Salt Filling Machine: The Complete Buying Guide In 2025

The use of salt is realized in almost all kinds of food manufacturing whether on industrial level or home kitchen. That's why, it is packed in powder form to facilitate easy usage. For its safe and hygienic packaging, Salt Filling Machine is designed.

This machine has innovative features to carry out the precise filling of salt into various forms of packages. It has high production efficiency s well as resilience. You just need to understand it's structure, working principles, and maintenance procedure to go with it. So, be ready to discover all these aspects of a Salt Filling Machine in this guide!

1.What Is A Salt Filling Machine?

Aipak Automatic Powder Filling Machine

Salt filling machine is also known as salt packaging machine which is designed with advanced technology to pack salt into various packages such as bags and containers. It is made up of 304 stainless steel which is fully corrosion resistant.

It uses automatic technology to carry out salt packing by first weighing the precise amount of salt and then filling it into packages. The machine is highly durable and flexible that it can withstand demanding operating conditions.

2.Write Down The Benefits Of A Salt Filling Machine?

Salt filling machine has numerous benefits which can uplift your business growth. Let us know them one by one!

Enhanced Efficiency

Salt packaging machine efficiently working- Picture Courtesy: landpack.com

Salt filling machine is highly automatic that each step is fulfilled by the machine. It ensures consistency in production process which ultimately leads to high output. Thus, it offers efficiency and reduce time waste.

Precision

Precisely filled salt and condiment bottles- Picture Courtesy: myborosil.com

Quality of both the material as well as packages is always considered paramount. Similarly, salt filling machine has high precision in weighing and filling which ultimately leads to the perfect finish.

Flexibility

Various types of salt packaging- Picture Courtesy: designandpaper.com

Salt filling machine is versatile enough to deal with various sizes and forms of packages such as bottles, pouches, and containers etc. It helps manufacturers deal with eclectic packaging formats.

Convenient Usage

Convenient usage presentation idea- Picture Courtesy: blog.sasken.com

The machine has user-friendly way of operation with intuitive touch screen penal. The emergency stop is suitable for abrupt shut down. Moreover, the machine has minimal downtime as a result of which it requires low maintenance.

Cost-effective

Salt filling machine has automatic technology to carry out salt packing. It reduce the reliance on operator for manual work. Hence, labor cost is removed.

3.Explain The Working Principles Of A Salt Filling Machine?

Salt filling machine follows simple working principles which can be easily understand by looking into the underlying details:

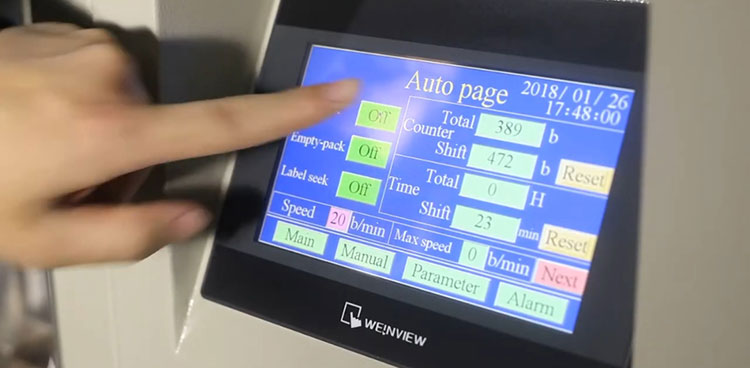

Machine Setting

Machine setting- Picture Courtesy: coretamp.com

The process begins with setting of machine where operator need to adjust the parameters of machine which include adjusting the speed, amount of salt, and sealing temperature etc.

Salt Loading

Salt loading- Picture Courtesy: coretamp.com

Now, the bulk of salt is loaded into the hopper of machine. It can be done either manually or by attaching a feeding station for continuous and efficient production.

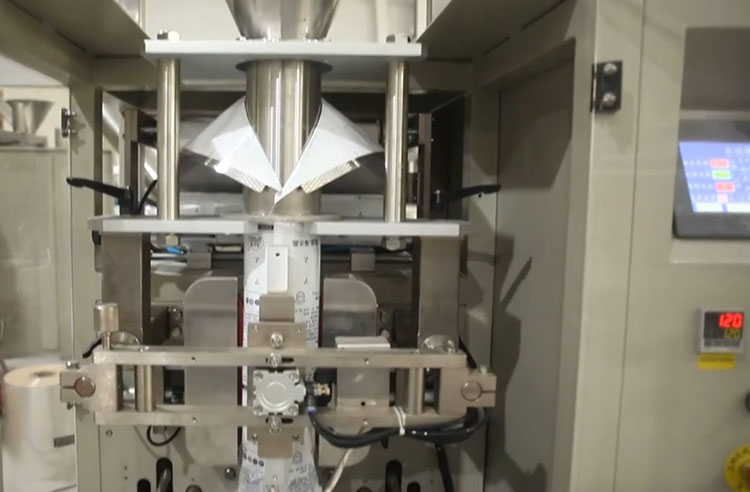

Bag Forming

Bag forming- Picture Courtesy: coretamp.com

As soon as the machine is turned on, film is unwinded from roll and folded to form a bag. Depending upon the type of bag such as pouch or sachet, the bottom and sides of package are sealed tightly.

Salt Weighing

Salt weighing- Picture Courtesy: coretamp.com

Moving forward, the machine intelligently measures salt as per the amount fixed in control penal.

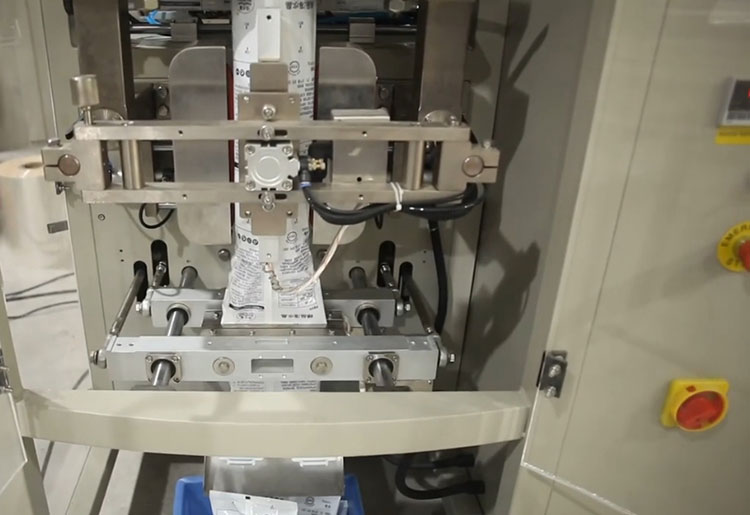

Salt Filling

The weighed amount of salt is then precisely filled into the formed bag. Over and under filling

Bag Sealing

Bag sealing- Picture Courtesy: coretamp.com

Once the bag is filled with salt, it is properly sealed to retain the quality of salt until it reaches consumer.

4.What Are The Types Of A Salt Filling Machine?

There are several types of a salt filling machine which are explained below:

| 1 | Filling System | Auger filling machine |

| Volumetric cup filling machine | ||

| 2 | Automation Level | Automatic filling machine |

| Semi-Automatic powder filling machine | ||

| 3 | Orientation Type | Linear filling machine |

| Rotary filling machine |

Auger Filling Machine

Aipak Semi Automatic Auger Powder Filling Machine

Auger filling machine is a specialized equipment used to fill the fine and powder with poor flowability. It has a swirling auger inside the hopper whose constant rotation led the material fall in bottles through filling head. The size of the auger hopper vary significantly and depends upon the buyer preference. Moreover, this machine has best precision ratio in terms of weight.

Volumetric Cup Filling Machine

Volumetric Cup Filler

Volumetric cup filling machine is another type of machine which is designed to fill the containers with a predetermined quantity of material through its displacement from machine rather than through weighing. It is ideal for free flowing powders like salt.

Automatic Filling Machine

Aipak Automatic Powder Filling Machine

Automatic filling machine is an advance machine with high efficiency and outstanding performance. It is made up of robust structure with 304 stainless steel as major construction material. It consists of a hopper, control unit, conveyor, electric cabinet, stable feet, and filling head etc. It carries out the salt filling into bottles and jars automatically where no human intervention is required.

Semi-Automatic Filling Machine

Aipak Semi Automatic Auger Powder Filling Machine

Semi automatic filling machine is another equipment tailored to meet the packaging needs of medium scale industries. It has precise structure with major parts including a hopper, control system, and conveyor etc. Although, the machine is cost-effective and user friendly, however, it requires manual intervention to proceed with salt filling into containers.

Linear Filling Machine

Solid Filling Machine Linear 4 heads weigher- Picture Courtesy: levapack.com

Linear salt filling machine is another type of machine with linear system for salt packaging. In contrast to rotary machine, it has linear structure which facilitate the efficient processing of salt, it's weighing, and precise filling into containers. The machine can process single bottle at the time. Its main components include stainless steel linear weigher, filling head, control unit, and electric cabinet etc.

Rotary Filling Machine

Aipak Multihead Weigher Rotary Packing Machine

Rotary Salt filling machine is unique design equipment with a rotary packaging unit. It can process multiple packages in a single run there by enhancing the production efficiency. The machine has heavy-duty structure with several components including main frame, multi-head weigher, rotary worktable, and conveyor etc. The machine is specialized in processing premade packages which reduce time spent on forming bags.

5.What are The Applications Of A Salt Filling Machine?

Salt filling machine has diverse uses due to the machine's flexibility to deal various types of powder and granulated products. These applications can be better understand by looking into the underlying details:

Spices Manufacturing Industry

Various spices in bowls- Picture Courtesy: proagri.co.za

Spice manufacturing industry revolve around the production and distribution of various spices and condiments such as black pepper, red chilli, turmeric, and salt. As most of these spices are available in powder form, so, they need proper packaging which is done through a salt filling machine.

Beverage Industry

Beverage powder doypacks

You may wonder how salt filling machine is suitable for beverage industry but it is true. Powder beverages such as milk shake powder, cola powder, and milk powder are all packed in bottles and packages by using this machine.

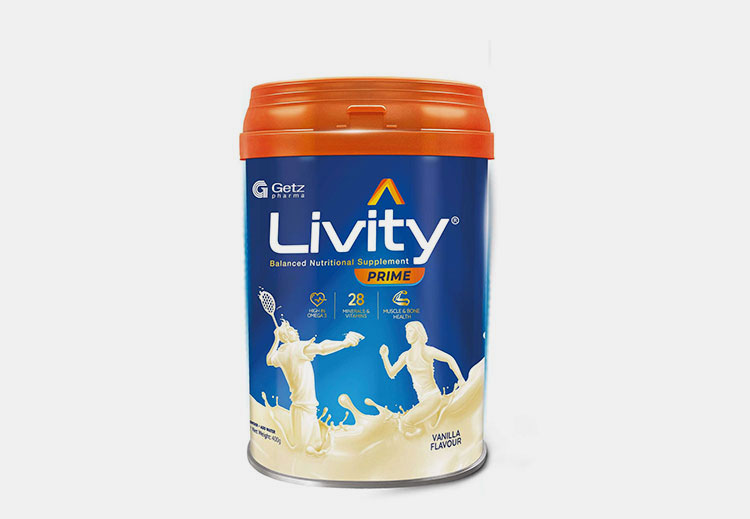

Pharmaceutical Industry

Nutritional supplement powder bottle- Picture Courtesy: mrmedicinemart.com

Pharmaceutical industry is an area where special attention is paid to hygiene and quality retention. That's why, powdered medication is packed by using an effective machine known as salt filling machine.

Cosmetic Industry

Cosmetic powders presentation idea- Picture Courtesy: dominique.com

Among other applications, cosmetic industry is a notable field where beauty care products such as face powder, glitters, eye shadow, and nail powder etc. These all products are easily filled by using a salt filling machine.

Agriculture Industry

Agriculture field seed sowing- Picture Courtesy: safigroups.net

Salt filling machine can also be used in agriculture industry for the packaging of seeds, agro chemicals, fertilizers, and pesticides etc. The enclosed environment of machine greatly helps in reducing the material escape from machine.

6.What Type Of Packages Are Made By Salt Filling Machine?

A salt packaging machine can deal with eclectic packages design which are enumerated as under:

Bottles

Bottles are small containers with narrow neck, a lid and usually with no handle. They are either made up of plastic or glass and reliable for salt packaging due to cost-effectiveness and convenient handling.

Jars

Various spices jars- Picture Courtesy: racks.lk

Jars are glass containers which are often large size with capacity to hold bulk of salt. Reputable brands may use jars for salt instead of other types of packaging to better retain the quality of salt.

Cans

Cans are metallic containers usually made up of aluminum or sheet of steel. They are suitable to keep the salt fresh for longer, therefore, can be easily filled by a salt filling machine.

Doypack

Sea salt doypack- Picture Courtesy: rezopt.com

Doypack is also called stand-up pouch pouch which is a flexible bag made up of plastic and laminated foil. It has flat bottom upon which the pouch can stand upright. It can hold large volume of salt and has high resistance to heat, light, and moisture.

Pillow Pack

Salt pillow pack- Picture Courtesy: behance.net

Pillow pack is a plastic bag used to hold salt in medium volume. Such packages have a pillow shape forming with top, bottom, and back sealing and are easily packed by a salt filling machine.

Stick Packs

Salt stick pack- Picture Courtesy: harrisonssauces.com

You may have seen stick packs of salt during traveling or in a restaurant. They are small size, long, and narrow packages holding single serving salt which are supported by a salt filling machine.

7.How To Maintain A Salt Filling Machine?

Maintaining salt filling machine is essential to ensure its long lasting performance. For this, you need to conduct a thorough maintenance schedule which include:

Operator maintaining a machine- Picture Courtesy: reverscore.com

Cleaning:Make sure to clean your salt filling machine regularly by removing salt, residues, and any other leftovers. It will keep your machine free from corrosion and bacteria.

Parameters Setting:Before starting the machine, always remember to set the parameters as entire working is based on it.

Lubrication:Lubricate the movable parts of machine on weekly basis. It will help in mobilization of frequently usable parts and promote smooth functioning.

Parts Changeover:Check for wear and tears in your salt filling machine which may appear in seals, gaskets, and O-rings etc. Replace the damaged parts with new ones.

Structural Adjustment:Structural adjustment refers to the setting of various parts of machine which is necessary each time when you are about to operate your machine.

8.Factors To Consider When Buying A Salt Filling Machine?

When buying a salt filling machine, it is necessary to consider several factors in order to get the most compatible one. Some of these factors are listed below:

Type of Machine

Vertical sachet packing machine- Picture Courtesy: iapack.com

As we have discussed earlier, that salt filling machine are of various types. Therefore, it is necessary to know about each type after which you will be able to choose the right one. For instance, semi automatic machine require operator intervention, while as, fully automatic machine is highly efficient. Similarly, auger filler is suitable for fine salt in contrast to volumetric filling machine for free flowing material.

Filling Mechanism

Auger filler- Picture Courtesy: penglaichina.com

Salt filling machine has two types of filling mechanisms namely auger filling and volumetric filling. Therefore, it is crucial to know the fluidity level of material you are producing and then opt for the relevant machine.

Quality Compliance

Quality compliance icon- Picture Courtesy: globalcompliancenews.com

Checking the quality of a salt filling machine is the most crucial aspect during its purchase. Thus, you need to be very careful in this regard for which you can check the quality standards such as ISO, GMP, and FDA etc.

Cost

Cost icon- Picture Courtesy: mckenzielake.com

As there are various types of machines available in market today each has different price. However, you need to look at your budget and decide the one which is suitable for your production.

Conclusion

To conclude, we hope you have found this guide about Salt Filling Machine a helpful one. The importance of the machine is growing with every passing day and the recent automation has further escalated the production efficiency. Moreover, it can support range of packages while having low cost and convenient operating procedure. So, if you are intending to purchase the best machine then don't forget to consider Aipak who offer you topnotch machine with high quality and one year of warranty. For further information please visit our website!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine