Sachet Cartoning Machine: The Complete Buying Guide in 2025

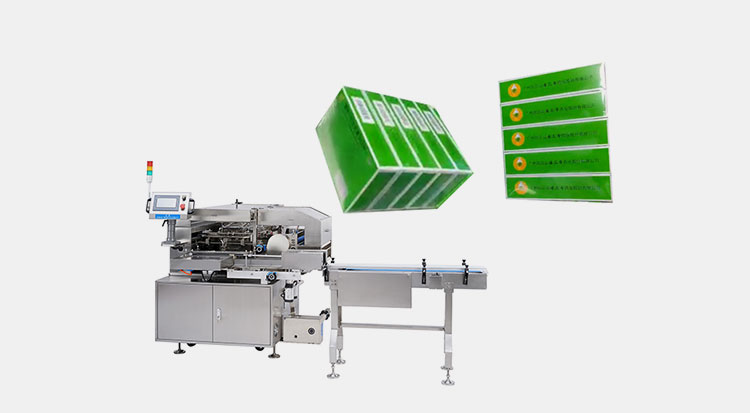

Are you packaging your products in sachets? Do you want to provide them with maximum protection? Then you should box them with a sachet cartoning machine. In this way, you can not only have protection during shipment and distribution but also create a beautiful display for grocery shelves.

A sachet cartoning machine is a transformative breakthrough in the world of packaging. You can streamline any packaging, whether oral medicated powders, instant coffee, or beauty samples with the utility of a sachet cartoning machine. It can be your reliable partner if you want unparalleled precision in cartoning.

How does it carry out the boxing process? And why does it have matchless popularity in modern manufacturing setups? To have answers to these questions, let’s get right into mechanics, advantages, types, uses, troubleshooting, and more about the sachet cartoning machine.

1.What is a sachet cartoning machine?

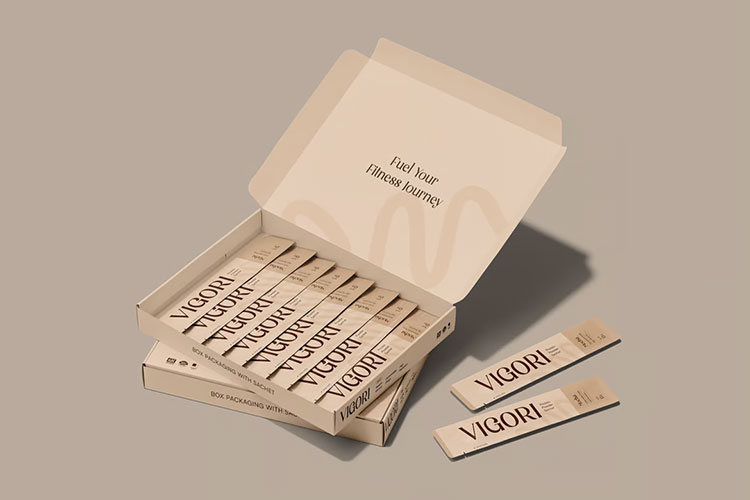

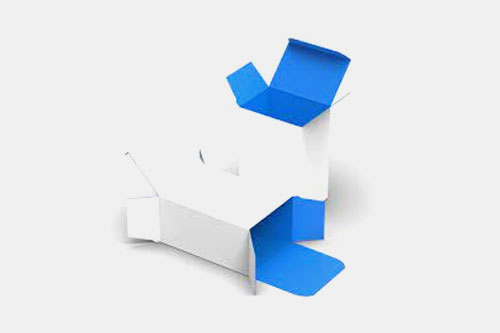

Sachet in carton

To put it in simple terms, a sachet cartoning machine is equipment usually employed at the last stages of packaging to place sachets in the box. This machine is integral in keeping sachets safe from physical damage that may lead to spilling of their contents.

This equipment is responsible for performing a series of steps, such as carton erecting, folding, product positioning, gluing, and ejecting to shape the cardboard or paperboard material into durable and robust boxes. It allows you and other manufacturers to load diverse types of sachets into cartons for easy transportation.

2.Why are sachet cartoning machines renowned in various manufacturing sectors?

A sachet cartoning machine is essential in every industry for complete packaging operation. Let’s face it, it’s pretty significant in keeping products safe and secure. Besides product production, it also has several useful benefits to industries due to which it is well-liked by manufacturers. So, without delay, let’s learn about the key advantages of a sachet cartoning machine:

Quick Sachet Boxing

Quick Sachet Boxing- Picture courtesy: Emenac Packaging

One of the major advantages due to which businesses favor a sachet cartoning machine is its rapid sachet cartoning. You can easily pack thousands of sachets per minute with this machine. It is an engineering marvel that allows you to produce a huge stock of cartons at the end of a shift. With its high-speed components, you can easily achieve your cartoning goal in less time.

Complete Product Protection

Complete protection- Picture courtesy: Envato

Loss of stock in shipping and product wastage are the biggest worries of any manufacturer. They want to safely deliver their product to customers without damage to external packaging and inner contents. Therefore, a sachet cartoning machine is their first choice because it provides an additional packaging layer to products.

The pack cartons are very good and sturdy barriers that prevent product deterioration from packaging crushing, tearing, and abrasion as well as from molding and pest infestation.

Great Quality Every Time

Great Quality Every Time

What is your topmost goal when you’re packaging? Surely it would be having consistent packaging quality in every batch. And you can fulfill this objective by installing a sachet cartoning machine in your setup. It is comprised of several error-detecting sensors that identify anomalies at every step of boxing and reject defective cartons.

In this way, your sachets are packed consistently and precisely, leading to great quality every time.

Versatile Cartoning Possibilities

Versatile Cartoning Possibilities

Sachets don’t have identical shapes and sizes every time. Also, distinct varieties of sachet cartons are present on display shelves. These different packaging possibilities only happen due to the flexibility and customization of the sachet cartoning machine. This exceptional equipment efficiently processes a wide array of sachets and cartons and has a role in your improved brand flexibility.

Save Packaging Expenses

Saving Expense

Although a sachet cartoning machine comes with a dent in the budget, still it has some remarkable long-term packaging-saving expenses. You can automate your packaging steps with this machine and save the need to hire more labor. This translates to less labor wages and less packaging mistakes.

It also places an accurate number of sachets in boxes, which minimizes the chance of under- or over-packaging. So, at the end of the shift, you’ll have lower product wastage, which further reduces your expenses.

3.What is the working of the sachet cartoning machine?

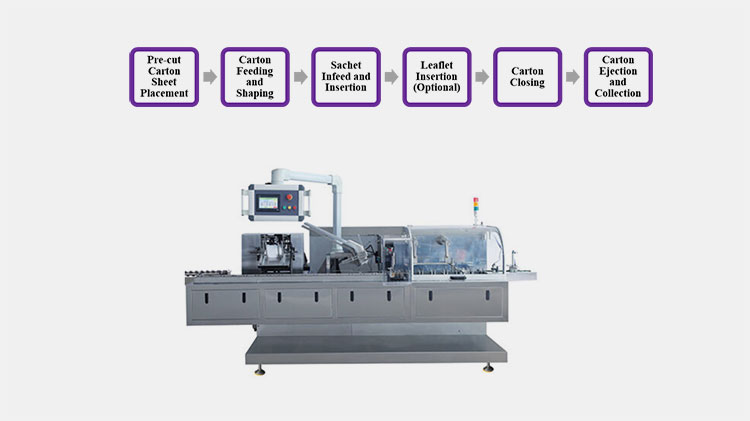

Do you think every type of sachet cartoning machine has the same working steps? This is not the case. Because the general working principle is the same in every equipment type but there are some slight changes in steps from machine to machine. Here is a step-by-step guide to the sachet cartoning machine operation:

Working Principle of Sachet Cartoning Machine

Pre-cut Carton Sheet Placement

First of all, a stack of pre-cut carton blanks is deposited on the carton magazine by the operators. This will help in the smooth and uninterpreted flow of operations.

Carton Feeding and Shaping

Afterward, on starting the machine, pre-cut blanks are picked out from the magazine and transferred to the carton erecting unit. Here, mechanical arms or vacuum suction components position the blank sheets upright and shape them into rectangular cartons. The bottom flaps are tucked inward to erect boxes.

Sachet Infeed and Insertion

Simultaneously, you’ll see that the machine takes the sachet from upstream sachet filling systems or these sachets are manually placed by working persons on the conveyor. These sachets are arranged in pre-defined configurations- either stacked or specially ordered- to align with the capacity of cartons.

As soon as sachets are received by a sachet cartoning machine are ready for packaging, then a precision-driven pusher or mechanical arm is used to deposit sachets into cartons.

Leaflet Insertion (Optional)

If you’re running pharmaceutical or high-value packaging, then your sachet cartoning machine may have an integrated sachet loader to place instructional guides, promotional brochures, and, patient information leaflets into cartons. Optical sensors present in the cartoning equipment aid in detecting the presence of leaflets in boxes before the cartons are moved to the sealing unit.

Carton Closing

Now that the sachets and leaflets are dispensed inside cartons, the next step is carton sealing. The system firmly closes the carton by either tucking flaps, applying hot glue, or using lock-style mechanisms.

Carton Ejection and Collection

In the end, correctly sealed cartons are transported to the carton collection area from there they are conveyed to further packaging stages, for example, labeling, bundling, or case packing.

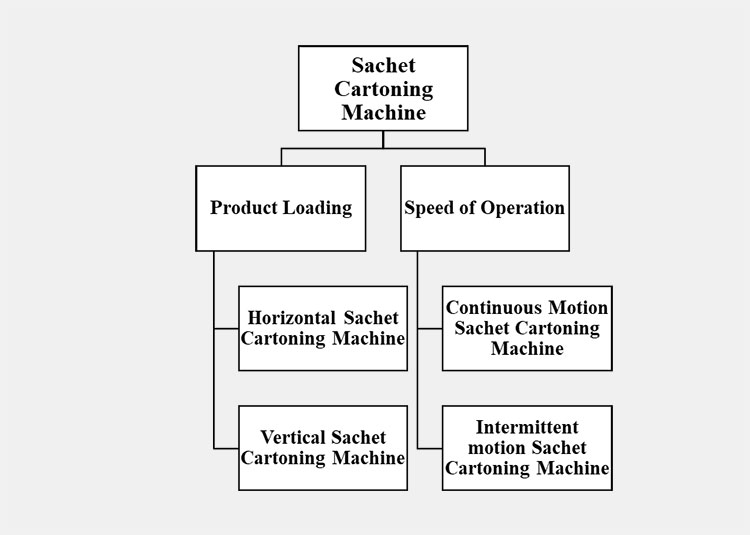

4.Do you know about the classification of a sachet cartoning machine?

You can get easily dazed by a huge assortment of a sachet cartoning machine in the market. These tons of choices can pose difficulty in picking the right machine for production. However, there is no need to overwhelm because we’re discussing the classification of a sachet cartoning machine below for your aid:

Based on Product Loading

Horizontal Sachet Cartoning Machine

AIPAK Horizontal Sachet Cartoning Machine

As the name suggests, this type of sachet cartoning machine feeds the sachet horizontally in the cartons. This means that sachets are loaded from the side of cartons. You can also use this equipment for placing multiple sachets in a single carton. It is usually found in facilities where higher productivity is required.

However, you need more floor space for installing a horizontal sachet cartoning machine.

Vertical Sachet Cartoning Machine

Vertical Sachet Cartoning Machine

Yes, you’ve got it right! This system generally places sachets vertically in the carton. It drops down sachet from the top and utilizes gravity for sachet loading. You need this kind of sachet cartoning machine if you’re dealing with a smaller or lightweight sachet. It is an excellent unit for plants with smaller space due to its vertical configuration.

However, it operates more slowly than its horizontal counterpart. And you can’t use it for packaging complicated carton designs.

Based on the Speed of Operation

Continuous Motion Sachet Cartoning Machine

Continuous Motion Sachet Cartoning Machine

This class of sachet cartoning machines runs continuously without taking any breaks or pauses. The sachets are traveling along the conveyor, thus ensuring fast packaging. As it doesn’t stop between processing stages, hence, it is considered a favored unit for mass-scale operations.

It is fully automated with reduced downtime; however, it is pricier than an intermittent motion cartoning machine.

Intermittent Motion Sachet Cartoning Machine

Intermittent Motion Sachet Cartoning Machine

It is the complete opposite of a continuous motion sachet cartoning machine because it finalizes the cartoning process by taking a break at every step. Every stage, like sachet insertion, carton closing, and ejection occurs one at a time. Therefore, it is slower than its continuous motion counterparts.

However, with this machine, you can easily accommodate frequent product changes and process different carton sizes and types. Moreover, it requires less capital.

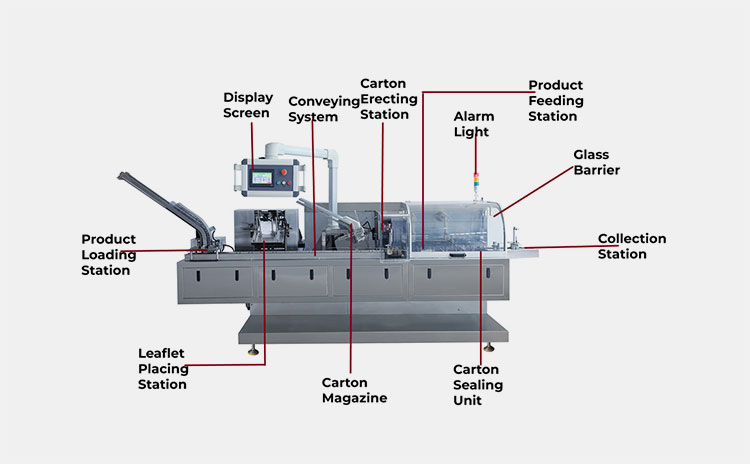

5.What are the structural design and components of the sachet cartoning machine?

You would be curious about the structural design of and parts that make up a sachet cartoning machine. It is indeed important to understand its structural build because this knowledge will be fruitful to you in maintaining and cleaning the said equipment. So, let’s explore various components of a sachet cartoning machine together:

Components of the AIPAK Sachet Cartoning Machine

| Product Loading Station | The sachets are first placed on this station either by the infeed conveyor (which carries them from the sachet packing machine) or by operators by hand. |

| Leaflet Placing Station | This component is found in some of the sachet cartoning machines and it places the leaflet on the sachet while they are traveling to the product loading unit. |

| Display Screen | It is the main part of the machine by which you can control and supervise it. It is a touchscreen with which you can program your equipment and adjust its settings. |

| Conveying System | It is the transporting system of a sachet cartoning machine and guides sachets and cartons to different stations of the equipment. |

| Carton Magazine | Usually before the start of the operation, the operators place a large pile of blank cardboard sheets on the carton magazine, and where mechanical arms or grippers transfer them to the carton erecting station. |

| Carton Erecting Station | Cartons are positioned upright and folded by a carton erecting station. It shapes your flat sheets into sturdy rectangular boxes by tucking in flaps or sticking them together. |

| Product Feeding Unit | How sachets are placed in the cartons? You can’t help but ask this question when you see cartons displayed on aisles. Well, this station is responsible for placing the sachets in the cartons. It has a mechanical arm that smoothly loads a stack of sachets in boxes. |

| Alarm Light | It is a type of safety system that is present in most of the sachet cartoning machines to inform you if there is any malfunction in the system. It lights up to alert operators. |

| Glass Barrier | This enclosure allows you to view the operation of the product feeding and carton sealing unit without directly accessing these stations. It is a transparent glass structure that prevents contamination of cartons by human operators. |

| Carton Sealing Unit | The function of this component is to secure your cartons by tucking the flaps or gluing them shut. In some cases, you can customize this part to apply tamper-evident tapes on cartons which helps to identify if the cartons are opened. |

| Collection Station | You’ll find this station at the end of the equipment and the packed cartons are piled on it and you can pick up these cartons from there and manually take them to the next-in-line packaging machine. Or these boxes are loaded to infeed conveyors that run through the whole production. |

6.In what industries is sachet cartoning machine utilized?

A sachet cartoning machine is a vital component of sectors that fill powders or liquids in small sachets. Manufacturers prefer to integrate this machine into their plants for definitive protection and branding. The key uses of a sachet cartoning machine, for those interested, are as follows:

Pharmaceutical Industry

Pharmaceutical Industry

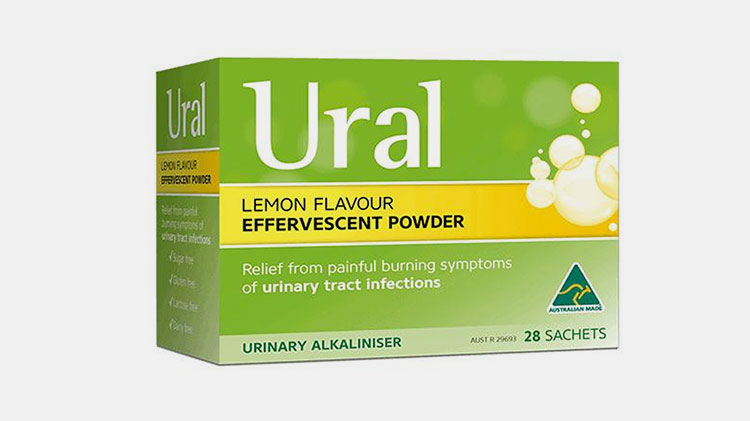

This industry is a primary consumer of the sachet cartoning machine. Because pharmaceutical brands need this equipment for accurately packing sachets in cartons. It is also favored because it supports leaflets loading in cartons for patient information. Different kinds of medicinal products and powders like ORS or liquids, such as cough syrups are filled in sachets and then are packed by this equipment.

Food and Beverage Industry

Food and Beverage Industry

Nowadays, numerous food and beverage powders and liquids, for instance, instant coffee, sugar, ketchup, condiments, soup mixes, spices, herbs, and more are packed in smaller sachets for portability, convenience, and portion control. You’ll easily box all these food sachets in cartons with a sachet cartoning machine.

It not only loads single sachets in cartons but is used for bulk packaging of sachets. Also, you can have tamper-proof packaging via this system.

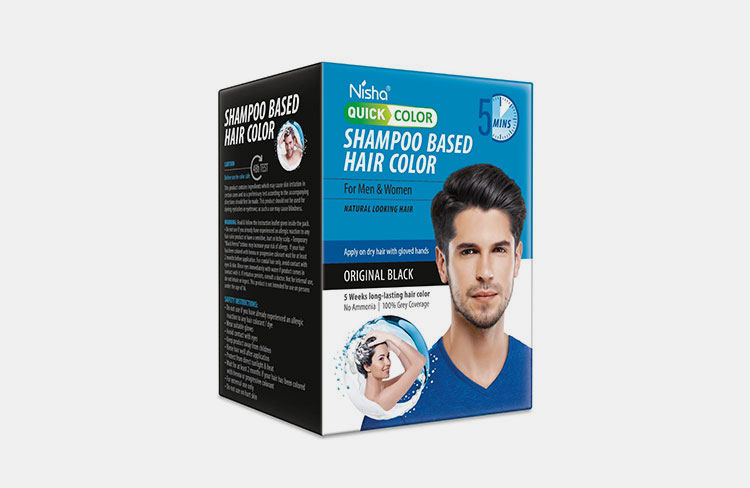

Cosmetic & Personal Care Industry

Cosmetic & Personal Care Industry

You surely would have seen promotional sachet samples of cosmetic and personal care products in appealing cartons. But you know, how do they end up in those boxes? This boxing is done by a sachet cartoning machine. With this machine, cosmetic brands create travel-sized sample packs to promote their products.

Nutraceutical Industry

Nutraceutical Industry

This era is all about health and fitness. Hence, more and more businesses are introducing different nutraceutical and health-boosting products. A sachet cartoning machine is a key system that facilitates every nutraceutical industry because it quickly and hygienically packages sachets of collagen powders, multivitamins, electrolytes, and herbal supplements into robust cartons.

This provides absolute protection to inner nutraceuticals against moisture, contamination, and temperature.

Agriculture Industry

Agriculture Industry

If you’re into gardening or are working in agriculture fields, then you must have handled a box of agrochemical sachets at some point. And this cartoning of fertilizers, pesticides, humus, and, manure sachet is performed only by a sachet cartoning machine.

It is an efficient solution that yields spill-proof packaging and allows agrochemical businesses to prevent their product contamination on the way to markets and consumers.

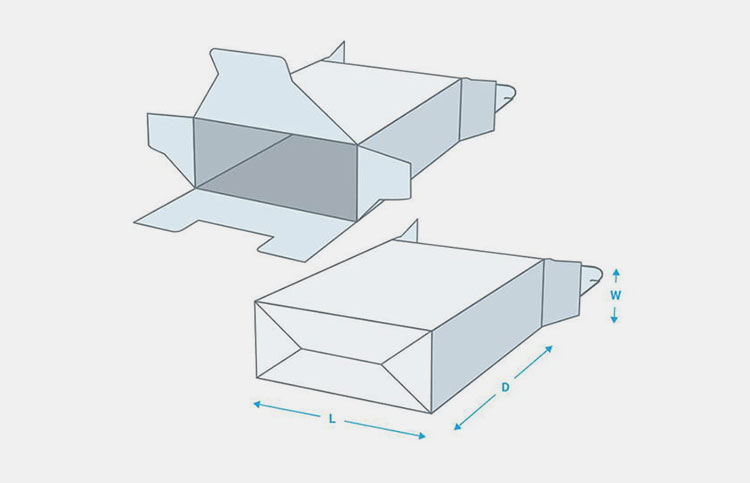

7.What types of cartons are handled by a sachet cartoning machine?

A sachet cartoning can pack a lot of diverse carton types for you. Hence, with the exceptional handiness of this equipment, you can create a unique brand image for your business. Let’s have a look at different carton types processed by a sachet cartoning machine:

| Folding Carton | It is the most frequently seen carton for sachet packaging. A sachet cartoning machine simply folds and seals this carton type because it’s already present in pre-cut or creased form. It is usually created from paperboard or cardboard. |

Folding Sachet Carton |

| Straight Tuck Carton |

It is a type of folding carton and is all-purpose used for a variety of product packaging. It is named such because its top and bottom securing panels are found on the same side and are folded in the same direction as well. It comes with tiny holes that keep the end tucked locked. |

Straight Tuck Carton- Picture courtesy: QinPrinting

|

| Reverse Tuck Carton | It is quite identical to a straight tuck carton, however; you’ll notice that its top and bottom flaps are present on opposite sides. So, they also fold in opposing configurations. It is best for storing lightweight sachets. |

Reverse Tuck Carton |

| Display Cartons | It is a box that is developed for the sole purpose of displaying or showcasing your sachets in a visually pleasing manner. It is an excellent marketing tool and helps in product promotion. It features a perforated front to easily open it. Usually, coffee sachets, tea bags, face creams, and hair color products are dispensed in it. |

Display Carton- Picture Courtesy: Packqueen |

| Sleeve Cartons | There are no bottom or top parts in this carton type. And it simply slides over another to store or access sachets. It has more rigidity and extra cushioning. One of the major advantages of this carton is its price as there are no closures and hence, less material is used for its manufacturing. You can pack your luxury cosmetic samples in this box. It features an elegant look and, therefore is a top choice for high-end branding. |

Sleeves Carton |

| Hinge-Lid Carton | This type of carton has a non-separable top that is flipped over for ease of opening and resealing. Its top part or lid is fixed to the carton along one side and you can swing it open and close like a hinged door. It can hold your herbal supplement and cosmetic skincare sachets. |

Hinge Lid Carton- Picture courtesy: PALAMO |

| Perforated Tear-Strip Carton | You can locate a small pre-scored or perforated strip on its top, which you can tear to open it. This ease of opening eliminates the need for scissors or other tools and is best for people who favor quick opening. |

Perforated Tear-Strip Carton |

8.Does the sachet cartoning machine support leaflet insertion along with sachets in the carton?

It is a reasonable question when you procure a sachet cartoning machine. To answer you in short, yes. Numerous sachet cartoning machines are designed to support leaflet insertion along with sachets. This machine has two main units that are involved in leaflet loading in cartons. Let’s discuss these components:

Leaflet insertion- Picture courtesy: CCL Health

| Leaflet Insertion Unit | This machine has an automatic leaflet insertion unit that either automatically folds a leaflet into the desired arrangement and then places it in cartons. Or insert a leaflet that is already in folded configuration in boxes. Moreover, with this component, you can pack one or multiple leaflets in your cartons. |

| Leaflet Verification Systems | Often high-tech models of sachet cartoning machines have integrated sensor-based vision system that detects the presence of leaflets in every carton. If it identifies any missing or misfolded leaflet, this equipment automatically separates the faulty carton from the main packaging. |

9.What sachet types are packed by a sachet cartoning machine?

Certainly, you can pack a variety of sachets with a sachet cartoning machine. The design of sachets is dependent upon your product as well as customer choice. Let’s discuss some widely boxed sachet types:

Flat Sachet

Flat Sachet

It is the most commonly found sachet type in the market. It has a rectangular or square shape with three or four side seals. You can dispense your pharmaceutical powders, coffee, cosmetic samples, and, spices in them.

Stick Pack

Stickpack

It has quite a distinct appearance from flat sachets because of its long and narrow structure. It often includes three side seals. Stick packs are popular for packing nutraceuticals like dietary supplements, energy drinks, and flavored products.

Twin Sachets

Twin Sachets

You also know them by the name of dual sachets. Why are they called as such? Because they are connected with each other and often hold two diverse products like two medications or food seasoning.

10.What kind of sealing technology does the sachet cartoning machine use?

This equipment employs a diverse type of carton sealing technologies to safely close your filled cartons. Some of these technologies are penned below for your knowledge:

Tuck-in Sealing

Tuck-in Sealing

In this method, your carton boxes are secured without the use of glues or other adhesives by simply tucking their flaps into pre-cut designated pockets. It is quite environmental-friendly but its downside is that it is less tamper-proof.

Hot Glue Sealing

Hot glue sealing- Picture courtesy: JORI MACHINERY

In this sealing method, the machine heats solid glue and then puts on the ends of the flaps to seal them. You’ll usually find it in high-end productions and is a highly durable and tamper-resistant sealing approach. But its disadvantage is that you need glue nozzles and heating.

Tamper-Evident Sealing

Tamper-Evident Sealing- Picture courtesy: PPSA

Sometimes, you require high security in packaging, and this is achieved by tamper-proof sealing. In this method, cartons are secured by perforated tear-open strips, stickers, and, labels. It allows users to know if the box is tampered with by any means.

11.What challenges are encountered in the sachet cartoning machine? How to resolve them?

Whether you belong to the pharma, food, or cosmetic industry, you can’t overlook the importance of a sachet cartoning machine. It allows you to pack quality products. But let’s be real, issues do occasionally arise with this equipment, messing up your whole packaging schedule.

However, by learning about common problems and planning strategies to rectify them, you can easily avoid these slowdowns. So, let’s discover some main challenges encountered in a sachet cartoning machine and its witty solutions.

Inadequate Glue Application

Inadequate Glue Application- Picture courtesy: Pillpack

Yes, this issue has a significant impact on the carton sealing. If glue is not applied properly on carton flaps, it could lead to carton opening during shipment and logistics and compromise product quality. Several factors are associated with this problem, for instance, fluctuations in glue temperature, the adhesive is of substandard quality, or, there is glue deposition in the nozzles of the glue applicator.

Right Solutions

To solve this issue, you can take the following steps: maintain the temperature of the glue within the specified range to attain maximum bonding strength. You should utilize adhesive of the highest quality and it should be compatible with carton materials. Also, clean gluing nozzles after every shift to have a smooth glue flow.

Sachets are not Conveying Correctly

Incorrect sachet fill- Picture courtesy: Yes Medical

Sometimes, during the cartoning process, you observe that sachets are not deposited in the right manner in cartons. This problem is usually because of improper sachet movement on a conveyor or their jamming on conveying systems. This issue can arise from mechanical wear or hindrances in feeding systems, mismatches between carton sizes and feeding systems, and defects in sensors.

Right Solutions

You’ve to start with conducting a solid check of the sachet feeder. It is best to ensure that the conveying system is free of blockage of any sort and product chute is working smoothly. Afterward, you have to modify and align the feeding system so that it can process irregular-shaped sachets. Lastly, it is proper to calibrate sensors daily so that they accurately detect sachets.

Jamming of Carton Stacks

Carton Jamming- Picture courtesy: Benison

In some instances, you’ll face this problem. The packaging cardboard sheets are jammed on the conveyor or get struck during the folding stages. This trouble normally happens because the carton sheets or sizes are incorrect, jamming of the conveyor, or damaged machine parts.

Right Solutions

Here are some simple fixes for this issue. First, select the right kind of box material. Particularly its thickness should be compatible with the working of the machine. Clear any type of obstacle on the conveyor to have a smooth carton movement. Also, if you notice any evident wear to the system component, then maintain and clean daily. If the damage is beyond repair, immediately get a new part.

Errors in Carton Folding

Errors in Carton Folding

In some cases, you’ll notice that your cartons are not properly folded. And this impairs the appeal of the product. Often this dilemma is caused by the inaccurate configuration of guide rails or the unsuitable thickness of carton materials.

Right Solutions

Rest assured; you can easily resolve this predicament by ensuring the calibration of guide rails on a routine basis. You must realign them after every batch so that they can accommodate your carton sizes. Also, pick out a carton material with the right thickness. Lastly, adjust the machine folding pressure to prevent crushing of your cartons.

12.What are the consideration points for planning to buy a sachet cartoning machine?

Yes, a sachet cartoning machine needs a huge capital but it is a worthy investment that serves you for many years to come. So, before setting the budget aside for the purchase, first, you should consider some essential points that will aid you in selecting well-matched equipment for your needs.

So, we’re mentioning some points to think about to assist you in your purchase:

Estimate Required Machine Speed

Estimate Required Machine Speed- Picture courtesy: Jochamp

It is a very pivotal point that you must think about before shopping for a sachet cartoning machine. Because different kinds of machines are built to have their specific speed. The equipment speed means how many cartons will it produce per minute.

As you already know the continuous motion sachet cartoning machine packages a massive volume of cartons per minute but it is more expensive. Therefore, you must buy a system that caters to your packaging demand efficiently.

Plan on Carton Size Range

Range of Carton

Most often, you pack a variable number of sachets in different cartons. This requires cartons of different sizes. So, plan ahead for your required carton dimension range. This will make it easier to figure out which sachet cartoning machine works best with your carton size needs.

Decide Material Packaging

Material of carton

Yes, you can make cartons with diverse materials, such as cardboard, paperboard, kraft paper, and other biodegradable materials. So, pick out your desired carton material before buying because incompatible packaging materials often compromise cartoning quality and machine operation.

Always ensure that your potential device easily handles your preferred material without needing extensive modifications.

Access Loading Mechanism

Access Loading Mechanism

It is a vital point that usually goes unnoticed when financing a sachet cartoning machine. Before finalizing your purchase, first access and test how carton feeding technology operates and check whether this gear is able to handle your favored material.

Measure Floor Space

AIPAK Cartoning Machine Line

The dimensions and build of an equipment can impact its installation and mounting in existing space. So, it is necessary to first measure your facility space so that your procured system will easily fit into it.

It is worth remembering that you would need a stable base to support heavy-duty equipment and would have to ground it accurately to minimize vibrations during its working.

Conclusion

To conclude this blog post, it is worth mentioning that a sachet cartoning machine is a high-performance equipment that aids you in rapid and error-free carton packing. Moreover, you can easily secure your sachet products in a wide range of cartons using this machine. With this system, you can’t only offer ultimate protection to your products on their journey to customers but also create a tempting product appearance to attract your potential customers. Now sold on the benefits of a sachet cartoning machine, then don’t wait and click on the link below to get AIPAK's best deals and offers. We are fully prepared to meet your needs in every way.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine