10 Advantages of Semi Automatic Capsule Filling Machine You Must Know

Semi automatic Capsule Filling Machine is actually designed for different set standards that are demanded by the different pharmaceutical industries. A Semi capsule Filling Machine is reasonable to fill size 00 to 5 capsules with powder, granules or pellets.

AIPAK semi automatic capsule filling machine

There are many different and distinct models in the semi automatic capsule filling machine which give a maximum running result from 25000 capsule for each hour to 45000 capsule for every hour.

Machines furnish the serious extent of computerization with more significant levels of filling weight precision. Semi automatic capsule filling machine is made according to GMP principles having all Stainless Steel covering. Semi automatic capsule filling machine having wide utilization in R&D labs, Research Institutions, Herbal and Nutraceutical arrangements, Unani & Ayurvedic prescriptions, Pilot group creations and so forth.

The semi automatic capsule filling machine is easy to use with some advantages that a normal capsule machine can't provide you.

Up to 25,000 capsules in 60 minutes, an exceptionally effective semi automatic capsule filling machine mechanism which guarantees a high degree of precision and can work with a scope of capsule sizes!

Thus, this article is about insights of the semi automatic capsule filling machine and it will explain 10 most vital advantages of using this machine.

Chapter 1- Great production rate

There are many certain factors that actually define the production rate of the semi automatic capsule filling machine. These factors include, ring, size of the capsule being used etc.

The rpm round per min is the other variable that defines the speed which is directly proportional to the production rate.

It also depends upon the machine which one you use. In that case the production rate of the machine may vary accordingly.

| Model | Machine 01 | Machine 02 | Machine 03 |

| Production rate | Up to 25000 Capsules per hour | Up to 35000 Capsules per hour | Up to 45000 Capsules per hour |

| Number of rings | 1 ring | 1 ring | 2 ring |

| Number of holes/ring | Size 00: 360

Size 0: 480 Size 1,2: 540 Size 3,4&5: 600 |

Size 00: 480

Size 0: 600 Size 1,2,3,4,5: 720 |

Size 00: 480

Size 0: 600 Size 1,2,3,4,5: 720 |

| Dimension | 1800mm (L) x 1100mm (W) x1700mm (H) | 1850mm (L) x 1100mm (W) x1700mm (H) | 2500mm (L) x 1100mm (W) x 1700mm (H) |

| Net weight | 800 kg approx. | 1000 kg approx. | 1200 kg approx. |

Chapter 2- Semi Automatic Capsule Filling Machine is a power saving option

It is more or less about the consumption of the electricity or any other source which these machines use while operating.

In electrical designing, power utilization refers to the electrical energy per unit time, provided to work something, for example, a machine being used in an industry. Force utilization is normally estimated in units of watts (W) or kilowatts (kW). The energy utilized by gear is in every case more than the energy truly required.

In fact, it is an important factor to be considered. How much power a machine is using is an important thing to keep in the mind?

For example, in the case of the semi automatic capsule filling machine the power is the key factor.

These are good options for you.

- It consumes less power.

- It consumes more power than a totally automatic machine whereas less than the manual machine.

- It is a power saver equipment as the operation does not consume extra power.

Well again the power factor which again differs on the type of the machine is being used and also the factor like capability. The machine with the low capacity might use the power from 2 to 5 kw whereas the machine with the quite higher capacity might reach from 5 to 7.5kw.

Chapter 3- High Filling Accuracy

It explains the accuracy that a machine does have while using it. By accuracy it means how many less error machines do have running.

These machines ensure exact and exact powder dosing. It doesn't make a difference whether you choose the manual, automatic or semi automatic capsule filling machine. Each machine has interesting insights and features that ensure an elevated level of correctness in the process to lessen conceivable wastage. How about we have a brief glance at how AIPAK company accomplishes this:

Semi automatic capsule filling machine:

To improve accuracy to the maximum extent of these semi automatic capsule filling machines, administrators may utilize the quantity of revolutions of the dosing circle to direct the capsule filling measure. Additionally, the powder feeder has an arguer that directs the powder filling measure.

In addition, our company’s semi capsule filler machines have an autonomous force and fixed point filling, other than a variable speed filling.

- Obviously, AIPAK company doesn't compromise on the precision and accuracy of the powder filling measure. A motivation behind why the organization puts resources into specialized developments to guarantee each encapsulator has the correct quality control measures.

- To improve precision of these encapsulator machines, administrators may utilize the quantity of revolutions of the dosing plate to direct the container filling measure. Likewise, the powder feeder has a drill that directs the powder filling measure.

Chapter 4-Easy to Operate & Machines are Simple to Handle

This is more about a brief summary about the operation and process and how it is handled.

It is the simplicity of the machine that makes you more happy and easy to understand that operating this machine is not rocket science. As it is really clear it doesn’t involve the whole automatic method, it has the manual process as well. Even then it’s quite easy.

All of our semi capsule filling machines are pretty basic and simple to work with. One doesn't need any unique training to work and keep the machine updated.

For example, most semi automatic capsule filling machines have removable screws and pins. This makes it simple and easy to collect and dismantle. However, it has a computerized part as well when it demands some skill sets. For the semi automatic capsule filling machines, they have a modular design for simple disassembling and assembling. Additionally, clients can screen and arrange all tasks through the human machine interface (HMI).

Regularly, one expert can handle even high production encapsulation machines.

Chapter 5- Adjustable/Adaptable Settings to Improve Production

This is more or less about the thing if you can change the setting of the machine while using it. Or it does it give you the ability to change its setting.

One of the biggest advantages of the semi automatic capsule filling machine is their ability to adaptable and changeable production rate.

Adaptable semi automatic capsule filling machine can therefore be defined as a machine paradigm that extends the intended utility of products and design through design and product adaptation. Design adaptability aims at reusing the same design for the creation of different products.

By adjust ability of the semi automatic capsule filling machine it means that it have the able to be changed to suit particular needs.

Chapter 6- The Design of The Machine Ensures Low Maintenance Operation

Maintenance cost is always a key factor to consider. This chapter is also about how these semi automatic capsule filling machines help you to save more money.

All of the semi automatic capsule filling machines have appropriate residue / dust dealing with ability according to the GMP necessities. That is, all the moving parts (mechanical parts) are completely encased to shield them from dust.

A vacuum powder stacking gadget for simple activity.

These include:

- Main turntable

- Dosing framework

- Control frameworks

- Electrical parts

Additionally, Semi automatic capsule filling machines include different advances, for example,

- Vacuum cleaning station

- Dust pull framework

Moreover, every capsule filling machine doesn’t matter which one, auto, manual or whatever accompanies a simple to utilize and comprehend troubleshooting manual. This likewise takes out the slow processing cycle of approaching and supporting the activity.

Keep in mind, all these will decrease downtime, which will influence production.

Chapter 7- Cost Benefit Ratio Over the manual capsule filling machine

Investing in our semi automatic capsule filling machine comes with many different advantages. I am very certain about you as a customer as well that you want a machine that is more beneficial for you in terms of cost.

These are some of the most amazing cost saving benefits you can achieve.

- A high creation yield – up to 45,000 cases for every hour relying upon the sort of machine of machine saves you the cost of spending more time.

- Guaranteed security gives you a chance to claim any guarantee any problem occurs in between the process.

- Reduced work costs since the machine requires just a single specialized staff to operate and deal with the procedure..

- It can fill most container sizes running from 00#, 0#, 1#, 2#, 3#, 4# and 5# which is another advantage of the machine.

- Less downtime of the semi automatic capsule filling machine and low maintenance isn't the last factor indeed not the least.

As you can notice and see that as well, these machines might cost a bit higher in the beginning. But, in the long run they are actually cheaper.

Chapter 8- Advanced Structure to Ensure Reliability and Efficiency

Efficiency and reliability is the part of the discussion here in this chapter.

To guarantee creation consistency and proficiency in the semi automatic case filling machine and even in automatic capsule filling machines, you need an encapsulator with more advanced structure and a progressive technology.

So, why are we the best for you and why should you select our semi automatic capsule filling machines?

The stainless steel structure

- The machine has a stainless steel structure that is solid and mostly can't hold any rust. This adjusts to the specified well being measures.

- Additionally, its plan includes an extended cam (somewhere in the range of Ru100 and Ru83). This improves the strength and life expectancy of the machine.

Actually, a lot of parts in this machine are produced using treated steel.

AIPAK CGN-208D2 Semi automatic capsule filling machine

Control system of new innovation

- To control most activities of the semi automatic capsule filling machine and completely automatic capsule filling machines as well.

- These may incorporate arranging the capsule, filling the capsule, rotating the dosing plate, and so on.

Electrical system also controls system

Clients can control the machine through the touch screen HMI board. The control framework controls both the mechanical and the electrical parts of the capsule filler machine.

Chapter 9- Semi Automatic Capsule Filling Machines are Safe

This explains the details how this machine is so safe even in case a mishap occurs.

An automatic capsule filling machine is made by assembling many different types of the components. They incorporate turning parts, for example, motor/engines and electrical parts of the machine.

Each of the automatic capsule filling machines has distinctive safety measurements to shield experts from potential wounds. These include:

Protecting clients from conceivable electrical shock

To start with, the machine has signs of the warning that alarm individuals of conceivable electric shock of any type. You can see this on the external front of the machine.

Besides, the electrical parts are completely encased. Nobody can get to this part when the machine is on.

All moving segments, be it siphons, electric engines, cams, shafts or apparatuses, are encased

Each compartment is encased with a lockable entry way. The entry way/ door has a security assurance switch. At the point when one opens the entryway, the machine will turn off automatically.

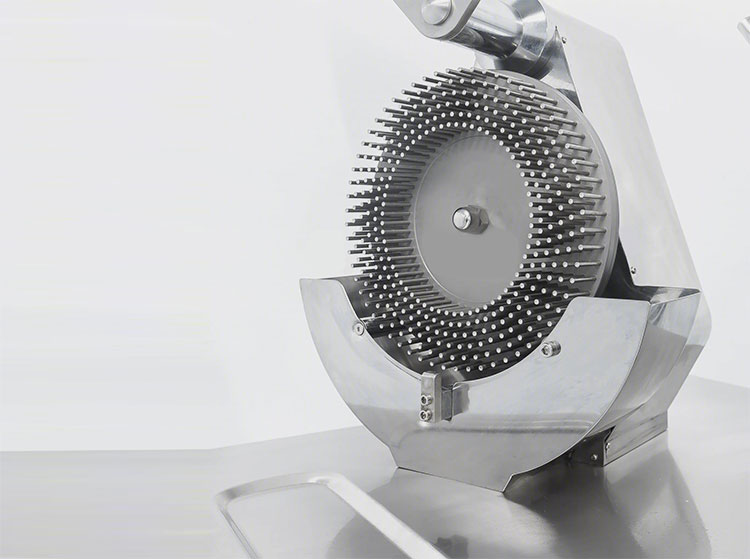

Powder filling & Capsule filling dosing disk

In the upper area (capsule hopper & encapsulator powder), the entryway is produced using a polycarbonate sheet. This is a shatterproof material and it can withstand high vibrations.

Our machines follow all security rules and guidelines

AIPAK company is an ISO guaranteed organization that adjusts to all security rules and guidelines. These incorporate the CE, GMP or cGMP prerequisites.

To put it plainly, you can trust on all of our semi automatic capsule filling activities.

Chapter 10- Semi Automatic Capsule Filling machines are cGMP and CE Compliant

This is nothing other than a semi automatic capsule filling machine and some standards.

The plan of our all semi automatic capsule filling machines adjusts to the CE and cGMP necessities. It doesn't make a difference whether you pick Auto/semi auto or manual capsule filler machines.

The Current Good Manufacturing Practice (cGMP) necessity is a significant normalization strategy in the pharmaceutical business. It guarantees appropriate quality control in the whole assembling cycle to guarantee security of pharmaceutical items.

A sign that a drug item follows GMP.

Our group of specialists work intimately with the U.S. Food Drug and Administration (FDA) to guarantee consistency of semi automatic capsule filling machines. It is thorough procedure to guarantee:

- Control of assembling measure

- Proper machine plan methods

- Monitoring and directing quality

Besides, all electrical segments and choice of material likewise adjust to the CE order. This eradicates any conceivable contrariness issues.

Above is CE stamping. You should know the distinction among genuine and fake CE stamps.

Conclusion:

In the end, the unique advantages which are written up in the article of this semi automatic capsule filling machine makes it unique. AIPAK has become an incredibly famous producer for creating high-effectiveness pharmaceutical machines with a wide assortment and amazing quality.

Don't forget to share this post!

Capsule Filling Machine Related Products

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours