See Standard Guidelines Before Buying Effervescent Tablet Tube Filling Machine in 2025

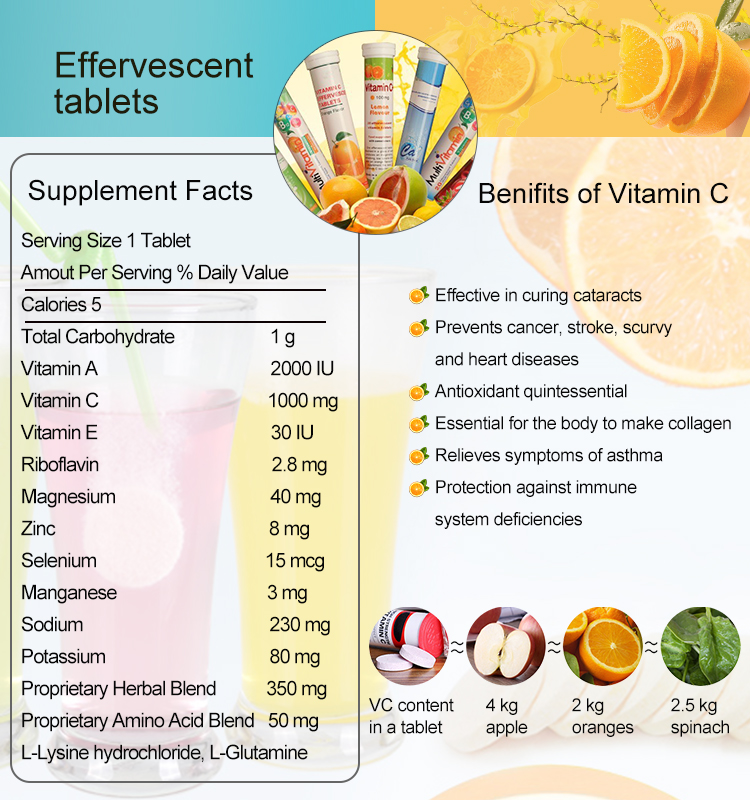

“BASICS OF THE DAZZLING FIZZ”

Effervescent tablets offer a unique way to deliver therapeutic effects considered as safer and attractive than conventional tablets. When you pour tablet into water, it starts with giving you positive results because effervescent tablets are reloaded with sparkling healthy fizz.

Major Advantages of the Effervescent Tablet:

1.Stimulating taste:

They are available in multiple refreshing and appetizing flavors. There is an exciting chemistry exists between fizz and flavor. Both flares up simultaneously with exciting taste and health.

2.Easy to digest:

They are readily soluble in water thereby easy to digest. Effervescent tablets dissolve itself before you consume, this property protects emergence of many gastrointestinal complications wherein conventional tablets may create digestive issues.

3.Keeps you Hydrated:

It is well-known that if water is refreshing and good. You’ll tend to have more and more which inevitably shoots up your hydration level as well as maintain water balance in the body.

4.User compliance:

These are highly patient compliant and easy to handle dosage form and do not require any efforts before administration. You need to drop an effervescent tablet in a glass of water, allow it to dissolve and healthy dose will be ready to consume.

Effervescent Tablets- Drop-Fizz-Drink- Picture courtesy: AGM

Have you ever thought about their formulations?

May be, yes?

An effervescent tablet is all about game between ‘Water and Fizz’. Many of you have observed effervescent tablets in a great packaged tubes that looks very appealing. And probably you might be wondering how this entire process occur to bring an amazing tube fitted, well organized and accurate dosage formulation placed in an attractive bottle.

Today, you’re going to grasp interesting knowledge about manufacturing equipment known as Effervescent Tablets Tube Filling Machine.

In fact, you’re at a right place to learn about Effervescent Tablets Tube Filling Machine, their functions, advantages, technical issues, key units, working principle and so on.

This blog will help you to provide basic guideline when you are buying for this equipment with basic applications.

Let’s get into it.

1.Explain Effervescent Tablets Tube Filling Machine?

AIPAK Effervescent Tablets Tube Filling Machine

Emergence of Effervescent Tablets Tube Filling Machine have opened a horizon for successful pharmaceutical industries to use this advanced technology for an efficient, accelerated, and well-organized work.

Effervescent Tablets Tube Filling Machine is a well-acknowledged equipment that enables packaging of effervescent tablets into tubes. Their unique design supports the packaging to place tablets one after another inside a tube prior to placing stopper.

2.What are the prime applications of Effervescent Tablets Tube Filling Machine?

Effervescent tablet tube filling machines are well proven technology that offers excellent features meant for packaging of effervescent tablets.

There are some promising aspects of Effervescent Tablets Tube Filling Machine while you deal with them, for instance:

1) This modern technology provides the best services for achieving an effective packaging of tablets in their individual tubes.

2) Their well-acknowledge functions spontaneously improves the quality of manufacturing units.

3) Effervescent tablet tube filler machines decrease manual manpower and time consumption.

4) They facilitate an appropriate filling of tablets prior to release as finished products.

5) The filled tubes are capped according to product and user specifications.

3.Do you know the advantages of Effervescent Tablets Tube Filling Machine?

1) Effervescent Tablets Tube Filling Machine are best way of packaging effervescent tablets and similar products that are intended for pharmaceutical, health and food industries.

2) There are some supplementary features of Effervescent Tablets Tube Filling Machine that you’re likely to come across. For instance, detection and rejection tab helps you in detecting error when tablets are thought to be less filled or in case of missing and losing stopper.

Effervescent tablets packaging- Picture courtesy Bright Shine

3) Effervescent Tablets Tube Filling Machine also deals with tablet counting which provide 100% accurate results. The sensor of machine detects exact and right number of effervescent tablets into the tube. Thereby, automatically place a stopper soon after detecting presence of tablets in a tube.

4) This machine requires 1-2 operators that efficiently cut down the extra expenditure on human workers. Not only this, but it can also deliver a significant extra quantity of work more precisely in a short period of time. The tablets fall aligned into the tube followed by a stopper. That’s it.

5) Effervescent Tablets Tube Filling Machine is designed to work at a constant speed without any breaks, day -off, or holidays. Therefore, entire execution process results in a great performance with more repeatability options than humans.

4.What are the key features of Effervescent Tablets Tube Filling Machine?

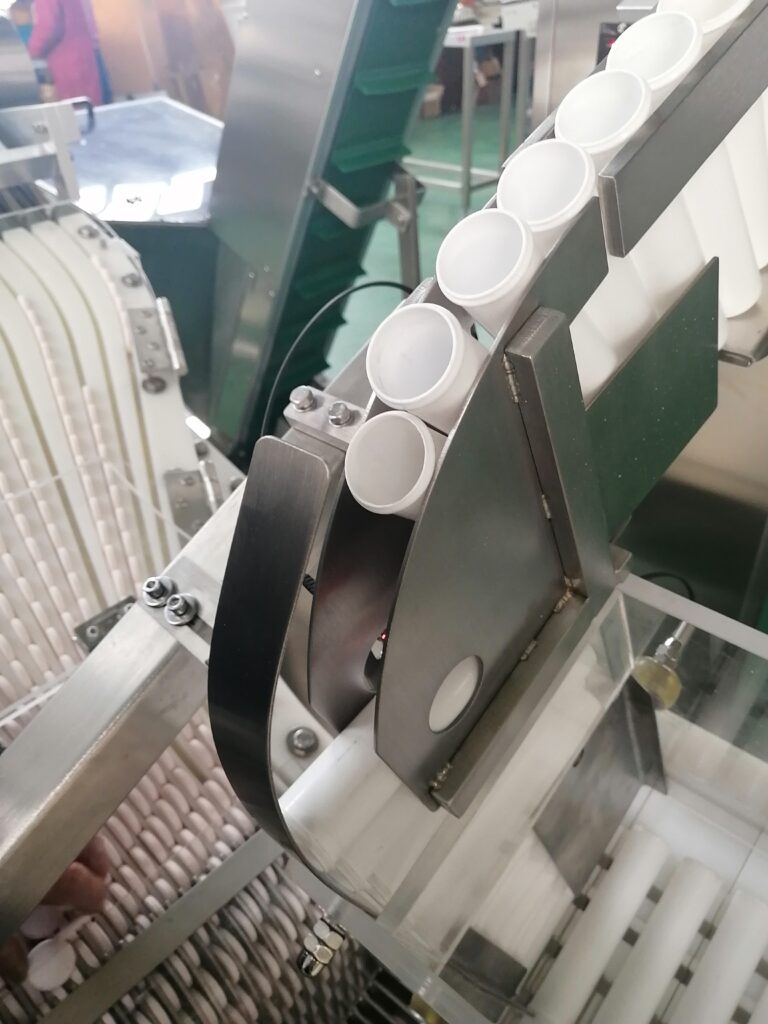

1) Cap Vibration system: A vibrating system of machine facilitates capping that are already arranged on rack for plugging on tubes. The process of loading caps on hopper can take place either manually or automatically.

Cap Vibration System

2) Effervescent tablet feeding system: You need to place tablets into the hopper either manually, automictically or using vibration system for packing.

3) Tube Feeding System: The tube feeding unit is designed to permit tube into hopper by help of vibrating system that automatically send it to rack. The direction of tube should be examined just before placing into a hopper.

Tube Feeding System

4)A Cap Pushing System: This system allows a capping process to plug a tube bottle automatically.

When you get an optimum number of tablets into a tube bottle. The system will automatically detect the presence of tablets and press the cap to close the tube. If there is no tablet or missing of tablet, system won’t let capping process.

Cap Pushing Process

5)Electronic Control Section: An electronic control selection provide a power to machine to operating essential functions. Effervescent Tablets Tube Filling Machine is basically controlled by

1) PLC (programmable logic controller)

2) Cylinder

3) Stepper motor with multifunction alarm-system

Electronic Control Section

5.Why Effervescent Tablets Tube Filling Machine is crucial for the manufacturing unit of industry?

Every successful industry utilizes Effervescent Tablets Tube Filling Machine due to following reasons:

1) The filling of effervescent tablets takes place in accordance with principle of rotation. In this way, it will lessen the labor count and improves productivity through an excellent automated system.

2) The structure of Effervescent Tablets Tube Filling Machine is based on modular concept. It carries a very few components hence make it easy to operate as well as effortless maintenance.

3) A highly advanced system of Effervescent Tablets Tube Filling Machine increases the accuracy ratio and cost-effective packaging process of effervescent tablets.

4) It offers an appropriate line integration that ultimately provide ‘all in one’ solution for manufacturing of effervescent tablets.

6.Do you know the packaging criteria of effervescent tablets?

The packaging of effervescent tablets is done in such a manner that they’re protected against humidity. Thus, this is accompanied with use of water-proof tubes made up of plastic, metal, glass, or foil that embody convenient sized strip of tablets.

- Glass Tubes

Glass tube presented with the highest degree protection against humidity. They are seal with metal cap surround with wax, and aluminum foil that commonly offers excellent moisture proof protection when opened or closed repeatedly.

It has ability to exclude moisture upon closing the cap tightly. In mean time, to prevent a premature effervescent reaction, a desiccant is kept ensuring moisture free environment for tablets. As you know repeatedly opening of bottle and using tablets forms greater air space. Therefore, accessibility of a desiccant is essential.

- Plastic Tubes

Plastic tubes packed Effervescent Tablet

The usage of plastic tube for storing effervescent tablets do not provide a greater protection as compared to glass tube, because they are permeable to moisture vapors. They are adequately mean of storage for those tablets that holds average content of hygroscopicity thus satisfactorily packed with moisture proof stoppers. These specialized stoppers are constructed according with plastic tube that contain a pouch of silica gel or other desiccants that preferentially enables the absorbance of water vapor present inside the tube.

- Metal Tubes

Metal tube for storing the effervescent tablets are extruded, smooth, and elegant tubes that are often made up of aluminum. They are popular in European regions for packaging of effervescent tablets. Like glass tubes, they are also impervious to humidity factor and protect effervescent tablets against premature effervescent reaction.

Metal Effervescent Tubes- Picture Courtesy- AllBiz

- Strip Wrapping

Effervescent tablets are now most often dispensed in advanced strip wrapped pouches that is arranged in linear strips and loaded in a paperboard box. Each effervescent tablet is hermetically loaded in its own position and significantly protected against atmosphere prior to use.

Strip Wrapping – Picture couresty -Dreamstime

The packaging of tablets is sealed with four sides while the material is fed from two reels. The product is sealed between layers of foil by temperature and pressure.

Strip Wrapping Process- Picture courtesy - Pharma education

There are multiple packaging materials are available in market for strip wrapping process. Out of them only few materials have ability to protect the effervescent tablets against humidity or physical damage.

- Blister packs

Blister packaging of effervescent tablets are most common primary storing system. Most often effervescent tablets are packed into thermoformed plastic blisters surrounded with foil backing. This packaging requires effervescent tablets to pressed from foil backing by pushing on the blister.

Blister Packaging of Effervescent Tablets- Picture Courtesy-InfoBloom

The packaging must reliable and hard to break. There packaging is fast and provide greater mechanical protection. There are two types of blister packaging, a cold stretch and thermoform blister packaging.

- Aluminum Foils

Aluminum foil is a popular, flexible, and absolute barrier to humidity, gases, and temperature. It is highly non-toxic and impervious to invasion of microbes.

It has exceptional heat conductivity; thus, it is a perfect choice for heat-sealing strip-packaging purpose. The packaging of effervescent tablets should be done in fixed pockets to minimize the inclusion of air.

Aluminum Foiled Packaging of effervescent tablets- Picture Courtesy-Shengli

The aluminum foil packaging machine is connected to effervescent making equipment, sorted by an automatic conveyor belt. Thus, tablets are collected to filling tube via conveyor belt and entire process is operated by PLC.

7.Can you explain the experimental design performed on Effervescent Tablets Tube Filling Machine?

By understanding basic experimental principle of effervescent tablets tube filling machine will help you to operate the system. Thus, this is crucial to identify how it work.

By can simply operate effervescent tablet tube filling machines by following certain specified steps.

Step# 1: Preparation

1) First begin with inspecting the machine as malfunction can affect your procedure.

2) If everything is OK, then switch ON the system.

3) Keep loading the empty effervescent tablets tubes into the hopper of machine.

4) Loading of pre-feeder hopper is also required corresponding to filling requirements.

5) Set the correct filling parameters by feeding on PLC control system using touch screen. For instance, acceleration of production, distance, and number of effervescent tablets for each tube.

AIPAK Effervescent Tablet Tube Filling Machine

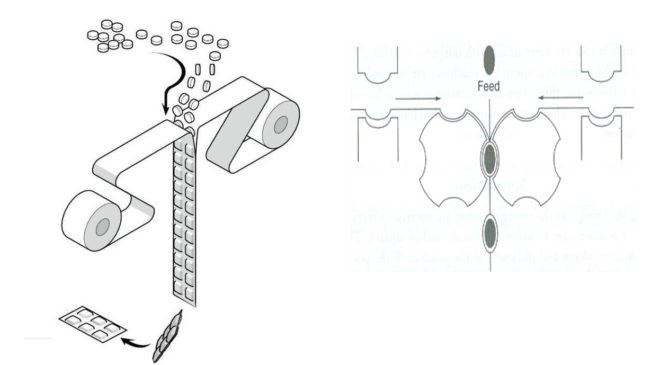

Step#2 Filling

1) Start the filling process by initiating from Control Panel, which will allow the effervescent tablet tube filling procedure accordingly.

2) By the help of hopper tubes comes forward to their right position for filling purpose automatically.

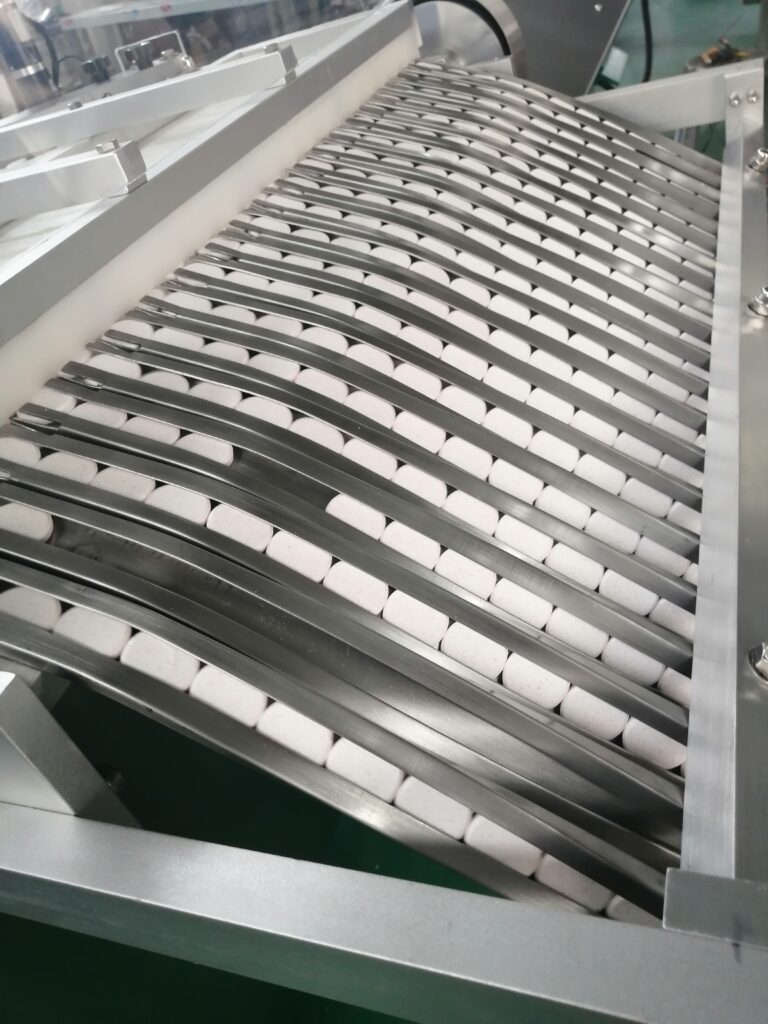

3) There are two channels available on machine that allow tablets where they are calculated and thus supplied to the filling station.

4) Then they are pass by filling tubes that rotate at a high velocity. This results in automatically standing up of tablets and slides directly into rotational waiting tubes gently. This effects of circulating air creates an air cushions that helps the tablets to be at center and protect them from hitting to the walls of tube. This is an extremely gentle process.

5) The speed of erection/standing up of effervescent tablets and filling is adjusted by number of rotations/seconds.

6) Effervescent tablet tube filling machine has a pneumatic stop that facilitates high accuracy in counting of the tablets.

Filling Process- Picture Courtesy : TR Packaging

Step#3 Monitoring Process

1) During this step Effervescent tablet tube filling machine will forward the filled tube automatically toward inspection stage.

2) Inspection process is carried out by monitoring the right number of effervescent tablets into each tube.

3) This process also assures if tablets are perfectly filled before plugging.

4) Non-conformity leads to rejection of tablets tubes.

Step# 4 Capping Process

1) In this process capping over the effervescent tablets’ tubes take place automatically.

2) A sensor identifies if a tube carries a cap. Thereby it allows tubes to forward intended for labelling process and rejects the tablet tubes without cap.

Step#5 Tube Labelling

An automatic self-adhesive labeling applications around the tube is taken place via PLC control. This is fully automatic process, that begins when bottle is received with help of conveyor belts. An automatic detector senses the presence of tube thus labelling process can be attained. If there is no bottle no labelling is done.

AIPAK Effervescent Labeling Machine

8.What are the industrial applications of effervescent tablet tube filling machines?

Effervescent tablet tube filling machines applications are widely used in various field of industrial production. Let have a brief look.

1) Pharmaceutical Industry

Pharmaceutical industry is most popular region that has a wide range of effervescent tube filling machine applications. In fact, if we consider the packaging of effervescent therapeutic dosage forms this machine is mandatory to attain the process. Therefore, all those industries that manufacture such dosage form must come up with this machine. Many companies prefer effervescent tablets tube filling machines because they make easy packaging process and are highly portable.

2) Food and Beverage Industry

The applications of effervescent tablet tube filling machine are seldom in food and beverage industries as compared to pharmaceutical industries. But there are certain specialize foods and beverages that must an appropriate packaging in respective tubes. Use of effervescent tablet tube filling machines ensures that all items are placed accordance with regulatory standards assigned for such tubes.

Effervescent Energy Drink

Nutraceuticals

Effervescent products are promising when it comes to dispense nutraceutical items. The applications of effervescent tablet tube filling machines are common for Pharmaceutical and dietary items, but this field is relatively less popular for nutraceutical products.

Nutraceutical – Picture Courtesy- Nexlife

Effervescent nutraceutical products provide a novel formulation for nutritional supplements. It has ability to hold large content of active nutrients in a single tablet which is easy to swallow with delicious taste. These products offer plenty of health benefits over conventional supplements like tablets or capsules.

9.What is package integrity test for the effervescent tablets?

The package integrity test of effervescent tablets concern with quality, originality, and packaging, for this purpose test is performed on sealed batch to ensure all parameters complies with assigned standards.

For effervescent tablets packaging hermetic packaging is mandatory to attain a reasonable shelf life of two-three years.

The test procedure involved storing of packages under given temperature and severe humidity. Though this test is not practically successful due longer test time such as 2 to 3 months.

10.How effervescent package integrity test is performed?

Packages comprising effervescent tablets are kept in a test chamber at constant temperature of 37°C with 80% of relative humidity for 3 months. If products show stability and no moisture content after being stored for three months, then batch is considered as satisfactory for final marketing process.

11.How accelerated integrity test is performed?

To perform accelerated integrity test, you do not require multiple steps procedures and time expenditure. The following procedures of integrity testing are robust, fast and reliable:

1) Vacuum under-water test

2)Detection of trace matter within seal

3) Purging by detectable gas

4) Seal Inspection using Infrared

5) An Electronic Airtightness tests。

12.What are major classification of Effervescent Tablets tube filling Machine?

The effervescent tablet tube filling machine is classified into two types that depends upon wide range of operations

1) Automatic Effervescent Tablet Tube Filling Machines

2) Semi- Automatic Effervescent Tablet Tube Filling Machines

1) Automatic Effervescent Tablet Tube Filling Machines (ONE-STOP- MACHINE)

As name suggests, it is a high speed, advanced form of equipment available in market opt for fully automatic filling purposes that hold number of benefits.

The entire aspect of operation is carried out by an automatic system. You can get auto-load products in an accurate sequence and filling process take place according to fed program.

The automatic series of effervescent tablet tube filling is also capable of offering auto-capping services for entire tubes after detecting the correct filling up of tablets.

Also, their auto-unloading system facilitates the segregation of inaccurate tubes automatically. The effervescent tablet tube filling machine’s control system is run by PLC programs to achieve 100% accurate results. Every step of tablet filling process is extensively monitored by a controlled system. So, you can count this machine even more reliable and effective than other tube filling machines. The presence of high sensor helps in improving the precision as well as automation.

These qualities of effervescent tablet tube filling machines take it to the next level.

AIPAK Automatic Effervescent Tablet Tube Filling Machine

2) Semi-Automatic Effervescent Tablet Tube Filling Machines

Semi-automatic, effervescent tablet tube filling machines can be operated by manually or automatically.

This machine allows to examine and run most of important parameter by self-operation. In simpler words, not all parameters are meant to run by an automatic system. They offer accurate, reliable, and high quality of effervescent tablet tube filling process.

This machine is ideal to run a small number of packaging. However, you can not consider it suitable for larger scale effervescent tablet tube filling.

Before, buying effervescent tablet tube filling machine you must need to consider the type of automation you required for packing effervescent tablets. So, you need to be careful when make to right choice especially for specific model you’re purchasing.

13.How does semi- automatic effervescent tablet tube filling machine work?

This machine works by following steps

1) Feed the effervescent tablets manually into storage hopper.

2) Enter the screen for auto-arrangement then enter the track when tablets arrive at filling station.

3) Similarly feed the caps into storage hopper and allow auto-arrangement then to enter the track when caps arrive toward capping station.

4) Machine will finish off the process of loading the effervescent tablets into tube bottles, capping, and releasing the tubes automatically.

14.What are main technical limitation of Effervescent Tablets tube filling Machine?

The technical limitation of effervescent tablet tube filling machines include:

1) This machine can entertain those tablets which are larger in size, though you will find technical difficulties when it comes to smaller tablets.

2) Effervescent tablet tube filling machine is not simple to operate like other tablet filling machines.

Therefore, to operate the system of effervescent tablet tube filling machines you need to undergo an extensive training from provider companies. In case of troubleshooting, you need to contact them, and customer support guidance will be provided to a trained technical staff.

3) As you’re well-acknowledged about this advanced form of technology for filling effervescent tablets into their respective tubes.

Therefore, the initial cost of effervescent tablet tube filling machine is extremely high than other conventional machines.

15.Do you know the technical specifications of effervescent tablet tube filling machines?

Before purchasing any machine, you must know the technical specification that you need for your objective.

The prime technical specifications of effervescent tablet tube filling machines are:

- Net Weight:

The Net weight of this machine should be approximately 600 to 100kilograms.

- Filling Range:

The filling range criteria of this machine must be in between 10 -30 pieces/tube while 10-80 tubes/minute.

- Power Supply:

Their power supply range must be 1.5kw, voltage 220V and frequency needed 50-60Hz.

- Tablet Thickness & Diameter:

The thickness of effervescent tablet to be filled into tubes should be 3-8mm and diameter range should be 12-30mm.

- Air Pressure:

The required air pressure limit should be 0.6Mpa with volume around 0.28 m³/minute.

16.Can you connect effervescent tablet tube filling machine with additional accessories?

Yes! you can easily integrate the effervescent tablet tube filling machine with other important parts required for packaging procedure include:

1) Effervescent tablet pressing device:

An effervescent tablet punching/pressing machine is a modern equipment used to press the granular material required for manufacturing of effervescent tablets. Not only this, but machine has also adopted different dosage formulations such as an aromatic or washing tablets and crucibles etc.

Therefore, after manufacturing effervescent tablets this machine can be integrated with effervescent tablet tube filling machines.

2) A package Machine:

This is a specialized machine that meant for packaging only effervescent tablet into each respective tube. This is an efficient machine that improves and delivers tablets into their assigned packaged form thus, it helps in improving accuracy and productivity. This machine also plays an important part at production unit of manufacturing process and for efficient function this is also integrated with other machines that involved in effervescent tablet tube filling process.

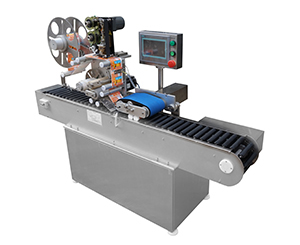

3) A Labelling Machine:

After achieving an accurate number of effervescent tablets into tubes with sealed cap, then it is time for final step of labeling process. A labeling/tagging machine is well-equipped device that works automatically to label surround tubes.

17.What are the features of Effervescent Tablets tube filling Machine?

The prime features of effervescent tablet tube filling machines are as follow:

1)Automatic Tube Feeder:

In this section, effervescent tablets are loaded into tube feeder which enables further operation toward tube filling channels.

2) Automatic Vibratory Filling of Effervescent Tablets:

The filling of effervescent tablets is taken place accordance with principle of vibration that can improve efficiency and reduce labor cost.

3) Automatic Cap Sealing:

This section automatically detects the lining of effervescent tablet tube in right position then places the cap over the tube soon after detection. If tablet is missing or tube location is inappropriate machine will automatically detect and reject the sealing process. It enables automatic counting properties that generate 100% accurate results.

‘OK’ tubes are further taken for an integrated labeling device.

Automatic cap sealing- Picture Courtesy -Ruian

4) PLC + HMI Controlled System

Human Machine Interface (HMI) transmit with Programmable Logic Controllers (PLCs) to achieve and demonstrate information for operators to understand. These control systems are important to function like examining and tracking the performance of process in a sophisticated way. For instance, switching ON and Off, Machine acceleration/rotation/temperature and other important parameters required to run a system.

18.What are the benefits of taking effervescent tablets?

Indeed, regular oral solid dosage forms such as tablets, capsules are extensively demanding medications for treatment. But they have slow absorption and distribution rate.

Therefore, to overcome this problem many pharmaceutical companies’ approach to develop various drugs in the form of effervescent tablets.

Effervescent tablets have significant benefits such as:

1) They are suitable alternative for regular tablets for those patients who suffer with swallowing problems.

2) When you drink effervescent tablets, it increases your body hydration due to with greater liquid intake.

3) Effervescent tablet distributed uniformly preventing any limited concentration of ingredient at certain part of digestive tract, thereby less chances of causing irritation and lead to cause an efficient ingestion.

4) Effervescent tablets are delicious in taste due to added delicious flavor and sweeteners than regular tablets that often accompanied with metallic taste.

5) As we know regular tablets slowly and steadily dissolves in stomach thus provides lower absorption of nutrients. Whereas effervescent tablets are pure-bio available formulation.

19.What are disadvantages of effervescent tablets?

- Most of excipients utilized in the manufacturing of effervescent tablets are relatively expensive.

- The manufacturing process of effervescent tablets requires special production unit.

- The composition of effervescent tablet are high in sodium or potassium content. These contents are incompatible for those patients who suffers cardiac failure or cardiac insufficiency.

- Some of effervescent tablets are bulky in comparison with tablets or capsules.

- Sometimes it is extremely difficult to obtain a pleasurable taste for those drugs which hold unpleasant flavor.

- Sometimes temperature or active ingredient cause a longer disintegration time up to five minutes.

20.What are the other types of effervescent tablet filling machines?

The effervescent tablets can be packed by different types of machines such as:

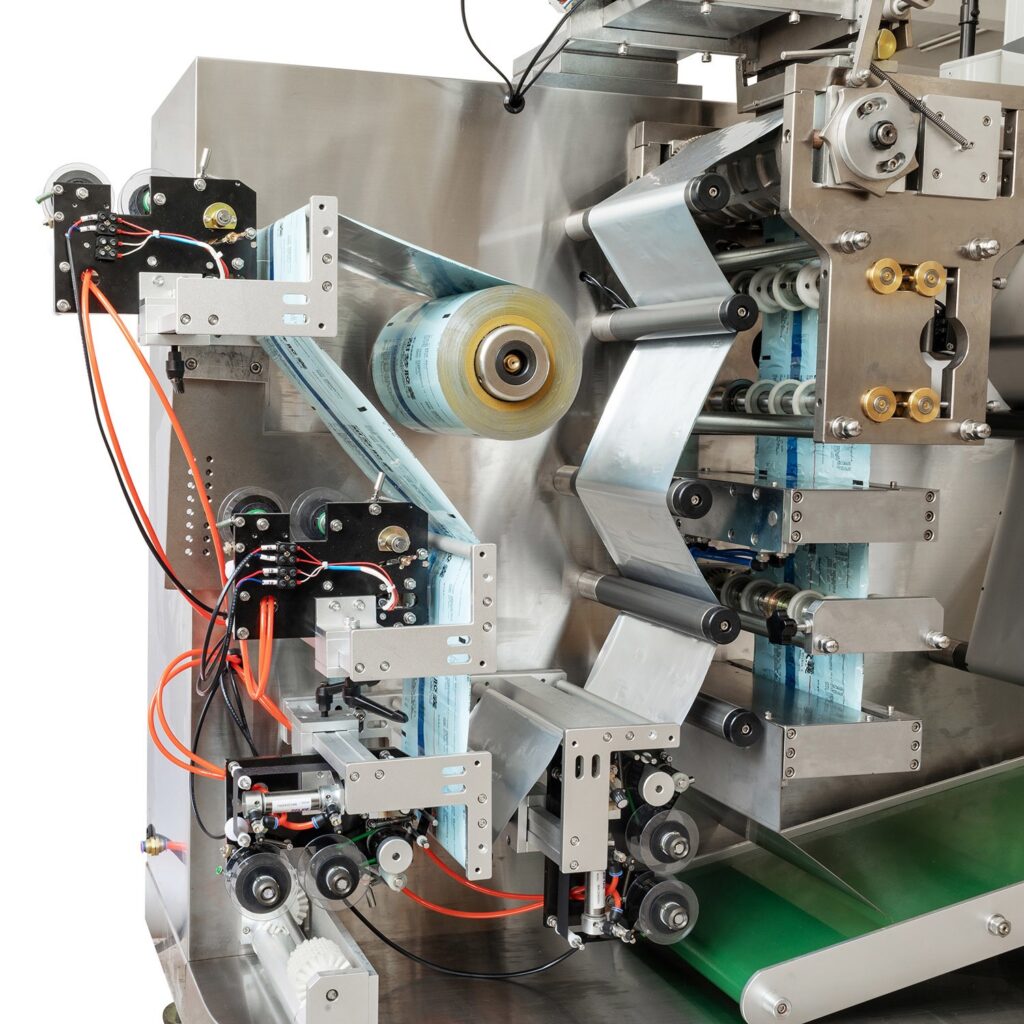

1) Effervescent Tablets Strip Packing Machine

This machine facilitates four-sided sealing of pharmaceutical ingredients by using foil pack which is extensively known as strip pack. This type of packaging produces high quality of airtight sealing.

Effervescent tablets strip pack machines- Picture Courtesy- Ruian

2) Tube Labeling Machine

Tube labelling machine is developed for labeling of a particular tube. This machine complies with GMP standard made up of stainless steel consist of long conveyor belt that allow feeding of tablets by PLC control system.

3) Tablet Candy Roll Wrap Up Machine

This machine is developed to wrap various pieces of effervescent tablets into an aluminum foil or laminated material. Entire process of this machine is run by PLC control system. It is flexible and reliable machine which is easy to operate and maintain.

This machine is fully automatic system that alarms in case of complexities such as absence of tablets, wrapping paper or technical fault.

4) Effervescent Tablet Paper Wrapping Machine

Effervescent Tablet Paper Wrapping Machine- Picture Courtesy- ECVV

This machine is developed to wrap a large piece of effervescent tablets into a wrapping paper. The entire movement of this machine is adopted by PLC controlled touch system. This is an easy to operate system carrying reliable and stable functions. This machine is made up of stainless steel and meets GMP requirements.

5) Effervescent Tablets Packing Machine

Effervescent tablet packing machine is single roller machine that continuously generates the packing of pressed effervescent tablets. This machine is developed to assist the packaging of tablets in a row inside the tube prior to plugging.

6) Desiccant Filling and Sealing Machine

Desiccant filling and sealing machine are utilized to get an automatic feeding of desiccants and seal the pouches.

This machine is broadly comprising of feeding, washing, product counting, detection, and other functions.

7) Effervescent Tablet Press

An effervescent tablet punching/pressing machine is a modern equipment used to press the granular material required for manufacturing of effervescent tablets. Not only this, but machine has also adopted different dosage formulations such as an aromatic or washing tablets and crucibles etc.

21.Do Effervescent Tablets tube filling Machine complies with GMP standard?

Effervescent tablet tube filling machines are extremely effective machines designed and incorporated with well- equipped machine contemplating pharmaceutical cGMP standards that allow superb accessibility toward machine usage.

22.What are the dissolution criteria of administering effervescent tablets?

When you put effervescent tablet in water it liberates carbon dioxide in air and encourages disintegration. It takes couple of minutes to dissolve tablet completely in water and forms a miscible solution.

The liberation of carbon di oxide is outcome of a chemical reaction which takes place between carbonate and organic acid (prime ingredients of effervescent tablets) such as sodium bicarbonate and tartaric acid.

Therefore, presence of high content of alkali salts, the ingestion process accompanied with temporary elevation of stomach pH in turns, fast gastric emptying time, and rapid intestinal absorption of drug ultimately maximum bioavailability.

23.What happened when you chew effervescent tablets?

Most often over the counter drugs are taken via cutting, chewing, as whole or by crushing. But this way to taking medicine is not suitable for specific drugs as they required proper swallowing. Effervescent tablets are not intended to swallow as whole.

The require a specific amount of time to dissolve completely in water. This tablet may harm you if you do not follow the proper instructions of drug administration mentioned on the label. Because it may affect the rate of absorption and action.

24.Do you know how to manufacture of Effervescent Tablets?

The manufacturing process of tablets takes place via direct and compaction by granulation method. While traditional method of wet granulation is seldom used process.

The granulation process plays a significant role in manufacturing of effervescent tablets. Granulation process may help to shape a fine free- flowing powder into dust-free granules that can be progress more easily for further process.

25.Can you manufacture effervescent tablets using dry granulation method?

Dry granulation process is only effective for non-effervescent and less reactive effervescent products. Hence this method is not preferable to run effervescent tablet manufacturing process.

Roller compaction is most popular method of dry granulation which is achieved by using two counter rotational rollers. These roller helps in compaction of powder particles then compressed them into a ribbon form. This ribbon is further treated with milling to get a desirable particle size. Roller compaction process provide high yield output, easily operated, and require minimal supervision.

26.What is formulation methodology of effervescent tablets using wet granulation method?

Wet granulation is extensively used method of agglomeration at manufacturing sector of pharmaceutical industries. This process simply includes the wet massing of powdered particles with granulating liquid, followed by wet sizing and eventually drying.

27.What are important steps of wet granulation?

Important steps involved in the wet granulation are followed:

- A) Mixing of a drug and their excipients.

- B) Preparing a binder mixture.

- C) Combination of binder mixture with powder mixture to create a wet mass.

- D) Drying of wet granules.

- E) Addition of disintegrant, glidant, lubricant with mixed granules.

28.What are advantages of wet granulation for manufacturing effervescent tablets?

The advantages of using wet granulation method for effervescent tablets are as follow:

- A) It allows noticeable mechanical handling to powders without losing the quality of mixture.

- B) This method improves powder particle size and sphericity.

- C) This method facilitates the uniformity in powder density.

29.What are the common degradation factors for effervescent tablets?

The common factors behind degradation of effervescent tablets are as followed:

- A) The packaging material have ‘0’ vapor transmission rate. Therefore, moisture can be easily entered into the packaged material and may cause degradation.

- B) when the seal of foiled pouch is compromised too much dust from manufacturing area may entered inside packaged material or malfunctioning of machine may not wrap the product appropriately.

- C) When the ingredients of effervescent tablets do not comply with each other, it results unpredictability in final product. Therefore, each staff much learn the fundamental of raw materials for successful effervescent products.

30.Do you know the type of binders used for binding effervescent tablets?

Effective binders used to for effervescent tablet is Polyvinylpyrrolidone or PVP.

PVP can added blended in dried as well as wet form. Furthermore, Mannitol, water, or PEG 6000 can also be employed as an effective binder.

31.What is an estimated cost of Effervescent Tablet Tube Filling Machine?

When you buy a fully automatic machine it will cost you higher compared to semi-automatic machine. Moreover, price of machine is also dependent upon type of production unit. For instance, mostly bigger production of effervescent tablets machines is very expensive as they hold a significant production capacity. The average worth of effervescent tablet tube filling machine varies from 17,000 to 50,000 $.

32.What are consideration factors that you keep in mind before buying effervescent tablet tube filling machines?

Before buying tablet tube filling machines you should give your best to determine your specific needs.

The important consideration points are as follow:

A) Size and Design

Before spending money on buying machine, it is important to keep machines size and design in your mind. Because machine size determines how much capacity it carries to fill a particular size of tubes within assigned duration. For example, in some cases, you will require a pretty small unit for filling effervescent tablets for smaller production batches. But, for reasonably larger batches for excessive commercial use, you must opt for a larger effervescent tablet tube filling machine. Additionally, you must select a right machine and design that can perfectly fit into your workstation. By following such factors, you can significantly enhance the reliability and efficiency of machine.

B) Speed

Now a days, to expand your business successfully among your competitors you need to quicken your production rate. You can develop your business growth efficiently with powerful, accurate and relatively faster production equipment’s.

This is a perfect way to get into market!

In a nutshell, you must consider speed or rate of effervescent tablet tube filling before buying an effervescent tablet tube filling machine.

C) Power consumption

Purchasing and establishing a suitable production equipment is crucial for manufacturing unit of pharmaceutical industries. As you know that electric consumption is growing rapidly due to increased industrialization sectors.

Whenever you decide to invest money on equipment simultaneously you also consider the remaining areas of reducing expenses. Thus, at this point power consumption comes to play.

Always remember the duration of your machine functioning such as amount of batches production at targeted time. Therefore, you can not ignore the power consumption factors but you can control it.

In a nutshell you should find a model that can utilize moderate power consumption with maximum output. Never go for those machines that utilize more and more power to give you results.

D)Usability

To buy a machine is a fundamental factor and you need be well acknowledged about the machine you are looking for.

Always try to test all operating systems and verify if you can operate the system or not.

In other words, you should look for user friendly equipment’s before buying any equipment.

E) Used Or New

Entrepreneurs who are looking to initiate a production unit should always start up with an excellent quality equipment’s. Ideally you should purchase machine from those suppliers who provides you the equipment warranty with proper documentations. Moreover, the status of the company in the market must be checked.

F) Manpower Engagement

The manpower engagement for machine must be identified as it can increase your cost by operating the system.

The cost factor is very important behind determining the success of any business. Therefore, it is mandatory to look for those machine that requires less manpower engagement. For instance, a semi-automatic effervescent machine requires much dedicated staff than fully automatic effervescent tablet tube filling machines.

33.Is Effervescent Tablet Tube Filling Machine meet the targeted quality standards?

Quality standards are established by regulating bodies therefore it is necessary for all equipment to meet all the reequipments necessary for health and safety sectors. The effervescent tablet tube filling machines complies all the necessary standard assigned by governing bodies. Such as

1) C.E Quality Standard

CE marking suggests this machine has been properly evaluated by a manufacturer and considered to meet European union safety, health, and ecological preventive requirements. CE marking is mandatory for product manufacturing unit.

2) cGMP- Quality Standard.

The Certified Government Meeting Professional designation ("CGMP") is intended for manufacturer and suppliers whose work is mainly governed by the assigned standards by federal government. For instance, manufacturing unit, packaging, quality control etc.

3) Food and Drug Administration Quality Standard -FDA

The effervescent tablet tube filling machines complies with FDA standard that ensures machine is significantly fit to proceed all operation that meets all health and safety standards.

4) International Organization for Standardization -ISO

An ISO is best known standard required for every well-established system. ISO organization is comprising of over 160 countries. ISO certification provides standards of the machine or system to improve overall efficiency of product.

Effervescent Tablets Packing Machine Related Products

Effervescent Tablets Packing Machine Related Posts

Effervescent Tablets Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling MachineCartoning Buyer's

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours