AIPAK High-Speed Sachet Packaging Machines – Precision, Flexibility & Reliability

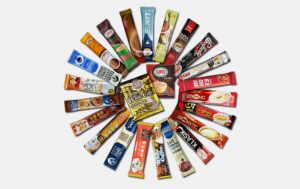

Ideal for powders, granules, liquids & pastes | Supports 3-side, 4-side, spout,

and tear-off sachets | Hundreds of installations worldwide

AIPAK Sachet Machine

AIPAK sachet machine is more than just a packaging device—it is a smart solution designed to deliver precision, efficiency, and flexibility across industries. From pharmaceuticals and nutraceuticals to food, cosmetics, and household products, sachet machines make it possible to package powders, liquids, gels, or granules into single-dose, hygienic, and easy-to-use sachets. With modern designs integrating automatic sealing, accurate dosing, and customizable pouch styles, the sachet machine not only improves production speed but also enhances product safety and consumer convenience.

Possible Sachet Shapes

sachet with several bars

sachet with flat seals

shaped sachet with crosswise corrugation

sachet with standard tear-off cut

sachet with tear-off notch

Why Choose AIPAK Sachet Machines

Versatile for Multiple Product Types– Whether powder, granule, liquid, or paste, one machine handles them all.

Precision & High Efficiency– Servo-driven filling and sealing deliver tight tolerances and high throughput.

Flexible Packaging Styles– 3-side, 4-side, spout sachets, tear-off notches, and multi-shape options.

Fast Changeovers– Quick-die-change system allows format adjustments in minutes.

Hygienic, Maintenance-Friendly Design– All contact parts in stainless steel, tool-free dismantling, CIP cleanable.

Reliable Support & Warranty– 12-month machine warranty + lifetime technical support + global spare parts.

Sachet Machines Industry Applications

AIPAK sachet machines are engineered to meet the needs of diverse industries where precise dosing, hygiene, and product protection are critical. By offering flexibility in pack sizes, materials, and filling options, they ensure consistent quality and efficiency across multiple sectors.

Pharmaceutical Industry

Sachets are widely used for single-dose medications, powders, oral rehydration salts (ORS), and dietary supplements.

Example: Packing paracetamol powder, oral electrolyte sachets, or probiotic powders.

Food & Beverage Industry

Ideal for portion control and convenience packaging of seasonings, sauces, and drink powders. for food &beverage products.

Nutraceuticals & Dietary Supplements

Sachet packs are a preferred format for vitamins, collagen powders, and functional blends that require moisture-proof packaging.

Example: Daily-use vitamin C sachets, collagen peptides, or herbal blends.

Cosmetics & Personal Care

Perfect for sample distribution or travel-size packs of creams, lotions, and liquids.

Example: Sachets of shampoo, moisturizers, face masks, or serums used in retail promotions.

Veterinary & Animal Health

Used for animal supplements, deworming powders, or water-soluble treatments.

Example: Electrolyte sachets for livestock, nutrient supplements for pets, or antiparasitic powders.

Chemical & Household Products

For detergents, cleaners, and agrochemicals that require safe, leak-proof packaging.

Example: Laundry detergent sachets, dishwashing liquids, or water treatment powders.

Sachet Machine FAQ

Q1: What kind of products can a sachet machine handle?

AIPAK sachet machine supports powders, granules, liquids, pastes, and gels—ideal for spices, sauces, shampoo, chemicals, pharmaceuticals, etc.

Q2: What sachet styles are supported?

3-side seal, 4-side seal, spout sachets, tear-off notches, central seal, gusseted sachets, etc.

Q3: How fast is the production capacity?

Typical machines run from 20 to 150 sachets per minute (depending on model, product, and sachet size).

Q4: Is it easy to switch formats / sizes?

Yes. Our quick-die-change system and recipe memory allow format changeovers in minutes.

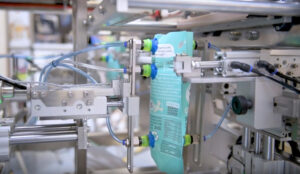

Q5: Can this sachet machine be integrated into existing production lines?

Absolutely. It supports integration with dosing (auger, pump) units, conveyors, labeling, and other packaging equipment.

Q6: Are these sachet machines hygienic and food-safe?

Yes. All parts in contact with product use stainless steel, smooth surfaces, and CIP-compatible design, compliant with GMP / food safety standards.

Q7: What technical support and warranty are provided?

We offer 12 months full warranty (excluding wear parts), lifetime technical support, spare parts supply, on-site service, remote diagnostics, and operator training.

Q8: How long is lead time and how is shipping handled?

Standard models typically ship within 30–45 days. We support sea / air / rail transport and assist with export documentation / customs.

The Buyer's Guide

Sachet Machine: An Ultimate Buying Guide in 2025

Sachet machines are fascinating. They are used to pack wide-spectrum products broadly. If you are completely unfamiliar with sachet machines, then in this article you will read all about the major capabilities of sachet machines.

Our deliver knowledge will expand your understanding of sachet machines that you work with or planning to begin the work. From basic overview to beyond, let’s commence the journey!

1.What is a sachet machine?

AIPAK sachet machine

A sachet machine is a specially designed equipment used to prepare a sachet package that is affixed around three or four sides.

Hence from film to the sachet, every step assures you product safety, security, and freshness.

Ranges from high viscous to solid powders, sachet machines can benefit you as maximum product volume can be filled per sachet saving the packaging cost.

2.What are the industrial applications of the sachet machine?

Sachet machines are equipment that is used to package different materials including lyophilized powder, beauty products, the kitchen holds items, and many more.

At various levels of automation, this product category comprises equipment that forms, fills, seals, wraps, cleans, and packages. Sorting, counting, and accumulating machines are also included in packaging through sachet machines.

Sachet machine is a basic and important equipment for many industrial usages with following applications.

Chemical Industry

Companies that manufacture industrial chemicals include diagnostic chemicals, different types of dyes, chemicals used for research experiments, and household items like washing powder, etc. The sachet machine packs more than thousands of different products in different sizes based on the requirements.

Pharmaceutical Industry:

Sachet machines are an integral part of the pharmaceutical industry which covers the packaging in the streamlined products of mainline pharmaceutics, research, and development, and generic.

Cosmetic Industry:

A cosmetology field is a company that makes cosmetics. The sachet machine fulfills the requirement in packaging everyday grooming items, such as shampoo and beauty creams, as well as those that make a person smell nice, such as fragrances

Agriculture Industry:

The small packets of different items need in livestock production, crop production. The sachet packaging covers the packaging of urea that needs in subsistence agriculture. The machine is also very useful to pack pesticides, herbicides, fungicides, insecticides, and fertilizers which are agricultural chemicals that can be used to control pests and disease or to control and stimulate growth.

Food and Beverage Industry:

The food industry is the largest industry in the world. This machine is useful for packaging from Dairy products, beverages, bakery items, Masalas to grains and legumes. This machine also helps in dairy, juices, baby food, cereal, confectionery, and noodles.

Electronic Industry:

The sachet machine covers the electronic industry to packing the market available hand-free, computer holding items, and others.

3.How will you benefit from a sachet machine?

Because a sachet machine automatically folds, fills, closes, and cuts sachets to a predetermined size. Therefore, very little material is used to package the product.

That’s why material science and industrial engineering have both contributed to packaging innovation through the usage of sachet machines.

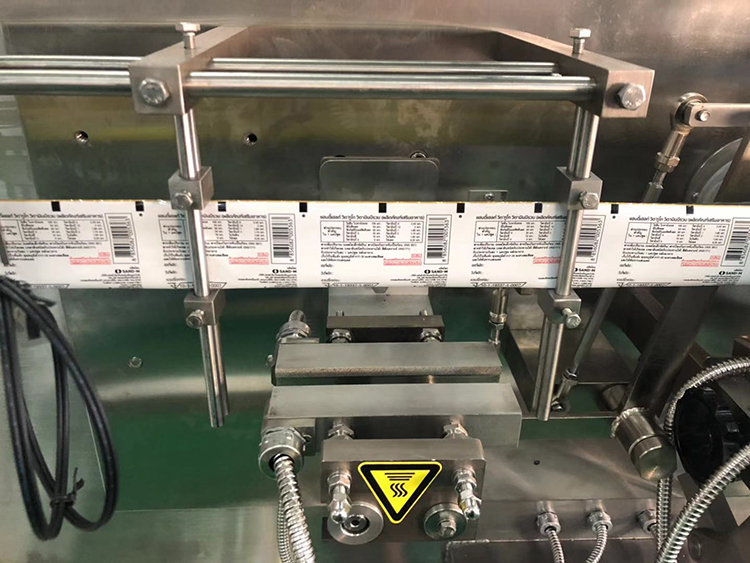

Labeling

The placement of labels is required for many high-volume products, even if the artwork and identification are pre-printed. This machine's packaging includes labels and extra information such as color or flavor variations.

Storage of Materials:

The machine maintains the integrity of packaging materials and is stored properly to ensure safe usage. These machines seal the products that keep them clean and free of contamination) and making them fit for consumption.

Increase shelf life:

Sachets are made by sealing flexible barrier films on all four sides to protect the inside contents from light, moisture, and oxygen. Packaging also reduces rancidity in any food items and the spoilage of chemicals.

Flexible Packaging

Sachet machines manufacture square or rectangular, three or four-sided sealed sachet packages automatically create a square or rectangular four-sided sachet packet. Inexpensive, reliable, and customizable, the four-sided seal sachet packing machine.

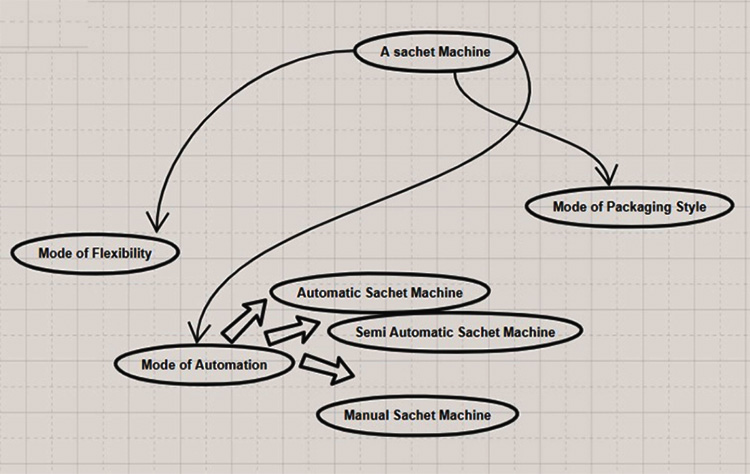

4.What are the basic types of a sachet machine?

Sachet machines are the commonly used type of packaging machines and are used in nearly every industry.

A sachet machine is classified into three basic modes.

- Mode of Automation

- Mode of Flexibility

- Mode of Packaging Style

Ⅰ.Mode of Automation

A sachet machine is utilized in a high production designed in various features. The applications of machines performed are increasingly improving to deal with bulk production. According to automation, a sachet machine is divided into the following categories.

- Manual Sachet Machine

- Semi-Automatic Sachet Machine

- Automatic Sachet Machine

Manual Sachet Machine

A manual sachet machine is a precise machine with intelligent options to pack a specific quantity of packaging utilized across broad spectrum fields.

This is compact and low-cost equipment that carries out the operation with manual handling.

Semi-Automatic Sachet Machine

A semi-automatic sachet machine is a way more innovative, and economical option of packaging compared to a manual sachet machine.

Except for manual feeding and manual discharging, entire functions are performed by a semi-automatic sachet machine.

This is a suitable machine for large production.

Automatic- Sachet Machine

An automatic sachet machine is utilized in a high-volume production line featured with programmed automation, easy-to-use, that saves your time and cost.

Ⅱ.Mode of Flexibility

According to the mode of flexibility, a sachet machine is broadly divided into two basic types.

- Horizontal Sachet Machines

- Vertical Sachet Machines

Horizontal Sachet Machines

Horizontal sachet machines are extensively used to fill and seal products of various volumes and kinds. These machines form the sachets and fill these at the same time. The packaging material or film travels across different stations horizontally.

The sachets are formed inside the forming tubes in this type of sachet machine while the products are moving on the conveyors. The edges of the sachet are sealed by the horizontally placed sealing jaws.

Cereal bars, confectionaries, and foodstuff are packed by horizontal sachet machines.

Vertical Sachet Machines

The films or packaging sheet moves vertically in the vertical sachet machines. Sachets are made at the top of forming tubes in these machines.

Vertical sachet machines usually seal materials with overlaps and transverse seals. Overlap seals and transverse seals are made at the bottom of the sachet and sides respectively.

The packaging in vertical sachet machines occurs when products go inside the forming tube and rollers move the film to form the channel. The forming station makes a circular sachet from the plane film.

Sealing bars bind the side edges of the sachet while horizontal jaws glue the top and bottom end of the sachet.

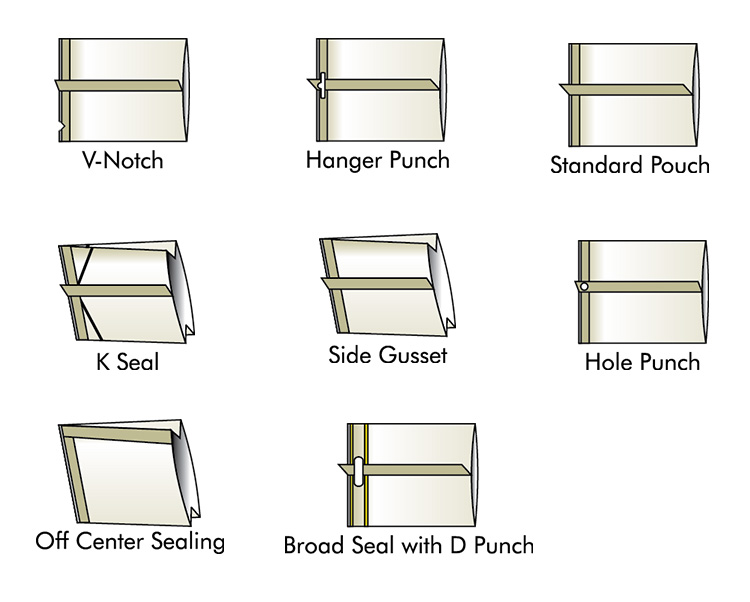

Ⅲ.Mode of Packaging Style

The sachet machine is also categorized according to the mode of packaging styles.

Three Side Seal Sachet Packing Machine

Three-side seal sachet packing machine that creates three-side sealed sachet. This sealing is achieved by using a forming cube known as sachet former. For different sizes (3gm, 10gm, 100 gm, etc) different formers are required. Each sachet machine is capable of the application of three to four formers.

Four Side Seal Sachet Packing Machine

This type of packaging machine has similar operational values as three side seal packing machines except for formers and sealers.

You will need different formers for four side seal sachet. Besides this, you’ll be required four side sealers in this machine.

Center Seal Sachet Packing Machine

This is an easy-to-understand and easy to operate machine. This machine transforms a lay-flat sheet film into central seal sahcet with various formats.

5.What is the difference between vertical and horizontal sachet machines?

Vertical and horizontal sachet machines are the most popular forms of flexible packaging. The main working principle in these both machines is the same but there are a few differences in both the machines.

These differences are:

Movement of Film

In the vertical sachet machine, the film moves vertically in the machine when it goes across different processing stations, whereas in the horizontal sachet machine, the movement of the packaging sheet is in the horizontal direction.

Space

Vertical sachet machines are generally inexpensive and need small space for their operation. Whereas, horizontal sachet machines are large, costly, and need huge space for operation.

Speed

Horizontal sachet machines have high production efficiency and speed than vertical sachet machines.

Filling

Vertical sachet machines can have one filling system at a time while horizontal sachet machines can have multiple filling systems at the same time so can package different products simultaneously.

Usage

Horizontal sachet machines are used in mass production lines while vertical sachet machines are suitable for small and medium productions.

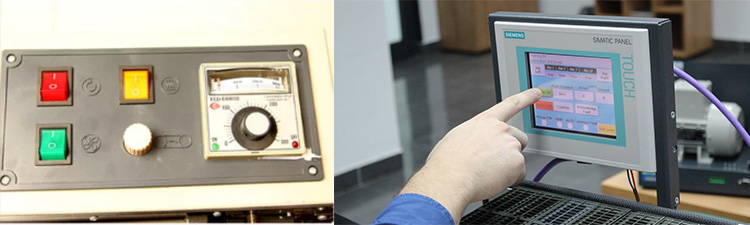

6.What is the difference between a manual sachet machine and an automatic sachet machine?

A sachet machine is available in different forms in the market. There are major differences between manual and automatic sachet machines that you must know.

| Manual Sachet Machine | Automatic Sachet Machine |

| A manual sachet machine is small and economical packing machine that perform filling, labeling, and sealing. | Automatic sachet machine is a versatile, innovative, and fast performance machine for filling, labeling and sealing the sachet with ready pack removal conveyor lines. |

| Suitable for small to moderate batch production. | Suitable for moderate to bulk production. |

| Feed and removal of sachet achieved by hands | Except in feeding material entire procedure is done by the machine itself. |

| Machine is available in low cost | Machine is available in high cost |

| Working on manual sachet is lengthy. | User-friendly and cost effective. |

| Control panel with temperature and speed regulators. | HMI Interface- Touch Display |

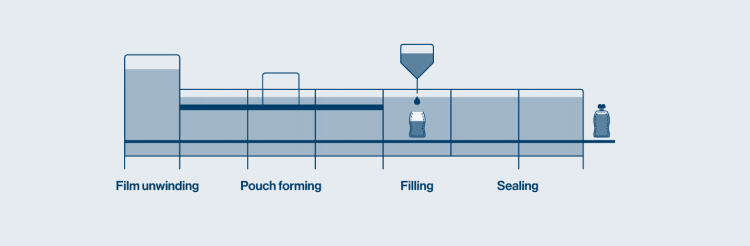

7.What is the working principle of a sachet machine?

The four basic steps in the working of sachet machine are

- Film Unwinding

- Sachet Forming

- Filling

- Sealing

Sachet machines perform filling and sealing at the same time. Filling in the sachet occurs from the top open part of the sachet.

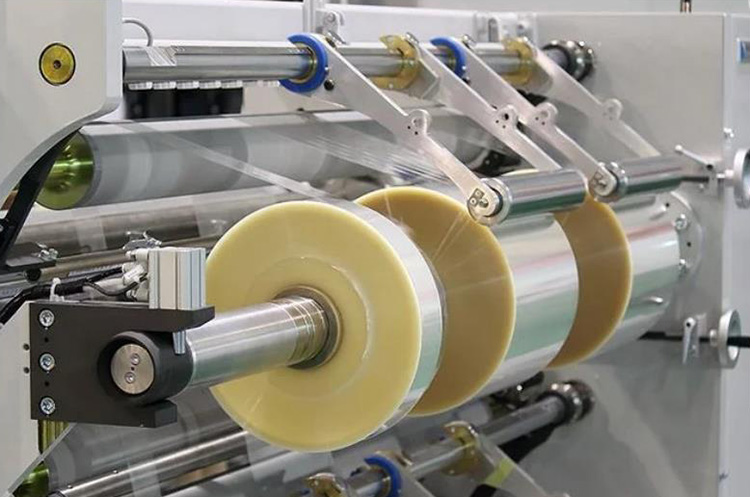

Film Unwinding

In this step, film rollstock is unwound by the rollers, transport belts, and the dancer’s arm. Film usually made up of aluminum or PE is positioned on rollers, which are present at the base of the machine.

Servo motors and dancer’s arms prevent the film from drifting and keep it under tension.

Printing

This step is optional. As the film goes through the printer, the date, batch code, logos, etc are printed on the film.

Sachet Forming

The film moves to the sachet forming station after printing. This unit places the edges of the film side by side to create a sachet. Sealing jaws are used to seal the vertical and bottom side of the sachet.

Filling

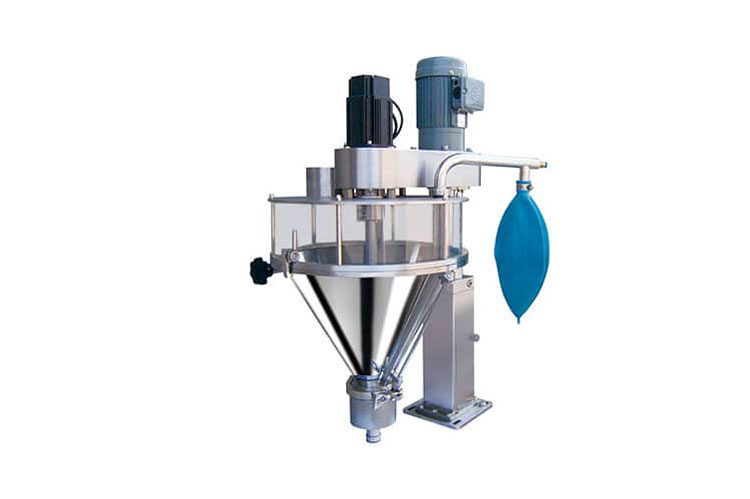

Feeding units or auger fillers are used to fill the sachet with products. The product is dropped in the sachet when it is ready.

Sealing

After the product is packed in the sachet, the top edge of the sachet is sealed by sealing jaws. These jaws press the two top edges together, sealing them with heat or ultrasonic sealing.

Cutting knives are used to cut the sachet by moving inside sealing jaws. Afterward, jaws open up and the sachet is released.

8.What are the major components of the sachet machine?

It is essential to know about the components of sachet machines because this aids in solving the issues that arise in these parts during the normal machine operation.

The sachet machine is divided into four basic areas

- Filling

- Sachet Forming

- Feeding and Printing

- Sealing

Various parts function in the above-mentioned areas. These parts are classified into two major categories

- Hardware

- Software

Ⅰ.Hardware

The hardware components of sachet machine are described below:

Feeders

These parts fill and load the products into the sachets. These parts have built-in sensors for accurate dosing of the products. First, the bulk products are loaded in the feeding unit, which then packs them into sachets.

Hopper

The sachet packing machine contains a hopper to hold packaging ingredients and dispense them toward the bottom when required.

Film Unwinding Rollers

These rollers unwind the film from the rolling stock. These parts are either unpowered, use friction brakes to unwind the packaging material, or can be powered by motors. These also provide necessary film tension. These parts also have a utility knife for cutting the film.

Dancer’s Arm

Dancer’s arms are essential in keeping the film under tension. These dancers' arms move in an upward and downward direction to maintain film tension when the film is being unwound. These parts also aid in maintaining sachet count and keeping the film on track.

Sensors

Many types of sensors are present in sachet machines such as:

- A diffuse sensor is used to identify the end portion of the film.

- An inductive sensor is used for detecting errors in the movement of the dancer’s arm.

- Registration sensor aids in checking registration marks which help in the synchronization of cutting and sealing processes.

- Optical sensors are crucial in detecting the edge for trim.

Registration Section

In this section, registration sensors are employed for detecting the registration mark which aids in the final placement of the end seal of the sachet and the cutting of the sachet. It also provides a tracking mechanism that prevents the film from drifting informing section.

Forming Tube

The forming tube is a cone-shaped structure in which the flat plane packaging materials is altered to form circular or tubular-shaped package. The size and design of forming tube depend upon the type of product and packaging film.

Pull Belts

These pull belts aid in providing force for pulling the film through the sachet machine. These are the vacuum belts that offer better gripping.

Sealing Jaws

There are two kinds of sealing jaws:

Horizontal or Cross Sealing Jaw

These jaws seal the top side of the filled sachet and perform the bottom sealing of the next one. It also cuts and separates the sachet from each other.

Vertical Sealing Jaw

These are square or box jaws that move in the upward and downward direction to seal the sides of the packaging film.

Ⅱ.Software

The parts that comprised of software are:

Servo drives

Servo motors are employed for the purpose of controlling fill cycle. These control the main injector and speed of the sachet forming process.

PID control

PID control assists in providing precise control of film unwinding by regulating various devices like motors, gears, and brakes. It also regulates the temperature of various components.

VFD

Variable frequency device or VFD is used for controlling the speed and torque of power supply of sachet machine.

9.What is the sealing system of a sachet machine?

The sealing system of sachet machines is described below:

Heat Seal

It is the classical way of sealing the sachet. It joins two layers of the film by using heat. In a heat seal, heat is applied to polymer layers by the means of a heated die or sealing rod.

It is robust and inexpensive but carried out in many steps to ensure the quality of sealing thus increasing machine space print.

10.Can a sachet pack machine deal with different products, sachet sizes, and styles?

Firstly! whatever the status of your product whether granules, powders, liquid, or viscous content. A sachet packing machine is an ideal packaging solution for it. But you must know the type of filler you require to integrate with the machine.

For instance:

Liquid Filler

Liquid fillers are meant for materials like lotions, pastes, gels. You’ll find the use of such filling systems in the food, beverage, and pharmaceutical industries.

Auger Filler

This filling system is used for the volumetric measuring of bulk contents, i.e., powders, granules. They dispense the content by a vibratory container that rotates by a revolving screw.

Volumetric Cup Filler

This filling system caters to free-flowing and non-dusty powders and granules, i.e., spices, sweeteners, etc.,

Secondly, if you’re thinking of different packaging styles by using one machine. Then it won’t be possible for the same sachet machine. Indeed, you’ll be required little modification in sealing styles. The basic sealing styles are 3- side sealing, central sealing, and 4-side seal sachet.

Thirdly, you can pack various sizes by adjusting the setting of the machine. The process of adjusting the sachet machine is termed as ‘changeover’. Different manufacturers offer their changeover capacity and changeover timings. You must prefer those machine that has rapid changeover which will save your time during production.

11.How can you improve the operational efficiency of a sachet machine?

To increase the operational efficiency of a sachet machine you must follow the basic six steps:

Increase Automation and Implementation

Automation and implementation are the key rules to improve operational efficiency than ever. Integrating automation with outdated components is ideal to improve the operational performance of the machine.

Maintain Safety

This is an important step for an efficient facility and worker safety. Maintaining a company-wide focus on safety may help in the rectification of going wrong and downtime.

Employee Training

Employee training encompasses a broader range such as best practices and company-specific protocols etc. Be sure your employees are trained best for machine operation, safety and troubleshooting.

Immediate Addressing of Machinery Malfunction

If you find any issue running with a sachet machine. try to repair immediately as additional damage may have happened beyond immediate repair.

Create Inspection Schedule

To get an efficient process, inspect and maintain your sachet machine schedules.

Facility Floor Layout

For desirable processes, your facility flooring must be laid out according to machines setup.

12.Tips and Tricks: What is the troubleshooting of a sachet machine?

A problem in smooth machine operation can result in unplanned downtime and wastage of time, money, and effort. If you find the solution for your problem, then you can avoid huge downtime and frustration.

Some tips and tricks are detailed below for helping out sachet machine operators and providing information regarding defects in sachet machines.

Ⅰ.Film Sticking to Sealing Bar

Sometimes the packaging material gets stuck to sealing bars.

Cause

- Temperature is high

- Huge sealing pressure

- Improperly cleaned sealing jaws

Remedy

- Reduce the heating temperature

- Lower the sealing pressure

- Properly maintaining the cleaning schedule

Ⅱ.Jamming of Film Belt

The film belts get jammed and become difficult to move

Cause

- Belts are very tight

- Drive gears are not working properly

- The cables of the feeder motors are not plugged in.

- Worn out bearing in the driveshaft

Remedy

- Lose the pull belts

- Check the drive gear.

- Properly plug the cables of the feeder motor

- Replace the old bearing in the drive shaft

Ⅲ.Inconsistent Sachet Length

The sachets produced having various lengths

Cause

- Tension in Dancer’s arm is not adjusted properly.

- Belts are not cleaned.

Remedy

- Adjust the tension of the dancer’s arm.

- Properly clean the belts with sanitary cloth.

Ⅳ.Difficulty in Film Unwinding

Sometimes the film is hard to unwind.

Cause

- The friction coefficient of the film is too high

- There is an accumulation of dust and debris in rollers

- The increased pressure of the pull belt

- Misalignment of forming tube

Remedy

- Use the film having a lower coefficient of friction.

- Cleaning rollers of foreign objects and debris

- Reduce pressure on pull belts.

- Properly align the forming tube

Ⅴ.Scratching

There is the scratch of the outer layer of the sachet which can penetrate the inner layer.

Cause

- There is a leftover plastic polymer on the sealing bar.

- Sachets are scrapped over the racks or other equipment.

Remedy

- Lower the heating temperature and clean the sealing bar area.

- Care should be taken to prevent the scrapping of sachet during shipment and storage.

Ⅵ.Delamination

Sometimes the outer and inner layers of the sachet separate from one another.

Cause

- The sealing bar is hot.

- Two layers are not properly bonded together.

- The sachets swell during retorting.

Remedy

- Lower the temperature of the sealing bar.

- Properly seal the layers of the sachet.

- Remove the air in the retort sachet so that sachet does not swell during retorting.

Ⅷ.Leakage in sealing

Improper sealing or loss of seal bond integrity causes seepage of the product.

Cause

- The sachet is cut or punctured during processing or handling.

- Settings of sealing bars such as temperature and pressure are not accurate.

- There is contamination in the product filling area.

Remedy

- Properly handle sachet during shipment.

- Adjust the setting of the sealing bar.

- Clean the filling area of grease and moisture.

Ⅶ.Embossing

There is slight impression raised on the sealing material.

Cause

- Sealing area is contaminated because of grease and oil.

- There are defects in sealing bar and anvil.

Remedy

- Clean the sealing area.

- Check the sealing bar and anvil for defects.

13.What are the key consideration factors before purchasing a sachet machine?

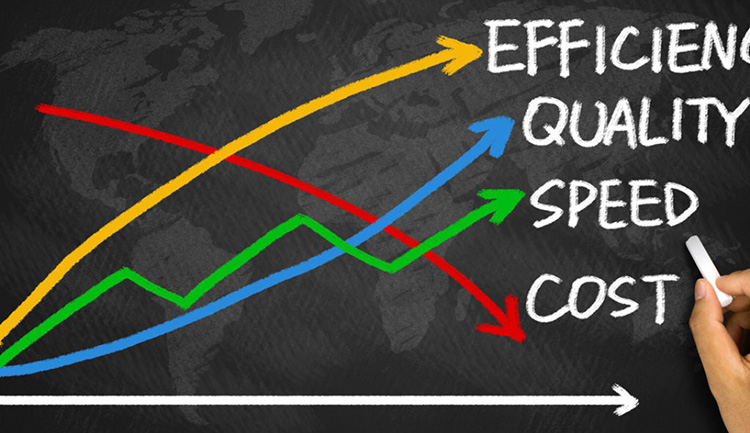

Ⅰ.Quality And Efficiency Aspects:

Various automated approaches are available on the market to ensure that the relevant ingredients are packaged, and the product is appropriately produced.

Before buying a sachet machine you must check different types of sensors that can be used to monitor various aspects of the filling and packing of sensitive items in order to maintain quality and efficiency.

Ⅱ.Needs Specifications:

If the producer wishes to prevent risk and make sachet packing cost-effective, then specify the following points before buying:

- Product characteristics and specs (e.g., liquid, or solid)

- Product Processing Parameters (E.G., Temperature Ranges Machinery Will Need To Operate In)

- Packing and sealing materials and criteria

- Labelling materials and criteria

- Basic pack proportions (this involves stability, as well as measurements like neck size.)

- Required pack weights or volumes (as well as the degree of precision)

- Ancillary items (e.g., promotional leaflets)

- Legal obligations (i.e., legislation applicable to the machinery and the product)

- Hygiene norms (e.g., for aseptic processing of food products)

- Compatibility with other packaging line equipment

- Electrical and installation standards

- Maintenance, staffing, and training requirements.

Ⅲ.Automation:

You must consider that the machine involves less labor while packaging. Due to the automation system, machines are easy to operate, friendly, and can save your time.

Ⅳ.Providing Services

Once the contract is signed, your vendor must commit to the level of services, accessibility of spares and service engineers, quality of documentation, and training for internal staff.

Conclusion

AIPAK is a professional production counter of pharmaceutical equipment. They offer bespoke sachet packing equipment that meets your diverse and customized needs. AIPAK is an ideal solution for boosting your production line with distinct engineered equipment. Want to make a purchase? Feel Free to Contact Us Right Now for expert consultation, support services, and qoutation.

Sachet Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586