Sharing Of Manufacturing Experience On Fluidized Bed Granulation

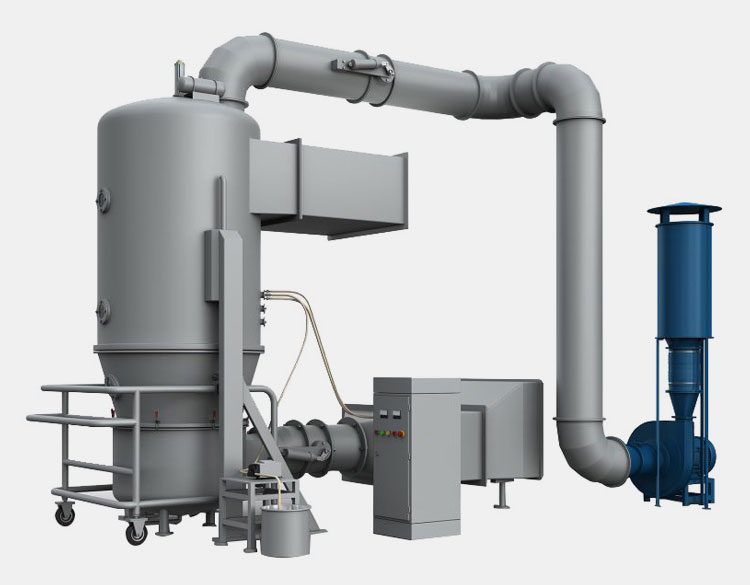

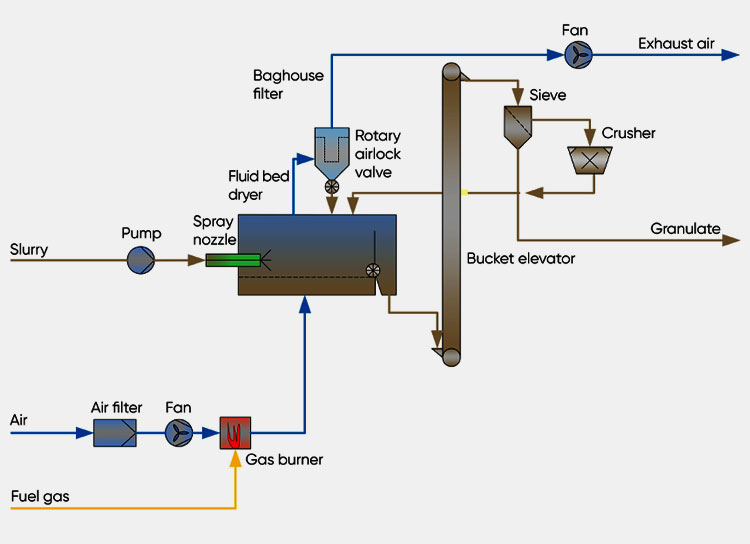

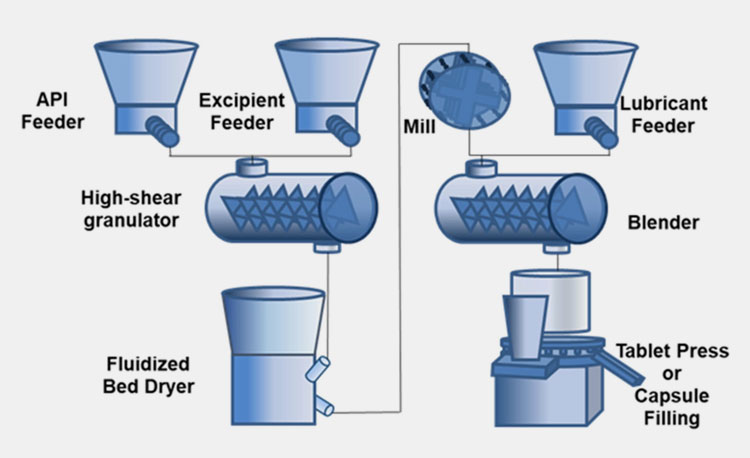

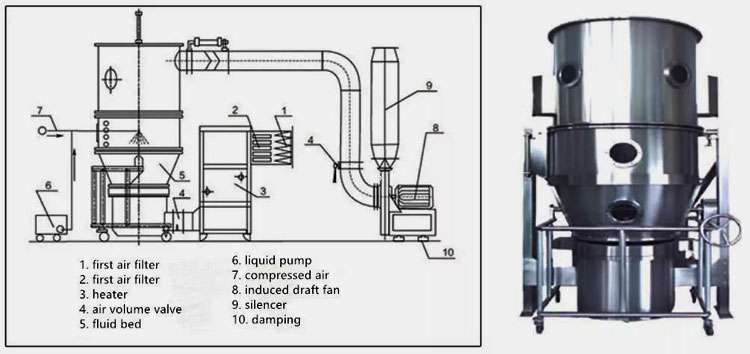

The fluidized bed granulation is also called boiling granulation or one-step granulation. It puts the material into a closed container at one time, and uniformly mix the material in the container.

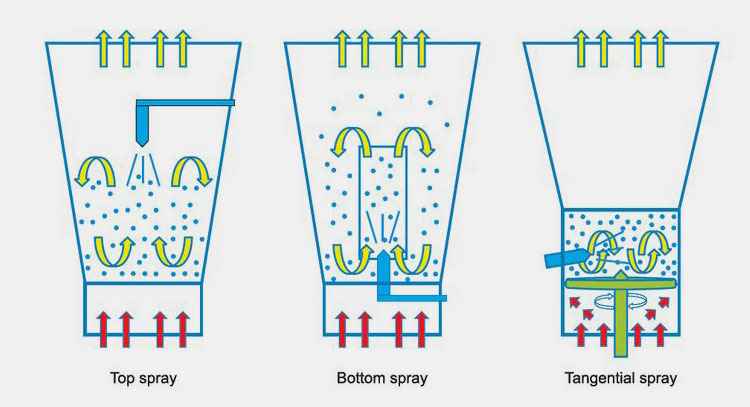

Then the adhesive is sprayed at a uniform speed through the fluidized bed granulation so that the adhesive and the material are fully mixed. The material flows in the container to form small particles, and the hot air is sent through the bottom end to collect the finished dry particles.

The entire fluidized bed granulation process is predominantly divided into 4 steps: material preheating, liquid spraying, drying and cooling.

Material preheating

The industry professionals indicate that actually there are two main purposes of empty machine preheating before material preheating.

One is the initial inlet air volume of the fluidized bed granulation is generally unstable, and the parameter can be ensured to be stable after the equipment is run for a certain time by air preheating, so as to avoid the adverse impact of parameter instability on material preheating.

The second is through the machine preheating, which can greatly reduce the material preheating time and lift rate.

Suggestions on parameter setting during material preheating: Since the material fine powder is extremely high and the static electricity is relatively large at the beginning, it is recommended to utilize a lower air inlet volume to ensure the fluidized state of material, so that the frequency of the bag shivering of the fluidized bed granulation is as high as possible.

Taking the material temperature as the jump point of the procedure and the temperature of the material at the jump point is slightly different due to the nature of the product and the production batch. It is generally 45-50 degrees.

Liquid Spraying

The industry professionals suggest that before you perform fluidized bed granulation each time, especially when using a binder, you need to perform a liquid spray test first, and record the liquid spray curve, which is the spray rate corresponding to the number marked on the peristaltic pump.

Observing the binder’s atomization state under a stated atomization pressure. The judgment standard: When atomizing liquid spray, the palm and the direction of spray liquid quickly pass through the entire spray surface vertically, and it is appropriate that the palm has no obvious moist feeling.

Suggestions for parameter setting in liquid injection stage: In the initial stage of spraying, the particle size of the material will gradually increase from small to large. In order to ensure the fluidized state, you can adjust the air intake volume accordingly (from small to large).

The bag shaking frequency of the filter bag can be set relatively high when the liquid spraying begins. When the material gradually becomes granular, the bag shaking frequency and time can be appropriately reduced.

The spray stage generally takes time as the jump point. If you are in the process exploration stage, it is recommended that you take samples from the fluidized bed sampling port regularly to observe the state of the particles, especially to prevent the particles from being too wet.

In addition, in order to ensure particle quality and improve production efficiency, it is recommended to divide the whole spray process into several spray rates (generally 2-3) for gradient granulation.

You need to regularly record the relevant parameters of the system (including air inlet air volume, air inlet temperature, exhaust air temperature, material temperature, liquid spray pressure, atomization pressure, material pressure difference, filter bag pressure difference, filter bag shaking frequency and time).

A good fluidized bed granulation process has a plateau at each injection rate gradient where all of the above parameters remain stable.

If the parameters of the system are constantly changing throughout the spray state, even if the particles prepared are better, it does not necessarily mean that your technology is better, especially if the reproducibility is likely to be poor.

Drying

After spraying, the material should be dried. Generally, the drying temperature should not be too high, otherwise it is easy to cause over-drying. In the process exploration stage, it is generally necessary to take samples when a certain material temperature is reached, and measure the LOD of the particles.

When the LOD is within the set range after drying, if you don't know the LOD value that should be achieved, 1%-1.5% is generally recommended for ordinary tablets.

It is generally recommended that the LOD value in a fluidized bed granulation machine should not be higher than 2% , but these recommendations do not apply to the following products: sustained-release tablets (the LOD value after drying is generally relatively high), blank tablets and traditional Chinese medicine tablets (the granules are generally difficult to dry, very It is difficult to reach below 2%).

When the process is mature, the drying time can be used as the process jump point in a fluidized bed granulation machine, because the particles can reach a certain material temperature after drying for a certain period of time, corresponding to the corresponding LOD.

Cooling

There is not much to explain, as long as it is left to cool, generally the temperature or time of the material is used as the jumping point of the jumping procedure.

Fluidized bed granulation has many advantages, for example, the dry mixing, wet mixing, mixing, granule forming and drying of materials are all completed in the same fluidized bed granulation, which reduces a lot of operation links and saves production practice.

A Fluidized bed granulation also allows production to take place in a sealed environment, which not only prevents external contamination of the drug, but also reduces the chance of contact with irritating or toxic drugs and excipients.

Pharmaceutical equipment experts also put forward operational recommendations for the vast number of customers: drug quality is a key consideration for customers.

In order to ensure the quality of drugs, it is necessary to avoid contaminating drugs in the process of using fluidized bed granulation. When you turn on the system to fluidize and dry hot air, it must be heated, filtered through medium and sub-efficiency filters, and dehumidified if necessary.

In addition, fluidized bed granulation needs to be thoroughly cleaned in use, especially when changing drug varieties. After each granulating, the filter bag should be cleaned. Only in this way can the contamination be kept away and the quality of the drug be guaranteed.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine