Reviw On The Pharmaceutical Packaging

The first thing that attracts you when you go for shopping is the packaging of the product. Attractive colors, designs, labelling and the type of packaging material all work in unison to deliver the product from the market shelves to your home.

Packaging is an integral part of any product but when it comes to pharmaceutical products there are certain standards that are to be met in order to protect the contents from deterioration, accidental spillage, ingestion and opening, in addition to maintaining an appealing look.

What is pharmaceutical packaging? What are types of pharmaceutical packaging? What is primary packaging and secondary packaging? An insight to all these mind rattling questions and many more is being presented in this article REVIEW ON THE PHARMACEUTICAL PACKAGING. Without further delay let’s proceed!

1.What Is Pharmaceutical Packaging?

Pharmaceutical packaging also called as drug packaging is the process that encompasses all the operations right from the beginning of manufacturing of drugs to distribution to intended consumption.

For reasons known pharmaceutical packaging is regulated and has each and every feature recommended by local and international regulatory bodies that sets it apart from other counterparts in the market.

From safety to branding to instructions on usage to marketing, typical pharmaceutical packaging provide safety to consumer, protects the content from degradation, prevents microbial contamination throughout products’ shelf-life.

2.Characteristics And Purpose of a Pharmaceutical Package.

Being a regulated industry no matter what region of the world you are in the norms and decorum of pharmaceuticals are laid on rules, regulation and SOP’s governed by local and international authorities; same is true for pharmaceutical packaging which should have following characteristics in order for it to be affectively be used by manufacturer;

Non-reactive nature: First and foremost a pharmaceutical packaging material should not react with contents that it contains i.e. it should not promote leeching, adsorption and

Sturdy: Pharmaceutical packaging should have enough mechanical strength to withstand pharmaceutical operations i.e. sterilization, filling, transport, handling, etc.

Safety:Pharmaceutical packaging should provide a certain degree of safety to the product whether from microbial contamination, environmental factors, adulteration, and tampering.

Content information: Pharmaceutical packaging is not only limited to containers and boxes and tubes but also includes inserts and labels that provide information related to the medicines.

Identification: Pharmaceutical products can be tracked by brand name, batch / lot number that identifies when that unit was made, and by which manufacture. It should also contain manufacturing and batch expiry dates.

Publicity tool: Marketing of medicines is quite tricky it is a blend of aesthetic and caution, intrinsically pharmaceutical packaging should be elegant and attractive to consumers without compromising above mentioned featuring.

3.What Are Different Types of Pharmaceutical Packages, Containers, And Closures?

There are various kinds of packaging products made of different materials present in the pharmaceutical industry which helps to serve purposes as per their nature of dosage form. We will be discussing here a few of them for you to consider.

Single Dose Containers

Their name itself indicates their purpose; they are made for one time use only. E.g.: Glass ampules.

Multi Dose Containers

The dose contained in them is intended for use as many times as required by the patient or instructed by the doctor . E.g.: Vials for multi dose, plastic medicine bottles.

Well Closed Containers

Their purpose is to prevent the medicine inside the container from any sort of contamination or loss.

Airtight Containers

Such packaging does not allow air to enter inside and interact with the product’s integrity. Once opened, they can be closed again for their action.

Light Resistant Containers

There are few drugs which might be harmed by the light rays and for such drugs usually amber colored glass bottles are used.

Tamper Resistant Closures

Such containers have tamper proof fitting on the lid which shows whether the seal is packed or opened.

Child Resistant Closures

Some containers have a special type of cap or closure that is intended to decrease harmful chances of children ingesting the drug.

Strip Packaging

It is a kind of single-dose packaging in which the product is enclosed between two thermally sealed films.

Blister Packaging

It is a kind of packaging usually for unit doses, in which a cavity is there filled with the required drug lidded by a thermally sealed film.

4.Advantages and Disadvantages Of Different Raw Materials Used In Pharmaceutical Packaging

Variety of starting materials are used to be incorporated in pharmaceutical packaging like mostly glass, plastic etc.

Advantages Of Glass as A Raw Material

- Glass provides great protection.

- It is economic friendly and is easily available in many sizes and shapes.

- It provides good impermeable characteristic due to its strength and rigidity.

- It holds FDA clearance.

Disadvantages Of Glass as A Raw Material

- The biggest drawback is its fragility and heavy weight.

Advantages Of Plastic as A Raw Material:

- One of the greatest advantages is that it is cost-effective and of lightweight which also makes it easily transportable.

- Unbreakable and leakproof

- They do not have any odor and are inert to products.

- Suck back quality which restricts product dozing.

Disadvantages Of Plastic as A Raw Material

- Physically unstable due to properties like adsorption, light weight.

- Allows permeability to gases, light and moisture.

- Cracking due to stress

- Collapse or destruction in shape due to swelling in plastic owing to any reason.

5.What Are Factors That Influence the Selection of One Type of Packaging Over Other?

Before you can select your desired type of packaging format, there are some factors that you must consider:

- The nature of the drug and its excipients.

- Patient’s age (whether they are children, elderly, or adults)

- Type of market where it will be traded (Target audience) , whether for use within the country or for export .

- Transportation system carried for the purpose of delivery of the product (whether it needs fragile care regarding packaging)

- Manufacturing practices like consideration of the emergence of a new product or revised version of the same product, any improvements carried in the issue of good manufacturing practices.

6.What Are Requirements of FDA And Other International Regulatory Bodies?

Food and Drug Administration (FDA) is an organization that has set out some laws to assess drugs and their packaging manufactured in pharmaceutical industries. The manufacturers have to convince the organization that they have met the criteria for drug packaging and ensure them that the packaging will good enough to protect the drug from any contamination or damage and maintain its purity, strength, shell life and efficiency.

FDA has passed a Food and Drug Administration Act which states the kind of materials manufacturers can use to produce their packaging containers known as Generally Recognized as Safe (GRAS). These materials are safe to use and are of good quality.

One of the most important point FDA stresses is that the packaging material used should not react with the drug in a way that it contaminates it, reduces its efficiency or affect the quality or purity of the drug.

Thus, the manufacturers have to get their packaging material approved by FDA before shipping it out for sale. If FDA has approved that the packaging material is safe to use and meets all the requirements needed to qualify for the approval, then it can be sent out for shipping.

7.Coding For Pharmaceutical Packaging

Coding is programming used in pharmaceutical packaging for a number of reasons. It is computer-generated code that can read by machines such as a barcode scanner. This scanner then interprets the code and provides the information it carries such as the manufacturing date and expiry date of the drugs, packaging material information, company’s address etc.

Technology Of Barcodes

There are different kinds of technology employed for the coding of packaging.

Symbologies

The mapping between messages and barcodes in the form of single digits or characters is called symbologies. Its types are

Continuous Vs Discrete

In continuous one-character ends with a space and the next begins with a bar. In discrete, symbologies begin and end with bars.

Two-Width Vs Many Width

In two-width, bars and spaces are either wide or narrow. In many widths, symbologies are multiples of a basic width.

Scanners

These scanners read the code and provide information. A barcode scanner is the earliest and the most economical way that is built from a fixed light followed by a photosensor which is scrubbed across the barcode.

Thermal Transfer and Inkjet Printers

Thermal transfer produces higher-quality images with premium color saturation, similarly, inkjet printers are also used to obtain quality images. The thermal transfer technique is more durable than inkjet as it is composed of fewer parts. It tends to generate high-quality barcodes without implementing the ink.

8.What Are the Hazards Encountered by Pharmaceutical Packages?

Hazards are potential harm or any damage which can happen to a package. There are different types of hazards that can damage the packaging of pharmaceutical packages.

Mechanical Hazards

Shock Or Impact Damage

When the packages are being shifted from the warehouse to their destination, they can get damaged due to shock. This can be prevented by using a cushion that acts as a shock absorber.

Compression

When the packages are stacked up on top of each other, pressure builds up and the material inside the package gets compressed and becomes damaged.

Climatic Or Environmental Hazards

Temperatures

Extreme temperatures can make the packaging material vulnerable to chemical breakdown due to its specific melting and boiling points. Very high temperatures can degrade the material and make them purposeless.

Moisture

If moisture or water vapor make their way inside the packaging, they can change its physical appearance of it such as the colors and texture of the product. They can also affect the chemical composition and cause material degradation.

Atmospheric Gases

The cargo aircraft carrying these products are flying thousands of miles above sea level. The atmospheric pressure at this level is very low, making the packaging vulnerable to damage.

Light

Some packaging materials degrade when light falls on them. This can be prevented by the complete closure of the package.

Biological Hazards

Care should be taken to ensure proper packaging of the products in an extremely clean environment. This prevents the growth of yeast and bacteria, which can damage the product.

Chemical Hazards

If the material used to package the products is not compatible with it or is not safe to use, it can undergo chemical reactions on its contact with the product inside, contaminating it and making it unsafe to use.

CONCLUSION

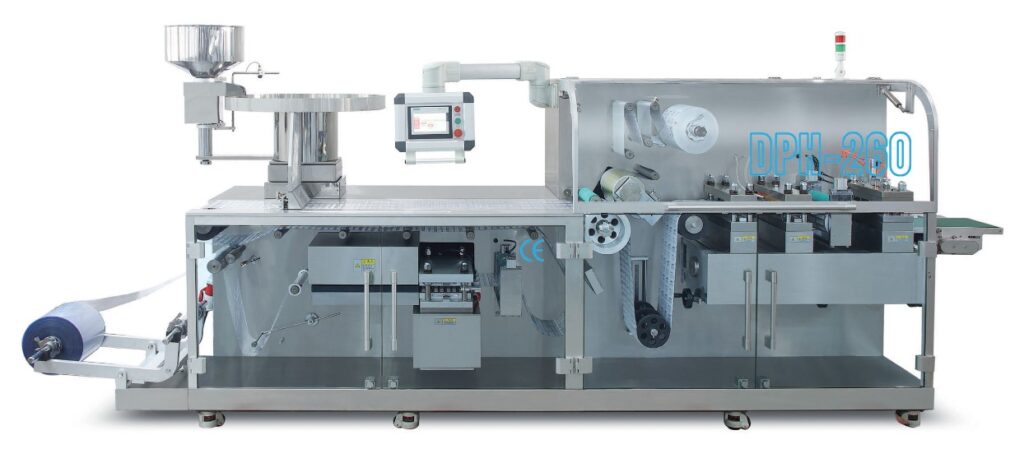

Good pharmaceutical packaging must offer protection, identification, flexibility, and stability for a product from transportation to end-users. You must assess a thorough background when it comes to selecting a packaging material. A Review on Pharmaceutical Packaging must concern with major issues like child resistance, tampering, dosing, and information. You May Contact Us, For More Information and Inquiry About Packaging Machines. We’re Here to Serve You With a Free- Consumer- Support Program.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours