Rotary Tablet Press:The Complete Buying Guide in 2025

A rotary tablet press is also termed as ‘multi-station-tablet press. This machine is termed rotary because the head of the machine which firmly holds the upper and lower punches and dies in place rotates.

A rotary tablet press has multiple rotating tooling stations that facilitate powder granules into a compact form. Rotary tablet press demonstrates a high- productivity ratio, with minimal labor cost.

If you want to invest money in buying a rotary tablet press, then we welcome you to read this blog. Here, you will find all mandatory information about the tablet, and rotary tablet press such as applications, installation, troubleshooting, maintenance, and cleaning.

Let’s get into it!

1.What is a rotary tablet press?

AIPAK rotart tablet press

A rotary tablet press is a mechanical device composed of several tooling stations that rotate in order to press the granules, powdery mixture to form a tablet of uniform size, weight, and given shape.

Rotary tablet press is developed to meet the real-time production of tablets. This machine is designed to support optimum conditions essential for quality production of tablets, such as:

- Thickness

- Hardness

- Stability

Rotary tablet press is applicable in various industrial units including, pharmaceutical, nutraceuticals, cosmetics, foods, confectionery, and much more. The following manufacturing units require higher tablet production that’s why the rotary tablet press is the suitable and preferable option. Rotary tablet press yields a high-profit margin due to a high productivity ratio with minimal labor that ultimately meets up high demands for the tablet dosage form. Hence, this machine is of prime importance if you want to become a successful competitor among all pharmaceutical or relevant companies.

2.What is the working principle of a rotary tablet press?

The working principle of a rotary tablet press is extremely simple that involves hydraulic pressure or application of pressure.

Tablet mixture or granules are packed into Die cavity followed by applied pressure with the help of punches such as upper punches and lower punches.

Rotary Motion- Working principle of rotary tablet press

One wheel or main roller is located on the upper side of the upper punch and one wheel or main roller is present below the lower area of the lower punch.

When compression is applied, the pressure of both punches is transmitted on filled powders into a die cavity and this transforms powders or granules into the form of a tablet.

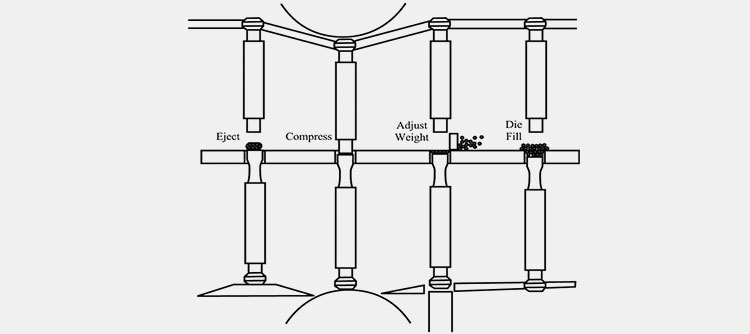

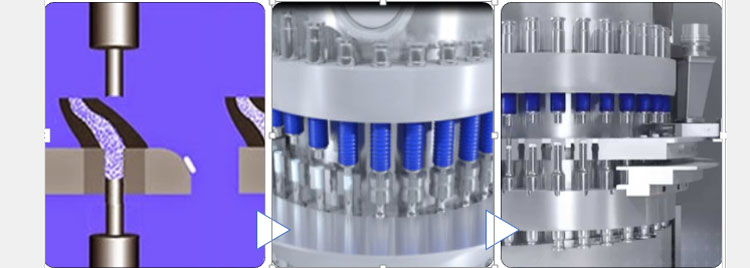

The stages involved during this process are :

- Filling

- Metering

- Compression

- Ejection

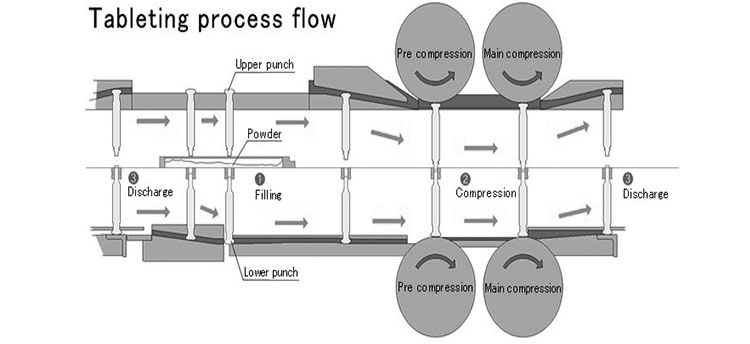

1.Filling

The filling is the first stage of tablet compression. In this stage, filling material is packed into the die cavity. The estimation of filling weight can be achieved by a lower punch in the die.

To ensure filling material is completely loaded into the die cavity, powders or granules are overfilled. Powder or granules from the hopper is introduced into the feeder. From feeder powders or granules are loaded into the die cavity.

Filling- Rotary Tablet Press

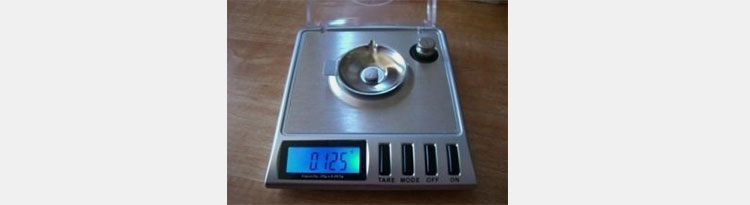

2.Metering

This is the second stage of tablet compression, where weight is adjusted according to the specification of tablets mentioned in the manufactured Batch record.

An excessive material is removed from tail over die that clears the extra granules when a lower punches cross over the weight adjustment cam. Thus, the weight of a tablet is determined and adjusted by rotating the knob connected to the shaft of the weight adjustment cam. A knob rotation can be done either clockwise or anti-clockwise.

An illustration of Rotary Tablet Press

On one side, the weight adjust cam turns upward that lift the lower punch in Die cavity thus filling space get lowers and the weight of the tablet also gets lower as fewer granules are loaded in less space.

While in the opposite direction lower punch moves down in the cavity that rises the space in the die cavity, so the weight of a tablet is also improved.

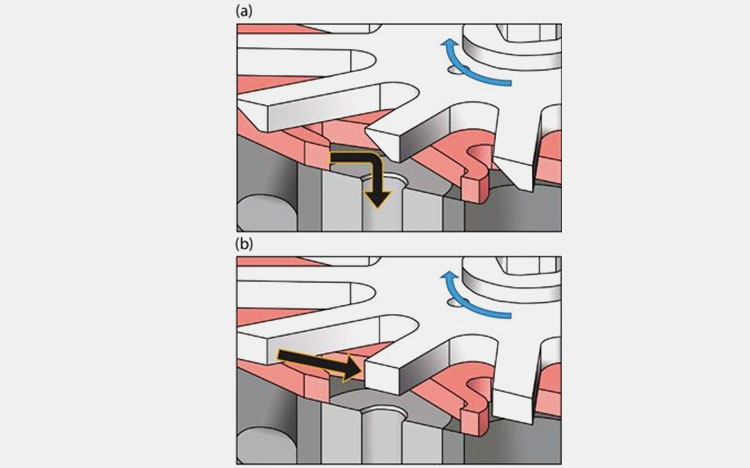

3.Compression

The third, and most important stage is compression. Because in this stage, powder or granular mixture is encounter to compression to form a tablet dosage form.

Compression- Rotary Tablet Press

As we mentioned earlier, the compression is applied using two main rollers, for e.g., upper roller and lower roller.

So, when punches come closer and pass-through spaces, pressure is transmitted to granular or powdery material to form a tablet.

This pressure also helps in determining of hardness and thickness of the tablet.

The lower wheel is connected to a knob and moves up or down by rotation of knob clockwise or anti-clockwise direction.

4.Ejection

Ejection is the fourth and last step of tablet compression. In this stage, an already formed tablet is ejected from the die cavity via lifting the lower punch with the help of an ejection cam. An ejected tablet is assembled into a tablet container using a discharge chute with help of take-off blades. A take-off blade is integrated into the backside of the feeder.

Ejection- Rotary Tablet Press

Filling- Compression- Ejection- Rotary tablet press

3.What are the industrial applications of rotary tablet press?

The rotary tablet press is a piece of ideal equipment that is valid for a wide range of industrial applications. For instance:

Rotary tablet press

1) Pharmaceutical Industry

No one can deny the importance of rotary tablet press in the development and manufacturing of pharmaceutical goods. Pharmaceutical industries extensively utilize rotary tablet press as a prime tool to achieve quality tablet dosage form in bulk production.

Rotary tablet press offers maximum tablet output such as 9000 to more than 2,50000 tablets per hour. That’s why a rotary tablet press not only saves your time, but it meets up high production demands for tablet dosage form required by a large healthcare sector such as hospitals, clinics, pharmacies, etc.

A rotary tablet press is a compact machine that allows smooth and fastest production line with many unique features that has ability to run a large-scale tablet production.

Additionally, a rotary tablet press competes with other machines due to higher automation, superior consistency, and offering much larger presses, and reduced downtime.

2) Nutraceutical Industry

This is well- known that the manufacturing of nutraceutical tablet dosage form is not only challenging but time consuming and expensive process.

Because the formulation of nutraceutical products is different from pharmaceutical products that involve the incorporation of sensitive material such as vitamins, minerals, sometimes sticky substances, etc.

This job is perfectly done by a rotary tablet press.Do you know how?

The entire construction of the rotary tablet press is made up of stainless steel. Also, unique features, rapid production under a safe and hygienic production environment yields quality outcomes to end-users.

3) Food and Confectionery Industry

A rotary press tablet machine is a reliable machine that is perfectly suited for the application of food and confectionary items have been in high demand for the last few years as this machine offers exceptionally robust patterns and designs.

You can manufacture carbonated soda tablets, fruity flavor tablets, chocolate tablets, and much more. This is the safest mode of machine that will make your manufacturing production line extremely quicker and consistent. That’s the reason every food and confectionary industry prefer rotary tablet press as a first choice for tablet manufacturing unit.

For example, chicken or stock cubes, sweeteners for diabetic patients, fructose, or dietary supplements.

4) Cosmetic Industry

The cosmetic industry is intended to use rotary tablet press for the manufacturing of skincare products. For instance, bath tablets, bath salt, or bubble bath. Rotary tablet press has the capability to compress those granules or mixtures that are difficult to compress or require special manufacturing compression. Furthermore, skin care products strictly adhere to the principles of GMP and quality assurance. Thus, all these requirements are fulfilled by using a rotary tablet press.

5) Sintered Metal, Ceramic, and Electrics

A rotary tablet press is suitable to deal with compressing hard metals or those substances that are difficult to compress.

Because their special Tooling system offers a wide range of metal compression power that is suited for dealing with abrasive substances.

Sintered metals are broadly used for the manufacturing of automobile parts. These are strong metals most often available in the form of compact tablets.

For which their manufacturer demands rotary tablet press that is capable to compact the metal sintered powder into metallic tablets. Similarly, many ceramic and electric manufacturing industries use rotary tablet press for the compression of ceramic, hard metals and coal, etc.

Hence, the rotary tablet press is also one of the most important manufacturing tools require for this purpose.

Coal Tablet- Rotary tablet press

Zinc Sulfide Sintered Tablets

6) Veterinary Industry

Rotary tablet press is of prime importance when dealing high production demand for veterinary tablets. A rotary tablet press supports the veterinary manufacturing sector and easily fulfills the ongoing medicinal requirement (pet animals, farmers, poultry, etc). Rotary tablet press can perfectly assess the product behavior, measurements, and quality to deliver safe and potent veterinary medicinal goods.

7) Chemical Industry

The manufacturers of the chemical industry necessitate rotary tablet press for manufacturing chemical tablets. There are many chemical hazardous, irritant, and corrosive in nature substances that are available in tablets form, such as sodium hydroxide, acidic buffers, etc.

You might be wondering about their manufacturing because they are available in accurate doses with a uniform physical appearance.

A rotary tablet press can do this job efficiently. That’s why a rotary tablet press is considered essential equipment to deal with chemical substances with the safety and security of the operator and environment.

Based on production capacity rotary tablet press offers an accelerated tablet formation with reduced chances of chemical interaction and errors.

Chlorine tablets- Chemical Industry- Rotary tablet press

8) Agriculture Industry

Rotary tablet press is suitable equipment for manufacturing agricultural products such as pesticides, growth-promoting tablets, etc.

This machine has the ability to optimize the product feeding system for sticky or non-free-flowing products. Hence, rotary tablet press can perfectly manufacture and deliver different types of substances in tablet form to promote agriculture requirements.

4.What are the important components of a rotary tablet press?

Few important components of rotary tablet press are given below:

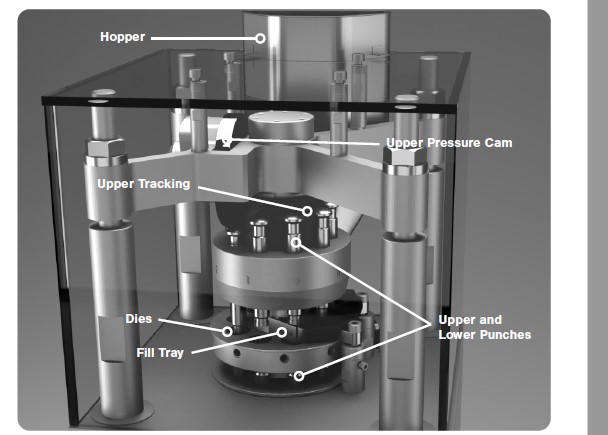

1.Hopper

Hopper is the channel in which dry powder is stored; this powder will be compressed into a tablet later.

2.Fill Tray

The function of the Fill Tray is to transfer dry powder into the Die bore and to drive the tablet in the Ejection Chute.

3.Die

Die is the channel that holds the powder, and then powder is squeezed to form a tablet. This channel can control two factors

- The shape of the tablets

- Size of the tablets

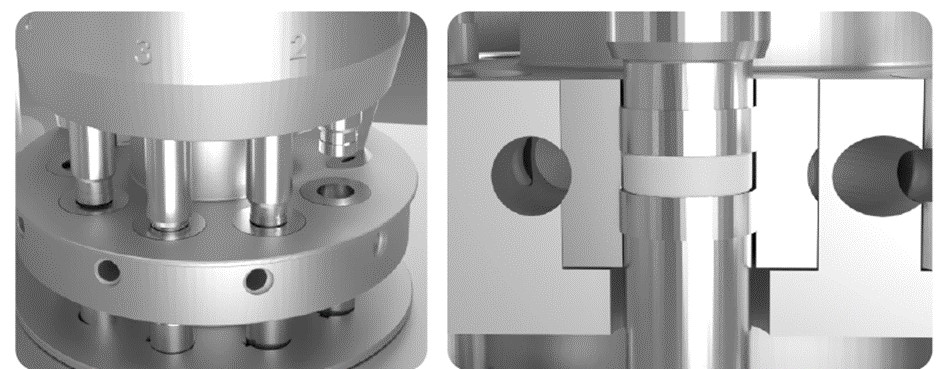

Punching Die- Rotary tablet press

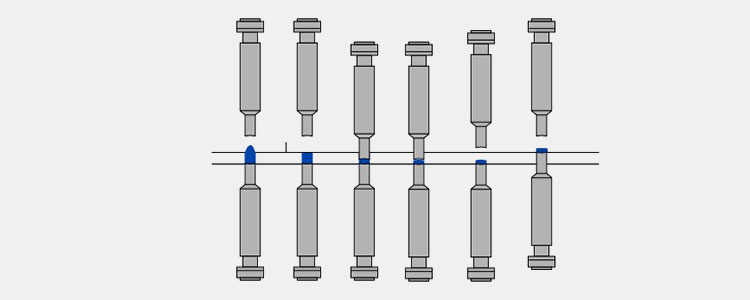

4.Upper and Lower Punch

Upper Punch is pressed downward and puts pressure on powder so that it can be squeezed into the tablet. Lower Punch stores powder and also apply pressure on powder. After the tablet is created, a lower punch is forced upward to remove the tablet from the Die.

Rotary Tablet Punches

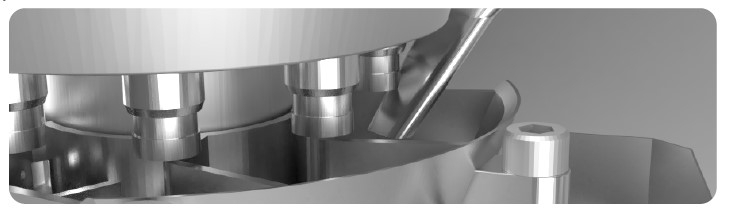

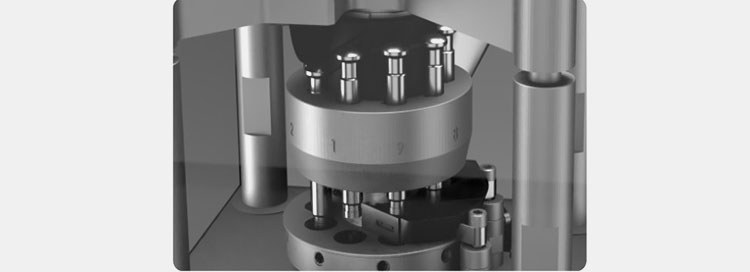

5.Turret

In this component of the machine Tooling components (Die, Upper, and Lower Punch) are placed.

Turret- Rotary tablet press

6.Upper and Lower Tracking

Movement of the Tooling components is directed by upper tracking and lower tracking.

Upper and Lower Tracking

Upper and Lower Tracking

7.Upper and Lower Pressure Cam

The pressure to drive upper punch and lower punch downward and upward respectively is supplied by Upper-Pressure Cam and Lower Pressure Cam. These two-pressure cam force upper and lower punches to condense powder and form tablets.

8.Lubrication System

Nowadays modern rotary tablet press machines have a built-in lubricating system that allows lubrication to those parts of the machine automatically that required after certain periods. Hence it will save your time and maintain the quality of the machine.

9.HMI OR Human Machine Interface

A rotary tablet press has a touch screen system that offers easy input of running data.

This is an easy-to-operate machine that allows feeding data by entering the instructions into the system and the rest of the job will be performed by an automatic rotary tablet press itself.

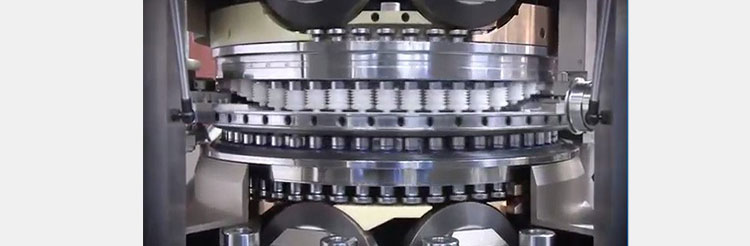

5.How many types of rotary tablet press are there?

There are basically two types of rotary tablet press:

- Single rotary tablet press

- Double-sided rotary tablet press

The main difference between single and double rotary tablet press is that you may use a mini-tablet press or single tablet press using single Tooling such as Die, upper and low punch.

Whereas, on the other side, a double-sided rotary or multiple-punch rotary tablet press is an extensive machine that requires various tooling systems to execute the process.

Single rotary tablet press is ideal machine for R&D, clinical and small-scale productions. It is also used to minimize the wastage when high value ingredients are applied for tablet formulations.

Single rotary tablet press is also recognized as lab tablet press machine.

A double sided rotary tablet press is a highly capable machine that delivers tablets in high acceleration and compression up to the requirement of the protocol.

Furthermore, it has a high-speed mechanical device for compression that has been developed for action of punches and dies. This machine is ideally chosen for large scale production units of various industries.

Single Rotary Tablet Press- Photo Credit- Tablet Press Company

Double-Sided Rotary Tablet Press

6.What are the basic installation steps of a rotary tablet press?

The installation of a rotary tablet requires few basic steps:

- Unpacking

- Lifting

- Adjustment

1) Unpacking:

The unpacking of the rotary tablet press should be done very carefully. As the machine is secured in a wooden pallet, so opening or unpacking the machine you must open the top of the case later move for sides of the case.

Always remember rotary tablet press should be dispatched with a toolkit separately.

Therefore, every received kit should be obtained first before unpacking the machine. After opening the box uncover the machine from the plastic covering.

ToolKit- Rotary Tablet Press

Unpacking Instrument- Rotary Tablet Press

2) Lifting

The movement of the machine may be done directly using the hook on the top of the rotary tablet press. Before moving the machine ensure eyebolts are fully cantered and at the right position. Life the machine straight and place it in the assigned position. This should be placed on a rigid stage/platform with 2 feet of height.

Pharmaceutical Machine Lifter

3) Levelling

Rotary tablet press should be mounted on anti-vibrational pads or platform. Most often rotary tablet press does not require any levelling. But smaller or lightweight machines may require adjustment, therefore, anti-vibrational pads must be used to adjust the machine base plate.

7.What are the precautionary features of a rotary tablet press?

Excellent instrumentation of rotary tablet press meets all safety and practical standards of cGMP.

- The presence of a magnetic clutch allows smooth and rapid operation during the manufacturing process.

- For safety, a rotary tablet press is provided with interlock guards or barrier guards that automatically shut off the machine when a guard is opened.

- For safe and smooth working internal parts of the machine are provided with an internal helical ring and pinion drive (smoothly drive the shaft for pressing tablets).

- Setting option of rotary tablet press is present outside the machine

- The presence of continuous lubrication allows lubrication of machine parts in specific intervals.

- Load pressure or pressure release point helps to release the pressure that arises during production.

- A separate electrical panel is available to assist in easy cleaning of the machine at an interval of time. This will protect the sensitive parts of the machine and operator from electric mishaps.

Separate Electrical Box (1. motor speed, 2. magnetic contactor & starter, 3. Breaker, 4. Fuses, 5. Terminal block, 6. Power relay)

8.How to maintain a rotary tablet press?

Rotary Tablet Press

In order to have a fully operational machine that lasts long, it is essential that the maintenance schedule of the machine is kept. Greasing and cleaning of the machine are important parts of the maintenance procedure.

General Maintenance

- For the prevention of friction in machine parts, it is essential that grease parts must be appropriately lubricated.

- Always use the right amount of lubricant as an excess lubricant can drip in machine parts and can affect the function of the machine.

- Before putting machine parts back together after cleaning, make sure these parts are properly dried and oiled.

- Always check nuts and screws immediately before and after working of the machine as these nuts and screws get loose during the operation of a rotary tablet press.

- Machine parts especially Tooling must be properly stored in a sealed container and placed in lubricants after working the rotary tablet press.

Lubrication

The machines which are lubricated according to the schedule have operational life that lasts for a long time. It is vital to grease parts because they get stuck and affect the working of the machine. For proper lubrication follow these steps

1.First, uplift the Hopper part and unfasten four screws located at the top of Perspex Casting and release it.

2.Release upper and lower punches.

3.Grease the heads of Punches with grease.

Heads of Punches- Rotary tablet press

- Grease the barrel of Punches with oil.

- Oil the Upper Tracking with grease.

Upper Tracking- Rotary Tablet Press

- Open the door located on the left side of the panel.

- Grease is applied for lubrication of the Lower Pressure Cam Shaft and Pressure Adjustment Gear.

Lubrication Schedule

- Examine Drive Shaft Bearings, Turret Bearings, Lower Tracking, Pressure Adjustment Gear, and Fill Adjustment Gear after 3 months or after production of 100,000 tablets, clean these parts with a dry cloth and grease them.

Turret Bearing

- Lubricate the Lower Pressure Cam Shaft and Upper-Pressure Cam Shaft with after formation of 100,000 tablets.

- Grease Upper Tracking before starting tablet production.

- Lubricate Tooling Heads.

- Store Tooling in mineral oil after cleaning.

- Lubricate Tooling Barrels as they are placed in the press every time.

- Examine gearbox after 3 months and lubricate with Gear Oil.

During the working of the machine, the excess powder gets deposited into machine parts Tooling, Fill Tray, Turret, and Upper Tracking and then these parts get jammed.

So for the proper working of the machine, it is essential to clean parts of excess powder and debris.

Remove Part

- First take out Hopper, Perspex Casing, the Fill Tray, and the Tooling

- Detach all the doors of the panel.

- Remove powder from difficult-to-access places with the help of a brush.

- Use the vacuum to clean the top portion of the machine.

- Make sure to clean the top panel at the position where Turret is located.

- All the area inside to steel panel door must be cleaned with a vacuum.

- Ensure that both the portions and every side of the base are cleaned by vacuum.

Cleaning of Parts

- Take out every part one by one from the machine and dip these parts into water mixed with soap.

- Make sure every part is thoroughly cleaned of dust and powder.

- Use a clean cloth to gently wash every part with soapy water.

- Use brush to clean the places which are difficult to access. Tooling components must be cleaned with soft materials such as soft pipe cleaner and soft cloth.

- Remove excess water from the water after cleaning.

- Use a clean cloth to sanitize parts.

- Then oil parts.

Cleaning of Base and Turret

Base and Turret of rotary tablet press

- Get rid of adhesive materials from Turret and Die by using brushes that are provided with the machine.

- Use cleaner to clean areas of Turret and Tooling.

- Remove surplus cleaner with water and then remove water with a cloth.

- Disinfect the base with a clean cloth.

9.What are the advantages of a rotary tablet press?

Rotary tablet press is an extensive tablet pressing machine that has several advantages such as:

1. High Production Output

A rotary tablet press is good and a powerful machine that yields quality product output that is hundreds of times greater than a single punch tablet machine.

This is an ideal machine for continuous tablet production that ranges from more than 200,000 high-quality tablets per hour. Therefore, this machine is recommended to run high production units of tablet manufacturing sectors.

2.Safe Production

The rotary tablet press utilizes upper punches and lower punches that create pressure. This pressure is mild and constant that can be easily discharged and reduces the chances of lobes phenomenon (instability or vibration during the process).

Rotary tablet press has adopted pressure rollers for rising of pressure. Furthermore, punches are firmly arranged in order to combat shock phenomena. These parts cumulatively allow stable and noise-free production.

Rotary tablets machine allows the production of tablets with accurate and uniform weights. It is comprised of a fixed feeder that has a long feeding time. Air can easily discharge with fewer chances of granules stratifications.

5.HMI

An HMI-based system of rotary tablet press easily manages the modulation of tablet hardness, thickness, and other important parameters necessary for tablets production such as speed, production per hour, etc.

10.Are multiple punch rotary and rotary tablet press the same?

Yes, Multiple punch rotary and rotary tablet press are the same equipment that follows the same working principle. The term rotary indicates the movement of upper punches, lower punches, and dies are around an axis in a rotatory motion.

As the head of the rotary tablet press moves, it simultaneously rotates associated parts that compress the tablet granules into a compact form.

11.What is the technical troubleshooting of rotary tablet press

Problems arise during the operation of the machine, which affects the production of tablets and also causes deterioration of machine parts.

There are several solutions by which these problems can be managed. You should be aware of the function of every component of the machine to solve these issues.

The most common issues are

1.Freezing and Locking of Rotary Tablet Press

Sometimes machine gets jammed or struck which affect the manufacturing of the tablets.

The possible reasons for this issue are

- Grease points are not oiled properly.

- Excess pressure inside Tooling.

- The surplus powder is deposited in the machine part.

These issues are solved by frequently oiling the grease point and also the areas in which a huge amount of friction is produced. In order to release excess pressure, the pressure knob located at the left side of the machine should be rotated clockwise. For removing surplus powder you should take apart Turret and Tooling components and clean them.

2.Abnormal Sounds

Sometimes knocking sounds can be heard from the machine. This problem is caused by various reasons such as

- Excess pressure in the machine

- Nuts and screws are loose.

- The V Belts are loose.

- Oil in the gearbox is not according to level.

The pressure knob present on the left side of the machine should be turned anti-clockwise for getting rid of excess pressure. Tauten the loose parts of the machine and get new V Belts to stop the knocking sounds. Also, you should inspect the level of the oil gearbox.

3.Encountering resistance during manufacturing

Every now and then the problem of resistance in rotary tablet press parts is encountered. This problem is because of force which is faced by machine parts that cause difficulty in their movement. Resistance arises due to:

- Damage, locking, improper cleaning, and greasing of high friction areas.

This issue is solved by proper lubrication, oiling, and greasing machine parts especially in areas of high friction. You must also thoroughly clean each and every part of the machine.

4.Vibration in Machine

Sometimes you feel that your machine is producing excess vibrations which affect the production process. This problem is occurring due to the fact that

- V Belts are old.

- There are no pads that counter the vibrations in the machine, or they are old.

- Parts may be slack.

These issues are resolving by replacing V Belts and getting new anti-vibration pads. Anti-vibrations pads must be placed at the bottom of the machine. Inspect and tauten machine parts if they are loose.

5.Debris in Machine Components

Every now and then excess powder is stucked into machine parts and causes the jamming of machine parts. The powder is leaked in machine parts because of several reasons like:

- The powder is rotating very fast.

- Fill Tray is not up to the level.

These are solved by decreasing the rotation velocity of powder and also by adjusting the level of Fill Tray and Fill Tray Scrapers.

6.The powder is sticking on Upper Punch

When the powder gets stuck on the upper punch it can hinder the movement of the upper punch in the downward direction and affect the formulation of a tablet. This problem occurs due to

- Damage to Tooling

- Design of Tooling can also cause sticking of powder.

You should take out every part of Tooling and replace them, this will solve the problem. Also, check the formulation of a tablet as this may also cause sticking.

7.Broken or Shattered Pill

This is the most considerable problem which affects the manufacturing process. This also increases the time and cost of the production process. Various factors produce this problem such as

- Poor quality and imprecise quantity of ingredients and formulation

- Inadequate amount of dry material is passed from Fill Tray into Tooling

- High pressure

In order to solve these problems first, you should check the quantity and quality of ingredients and also check for the errors in the formulation. Alter level of Fill Tray and Fill Tray scrapers so that adequate material should be fed into Tooling.

8.Soft Tablets

Even now and then machine manufactures soft tablets or pill of inadequate weight, and these poor-quality tablets impact the cost of manufacturing. This issue arises because of

- Insufficient pressure produced by Punches

- Consistency of Mixture

These issues are countered by checking the errors in the formulation and also, by moving the pressure knob found on the right side of the rotary tablet press in an anti-clockwise direction.

9.Tablets get cracked during ejection

Sometimes you see the tablets get broken when they are ejected from the Rotary Tablet Press. This is caused because of

- The ejection Cam is not properly cleaned.

- Ejection Cam is old

These issues in the ejection cam are solved by taking out Turret and examining and cleaning the ejection cam. If the ejection cam is old, then you should replace it with the new one.

12.What advancements in the technology of rotary tablet press have been developed?

The rotary tablet press was invented first as the single punch machine that was only utilized to compress a single tablet each time. With demands and requirements, a rotary tablet press was developed that can manufacture many tablets in each round.

With time, various modifications, advancements have been established in the rotary tablet press to process more reliable, robust, and fast production.

The main factors for improvements are as follow:

- To make rotary tablet press more efficient

- Upgrade the quality

- User safety

- Tooling safety and

- minimizing the cross-contamination

Prime Advancement in Rotary Tablet Press

- Auto-weight adjustment of the tablets

- Rejection mechanism

- Online analysis of weight variation of tablets

- De-dusting with a metal detector

- Visual indicator

- Exchangeable Turret

- Rota-heads

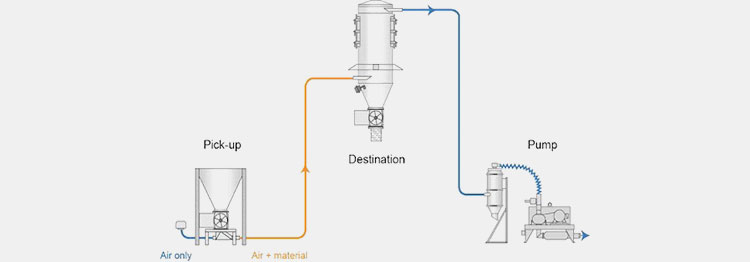

1) Vacuum Feeding

The tablet compression process begins with the filling of powders or granules in the hopper of the rotary tablet press.

Conventionally feeding of material into rotary tablet press was done manually, which results in cross-contamination, the risk for operator poor feeding, less volume, weight variation, etc.

Advancement

- Now, an advance rotary tablet press has an auto-feeding system that with help of an air vacuum system automatically supplies tablet material from container to hopper which is controlled by a sensor.

- The rotary tablet press is available in a closed system hence low chances of cross-contamination

- Protected from dust

- 100% User- friendly

- No volume variation

- Smooth feeding

2) Rejection Mechanism

Due to weight variation, inconsistency, or hardness may occur.

In the old rotary tablet press, soft, low-weight, or inconsistent tablets were not removed automatically.

Advancement

- Auto- rejection system is installed that can segregate good and bad quality tablets

- Input range system of rotary tablet press automatically analysis the tablet above or below the rejection range

3) Visual Monitoring

Visual monitoring such as the HMI system is utilized to improve the quality of the product. Abnormality in the weight or hardness does not give alerts.

Advancement

- Now, you can graphically view the running parameter on HMI

- Any variability system is easily observed by a user

Any changes in the protocol can easily be made in a running system

4) Visual Alarm System

There was no concept of an alarming system in an old or conventional rotary tablet press machine.

Advancement

- Todays, critical parts of the rotary tablet press are attached with an alarming system, that alerts you in case of a mishap

- An alarming system is indicated on HMI, that can highlight the specific affected area

- Visual alarming system ensure operator safety

5) Metal De-Duster

In conventional rotary tablet press, tablets were passed through a separate de-dusting and metal detecting system that was indeed a time-consuming process. Additionally, this integrated system dictated a high production area.

An Advanced Rotary Tablet Press Machine with a Closed Housing Unit. Photo Credit- Korsch Tablet

Advancement

With the advancement in technology of rotary tablet press, now you can find both systems incorporated into a single unit that can efficiently perform de-dusting and metal detection tasks. Furthermore, this system does not occupy a larger space as well as energy.

6) Self-Maintenance

Up till now, you need to follow the weekly, monthly, and yearly maintenance protocol required for the machine. Therefore, it self-maintenance parameter is introduced in the rotary tablet press machine.

Advancement

- Presently, automatic lubrication and oil system allow central lubrication of machine tools such as pressure rollers, racks, tooling, etc., when required. Hence you do not need to inspect or worry about it as this system ensures extending the working life of the machine.

Rotary Tablet Press Machine

7) Advancement in Tooling

There are multiple advancements in tooling system has been used such as:

A) Multi-Tip Tooling

As it names shows, multi-punch tooling is introduced

- Die with more than one die.

- Force-feeding is introduced that ensures a uniform filling of material into dies and protects instability in weight and sizes.

B) Exchangeable Turret

- A turret which is considered the heart of rotary tablet press was introduced in a flexible and exchangeable form. Previously to change a Turret takes a longer time nearly 3-5 hours for the next protocol.

- Advance rotary tablet presses are well-designed machines that offer a flexible Turret removal from the machine with all punches and dies with ease. While you can install another Turret completely by replacing the older one for the next product.

13.Do rotary tablet press machines conform with international quality standards?

For a good quality manufacturing machine, you always seeking quality standards certifications that assure the machine is safe, robust, reliable, and perfect to meet your production demands.

A rotary tablet press is an ideal machine that meets all the basic quality standards assigned by international governing bodies.

1.cGMP Compliance

Rotary tablet press is considered as most trusted and demandable product for pharmaceutical, nutraceutical, food, and other healthcare units.

The basic make-up of this machine is done by stainless steel. Therefore, a rotary tablet press offers up-level sanitation and safety to end-user.

Rotary tablet press is CE certified equipment entails quality standards are regulated by European directives and regulations.

3.FAT test

Rotary tablet press is FAT verified equipment that entails machine is highly validated and capable to facilitates all working specifications to the end-user.

4.ISO Certified Machine

Rotary tablet press is suited to meet quality assurance and standardization parameters required for the manufacturing department of industry.

5.FDA Compliant

Rotary tablet press is FDA compliant machine that entails this machine is highly robust, effective, reliable, and safe without any false aspects.

14.What are the important consideration factors involved in purchasing a Rotary Tablet Press?

Before buying a rotary tablet press you must consider the following important points that will help you to choose the right machine for your production unit:

- Your Production Capacity

Choosing the right rotary tablet press for your production unit needs a critical evaluation for a streamlined manufacturing process. Vendors may offer you rotary tablet press that hold various sizes and capacity specifications. For instance, tablets productions range from thousands to lacs per hour.

Therefore, you must know the production capacity that will help you to select the right machine for tablet production.

- Considering your Budget

Buyers must consider the budget before buying a Rotary Tablet Press. There are many rotary tablet press available in the market that offers a lower operating expenditure and yield high productivity. Therefore, you must scrutinize for equipment that can save you production costs with a high-profit margin. Moreover, always buying Tooling and equipment from the same vendor. If you purchase Tooling and machine from different vendors, it will directly affect machine’s efficiency and causes assembling problems.

- Always opt for a Competitive Vendor

The strength of suppliers is customer satisfaction. They will always provide you pre-sale and post-sale cooperation.

They will give you useful services, suggestions, and tools that you require with cleaning, maintenance, or installation packages.

Then, you must look for a competitive, experienced, and loyal manufacturer of pharmaceutical equipment.

- Low Power Consumption, Low Noise, High Production

Various rotary tablet press are dealt with power consumption independently. You must consider a fully automatic rotary tablet press machine that yields an ultra-high rapid production of the tablet with an advanced electric software control system.

Conclusion

We hope this informative blog has helped you a lot.

Tablets manufacturing is regarded as a complex oral drug delivery system and to manufacture them you must properly assess their designs, formulations, and development equipment.

A rotary tablet press certainly encompasses all complex parameters that produce perfect quality tablets for large-scale production units of the industrial sector. Hence, a good relationship with the supplier and well-acknowledged instrumentation of rotary tablet press is crucial in the success of the quality tablet manufacturing process.

Tablet Press Machine Related Products

Tablet Press Machine Related Posts

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine