Semi-automatic Capsule Machine: The Complete Buying Guide In 2025

Are you looking for the suitable capsule filling solution for your business right now? Have you ever thought about owning one type capsule machine for your production? How would you thought about semi-automatic machine or automatic capsule machine? Is the semi-automatic capsule machine right for your business?

To find all the answers, you need to explore this post now about the complete buying guide of semi-automatic capsule machine. It covers all the information and solution about the semi-automatic capsule machine you want to know about. Let's get started now!

1.What Is Semi-automatic Capsule Machine?

AIPAK Semi-automatic Capsule Machine

Semi-automatic capsule machines require you to use a combination of manual and mechanical methods to fill different materials, such as powder, pellets, granules, or combinations, into empty capsule shells. It can automatically help you complete the process of separating, sorting, filling and sealing the capsule shells. However, you need to manually change the mold.

2.What Are The Different Types Of Capsule Machine?

According to different degrees of automation, capsule machines can be divided into manual capsule machines, semi-automatic capsule machines and fully automatic capsule machines.

Manual capsule machine

Manual capsule machine-sourced: kahaninternational

It has a smaller model and a simpler structure. The full manual mode can meet the needs of your laboratory or small production rate. The efficiency of manual capsule filling machines is very low. The number of capsules that can be filled at one time is very small, and most of the work needs to be operated and completed manually.

Semi-automatic capsule machine

AIPAK semi-automatic capsule machine

Semi-automatic capsule filling machine is mainly a capsule filling machine that combines the advantages of manual and automatic modes. It can automatically complete the arrangement, separation, filling and sealing of capsule shells. However, you need to manually change the mold. This capsule filling machine is durable and easy to maintain, and can bring you efficient capsule filling results.

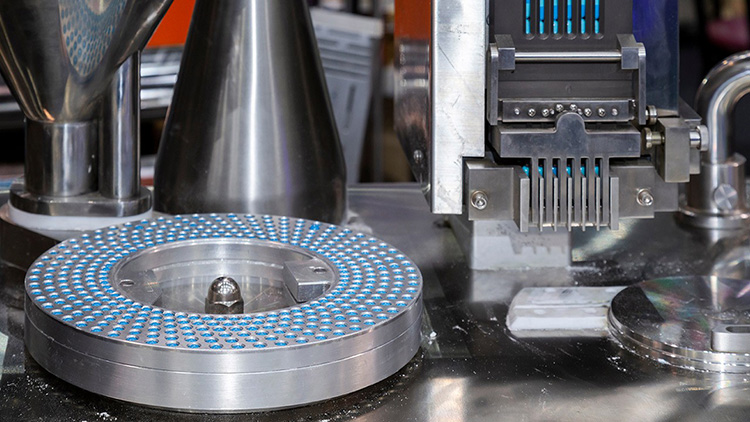

Fully automatic capsule machine

AIPAK fully automatic capsule machine

The fully automatic capsule filling machine has the highest efficiency, the highest output and the lowest labor consumption. By achieving full automation, you can complete all processes such as arranging, loading, filling and ejecting the capsule shell without manual loading. High efficiency and low dependence on labor.

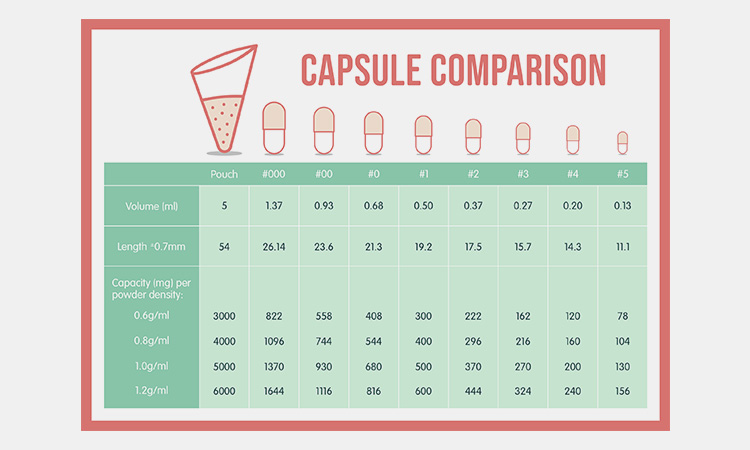

3.Which Types Of Capsule Can You Fill Using The Semi-automatic Capsule Machine?

Capsule size chart-sourced: blatepapes

Most types of capsules can be filled by semi-automatic capsule filling machines. Among them, the most widely used capsule shell models on the market are: #000, #00, #0, #1, #2, #3, #4, #5. Here is the capsule size chart below:

| Capsule size | ||||||||

| #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 | |

| Formulation Density | ||||||||

| 0.6 g/ml | 822 | 540 | 408 | 288 | 216 | 162 | 120 | 78 |

| 0.8 g/ml | 1096 | 720 | 544 | 384 | 288 | 216 | 160 | 104 |

| 1.0 g/ml | 1370 | 900 | 680 | 480 | 360 | 270 | 200 | 130 |

| 1.2 g/ml | 1644 | 1080 | 816 | 576 | 432 | 324 | 240 | 156 |

| Capsule overall length | ||||||||

| mm | 26.1 | 23.4 | 21.6 | 19.4 | 17.6 | 15.7 | 14.3 | 11.1 |

| Tolerance (mm) | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.4 |

| Inches | 1.029 | 0.921 | 0.85 | 0.764 | 0.693 | 0.618 | 0.563 | 0.437 |

| Tolerance (inches) | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.016 |

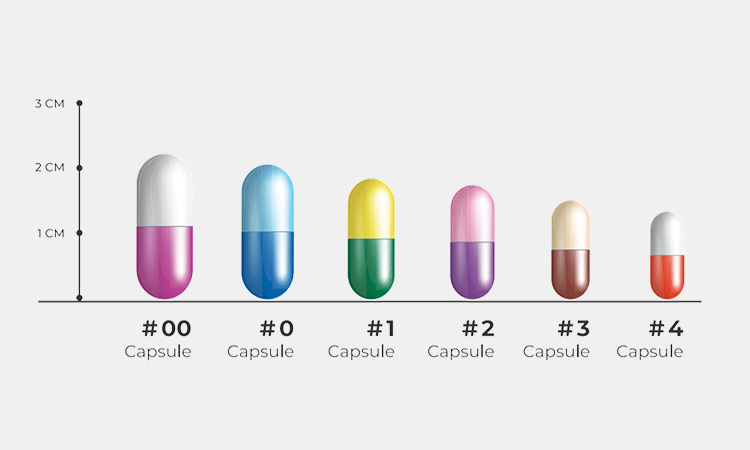

4.Are There Any Recommended Capsule Size You Can Use The Semi-automatic Capsule Machine?

Recommended Capsule Size You Can Use The Semi-automatic Capsule Machine-sourced: multicaps

The capsule shell models most recommended by AIPAK are 00, 0, 1, 2, 3, 4, and 5. These are the capsule shell models used by the semi-automatic capsule filling machines on the market. The reason is that the capsules of these models are of moderate size and have similar density of contents. The space in each capsule is suitable for most powders and granules that need to be filled on the market.

5.What Are The Various Types Of Material You Can Fill With The Semi-automatic Capsule Machine?

All types of powder, pellets, granules and combinations can be filled with the semi-automatic capsule machine.

Powders

Powders-sourced: dragonherbs

Many drugs are filled into empty capsules in powder form. Powders have good flowability and good filling density control, which is very suitable for sealing with capsule shells.

Pellets

Pellets-sourced: medicalplacebo

Semi-automatic capsule machine can fill pellets into capsule shells intact and active.

Granules

Granules-sourced: octaviuspharma

Many slightly larger granules can also be filled using semi-automatic capsule machine.

Combinations

Combinations-sourced: georgeinstitute

Many special drug formulations may require different degrees of powder, pellets and granules. Semi-automatic capsule machine can easily fill these mixtures into capsule shells.

6.What Are The Capsule Machine Type Comparison?

It can compare the relevant situations of different capsule machine models from different angles:

AIPAK Capsule Machine Type Comparison

| Machine Type | Cost | Output (capsules/hour) | Flexibility | Operator Engagement |

| Manual type | Low | 100–2,000 | High | High |

| Semi-automatic

type |

Medium | 10,000-40,000 | Medium | Medium |

| Automatic type | High | 228,000-468,000+ | Low | Low |

7.How To Improve The Efficiency Of Semi-automatic Capsule Machine?

If you do not want to use a more automated fully automatic capsule filling machine, but want to improve the efficiency of a semi-automatic capsule filling machine, you can do so by:

Improve the operator's proficiency

Improve the operator's proficiency-sourced: fplushealthcare

The productivity of a semi-automatic capsule filling machine is fixed according to the selected model. Generally, its production capacity is about 10,000 to 40,000 capsules per hour. If the operator's efficiency is improved, the productivity of your semi-automatic capsule filling machine can also be improved.

Ensure material consistency

Ensure material consistency-sourced: qualitysupplementmfg

Generally, semi-automatic capsule filling machines are more flexible. You can adapt to different models and sizes of capsules by replacing different capsule trays. Therefore, try to use capsule shells of the same material, size and shape, which can reduce the chance of you changing the capsule tray and thus improve productivity.

Perform regular equipment maintenance

Perform regular equipment maintenance-sourced: ruidapacking

The semi-automatic capsule filling machine has a simple structure and is easy to maintain. Daily maintenance can greatly reduce your investment and improve your production efficiency. It can prevent you from always encountering various problems such as jamming and inaccurate filling during use.

8.What Can The Semi-automatic Capsule Machine Bring You?

The semi-automatic capsule machines can bring you:

High flexibility

High flexibility-sourced: gainjoy

Almost all capsule sizes, types and materials are suitable for semi-automatic capsule filling machines. All capsules can be filled by simply replacing the capsule tray. High flexibility and low cost, very suitable for various flexible capsule production lines.

High cost-effectiveness

Semi-automatic capsule filling machines are low-cost and high-return equipment. Low investment rate and high return. It can bring you high cost-effectiveness and facilitate your company's production and operation.

Low maintenance

Compared with fully automatic capsule filling machines, semi-automatic models have simpler machine structures, components and materials used. They provide great convenience for operators to carry out their work.

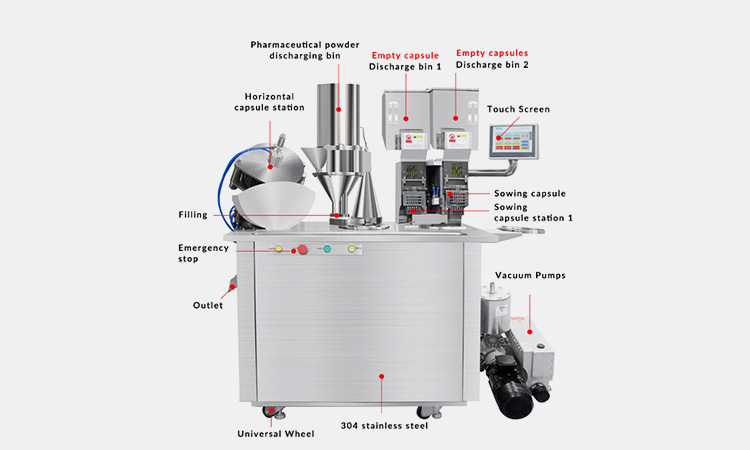

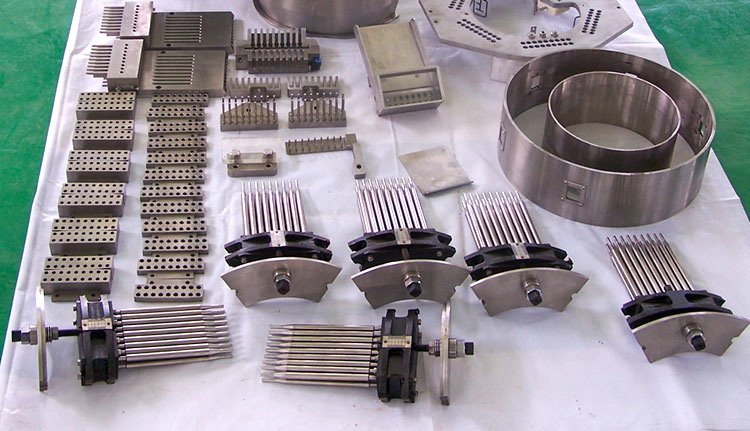

9.What Are The Main Components Of Semi-automatic Capsule Machine?

Compared with the fully automatic, semi-automatic capsule filling machine, the equipment structure is simpler.

Main Components Of Semi-automatic Capsule Machine-sourced: markwell

Pharmaceutical powder discharging bin

The pharmaceutical powder discharging bin is mainly used for loading and storing the materials need to be filled into the capsules including powder, pellet, granules or combinations. It mainly adopts the shape of a funnel to facilitate the flow of powdered materials and subsequent filling.

Empty capsule discharge bin

It is a loading bin that helps you load and store the empty capsules that needs to be filled in the next step. Connected below this funnel is the capsule sorting and capsule removal mechanism. After being loaded into the empty capsule discharging bin,the capsules will be sorted, arranged and separated.

Touch screen

You can use the touch screen to set the capsule filling parameters that meet your work needs, including capsule filling efficiency, speed, time, etc.

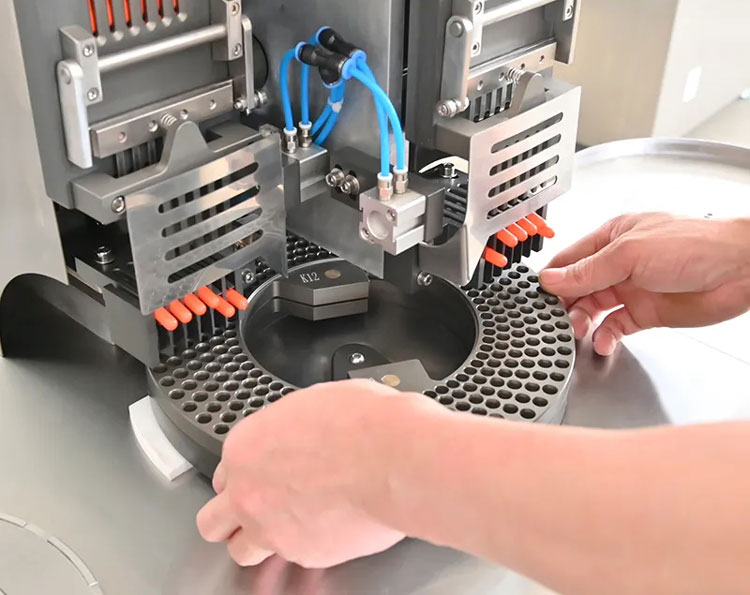

Sowing capsule

This mechanism is also called capsule tray or capsule mechanism. This part may help you arrange and sort the capsules by separating the capsule bodies and caps for next step. After been sorted and arranged, the capsules will be filled with different materials.

Filling station

The capsule shells that have been separated and evenly spread on the capsule tray will be manually transferred to the filling station by the operator. The discharging bin will evenly fill the capsule shells with the material.

Horizontal capsule station

The horizontal capsule station is also called a capsule locking or sealing mechanism. Its main function is to lock and seal the filled capsule body and capsule cap. It is equipped with a compression mechanism that can apply pressure to the filled and sealed capsule shell, making the capsule shell seal more tightly.

Emergency stop

If any emergency occurs and there is no time to stop the machine, you can immediately touch the emergency stop button. It can help you stop the machine in an emergency without damaging the machine to avoid losses.

Outlet

Filled capsules are detected and ejected from the outlet. You can place a capsule collection device underneath.

Universal wheel

With these four wheels, you can push the device to wherever you need it and use it.

Vacuum pump

The vacuum pump can provide a stable and continuous power for your equipment. Generally, high-quality brand parts are used to support the operation of your equipment.

10.What Is The Working Principle Of Semi-automatic Capsule Machine?

AIPAK semi-automatic capsule machine working principle

The working principle of semi-automatic capsule filling is relatively simple:

You can load the empty capsule shells and the materials to be filled manually or automatically. Make sure they are not damaged or contaminated.

Capsule shell separation. The loaded empty capsule shells will be separated to facilitate the subsequent material filling and capsule shell sealing.

Capsule transfer. The successfully separated capsule body and capsule cap will be transferred to the capsule tray.

Material filling. The capsule body transferred to the capsule tray will be filled with the powder or granules for your needs.

Capsule sealing. The filled capsule body will be locked and sealed with the capsule cap. Then it will be pressed with good manner.

Capsule collection. The filled and sealed capsules will be inspected and then collected for further packaging.

11.What Are The Step-by-step Guide To Use The Semi-automatic Capsule Machine?

AIPAK step-by-step guide to use the semi-automatic capsule machine

If you are an operator, you can follow this guide below to learn how to control and operate the semi-automatic capsule machine:

Pre-check

Before using the equipment, be sure to check whether there is any residue or stain in the equipment. Before using, clean and maintain the equipment thoroughly.

Loading

Before starting the equipment, load enough capsule shells and materials to be filled, and store them in the discharging bin for later use.

Start

After starting the equipment, the capsule shells will go through the steps of separation, capsule removal, filling, sealing and ejection.

Collect

Collect the filled and sealed capsules, and then screen, pick and check them, and remove the unsuccessful or missed capsule shells.

Cleaning and maintenance

After each use of the equipment, the capsule shells and unused materials in the equipment must be collected and cleaned. Check and maintain the machine.

12.How To Determine The Production Capacity Of Semi-automatic Capsule Machine?

There are several points that would help you how to determine the production capacity of semi-automatic capsule machine. They are:

Capsule sizes, shapes and formulation

Capsule sizes, shapes and formulation-sourced: setylose

Although the efficiency and production output of semi-automatic capsule filling machines are similar, there are still several aspects that can affect its production capacity. If the capsule sizes, shapes, and formulation are consistent and do not need to be replaced midway, then the production capacity of the equipment is high.

Operator skill

Operator skill-sourced: ruidapacking

For the same semi-automatic capsule filling machine, the higher the operator's proficiency, the higher the production capacity of semi-automatic capsule machine.

Manufacturer description

You can learn about the production capacity of semi-automatic capsule machine through the manufacturer's description of the equipment or the production manual. Generally, the more refined the workmanship and the more reasonable the design of the semi-automatic capsule machine, the higher the productivity.

Machine design

The more refined the equipment is, the more reasonable the distribution of each part is, or the higher the quality of each part is, the higher its production capacity is.

13.How To Control Quality In Semi-automatic Capsule Machine?

According to the following aspects:

Capsule and raw material quality

Capsule and raw material quality-sourced: xi'anhaoze

Before starting the equipment, check the quality of capsule shells and filling materials. Remove unqualified capsule shells or contaminated filling materials in advance.

Equipment calibration

Equipment calibration-sourced: fplushealthcare

Equipment calibration is also very important. This is related to the subsequent filling accuracy and sealing integrity. Good equipment calibration can improve the quality of capsule filling for you.

Visual inspection

Visual inspection-sourced: 10in6

In the process of using the equipment for capsule filling, in addition to the necessary operating procedures, you also need to supervise. To prevent problems.

Environmental control

The capsule filling process must be a sterile and uncontaminated environment. Therefore, the cleanliness, temperature and humidity control of the environment are very important.

Sample testing

Random observation and testing of the finished capsules can ensure batch high-quality capsule filling.

14.What Are The Technology Advancement Of AIPAK Semi-automatic Capsule Machine?

There are plenty technology advancement of AIPAK semi-automatic capsule machine you may know. They are:

High accuracy

High accuracy-sourced: aligned-tec

AIPAK semi-automatic capsule machine applies the high-precision capsule locking and filling mechanism, with a novel structure, can ensure high-precision capsule filling for you.

High quality capsules

High quality capsules-sourced: wendao

In addition to excellent equipment, AIPAK can also provide you with high-quality empty capsule shells to meet your filling needs of different materials.

Enhanced productivity

Enhanced productivity-sourced: dandong

Even if it is a semi-automatic type of equipment, AIPAK semi-automatic capsule machine can provide you with high-quality and efficient capsule filling.

Ease of operation

Ease of operation-sourced: grabil

AIPAK semi-automatic capsule machine is simple in design and equipped with detailed and professional instructions for you to read and learn. It provides convenience for your later learning and operation.

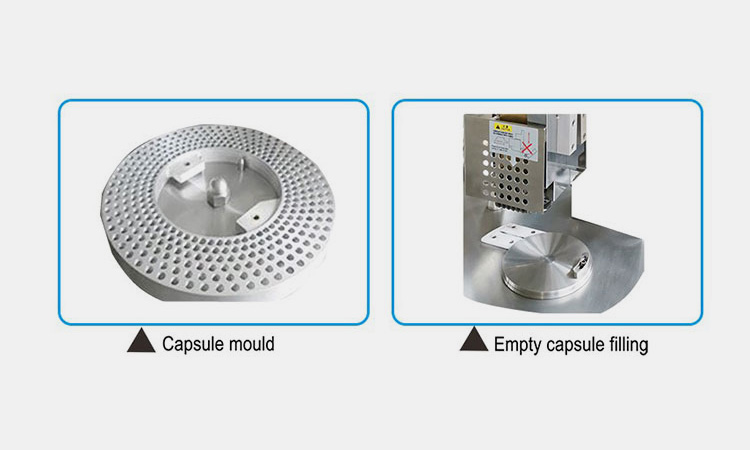

15.Are There Any Support Equipment You Need To Use Alongside The Semi-automatic Capsule Machine?

If you want to a complete capsule filling system, you can add these two equipment. It includes:

Capsule polishing machine

AIPAK capsule polishing machine

Connecting a capsule polishing machine can help you sort, classify, polish and remove static electricity from capsules. It is also very practical for removing light, loose, incompletely filled or sealed capsules.

Capsule counting machine

AIPAK capsule counting machine

The capsule counting machine can help you count the filled and sealed capsules. Then the counted capsules are bottled. This equipment is compact in design, stable in structure and low in noise, making it a perfect fit for your capsule bottling line.

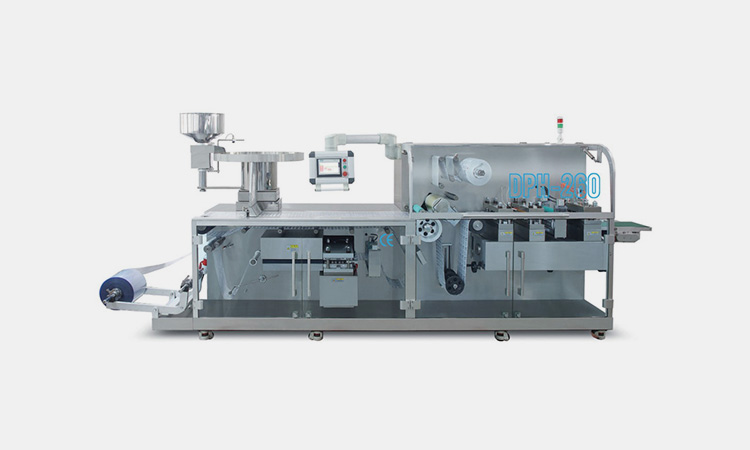

Blister packaging machine

AIPAK blister packaging machine

The blister packaging machine can help you pack the filled capsule shells into blisters safely and completely. With servo drive, this machine is fast, accurate and quiet, making it a perfect fit for your capsule blister packaging line.

16.What Are The Safety Precautions When Using Semi-automatic Capsule Machine?

Safety Precautions-sourced: neuroleadership

When operating and using the semi-automatic capsule machine, you need to pay attention to the following details. They are:

Wear personal protective equipment

Some sensitive drugs are very sensitive and strict to environmental pollution sources when filling. Therefore, when filling such drugs, wear personal protective equipment to avoid contaminating the drugs.

Electrical safety

Before using the equipment, check whether the power supply of the equipment is normal and whether the power cord is damaged. At the same time, you need to ensure that the equipment is properly grounded and operated safely.

Machine placement

The equipment needs to be placed in a safe, stable, clean, tidy, contaminant-free and obstacle-free space. Keep away from fire sources before and during use.

Emergency procedures

Before operation, the operator must learn and apply emergency procedures. No matter what failure or accident occurs, it can be handled quickly and smoothly.

17.What Problems You May Met When Using The Semi-automatic Capsule Machine And How To Solve It?

Problems You May Met When Using The Semi-automatic Capsule Machine-sourced: ruidapacking

Semi-automatic capsule filling machines will inevitably encounter many problems during use. According to the following tips, you can solve the problem well.

| Problems | Reasons | Solutions |

| Capsule misalignment | If the capsule is misaligned during the filling process, it will cause the capsule to not close properly; | To solve this problem, you can check, adjust and calibrate the capsule alignment system before filling the capsule; |

| Inconsistent filling weight | This is usually caused by inconsistent filling materials or inconsistent material fluidity; | Check the fluidity of the powder before filling;

Fill different powders separately; Check the hopper for blockage; |

| Machine blockage | It may be caused by the filling powder being too wet and sticky; | You can clean the hopper regularly to avoid it;

Make sure the powder has moderate humidity and good fluidity before use; |

18.Why You Choose Semi-automatic Capsule Machine Over Other Options?

Why You Choose Semi-automatic Capsule Machine-sourced: hrglobalindia

When comparing different types of capsule filling machines, why is the semi-automatic the most popular? There are several reasons:

Flexibility

Semi-automatic capsule filling can adapt to the needs of most molds. If you need to fill a wide variety of products and have a high demand for molds, then the semi-automatic model is your best choice.

Stable output

Although the output and efficiency of semi-automatic capsule filling are slightly less than that of fully automatic, it is more stable.

User-friendly

The semi-automatic capsule filling machine has less equipment complexity. It is more convenient for operators to learn and operate.

19.What Are The Key Features To Look For When When Selecting And Purchasing Semi-automatic Capsule Machine?

You can choose according to the following information:

Model and brand

Model and brand-sourced: mapandfire

Equipment of different models and brands may have very different user experience and equipment quality. You can choose a manufacturer that you trust or have a good reputation.

Production capacity

Choosing a machine with suitable productivity can greatly improve your production efficiency and reduce your production costs.

Quality

High-quality products are more stable and durable. The semi-automatic capsule filling machine provided by AIPAK can provide you with stable and long-lasting output capacity.

20.What Are The Maintenance And Cleaning Requirements You Need Learn About Semi-automatic Capsule Machine?

The daily cleaning and maintenance of the semi-automatic capsule filling machine are very simple. You can:

Disassemble and clean the parts

AIPAK disassemble and clean the parts

The parts of the semi-automatic capsule filling machine are very easy to disassemble and clean. Clean and disinfect the parts, and then assemble them after they are naturally dried.

Check the parts

AIPAK check the parts

After reassembling the disassembled and cleaned parts, check the hopper, filling system, cleaning and dosing system, capsule alignment and locking mechanism, etc.

Lubricate the parts

Lubricate all joints and parts that have high daily friction and frequent friction.

Conclusion:

It is very important to choose the appropriate product type according to your own business. If you want to control your capsule filling cost within the budget, or achieve a corresponding balance with productivity, according this complete buying guide of semi-automatic capsule machine, then then semi-automatic equipment is your ideal choice. Contact AIPAK now for more information if you want to know!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine