Shampoo Packaging: The Complete FAQ Guide In 2025

Hair reflects and enhances your personality. That is why people choose their hair products by paying great attention. Many of you spend hours and hours reading the information about ingredients displayed on the label of shampoo packaging. While people with a preoccupied routine are most attracts by its packaging and showy titles. Today, your manufacturing brand is well aware of these all customer-attracting strategies.

If you are selling shampoo or related products; it is your responsibility to take care of customer hair as well as the high expectations they’re hooked in.

In this article, you will get to know a series of production lines involved in shampoo packaging. I hope you’ll find it worth reading.

Let’s start!

1.What is Shampoo Packaging?

Shampoo packaging is a method of storing and presenting shampoo in a way that would attract you,the consumer towards it. In simple words, it is the practice to store the shampoo in containers and make it ready to be bought by buyers.

However, in industrial language it has actually become a science of attracting people to their product.

Hair industry is one of the highly competitive industry. To be a leading choice for your customers, one of the reasons you have to work on is the product’s appearance and aesthetics.

As discussed above, the packaging plays a vital role in sales of product. The ultimate goal of industries is to demarcate their product from others so that their’s stand out or is unique to customers and that goal is achieved by packaging.

The better the presentation the more strong impression it makes to you.

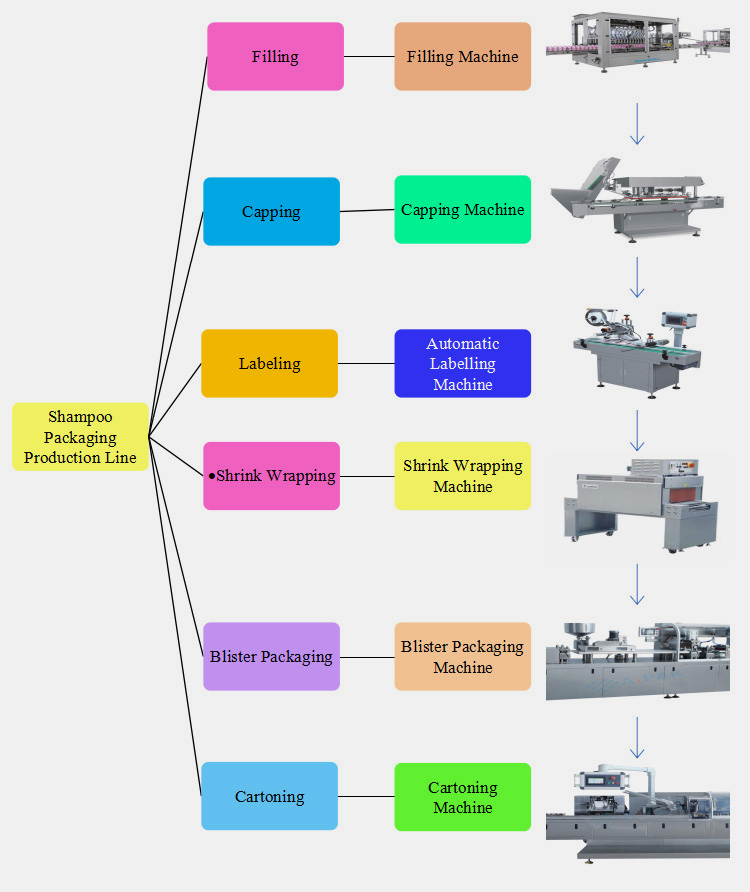

2.What is the Shampoo Packaging Production Line?

The production line of shampoo packaging machines involved:

Steps of Shampoo Packaging- Picture Courtesy: AIPAK Pharmaceutical Equipment

| STEP 1. SHAMPOO FILLING MACHINES | MACHINE PICTURE |

| Filling machines for shampoo bottles and other similar products are typically known as liquid filling machines. These machines are designed to automatically fill containers with a precise amount of shampoo.

They can be used to fill a wide range of products such as shampoo, conditioner, lotion, liquid soap, and more. There are various types of shampoo-filling machines available, including gravity fillers, piston fillers, and peristaltic fillers, each with its unique features and capabilities. The selection of a particular type of filling machine will depend on the specific needs of the product and the production process. |

|

| STEP 2. CAPPING MACHINES | MACHINE PICTURE |

| Capping machines are used in the packaging process for liquids such as shampoo. They are designed to place and tighten caps on bottles or containers, ensuring a secure seal.

Capping machines can range from semi-automatic to fully automatic and can include features such as torque control, cap sorting, and speed adjustment. Some popular types of capping machines for shampoo include screw cappers, snap cappers, and press-on cappers. |

|

| STEP 3. LABELLING MACHINES |

MACHINE PICTURE |

| Automatic labeling machines for shampoo are machines that are designed to apply labels to bottles of shampoo quickly and accurately.

These machines typically use a combination of mechanical and software systems to apply the labels to the bottles. Some of the innovative features of these machines include the ability to apply multiple labels to a single bottle, the ability to handle different bottle sizes and shapes, and the ability to print variable information on the labels (such as expiration dates or batch numbers). Overall, these machines are designed to increase efficiency and accuracy in the packaging process for shampoo bottles. |

|

| STEP 4. SHRINK WRAPPING MACHINES | MACHINE PICTURE |

| A wrapping machine is used to pack shampoo bottles or containers in a wrapping material, such as shrink wrap, cellophane, or plastic film. These machines typically include a conveyor belt that moves the bottles or containers through the machine, where they are wrapped and sealed. Some wrapping machines are designed to package multiple bottles or containers at once, while others can only package one at a time. They are widely used in production lines of shampoo, cosmetics, food, and other industries. |

|

| STEP 5. BLISTER PACKAGING MACHINES | MACHINE PICTURE |

Blister packaging machines are a type of machinery used to package liquid or gel products, such as shampoo, into individual blister packs. These machines are used to package shampoo in blister packs, which are sealed plastic trays with a clear plastic cover.These machines typically use heat and pressure to seal the packaging material around the product, creating a tamper-evident and visually appealing package. Some blister packaging machines can also include additional features such as product filling, card or leaflet insertion, and coding or labeling. |

|

| STEP 6. CARTON PACKAGING MACHINES | MACHINE PICTURE |

| A cartoning machine is a type of packaging machinery used to package products such as shampoo into cartons.

The machine typically operates by loading empty cartons onto a conveyor belt, filling the cartons with the product (in this case, shampoo), and then sealing the cartons shut. Some cartoning machines may also have additional features such as the ability to print on the cartons or add inserts to the cartons. These machines are typically used in the pharmaceutical and food industries. |

|

3.Why Shampoo Packaging is Important?

To explain the importance, I would like to tell you some benefits of shampoo packaging.

The actual presentation and packaging I talked above comes from few reasons, among which one of the important is the branding, one of the great and important ways of marketing. This enables a communication bridge between consumer and seller.

A good shampoo packagingprotects the shampoo from contamination, damage, and evaporation, helping to maintain the product’s effectiveness and shelf life.

Additionally, shampoo packaging often includes useful informationsuch as ingredient lists, instructions for use, and expiration dates.

Shampoo packaging also helps to make the product easy to use, by providing a convenient dispenser or nozzle for dispensing the shampoo. This allows the user to easily control the amount of shampoo used, which can help to prevent waste and make the product last longer.

The premium lookof your packaging also impacts a customer’s views about the product and could result in the purchase of product. And also, maintains the identity whenever the customer intends to go shopping again.

4.What Is Difference Between Adult and Baby Shampoo and Packaging?

You might be wondering what actually could be the difference between adult and baby shampoo because both of them is used for same purpose but for different age groups.

PH

The first difference is pretty basic which you could think of is that the baby shampoo is delicate. It is less reactive because it is more diluted than adult shampoo and it has a PH that is more or less Neutral and does not irritate baby’s eyes to a greater extent. While the adult shampoo has the high ratio of chemicals, PH.

SURFACTANT

The surfactants are responsible for the production of lather and also are the main cleansing agents that clean the dirt and others. This helps in less irritation of the skin of babies as their skin is sensitive and could cause adverse reaction to certain chemicals.

In short, the baby shampoos contain minimum sulfate based cleansers and surfactants in order to avoid irritation.

PRODUCT PACKAGING

Packaging plays an important role here. Because if parents buy a baby shampoo, they would want to select the safest product for their child , and therefore, all they have is the packaging that would tell them the info about the product.

PRODUCT PRINTING

You have to print the packaging really precisely and eye catchy for the information the parents would be interested in that would the info regarding irritation, fragrance, etc.

For the adult shampoo too, you have to have eye catchy packaging for the part an adult would be interested in, which would be the type of hair like curly, silky, straight, etc. condition of hair whether the hair is dry or greasy, etc.

BOTTLE SIZE

Baby shampoo is mostly packed in small-size bottles, whereas adult shampoo is packed in a large container i.e. 1000ml.

PACKAGING MEDIUM

There is a fun fact that baby shampoos are commonly available in transparent, or translucent packaging as compared to adult shampoos. It shows the particular brand has used zero colorants, and dyes in the product and it is safe and clear.

The concerns of buying adult or baby shampoo are different therefore the packaging should be according to those concerns in order to attract customers and increase sales.

5.Difference Between Men and Women's Shampoo Packaging?

When it comes down to gender, men's and women’s shampoos are no different from each other. Rather they are more or less similar. What makes the difference is the aroma part. Men have a more masculine aroma that attracts men while females have a more feminine, floral-type fragrance. Other than the aroma, the ingredients of both are similar.

THE BOTTLE

A key part of the marketing is showing adverts that depict men using a certain product and women using another. All the adverts express the same sentiment as the packaging. Namely, male things are used to sell male shampoo.

PACKAGING PRINT

In marketing terms, a male shampoo is more likely to reflect a car, a famous spy, or something else that men perceive as masculine. Failing this, they are likely to be plain and simple.

Women’s products are more likely to be floral and softer to look at and hold. The design of the bottle is often more natural, even holistic.

PRICES

Companies have realized that women are more likely to spend more money than men on products that make them smell good and have good packaging This is because smelling good and attractive product packaging are important to women, and they are willing to pay extra for it.

The companies take advantage of this by making their packaging more feminine and making the product seem better. Men and women who are brought up in different cultures are willing to spend more money on specific products.

6.What are Different Types of Shampoo Packaging?

Bottles

This type of packaging is commonly used for liquid shampoos, as the pump allows for easy dispensing of the product. There are several types of packaging that can be suitable for shampoo bottles with a pump.

Aluminium Bottles

Aluminum bottles are a type of packaging commonly used for shampoo and other personal care products. They are made from a lightweight, durable material that is resistant to corrosion and can be easily shaped and printed on. They also provide a good barrier against light and air, helping to preserve the contents of the bottle.

Squeezable Bottles

Squeezable bottles are a type of packaging for shampoo (and other liquid products) that are designed to be easy to use and dispense the product. They are made of plastic and typically have a nozzle or a screw-on cap that can be opened and closed to control the flow of the shampoo.

Jar Containers

Shampoo packaging in jar containers refers to the use of jars made of plastic or glass to package shampoo products. These jars have a wide opening at the top for easy dispensing of the shampoo and a screw-on or snap-on lid to keep the shampoo fresh and prevent leaks.

Bar Shampoos

A suitable packaging for bar shampoos is a container that keeps the bar dry and allows it to drain properly. Examples of this type of packaging include tins or cardboard boxes with holes for drainage. Some manufacturers also use biodegradable or compostable packaging materials, such as paper or plant-based plastics, to reduce the environmental impact of their products.

Pouches

Pouches are a popular packaging option for shampoo because they are lightweight, easy to transport and take up less space than other types of packaging. Pouches are also less expensive to produce than bottles and can be sealed airtight to keep the shampoo fresh.

Sachet

Sachets shampoo packaging refers to small, single-use packets of shampoo that are typically made from laminated material, such as plastic or foil. They are often used for travel, as they are lightweight and take up less space than traditional bottles of shampoo.

7.What Type of Shampoo Packaging Machines Are There?

If you’re specifically looking for types of shampoo packaging machines involved in filling purposes; then we have already enlisted them for you. Read below enlisted machines.

| VFFS SHAMPOO SACHET PACKING MACHINE | PARTS | WORKING |

|

The most simple, popular, and affordable shampoo packaging line. This machine is designed in a way where the entire series of working operations take place in a vertical fashion. |

Hopper: This is where the shampoo is loaded into the machine.

Auger filler: The auger filler is responsible for measuring and dispensing the correct amount of shampoo into the sachet. Film un-winder: This component holds the roll of packaging film that is used to create the sachets. Film registration: This component is responsible for aligning the film correctly in preparation for filling. Forming tube: The forming tube is used to shape the film into the desired sachet shape. Seal jaws: The seal jaws are responsible for sealing the sachet after it has been filled with shampoo. Cut-off knife: The cut-off knife is used to separate the individual sachets after they have been sealed. PLC control system: This is the brain of the machine, responsible for controlling all the other components and coordinating their actions. |

The working principle of the VFFS shampoo sachet packing machine is as follows:

The shampoo is loaded into the hopper. The auger filler measures and dispenses the correct amount of shampoo into the sachet. The film un-winder feeds the packaging film into the machine. The film registration aligns the film correctly. The forming tube shapes the film into the desired sachet shape. The seal jaws seal the sachet after it has been filled with shampoo. The cut-off knife separates the individual sachets after they have been sealed. The PLC control system coordinates the actions of all the other components to ensure the smooth operation of the machine. |

| PREMADE LIQUID POUCH PACKING MACHINE | PARTS | WORKING |

| A premade liquid pouch packing machine is a type of packaging equipment that is used to fill and seal pre-formed pouches with shampoo.

|

Filling head: This component is used to fill the pouches with the liquid product. It typically consists of a pump or a piston to dispense the product and a filling nozzle that controls the flow of the product into the pouch.

Sealing system: This component is used to seal the pouch after it has been filled. It typically consists of a set of sealing jaws that apply heat and pressure to the pouch to create a seal. Pouch feeder: This component is used to feed the pouches into the machine. It typically consists of a magazine that holds the pouches and a feeder mechanism that advances the pouches into the machine. Control system: This component is used to control the operation of the machine. It typically consists of a set of sensors, actuators, and a programmable controller that monitors and controls the various functions of the machine. |

The working principle of the premade shampoo pouch packing shampoo machine is as follows:

Firstly put the premade pouch into the machine. Through the filling head, the shampoo product will be filled into the pouch, then the sealing system will seal it. The control system will control the entire process |

| ROLL FILM HFFS SHAMPOO PACKING MACHINES | PARTS | WORKING |

Roll film HFFS (horizontal form fill seal) shampoo packing machines use a roll of film to create a pouch or bag, which is then filled with the shampoo and sealed. The main components of a roll film HFFS shampoo packing machine include:

|

Un-winder: This component holds the roll of film and unwinds it as the machine operates.

Forming rollers: These rollers shape the film into a pouch or bag. PLC control system: This component controls the operation of the machine and can be programmed to perform various functions, such as adjusting the fill volume, seal time, and film tension. Pneumatic system: This provides the pressure needed for sealing and other operations. Detection and alarm system: It ensures the quality of the package and detect any error. |

The major working principles of these machines include: Unwinding of the roll film: The machine starts by unwinding the roll of film and pulling it through the machine. Forming of the pouch/bag: The film is then passed through a set of forming rollers that shape the film into a pouch or bag. Filling of the pouch/bag: The pouch or bag is then filled with the shampoo through a filling nozzle. Sealing of the pouch/bag: The pouch or bag is then sealed at the top, creating a finished package. |

| SHAMPOO SACHET PACKING MACHINE | PARTS | WORKING |

| A shampoo sachet packing machine is used to package shampoo in small, single-use sachets. The machine typically has several major components, including:

|

A hopper: This is where the shampoo is poured into the machine.

A dosing system: This is used to measure and dispense the shampoo into the sachets. A sachet-forming system: This forms the sachets from a roll of material and seals them. A cutting system: This cuts the sachets to the desired size. A control panel: This allows the operator to control and monitor the machine’s functions. |

The working direction of the machine is as follows:

The shampoo is poured into the hopper. The dosing system measures and dispenses the shampoo into the sachets. The sachet-forming system forms and seals the sachets. The cutting system cuts the sachets to the desired size. The completed sachets are collected and packaged for distribution. The machine uses the combination of mechanical and pneumatic components to automate the process of filling, sealing and cutting the sachets. Most of the machines are also equipped with sensors, timers, and another advanced features to ensure accurate and consistent packaging. |

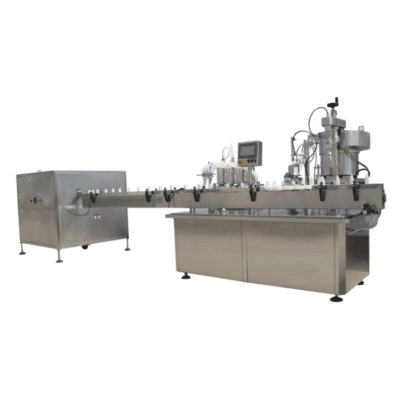

| AUTOMATIC VOLUMETRIC SHAMPOO BOTTLE FILLING MACHINE | PARTS | WORKING |

|

This machine is suitable for filling shampoo bottles in bulk quantity with high efficiency. This is a cost-effective solution in the term of labor and time. |

A shampoo storage tank: They’re used to store products to be filled. A filling nozzle: It helps in precisely filling of shampoo into assigned bottles.A control panel: It helps in feeding the command of the entire protocol.And a conveyor belt: This unit allows a smooth momentum of bottles throughout the process. |

The working principle of the machine is as follows:

Bottles are placed on the conveyor belt which moves them through the filling station. The filling nozzle is controlled by the control panel to dispense a specific volume of liquid into each bottle. Once the desired volume is reached, the bottle is sealed and moved to the next station for labeling, capping, or packaging. The machine can be programmed to fill different types of liquids with different viscosities, and with different fill volumes. The control panel also allows for adjustments to be made to the machine to ensure accurate and consistent filling. |

| AUTOMATIC STICK PACK SHAMPOO PACKAGING MACHINE | PARTS | WORKING |

| Stick pack packaging machines are used to package shampoo into small, single-dose packets that resemble a stick. These packets are also known as stick packs.

|

The main components of a stick-pack shampoo packaging machine are included

A filling unit: It is responsible for filling the shampoo into the packets. A sealing unit: It is responsible for sealing the packets. A cutting unit: It cuts the packets to the desired size. And a control unit: The control unit controls the operation of the machine. |

The working of a stick-pack shampoo packaging machine is relatively simple.First, the machine is loaded with a roll of laminated film, which serves as the packaging material.The film is then fed through the machine, where it is filled with shampoo by the filling unit.The packets then pass through the cutting unit, where they are cut to the desired size.The finished packets are then collected and packaged for shipment.The machine can be adjusted to produce different sizes of packets and can be integrated with additional equipment to print the packaging with branding or other information. |

8.How To Design Water Resistant Shampoo Packaging?

Nothing says cheaper than a water-resistant label and good packaging material for shampoo packaging. The most important factor that every manufacturer considers is that it should be water-resistant and oil-proof. Shampoo bottles or other types in bathrooms basically need special attention as their environment is moist and steamy.

A high-quality material is known for offering optimum protection against it. The commonly used material used for shampoo packaging include;

PET

It is the most commonly used packaging material having great water resistance and eco friendly.

LDPE

This is a highly flexible, durable, cost-effective, and squeezable option that is best known for its protection against moisture.

HDPE

This material is commonly used as it is highly impact-resistant, shock-absorbent, and affordable material for shampoo packaging

MDPE

This is also considered an excellent packaging option due to its drop and shock-resistant properties. This material is ideal for products used in a wet environment.

PVC

A commonly used shampoo packaging material, known for its durability and protection. It has the ability to produce great transparent material in a variety of colors, hence improving the buyer experience.

9.What are the Technical Problems and Solutions of Shampoo Packaging?

The shampoo packaging process is mostly encountered with filling and packaging problems but I will tell you some major troubleshooting tips. Have a look!

| Problem | Solution |

| LEAKAGE | The most common problem of cap leakage is either too much or insufficient twisting force.

A certain specified torque range is applied to ensure proper sealing. A secure induction sealing is done |

| FOAMING | This is the most common problem; filled shampoo has too much foam, therefore variation in filling quantity.

Increasing fill time allows the top foam to overflow. Check and correct the filling nozzle. |

| DRIPPING | A head dive functions like an arm. It is connected and controlled by wires. Its malfunctioning develops a dripping.

Disconnect the wires and replace the head dive for fast and accurate working. |

| NON-UNIFORMITY | An overflow filler is a device used to sense and adjust the filling level.

If the shampoo filling oozed out of the bottle; adjust the device by assessing the spacer attached to the filling nozzle. |

| OVERFLOW

|

During the filling procedure, shampoo normally overflows and goes back to the holding tank.

Check and confirm of tubes are completely sub-merged the product; otherwise it will form a back pressure and havoc with filling level. Check the volume and adjust filling head if required. |

CONCLUSION

Design shampoo packaging always needs special consideration whether machines or packaging material. Therefore, you must keep an eye on every impact of it. AIPAK Pharmaceutical Equipment Promises to offer Hi-Tech and affordable solutions for shampoo packaging. Please contact us now for procurement and product details. Happy Shopping!

Don't forget to share this post!

Syrup Filling Machine Related Products

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine