See Complete Automatic Cartoning Machine Importing Guide in 2025

Whatever industry you are in, you may see that cartons are one of the most visible and important packaging forms.

Actually, cartons are not only prominent nowadays on the shelves of super markets, but also critical containers in fast moving consumer goods handling, presentation and transportation.

A machine called automatic cartoning machine will help you erect your cartons, fill your product and seal your product that saves your manual cost as well as simplifying your working process.

Today you will see the complete automatic cartoning machine importing guide to assist you choose the most suitable one to help you skyrocket your business.

Do you want a carton-forming system?

If so, then you are studying the accurate guidebook for it. Today, a cartoning machine has performed an incredible deal for a lot of companies concerning stock packaging. It's been and nonetheless is the most common shape of product packaging.

Carton- Photo Credit: Wallpapercave.com

For example, pharmaceuticals, food processing, and chemical industries extremely depend upon this sort of packing for a potent, stable, and safe manner of transferring of their merchandise into the marketplace.

So it is essential to have an intensive understanding of the cartoning machine before buying so that you could have the high-quality out of it.

1.What is an Automatic Cartoning Machine?

An automatic cartoning system is an incorporation of light, mechanical, electric, and air high-tech systems installed to a pc to manage, guide, control, and adjust its functioning. Electricity is the main and crucial part of the automatic cartoning system function. Because it’ll give power to all the electric circuits which provide movement to all different processes. For example, moves of various components are in particular designed to supply certain preferred functions consisting of round movement at specific times from the mechanical part.

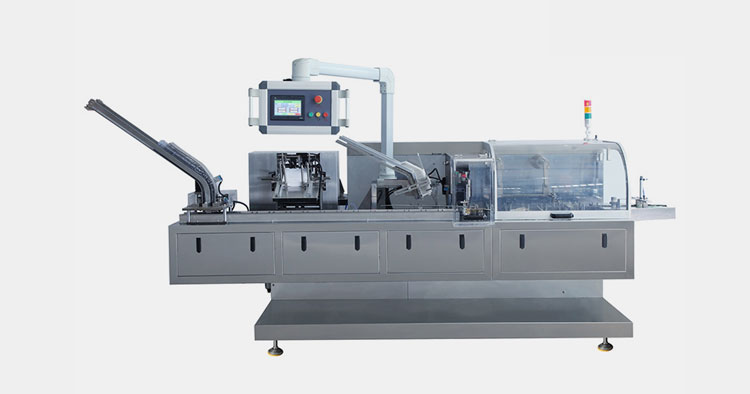

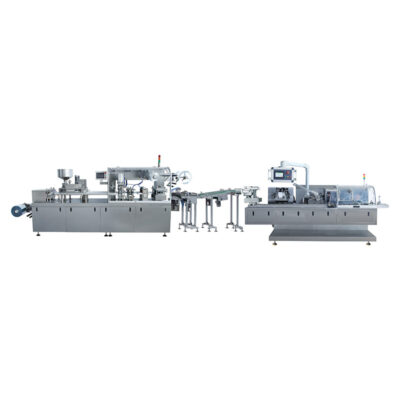

AIPAK Automatic Cartoning machine

Since the system is automatic, to regulate operations almost every control is under a computer control machine.

2.What is Carton made of?

These cartons are specially manufactured in the shape of paperboard from paper, also you can use thin layers of polyethylene (plastic a). A thin layer of aluminum is also added in shelf-stable cartons.

Shelf-stable cartons created of

- 74% of paper

- 22% of polyethylene

- 4% of aluminum.

3.What Products can be packed by the Automatic Cartoning Machine?

Basically, different kind of products can be stored in these cartons. Cartons can be shelf stable or refrigerated cartons. Both of them have the ability to stored different type of products.

Products in shelf-stable cartons include gadgets along with

- Milk

- Wine

- Soup and broth

- Soy and grain milk

- Juice

Juice Cartons

Refrigerated cartons contain about 80% paper and only 20% polyethylene. In refrigerated cartons following type of objects can be stored.

- Milk

- Juice

- Cream

- Egg substitutes

- Soy and grain milk.

Milk Cartons

4.Where is the Automatic Cartoning Machine Widely Used?

Automatic Cartoning Machine is as an essential part of every industry these days either your setup is large or small you need to pack your end product in its best way. So, the Automatic cartoning machine is widely used in the following industry

- foodstuff confectionery

- medicine

- cosmetics

- sundry goods, etc

Food Cartons-Photo Credits:NewDeli.com

Medicine Cartons-Photo Credits:Pinterest.com

5.How will you benefit from an Automatic Cartoning Machine?

There are many factors to keep in mind before making an investment in an automatic cartoning machine, mainly for fast-paced businesses, and which have busy packaging operations. While they can be pretty expensive but they offer a ton of advantages in your business and operations in the long run of your business. Here you'll find few reasons you must put money into an automatic cartoning machine.

Increased productivity

Using an automatic cartoning machine permits employees to your packaging operation to use packs quicker than they could manually. Your selected container may be flawlessly taped just with the push of a button. This permits your operations to pack things efficiently, at the same time removing the soulless challenge of manually packing boxes. In addition, there may be a human error in manual packaging procedures that could disrupt the operation or flow of your packaging line. With automatic cartoning machines, there's much less chance for packaging errors, causing much less downtime to your packaging operation.

Consistent sealing

When you are packing manually, it’s hard to be steady with the quantity of tape being used, frequently causing taping. In this approach, along the tape used your cash may be wasted. And let’s now no longer forget, if the tape in use isn’t eco-friendly, over taping can make a contribution to hazardous waste within the environment. And most importantly, over taping is unprofessional in appearance. Implementing an automatic cartoning machine into your packaging operation removes the ability of over taping and grimy finishes, in a result creates a professional-looking bundle. When the usage of an automatic cartoning machine, the proper quantity of tape wanted may be set, automatically sealing the container - developing a neat package deal for the end-user.

Compact Layout

Compact and affordable is the layout higher than the product dealing with the sort of kind of packing. A minimal and realistic plan is the utmost and crucial step that allows it to be deliberate such that manipulates open area and usage of assets. Automatic Cartoning machines deliver unmatched best quality consistency and control over the alternative available devices within side the market. For larger tasks, consistency is important and might improve branding openings, allowing greater noteworthy adaptability of the plan. Automatic Cartoning machines are established and industry-prestigious for looking after even the maximum fragile objects with such care that no system can ever do except it.

User Friendly

Easy to control is a system higher for the consumer in addition to the commercial enterprise itself. An automatic Cartoning machine is commonly easy to make use of and has low aid needed. Also, the device is compact and eventually, you may put it to use for exclusive businesses. Most assist some tape widths and on this way may be applied for one of kind items. Since it's an auto cycle moreover self-vacuum is getting used in the framework to get rid of the improvement of residue within the side of the device. This wipes out the need for added maintenance or protection which may be high-priced and terrible.

The benefits of automatic Cartoning machines are extensive spectrum and that they may be used within side the smarter and higher approaches indeed. There isn't any doubt that through the usage of the automatic Cartoning machine and auto procedure the operational productiveness will increase to the most level. Along with consistency, distinctive requirements, and higher asset the executives, now no longer handiest we obtain the higher challenge manufacturing price but, you may additionally manipulate the finances easily.

Save Cost

As noted in the factor above, making use of packaging manually can cause over-taping. Due to this, you have to face the wastage of material, which may be prevented by using an automatic cartoning machine easily. With this thing you can lessen cost with the aid of using shrinking wastage of material; cost is reduced with the boom in productivity of your business. After all, time is what matters in end.

Lower risk of injury

Repetitive stress harm dangers are reduced while applications are sealed automatically in place of manually. Automation eliminates a variety of the input generally required through a human to finish repetitive guide tasks, and an automatic cartoning machine is unarguable.

Dimensional Weight Charges

Less the dimensions much less the quantity and the gap it takes. Since among the main corporations with inside the courier corporations try to utilize dimensional weight estimating on everything in their floor bundles. Reducing the size is immediately associated with reducing the bundle size. Organizations and commercial enterprises those days want to rethink the way where they can bundle their items. Many different studies have been performed and determined 40% of the everyday package deal is wastage of the gap. Squandered area implies more transportation costs. Fortunately, the accurate size of the packaging on Demand resolves this issue, as you could make the littlest container manageable for the aspect you are dispatching. When you've got extra wastage it's the method it will additionally boom your price this means that much less profit. The accurate packaging in line with the bundle on-call solves such issues. This way, you could have the smallest feasible bundle.

Reduce broken returns

With the boom in steady sealing that automatic cartoning machines bring, a more potent seal is made. This facilitates to lessen the danger of the packaging peeling off at some stage in shipping and storage, securing the product inside. Now, we’re no longer announcing that integrating an automatic cartoning will clear up this trouble completely, as both the seal and carton need to be taken into consideration for security. However, automatic cartoning machines will truly contribute to a more potent cartoning. Have a look, how we helped any food corporation in reducing their failed shipments with a brand new answer for his or her machine.

AIPAK Automatic Cartoning machine

6.Why Automatic Cartoning Machine Special Important to the Pharmaceutical Industry?

In very few cases, a medicine producer can keep on manufacturing without packaging, that's a key procedure for a drug to go into the marketplace. Pharmaceutical Cartoner features as an alternative to manual cartoning with better efficiency. Although it's been more than 30 years since the first pharmaceutical Cartoner becomes made by the Chinese, as compared with the different pharmaceutical systems, improvement in the Cartoner industry isn't up to the mark. Despite a few mind-blowing signs of progress, the technology and advertising increase in China’s pharmaceutical cartons devices nevertheless have an extended manner to head because of many causes. Therefore, each producer and customer of the pharmaceutical cartoning system must inquire about its improvement and increasing trend.

There are a few necessities to be met for cartoning machines in pharmaceutical business applications. As mentioned in Article 4603, GMP compliance standard, the drug wrap page published with statistics identical with label content material needs to be controlled primarily based totally on labels. In different words, the outer bundle and labels of drugs have to be controlled in an equal manner. The necessities for cartoning devices are due to that of an outer package deal of drugs.

It appears that the cartoning machine with high-generation, exceptional, and high-velocity is a capacity enterprise, specifically the spotlight of time in the pharmaceutical enterprise which comes after GMP transformation, taking part in the big capacity marketplace and having the cap potential to march into markets apart from the pharmaceutical corporation, like food, every day chemical substances and pigment, etc. At the identical time, various derivation of cartoning machines and the producing and promoting of packing lines could be a brand new trend.

7.How many Types of Automatic Cartoning Machines are there?

There are many types of Automating Cartoning machine, you can explore them below:

Continuous Mode Automatic Cartoning Machine:

This is a high-velocity automatic cartoning machine that can be used in high-paced production lines. You can mainly use it to make solid stocks & cartons regularly, hardly requiring special handling arrangements. -Electromechanical system to promote all higher-velocity operations of the system.

In the following, you can check out the characteristics of an automatic continuous cartoning machine.

- The machine has some delicate detectors that can impulsively cease impact or completely stop the functioning of the system

- To provide power for most operations, there are Pneumatic and electrical components

To displays fault alarms automatically, displays, and counters for easy monitoring, a touch screen system is being used.

Automatic intermittent cartoning machine

The automatic intermittent cartoning machine is very similar to the automatic continuous cartoning machine. The automatic packaging mode is about 150 times slower. Due to the machine stopping and providing time for the packaging cycle speed is being reduced. You have the choice to use it for different kind of applications like injection trays, medicine cards, bottles, pills, ointments or rectangular objects.

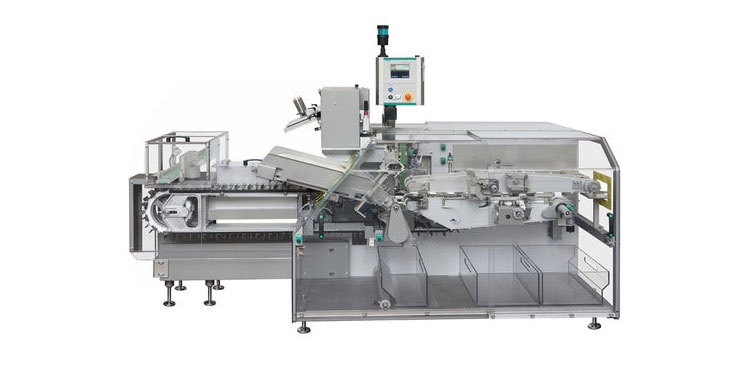

Automatic intermittent cartoning machine-Photo Credit:Medicalexpo.com

In the following you can check out the characteristics of an automatic intermittent cartoning machine:

- It has a full servo system/automatic control system or devices and a coincident belt drive system except a lubrication set up.

- To help feed and pack the box there’s an adjustable servo motor

- It has a servo system that can be operated on the touch screen configuration.

Vertical automatic cartoning machine

Vertical automatic cartoning machine feeds your merchandise or products and boxes of the feeding system vertically. It can handle a variety of products and is very suitable for processing cans, channels, and bottles. You can have its best usage in industries like the cosmetic pharmaceutical, and food industries.

In the following you can check out the characteristics of vertical automatic cartoning machine:

- The closely packed and flexible layout permits you to change the function at your desire to meet most industrial functioning.

- It combines the partial changes of modern technology format, which can realize the vertical feeding position of the carton.

- The upright position reduces the risk of product damage and eliminates long delays in the feeding system.

Vertical automatic cartoning machine

Horizontal automatic cartoning machine

The product is inserted into the box from the side of the box in horizontal cartoning machine. You can use this type of system for different kind of proposes like to pack food, including cakes and pizzas, vacuum-packaged coffee, or rice.

In the following you can check out the characteristics of horizontal automatic cartoning machine is:

- Electrical components such as the PLC control system of best brands are used to monitor the system.

- The man-machine interface is also used as a reliable working system.

- The non-vertical direction enhances the balance of the machine and is therefore easy to operate.

Horizontal automatic cartoning machine-Photo credits:zhpackagingmachine.com

But other than this we can divide cartoning machines into two other major categories. Now you can discover them in below:

1.Semi-Automatic cartoning machine

2.Automatic cartoning machine

Semi-Automatic cartoning machine

A semi-automatic cartoning gadget does now no longer has an automatic feeding machine that makes the operations simple for you. Lack of automated feeding machines lowers the throughput in addition to the velocity of manufacturing. Apart from that, you may want to hire many workers to have a powerful manufacturing unit. It has precise layout capabilities that permit it to deal with the cartoning of pouches, pouches, blister packs, bottles, sachets, and tubes. You can also additionally get decent layouts that permit the inclusion of different parts which include Box conveyors, Automatic folding machines, and Carton magazines with the capability of opening and then flapping the last carton.

Following are the advantages of the usage of a semi-automatic cartoning machine

- It doesn’t have high maintenance cost.

- Settable with protection gadgets which include HMI saves the unification of the gadget.

- It is versatile and lets in the cartoning of a big range of sizes and shapes.

- You may hire the usage of the semi-skilled worker because it does now no longer require using professional worker.

Fully Automatic Cartoning Machine

This is an extra intricate tool that does not require the involvement of an excessive amount of human help in its working. You can utilize it for the subsequent operations:

- Supplying of packaging materials.

- Folding the ears of the carton.

- Erecting the carton to the proper position.

- Ink-jet printing of the cartons.

- Hot spraying.

- Product insertion.

- Carton last.

- Stamping dates.

An automatic cartoning gadget is the satisfactory kind or sort of cartoning machine to seize all of the functionality of an automatic cartoning machine. It has the cap potential to test the unification of the carton to make sure that it is of the top standard.

It is available entire along positive add-ons which include:

- Inkjet printers

- Brochure insertion machine

- Folding systems

- Hot soften gluing systems

Automatic Cartoning machine products

On pc control unit all the tactics of the fully automatic cartoning machine rely upon. The control unit adjusts controls and all of the functions of the system with very less labor or human assistance.

8.Are there any Drawbacks of Automatic Cartoning Machine?

There are many benefits of Automatic cartoning machine but with every advantage there’re some drawbacks. Some of them are described below:

Centralization:

Automation entails a few degrees of centralization in packaging procedures. While generally, this is effective in area allocation and efficiency phrases, ensuring your operation can transform to a new, centralized configuration. For example, a distribution center with loads of loading docks might not deal with case sealing in a single or crucial location.

Capital investment:

An automatic cartoning machine can value everywhere from numerous hundred dollars to in extra of $50,000. Equipment can occasionally be leased or paid for on an installment basis.

Maintenance expenses:

In addition to the capital cost, the cartoning system calls for ongoing maintenance and generally a stock of substitute parts. These prices aren't usually extremely high. However, you have to be aware of them before move forward.

Application challenges:

Some distribution and production operations do now no longer effortlessly lend themselves to cartoning automation. Examples which are every so often — however now no longer usually — hard to automate:

- Refurbishing and restore operations, in which each bundle is distinctive.

- Extremely huge or extraordinarily small delivery cases.

- Extremely light-weight pallets/unitized loads.

- Irregularly designed pallets/unitized loads.

- Harsh indoor or outside environments that corrode system.

Extremely decentralized packaging operations GWC Packaging makes a specialty of cartoning automation, with alternatives that in shape each budget and throughout the target.

9.What are the Main Components of Automatic Cartoning Machine?

An automatic Cartoning machine collects different kinds of systems comprising mechanical, electrical, pneumatic, and delicate parts. They are all mixed to function collectively in this way so one can produce, remodel, or substitute efficiently mechanical power generated from the machine. Indeed, an automatic cartoning machine is a configuration of an extensive range of parts and components. Apprehending the basics of every element is critical in selecting an appropriate automatic cartoning engine. Again, it's far crucial to notice that this machine has loads of components and parts.

However, you'll find the details of the essential elements here. With such treasured information, you must think about the fundamental operating principles of an automatic cartoning machine.

In below principle components of automatic cartoning machine are described:

- Control Panel/section

- Electric Motors & Electric Panel

- Lubrication machine

- Carton Pack Tooling & Pneumatic

- An ink-jet printer

- A safety machine

- Conveyors, Rollers, Guide Rail and Carton Chute

Control Panel/Segment

By the appearance of recent advancements in automation, incorporation of numerous structures has been found out decreasing price involved in assigning people to have a check on such procedures. This makes one of the very critical parts of an automatic cartoning machine. The complete system has been set upped and layout to a control module (PLC) and selected automation. Control section of Automatic Cartoner can carry out and check the following:

- Number of cartons according to control

- Number of merchandise according to-p.c. Control

- Print control

- Electrical and fluid indicators

- Product Placement Control

Touch Screen of an automatic cartoning machine

Is it feasible to manipulate the entire automatic cartoning system from the panel?

Yes, it's far feasible to control and modify the manufacturing system from the control phase.

By the apprehension of an average person, the control panel is the system's 'brain.' Siemens has made it is less complicated with the aid of using combining the frequency-converter, PLC with an interface HMI. It permits your worker to command, cancel even automatically to prevent all operations if it is vital. The Human machine interface also lets the worker to alternate the framework or variables and necessities of the manufacturing system to obtain a preferred set factor inside a specific duration. Besides the managing aspect, the main panel is likewise set upped to alarm worker if breakdowns from different system’s components.

Electric Panel & Electric Motors

The crucial things for the automatic cartoning machine are utilized at the electrical panel. The electrical device additionally energies the pneumatic device to operate. You should not forget that all of the connections to the complete cartoning machine are contain by the electrical panel. You can assume that this segment is the 'heart' of the automatic cartoning machine considering all- mechanical devices and electric circuits are set-upped at this point.

What is an electrically-powered motor?

A tool that interchanges electricity into mechanical power.

Let’s just clarify it more, and an electrically-powered engine is a tool that utilizes electric power to produce a required motion.

Note: All movements and actions generated with the aid of using a cartoning machine while functioning or running is purely assigned to the working of motors.

Research and improvement on engines have spread out many programs which might be instrumental in developing an exceptional feature inside the automatic cartoning machine. Like automatic Cartoning machines, many different machines or motors are also properly confined and located at the lowest segment. The chains, bearing, gears, belt, and shafts are quite simply related through the gearing axis, help axis to the machine center-shafts to transmit movement to required sections.

For example, To reciprocal motion servo-pushed cams are coupled on motors. Yet, it no longer always suggests any engine may be replaceable used as margin for some other segment.

These motors are made with complete characteristics and features, i.e., RPM, phase, energy delivery, and watts. These functions make exceptional motors serve distinctive features in the carton forming system. It is critical to notice the above while addressing motor breakdown.

Also, the rate of those motors may be managed with the aid of using the operator through the HMI to adjust the parameters set on the frequency converter. These motors are layout with in-constructed safety gadgets such as

- Clutch breakers

- Torsion-overload protector.

From the gearing machine they can spark off disconnection of the principle power motor due to shielding system components through stopping harm because of overload. The motors create it feasible for the conveyor to run, cartons to transport alongside the rail, urgent mechanism paintings on the carton percent tooling, etc.

Automatic Lubrication System

The existence-time of belts, gears and bearing is decided through lubrication consistency. As in advance stated automatic cartoning machine is a device which is electro-mechanical. As most other mechanical structures, the shifting components have to be nicely lubricated to obtain top-rated performance. Service existence of belts, gears and bearing are pressurized through excessive temperature, moisture, humidity, and contamination.

Hence, absence of lubrication usage could badly affect the preservation price & time, and system production. Automatic cartoning machines are structured with an auto-mated lubrication system that guarantees processing operations are properly run. The lubrication system is mechanically sparking off to deliver a good enough quantity of proper lubricant to the shifting components. However, the appropriate lubricant must be furnished to the gadget throughout preservation interval.

This lubrication solution offers a possibility to grow productiveness and uptime. It additionally reduces hard work prices and extends preservation and restoration intervals.

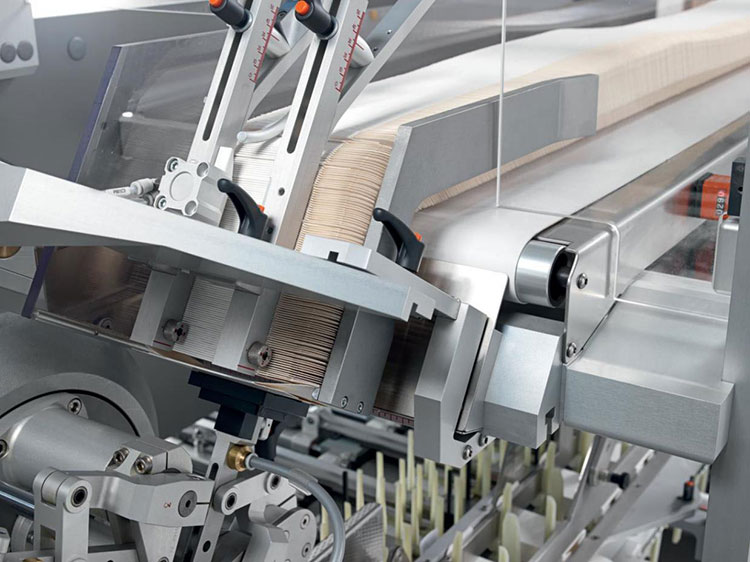

Cartoning Pack Tooling & Pneumatic System

Carton Suction Station

In this segment the system run over the actual cartoning. With the aid of using the pneumatic machine vacuum suction runs and comes into play while extracting empty cartons to start the cartoning procedure. The carton storage room is the segment used to place cartons. It includes front and back segments established with the front & middle plates. The middle-plate is movable, making it adaptable to the length of the carton. In front of a carton-forming system, you are capable of seeing the carton feeding.

Cartoning Pack Tooling & Pneumatic System-Photo credit:IMAgroup.com

On the opposite side, both of the brackets are mounted with a long hollow point. As a result, it can shift from one side to another. This lets in adaption in line with carton characteristics. Exactly in the front of the storage room there is a press tool. Alongside the sucking procedure, a sign is produced with the aid of using the carton press if blocked, broken, or deformed carton is made to impact an instantaneous forestalls of the system.

Other components systematically go with the drift from feeding section in which the main product is inserted into the carton. Before ultimately finishing on the carton in the last phase, the leaf folder is connected with the conveyor belt

An Ink-Jet Printer

A completely purposeful cartoning system must be mounted with an ink-jet printer, which must have writing alternatives minimum of 3 minimal rows. As the stock can be in the carton, it's even sensible to have pertinent records approximately the product. For example, expiry or manufacturing date or information you want to tell your consumer. These records being revealed must be high-quality as you have no idea what disagreement arises from clients or stores within the marketplace.

Inkjet Printing-Photo Credit:Packagingdigest.com

A Safety System

Since any gadget is an non-living object. It's far vital to heed precautions while dealing with them. That is the reason you must take good enough and complete protection techniques that include any system. One critical safety machine is the emergency or stop buttons that must be located interval alongside the different sections of cartoning machine for ease of getting right of entry in case of any disaster. Usually, this button is stressed out from the critical offering the system on a NC path while operational or now no longer.

If any of this buttons is in or drive, the system must now no longer provoke any system except the problem is solved and the button is pulled out. In that example, it will become NO means normally open, which means the energy circuit is open of that system. However, upon noticing uncommon packaging, undesired movement emanating from the shifting components, it's far advocated to push any effortlessly available emergency button.

This will reduce down energy deliver to the system. In the procedure, you will stop the disaster or losses. Another protection degree must be located in the right grounding and earthing of electrical circuit functioning within the cartoning system. This is to keep away from unsightly surprising from the frame of the gadget. The cartoning machine must be properly structured to lessen un-guarding the operator to empty threats and risks. It must have a properly special segment in which human operators can operate effectively without issues.

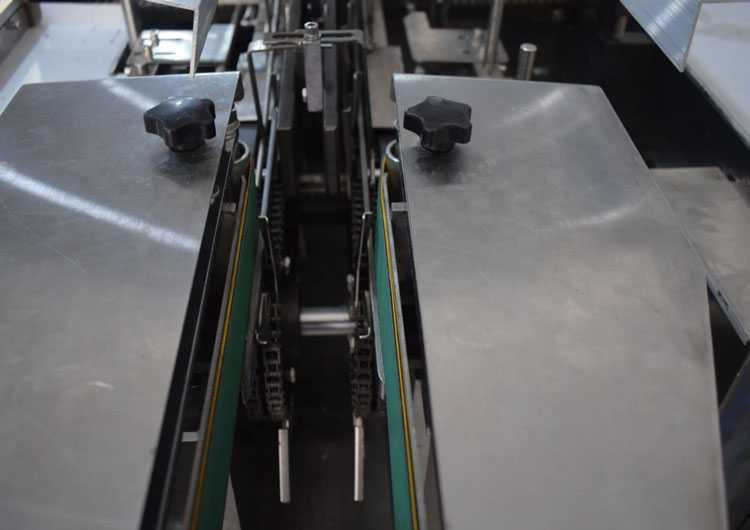

Conveyors Rollers, Guide Rail, and Carton Chute

Conveyors are connected with rollers to sell motion of cartons from one section to the opposite. They pull out their movements from operating motors which might be torque with an equipment box to decide the velocity of those motors. This element is crucial for the working of the cartoning machine due to the fact as soon as the product is packed; the carton travels to the subsequent phase. At the same moment, it's far being instructed with the aid of using the rail forming the path.

Parts of Automatic Cartoner- Photo Credit:hinebenmach.com

Depending on the producer, an automatic cartoning machine may be structure with a concept of shaft. The completely packaged stock is fallen from the cartoning machine for additional packing into larger packing containers for saving or transfer. You should always request for product guide from your producer of the system because it’ll help you to recognize each issue of the system.

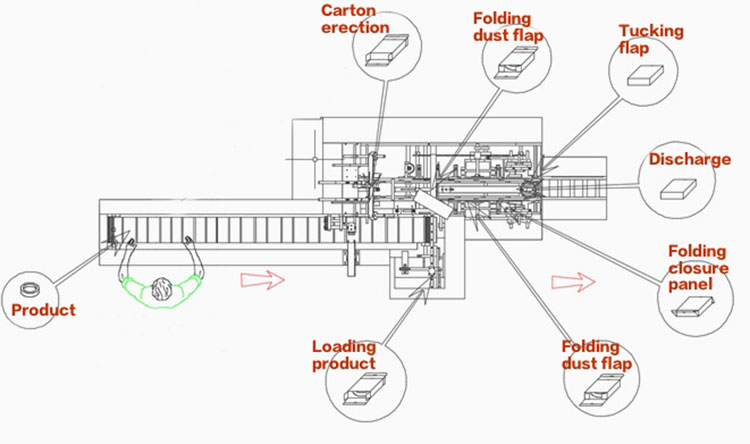

10.How does Automatic Cartoning Machine Work?

After having a brief knowledge about the basic components of Automatic cartoning machine, now it’s time for you to study about its working principle.

Step One: Carton erection

At first, the system automatically selects the clean cartons and shapes them to make an excellent carton. Through this process, the formation of the carton process is started. After this, the erection of the carton happens, and then you can position it inside the proper direction for packaging.

Step Two: Ear folding

In this segment, for accurate tucking in the system will fold the ears of the carton in practice. After this, before putting the end product ears can be folded and fix them collectively to protect the lowest part of the carton.

Step Three: Production Insertion

In the automatic cartoning machine, if the content/product can trickle down you have to insert your products from the upside of the cartons at the lowest.

Step Four: Carton Closing

After putting your end product, you may be packed the cartons by tucking them with inside the tongue into the carton. Depending on the sort of product, you may pack it through glue or staple to enhance the safety of the seal.

Step Five: Inkjet Printing and Date Stamping

In the last section, labels are printed down at the cartons and stamping the dates at the carton. It is going by a quality assurance level earlier than liberating it for storage.

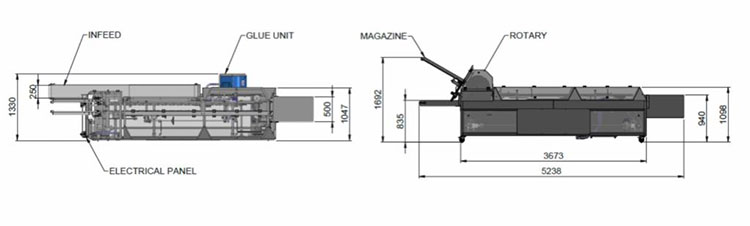

11.What are the Main Parts of Semi Automatic Cartoning Machine?

A semi-automatic cartoning machine does now no longer have an automatic feeding machine that makes the operations simple for you. Lack of automated feeding machines lowers the throughput in addition to the velocity of manufacturing. Now let’s discuss the few important parts of semi-automatic cartoning machine:

- Infeed Point

- Electrical Panel

- Glue Unit

- Grippers

- Magazine

- Rotatory

Main Parts of Semi Automatic Cartoning Machine- Photo Credit:tfreemantle.com

12.How does Semi-Automatic Cartoning Machine Work?

Semi-automatic Cartoning Machine makes use of the way for pulling the cartons as a result feeding them into the star wheel. Then, after the goods to be packed are placed into the carton manually, flap folding the cartons shall then be turned around to flap folding mechanism from the star wheel. After finishing touch of such procedures and output, the star wheel shall rotate the finished cartons to the carton push-out mechanism.

13.Are Blister and Inject able vial having the Same Packaging Method through Automatic Cartoning Machine?

No, blister and inject able vial have not the same packaging method through automatic cartoning machine. Because both of them haven’t the same structure and design. Inject able vials are more fragile, so we need to pack them carefully than blister ones.

Inject able Vials

14.Which Quality Standards should Automatic Cartoning Machine meet with?

When searching for an automatic cartoning machine, you must have to make sure that it approves the standard requirements. Acquiescence to the quality requirements saves you from drawing on by the producer.

It additionally makes sure that the system is secure to apply and has extended longevity. The primary quality standards that the system should comply with are:

- UL certification

- GMP great compliance

- cGMP compliance

- CE compliance

- ISO certification

15.How to Troubleshoot Common Problems of Automatic Cartoning Machine?

When you use a cartoning machine, you can revel in a few troubles within the packaging process. Here are a number of the issues you would possibly encounter and their solutions.

- Flat blanks being drawn:

Solution: To discover any breakdown at the system you can use a photoelectric sensor which includes multi-pulse automation and it’ll alert you. You will prevent the system at once and deal with the trouble earlier than it becomes uncontrollable.

- Restricted pace of the system:

Solution: To help in adjusting the pace makes the drugging board layout even affordable.

- Poor balance of the system after operating at an excessive velocity for an extended time

Solution: Use automatic control structures so one can permit an easy operating of the system.

- Carton Breakdown because of blockage or leakage air at the sucker tubing

Solution: The sucker tubing can be unblocked and changed the leaking sucker tubing with the right one.

- Aging Suckers

Solution: change the older suckers with new suckers

- Improper adjustment of the carton

Solution: For quicker and more suitable transportation of cartons you can prevent the system and modify the shop room

- Inextricablecarton blanks

Solution: Stop the system and eliminating the inextricable carton blanks and changing them with higher ones.

- Poor placement of vacuum suction

Solution: Maintains the vacuum complete vacuum machine and changes it correctly.

Cartoning Machine Related Products

Cartoning Machine Related Posts

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours