Ribbon Mixer: The Ultimate Buying Guide In 2025

Ribbon mixer is one of the most versatile equipment extensively utilized in various production sectors. It is ideal for mixing solid and various powders. This article aims to offer a better understanding of ribbon mixers. For instance, working principles, crucial components, types, automation, and limitation. We will also highlight some best features and efficient processing required for your production line.

Table of Contents

Ⅰ.What is a ribbon mixer?

Ribbon mixers are the light duty millers, generally used for effortless and homogeneous mixing of viscous powders like dry granules or re-sieved powders.

Major function of these mixers is low shear mixing of solid materials but these can be employed for blending of solid-liquid materials when high shearing force is not required. These mixers provide versatile mixing of heat sensitive low viscosity pastes.

These millers aid in coating of materials with other ingredients as well as vacuum drying.

Ⅱ.What are the industrial applications of ribbon mixers?

Now a day, ribbon mixers are the most sought after equipment, used in uniform mixing of variety of dry materials. Applications of ribbon mixers in some industries are mentioned below for your information.

Pharmaceutical Industry

Ribbon blenders are increasingly utilized in the pharmaceutical industry to mix a assortment of pharmaceutical ingredients. These mixers effectively blend solid pastes.

Ribbon mixers blend large volumes of drugs in small time duration. These are also used for mixing of capsule formulations.

Nutraceutical Industry

In nutraceutical industry, ribbon mixers are increasingly employed for mixing of various dry protein powders, vitamin and mineral supplements. These mixers coat solid materials with liquid ingredients to form nutraceutical formulations.

Food Industry

Ribbon mixers are commonly used in food and beverage industries to blend instant energy drinks, cake mix, spices, cereals, and dried food products. These mixers are useful in producing trail mix consisting of various nuts, seeds, chocolates etc.

Cosmetic Industry

Ribbon mixers are popular equipment in cosmetic industry used for mixing large quantity of paste in order to manufacture face powders, talcum powders, eye shadows, and other pigments.

Agriculture Industry

Ribbon mixers are widely used in agriculture industry to blend bulk amount of fertilizers, pesticides, and other coating solutions for seeds.

Chemical Industry

Ribbon mixers have major application in chemical industry as a various chemicals require mixing for producing detergents, resins, glues, cleaning solutions, carbon black, and other plastic polymers.

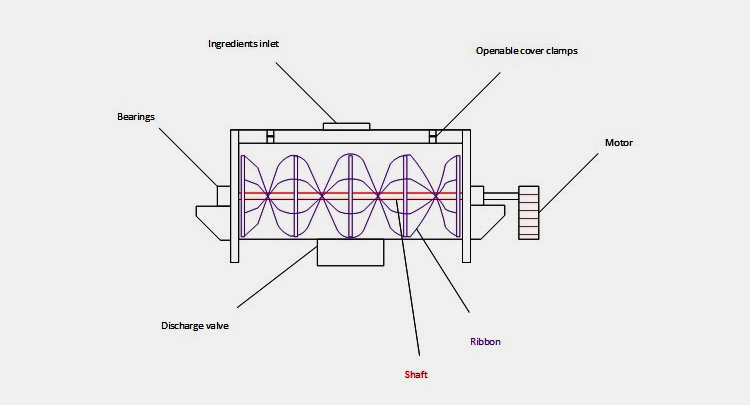

Ⅲ.What are the parts of a ribbon mixer?

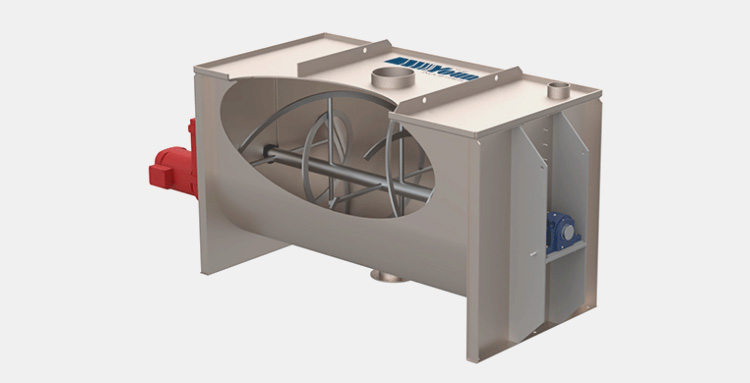

Ribbon mixer is efficient equipment consisting of various parts for thorough mixing of materials.

Some of these components are detailed below:

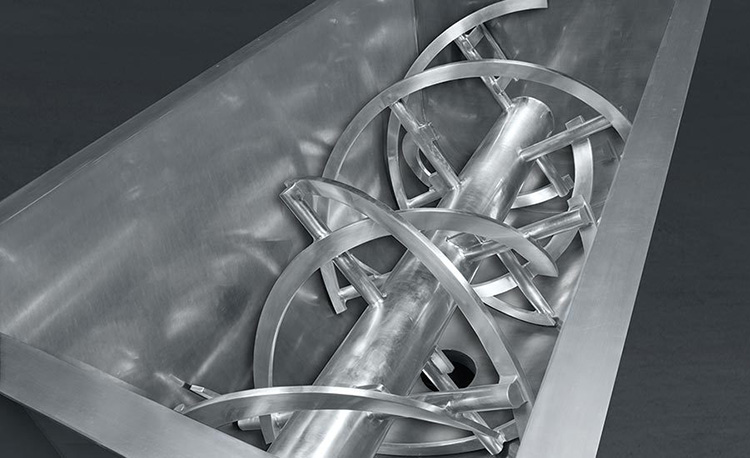

Mixing Tank

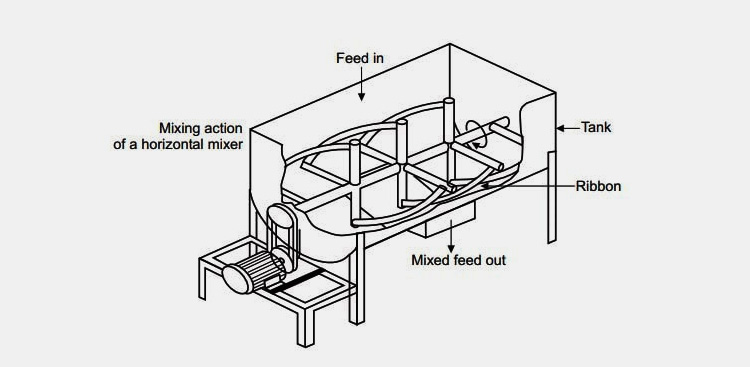

This is the main part of ribbon mixer where mixing and amalgamation of diverse dry powders occur. It is a U-shape like trough containing agitator. The size of this tank usually depends upon the type and amount of dry ingredients.

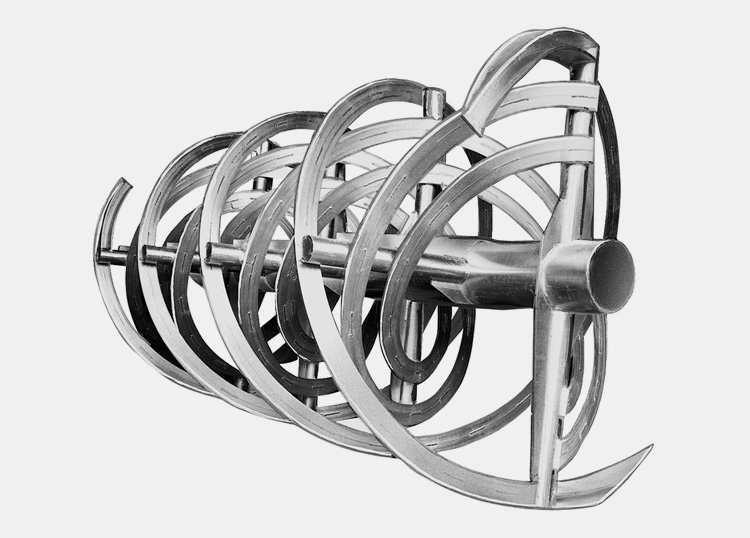

Rotating Shaft

This is a horizontal shaped tunnel and is rotated at high speed for swift motion of agitators. The speed of the rotating shaft varies and is usually dependent on the diameter of outer ribbon. The speed of this part is around 80 to 100 meter per minute.

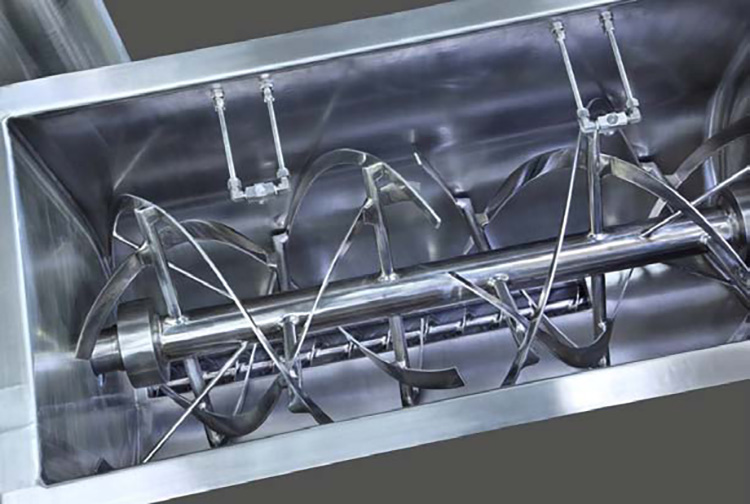

Agitators

Agitators are present at the middle of mixing vessels and have helical ribbon or spiral welded spokes. Agitators have two sets of ribbons -outer and inner- so this mixer is also known as double helical ribbon mixer.

The ends of agitator shaft are welded to edges of tank and are sealed to prevent leakage of material outside.

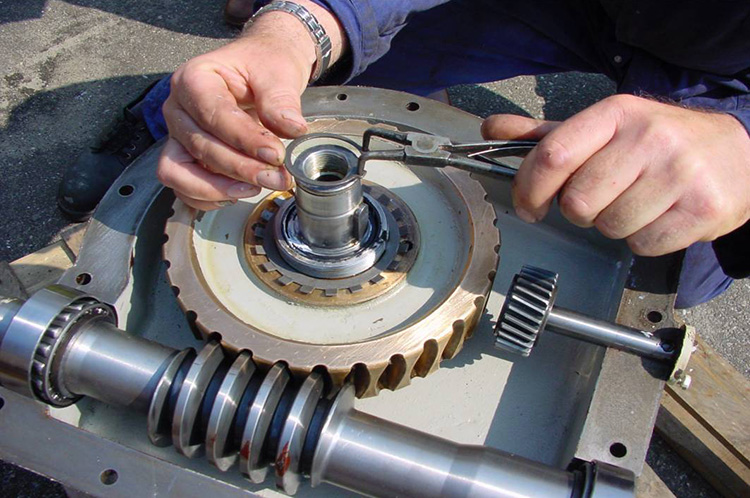

Drive System

Drive mechanisms are needed for efficient performance of ribbon mixers. These systems have drive belts and pulleys for providing necessary speed and torque for rotating shaft.

There are many kinds of drive systems like variable frequency drive, energy efficient motors, and explosive proof motors.

Robust drive system is composed of gearmotor which decrease the power consumption. Gear motor is one piece motor used for high start/stop periods and has superior life quality.

Feed Hopper

Feed hopper or nozzles are used for feeding dry powder, granules or liquids in the mixing vessel. These inlets are found at the top of trough.

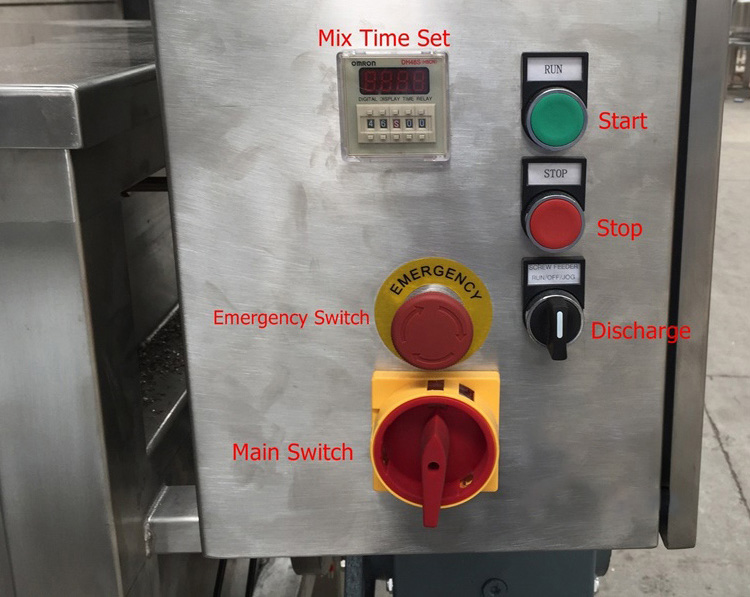

Control System

Ribbon mixer is equipped with sophisticated control panel for easy setup of operation and also aids in decreasing load on operator.

Control panel has main switches, emergency switches, safety buttons and alarms sensors for ribbon mixer operation.

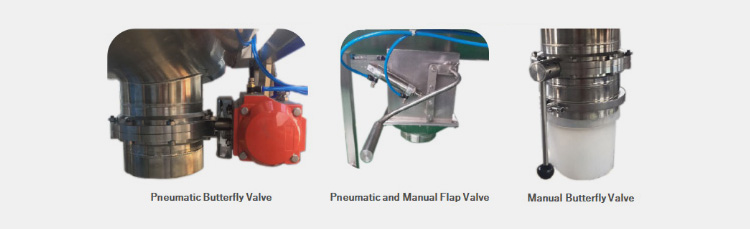

Discharge Valve

Discharge valve are present at the lower side of trough and is used to remove mixed materials from the mixing vessel. These discharge valves are essential in decreasing material wastage and spillage. There are many types of discharge valve like

- Butterfly valve

- Slide gated valve

- Spherical valve

- Flush bottom valve

Ⅳ.What is the operating principle of a ribbon mixer?

Mixing of dry ingredients in various industries is commonly achieved by ribbon mixer. These are frequently used for making solid-liquid suspensions, slurries and pastes.

Some of the steps in working of ribbon mixers are explained below:

Loading

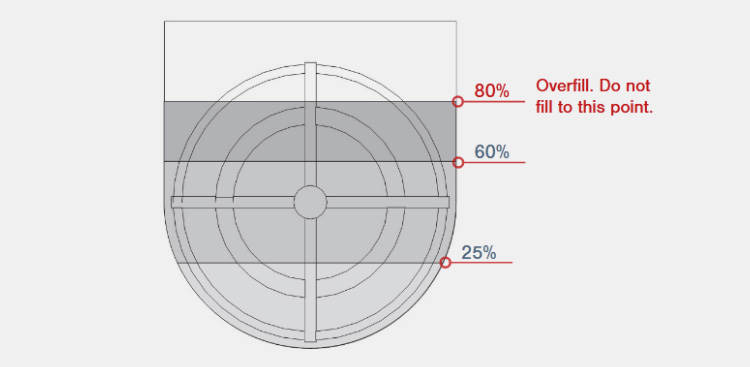

In first step, the material is fed to mixing tank via nozzles or hopper. These materials are filled 40-70% of total capacity of mixer which is about level of outer ribbon.

Mixing

During blending, the outer ribbons push materials from ends to the centre portion of vessel while inner ribbons work in opposite direction. The ribbons move the material around horizontal axis this radial movement of ribbons is vital for uniform mixing.

The mixing in ribbon mixer is accomplished in 15-20 minutes. The fast rotation of ribbon blades also assists in eradicating lumps from the material.

Discharging

Once mixing is complete, the paste or slurry is removed from the tank through discharge valves. The operation of valves can be performed both automatically and manually.

The movement of ribbon agitator aids in discharging of material.

Ⅴ.What are the different types and designs of a ribbon mixer?

Ribbon mixers are broadly classified in two different ways which are:

- Automation

- Processing

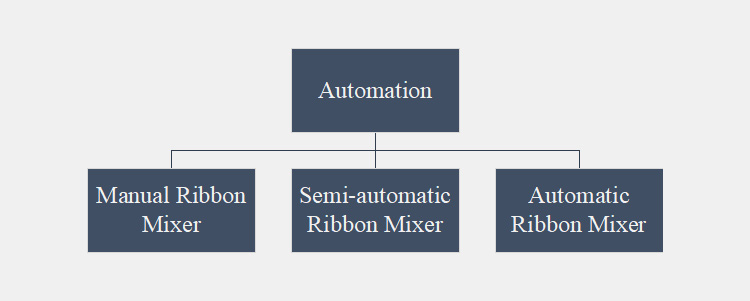

Types Based on Automation

There are three kinds of ribbon mixer based on automation.

Manual Ribbon Mixer

These are the small scale mixers having volume about 5 litres. Most of the functions like loading and discharging in these mixers are performed by hand. These are mostly appropriate for use in small laboratory and research establishments.

These mixers are used for mixing small quantities of powders. In manual ribbon mixer, the materials are added before starting the machine.

Semi-automatic Ribbon Mixer

These mixers are usually used for blending moderate amount of materials and are generally employed in medium sized industries. Some processes as loading are performed manually such in these mixers while other are performed automatically.

These mixers use more power than manual ribbon mixer.

Automatic Ribbon Mixer

These are huge mixer suitable for large production plant. These mixers have excessive working capacity of about 20000 to 25000 litres. Every procedure from loading to discharging is performed automatically by machine.

These mixers are equipped with touch screen HMI for controlling machine operation. These machines need enormous power to run.

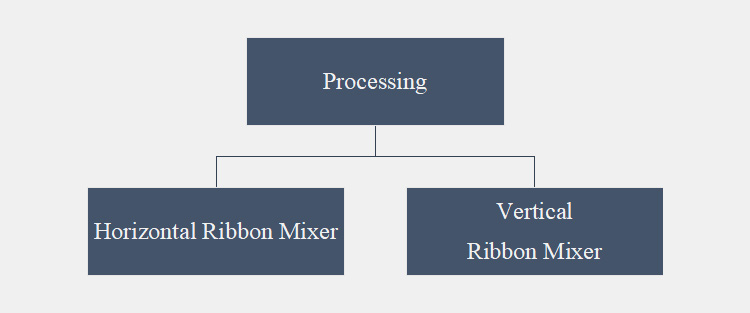

Types Based on Processing

Ribbon mixers are classified in two types based on processing.

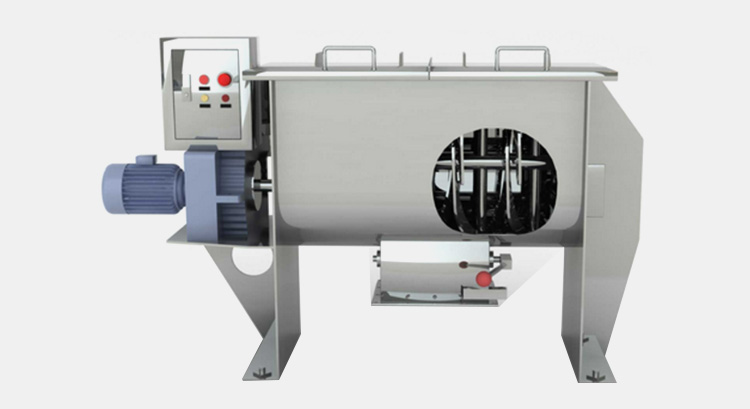

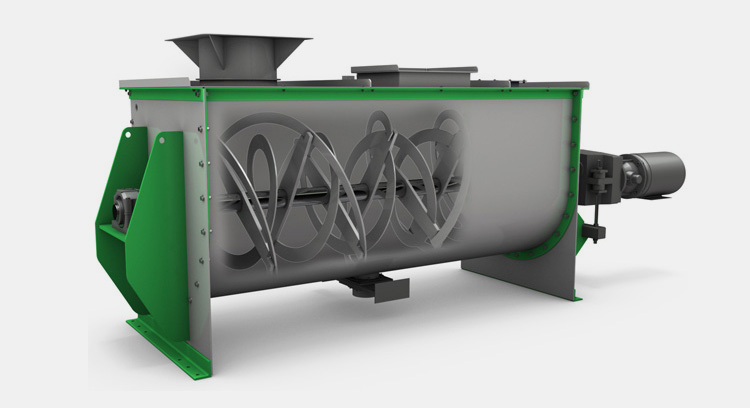

Horizontal Ribbon Mixer

These mixers are furbished with ribbons or blades fixed to horizontal shaft. These mixers move the load in all directions such as from top to bottom and from left to right. These mixers occupy small headspace and can easily handle every kind of material whether it is solid or liquid.

Mixing is achieved in small stretch of time with faster discharge and little cleaning effort.

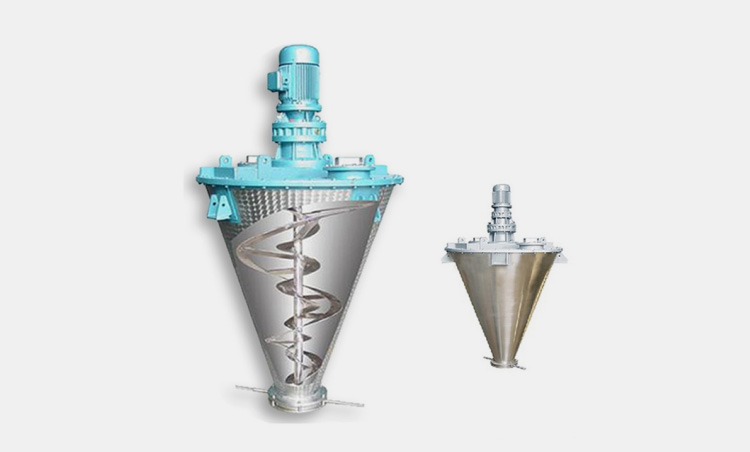

Vertical Ribbon Mixer

These mixers have vertical auger where material is circulated numerous time. These are used in small to medium industries and are composed of vertical screws for mixing. These mixer require little floorspace.

The screws move materials to the top and afterwards the materials fall down. This process is repeated multiple times to attain uniform blend. These mixers does not effectively mix liquid ingredients and require more time for mixing than horizontal mixers.

Ⅵ.What are the advantages of using a ribbon mixer?

Ribbon mixer makes worth of your investment. It is a most handy equipment to have in your mixing plant.

Some of worth penning benefits are discussed below:

Gentle and Homogeneous Mixing

Ribbon mixers have two different kinds of blades unlike other mixer and the counter current movement of blades pushes materials in reverse directions causing materials to mix uniformly and smoothly.

Long Service Time

Stainless steel is the main material used for designing outer covering of ribbon mixer. This material provides stability and quality to ribbon mixer, resulting in its long operational time. Usually the service time of this mixer is more than 20 years.

User-friendly Operation

Control unit of ribbon mixer is easy to operate. It is programmed to repeat process multiple times without requiring assistance from operation. This makes working of ribbon mixer cconvenient and burden-free for operator.

Efficiency

Double ribbon blades have high rotation velocity which results in efficient mixing. Triple mixing is very fast and saves a lot of time.

Prevention of Leakage

Ribbon mixer is fully sealed thus preventing the spillage of material outside. This feature of ribbon mixer minimizes operational cost and product wastage.

Maintenance

Ribbon mixers have simple design and its components are easily disassembled so requiring low maintenance effort.

Working Capacity

These equipments come in various makes and models having working capacity of 5 to 25000 liters.

Ⅶ.How do you clean a ribbon mixer?

Cleaning of ribbon mixer has prime importance as it gets rid of residues and is helpful in efficient working of mixer.

Few points that should be considered while cleaning ribbon mixer are:

- Inner surface of stainless steel material should be burnished

- Brush, compressed air, and water should be used to clean the ribbon mixer.

- There should be space between welds of ribbon mixer to avoid material accumulation.

- Do not remove agitator while cleaning unless specified by manufacturer.

Ⅷ.How do you optimize the ribbon mixer?

Ribbon mixers used in various industries generally have same design with few differences. You can optimize the design of ribbon mixer to reduce start-up investment and increase efficiency and work quality.

These tips will help you to optimize your ribbon mixer.

Space Requirement

Space is a major issue that affect footprint and design of mixer. This also impacts production capacity. Be sure to ponder on your space capability before purchasing ribbon blender to avoid cluttering and work accidents.

Mixing Time

Mixing cycle depends upon dimension of mixer and characteristics of mixing materials. It is advised to test mixer with your ingredients in advance for achieving best mixing cycle. Invest in that ribbon mixer which perfectly aligns with your mixing cycle.

Ingredients

Knowing about features of ingredients like their state, weight, friability, etc aid in optimizing the design of ribbon mixer. In this way, you will get right sized ribbon mixer suitable for your production.

Ascertain Production Size

The amount of mixing ascertains the dimensions and contour of mixer. Do not purchase large sized mixer if you have small production capacity.

Correct Agitator Design

Agitator profile influences the amount of mixing ingredients in one cycle. So choose right kind of agitator for your production as heavier agitator requires huge power.

Estimate Ribbon Design

If you need more mixing volume in less time then you need to scale up ribbon profile.

Establish Shearing Strength

Ribbon mixers typically have low shear but if you are dealing with shear sensitive ingredient then be sure to test ribbon mixer before buying.

Put in Right Discharge Gates

Discharge gate profile depends upon cycle time, ingredients, and subsequent procedures. Having multiple slide gates on your systems is feasible for your productions as these gates with air tight sealing remove material quickly.

Determine Horsepower

Normally ribbon mixer has 20 RPM speed but you should verify the accurate horsepower of your motor before purchasing. This is necessary for purchasing purchase right mixer that is compatible with your power capacity.

Ⅸ.What are the problems and troubleshooting of the ribbon mixer?

Mixing of materials in ribbon mixers is not without the problems but these problems can be easily overcome following tips given below:

Mixing is Consuming Plenty of Time

Sometimes the mixing is taking a lot of time resulting in low production capacity.

Cause

- The mixing tank is filled over the working capacity.

- The order in which ingredients are poured into tank is not accurate.

- The speed of mixer is less.

Solution

- The amount of powder in tank should not go beyond than 70% of tank’s volume.

- First pour smaller ingredients in tank then load large sized ingredients.

- Increase the speed as specified by manufacturer guide.

Blocking of Ribbon Agitator

You will see that agitator of mixer get blocked with ingredients and does not move freely.

Cause

- The bulk density of powder is very high.

- The batch size of ingredients is very large.

Solution

- Decrease the bulk density of powders.

- Lower the amount of ingredients in mixing tank.

Power Spillage

The materials get leaked from the edges of the mixing tank.

Cause

- Seals of mixer are old or damaged.

- Compression robes present in seals are dilapidated.

Solution

- Replace the old and damaged the seals.

- Get new compression robes for the seals.

Damage to Product

Sometimes the materials get impaired during mixing causing loss of efficiency.

Cause

- The mixing duration is huge.

- Speed of agitator is too much.

Solution

- Decrease the duration of mixing cycle.

- Reduce the speed of agitator.

Mixing Vessel Halt during Operation

The mixing tank stops rotating at some stage in operation.

Cause

- The amount of powders is very high.

Solution

- Curtail the batch size of ingredients.

Ⅹ.What are the future perspectives of a ribbon mixer?

Ribbon Mixers are used more and more in various industries like pharmaceutical, food, chemical. These mixers are mainly used for dry blending but are also used for preparing flowable slurries and coating solutions.

The increased use of ribbon mixers is causing the expansion of their market. It is expected that market revenue of ribbon mixer will upsurge from US$ 119 million in 2019 to US$145.4 million in 2026 with the CAGR of 5.4%.

The demand for premium quality ribbon mixers has shifted manufacturer priority for introducing high-end customized mixers in market. The industries are adopting mixers that have shorter mixing cycles and have reduced incidents of dead spots.

The future ribbon mixer will be completely automated and will be able to fulfil high mixing demands of industries especially food and pharmaceutical. These mixers will provide both low and high shear as per consumer need.

These mixers will be customized with FDA approved safeguards, multiple ports for spraying, vacuuming, and venting, air-tight computerized seals, automatic discharge valves, and PLC control panel for pre-programming operation instruction.

Conclusion

Ribbon mixers are widely used in pharmaceutical and food industries to mix various dry powders. These mixers are efficient and handle large mixing load in short time. You can easily optimize these mixers by considering your space requirement, production capacity, and power consumption. We are Here to Help! For Product Guidance, or Quotation Please Contact Us Right Now.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine