsule Machine

You can choose an automated die synchronization system. It does not require your manual control of die synchronization. You can adjust it directly on the PLC control system.

If your machine is not equipped with an automated die synchronization system, you can control the die of the soft gel capsule encapsulation machine and control their synchronization by manually adjusting and modifying the soft gel capsule encapsulation part.

14.Can You Polish Soft Gel Capsules?

Of course you can polish the soft gel capsules, and it may help you get rid of the debris from capsules. To facilitate your production efficiency, you can choose a soft gel capsule polish machine that suits your output.

Soft gel capsule polishing machine

Soft gel capsule polishing machine-sourced: capplustech

The soft gel capsule polishing machine can automatically clean the residue on the surface of soft gel capsules using cleaning materials. It mainly uses drum polishing to clean the surface of soft gel capsules and polish them to achieve a bright and shiny effect.

15.Are There Any Other Drying Options For Your Soft Gel Capsule Machine?

Drying tunnel-sourced: sedpharma

In addition to using a tumble dryer, there are other drying equipment options for you:

Drying tunnel

The soft gel capsules drying tunnel can provide you with a higher output of soft gel capsule dewatering and drying. It can also be customized to better fit your model.

In-line drying systems

The in-line drying systems are more suitable for soft gel capsule production lines. It can provide you with the highest output drying effect.

16.What Are The Suitable Condition For Soft Gel Capsule Machine?

When using soft gel capsule machine, the temperature and humidity that need to be controlled in each part are different. They are:

Clean room temperature and humidity control-sourced: prod

Gelatin melting room temperature and humidity control

When you are performing the gelatin melting, the temperature and humidity shall be controlled within 20-24℃ and 40-50%RH. This may guarantee you a good gelatin solution.

Material preparation room temperature and humidity control

Same as gelatin melting room, the material preparation room temperature and humidity shall be controlled between 20-24℃ and 40-50%RH.

Encapsulation room temperature and humidity control

When using soft gel capsule machine to make soft gels, the room temperature needs to be kept at around 20-24℃. Too high or too low temperature will affect the quality of soft gel capsules. Humidity control is best controlled at around 35-45%RH.

Drying room temperature and humidity control

Compared to encapsulation room temperature, the drying room temperature shall be controlled between 20-24℃. The humidity range can be controlled between 20-25%RH, and it is best not to exceed 30%.

17.How Does Soft Gel Capsule Machine Control Soft Gel Capsules Uniformity?

Although the soft gel capsule machine is very well made and generally does not have problems, how do they control the uniformity of the soft gel capsules? You can learn about the following aspects:

Soft Gel Capsules Uniformity-sourced: sawyerlabs

Gelatin preparation. When preparing gelatin, you must pay attention to the proportion of the material formula. Pay attention to controlling the flexibility and strength of the gelatin shell, so as to ensure the uniformity and quality of the soft capsules later.

Control dosage. To accurately control the filling dosage of the material, ensure that the mold roller can seal the soft capsule well, seamlessly connected, and will not cause leakage later.

Sealing and drying. After the soft capsules are filled and sealed, remember to use a dryer to remove excess moisture from the soft capsules to maintain the integrity and dryness of the capsules.

Quality inspection. Manually pick the dried soft capsules. Remove unqualified soft capsules.

18.Are There Any Other Auxiliary Equipment In Soft Gel Capsule Production Line?

In order to meet the production of soft gel capsules, you can also use the following equipment:

Prepare tank

The prepare tank can not only help you hold the drug content to be filled, but also help you boil and dose. It is equipped with a hot water jacket, which can help you heat and stir the solution, and it can keep the solution uniform and not precipitate, so as to facilitate your later filling and packaging.

Gelatin melting tank

The gelatin melting tank is the most basic equipment of the soft gel capsule machine. It can help heat and melt gelatin. By controlling the temperature, the tank can help you boil the liquid capsule shell material suitable for you and prevent the formation of bubbles.

Colloid mill

For some drugs that are hard or difficult to crush, you can use the colloid mill to crush and emulsify them, which is convenient for your subsequent boiling and production of drug solutions or gelation solutions.

Tumble dryer

The Tumble dryer can dehydrate and dry the filled and sealed soft capsules in time to prevent them from sticking and affecting the shelf life. It mainly removes moisture from soft capsules by gently stirring the capsules and drying them.

Vacuum pump

Vacuum pump can provide stable power for your entire filling and sealing process with stable and swift operation.

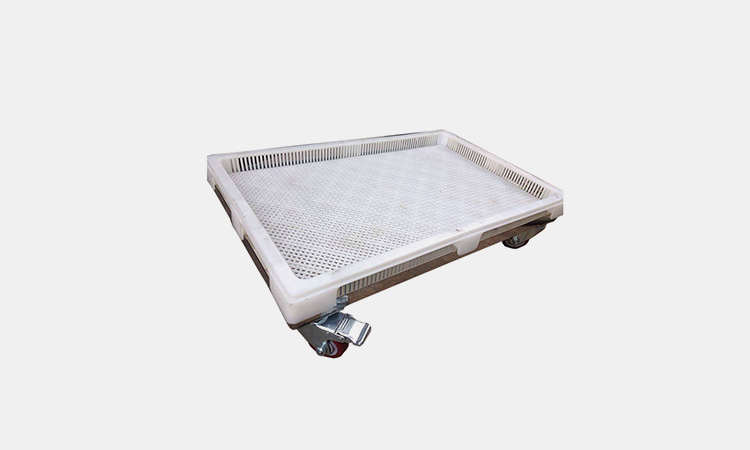

PVC tray

PVC tray is composed of multiple trays. They can be used separately or stacked. The baked and dried soft capsules need to be placed on the PVC tray for about 1-2 days.

Light inspection table

The soft capsules that have been left to stand cannot be packaged and used immediately. They need further manual sorting and quality inspection. The light inspection table can help you to screen and sort the soft capsules. Unqualified or poor quality soft gel capsules will be recycled.

Drying car

You may use the drying car to transfer at any time, which is convenient for subsequent packaging and printing.

19.What Are The Different Machines That Can Be Integrated Into Soft Gel Capsule Production Line?

If you want to have a complete soft gel capsule production line, what other machines can you choose besides the soft gel capsule machine? You can choose:

Capsule counting machine

AIPAK Capsule counting machine

After the soft gel capsules have completed the final quality inspection, you can use the capsule counting machine to count and fill them. It greatly improves your packaging and filling efficiency. It uses anti-high dust electronic counting technology, which can count for you quickly in a short time.

Blister packaging machine

AIPAK blister packaging machine

After finishing capsule counting, you can choose bottle packaging or blister packaging. If you choose blister packaging, then the blister packaging machine is your best choice. It can directly fill and seal the soft gel capsules in the blister packaging, and perform batch number printing and embossing, etc.

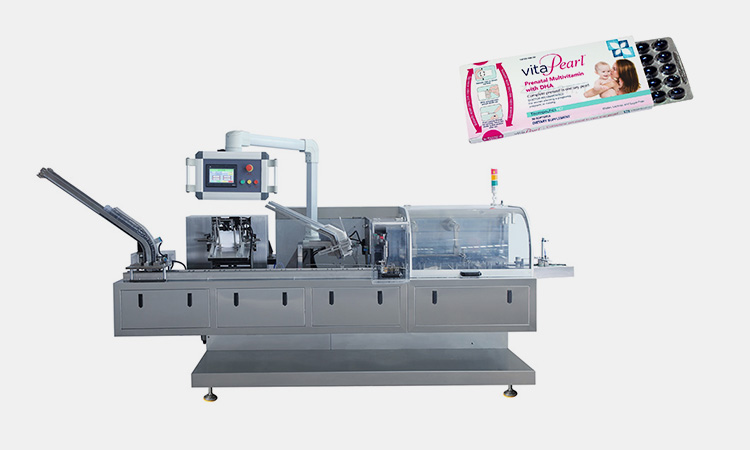

Cartoning machine

AIPAK cartoning machine

The cartoning machine may help you fill and seal your soft gel blister packs into the box with good quality and effects. You can customize your own outer packaging in advance. After completing the soft capsule blister packaging, the cartoning machine can directly inserted the blister packs into the cartons with high efficiency.

20.What Are The Key Considerations Before Purchasing A Soft Gel Capsule Machine?

If you are growing your own soft gel capsules business, or you want to start your own soft gel capsules business from right now, then you are strongly recommended to consider:

Soft gel capsule production volume

Soft gel capsule production volume-sourced: aligen

The first thing you need to consider is the soft gel capsule production volume. Different soft gel capsule machine models or automation levels have different soft gel capsule production capabilities. The higher the automation level, the greater the soft gel capsule production volume, and vice versa.

Soft gel capsule shape and size

Soft gel capsule shape and size-sourced: unitedmark

The soft gel capsule machine with a higher degree of automation has a poorer adaptability to different soft gel capsule shapes, and sizes. The capsule machine with a lower degree of automation can provide you with more soft gel capsule with good shapes and sizes.

Accuracy

In addition to finding a good supplier, the accuracy of the soft gel capsule encapsulation machine is also very important because it determines the quality of your final soft gel capsules. The more automated and better designed the machine is, the higher quality of the soft gel capsule effect you may have.

Conclusion:

After learning about the complete buying guide of soft gel capsule machine, you may want to find the most suitable soft gel capsule machine and the soft gel capsule making process now. If there are any needs of the soft gel capsule machine or the parts of soft gel capsule machine, you are welcome all the time. Or you can just view the AIPAK anytime!

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine