Rapid Mixer Granulator: The Complete FAQ Guide in 2025

Granulation is an essential process of tableting lines in many industries such as pharmaceutical, nutraceutical, herbal, chemical, etc. For granulation, rapid mixer granulators are a must-have unit. These types of equipment have compact structures and ergonomic designs that carry out both dry as well as wet mixing.

You can simply consider them as an investment for a long time. You can make good decisions about buying when considering all the aspects of the rapid mixer granulator that we’re going to discuss here. This guide “Rapid Mixer Granulator: The Complete FAQ Guide in 2023” will answer all your queries regarding rapid mixer granulators.

1.What is Rapid Mixer Granulator?

It is multi-purpose equipment used for high-speed mixing of dry powders, solvents, effervescent materials, and pellets. It is employed in both dry and wet mixing. Without it, ingredients are not uniformly dispersed and formed into granules.

These machines assist in better dispersion and amalgamation of drug ingredients, additives, stabilizers, cosmetic pigments, food materials, chemicals, etc.

Rapid mixer granulators employ agitation and high shear forces to homogeneously mix substances. These are used in the kneading stage of granulation before tableting.

2.What are the Advantages of Rapid Mixer Granulator?

Rapid mixer granulators are the need of various industries because they come with numerous benefits some of which are detailed below:

Short Mixing Time

Rapid mixer granulators are highly productive and can form wet granules in a short time. By using these machines, better mixing results can be achieved in a relatively short duration. Rapid mixer granulators are 4-5 times fast than other mixing and granulating systems. To form 0.5 mm to 1.5 mm sized granules it only takes about 5-10 minutes in these machines.

Uniform Mixing

These systems have a conical bowl shape design which does not allow dead spaces. Consequently, materials are efficient and thoroughly mixed leading to uniform granulation. Impellers of the machines help in homogenous mixing,

Excellent Granulation

These machines can form uniform, controlled sizes, and good-intensity granules. Furthermore, rapid mixer granules are capable of handling large batch loads and hence are used for producing granules at a large scale. These machines are also furbished with proper sealing systems that decrease the waste of granules.

No Contamination Risk

Since this machine is autonomous therefore it requires less handling making it suitable for processing formulation. The processing is completely hygienic and there is no risk of cross-contamination by the operator.

Easy Cleaning

As the mixing medium is completely discharged from the machines and there is no buildup of waste thus it is very easy to clean and maintain the rapid mixer granulator. These systems are also equipped with internal cleaning systems which aid in effective cleaning.

Ease of Operation

These machines are customized with an HMI touch screen and PLC control consequently it is easy to program and operate these systems. The data recipes can be adjusted and changed according to mixing requirements with just one click.

Safety

These systems have safety interlocks mechanisms on discharge valves which prevents the risk of unpredictable accidents during operation. Moreover, these machines generate less drug dust thus there is a low chance of dust exposure to working personnel. Rapid mixer granulators come with a safety cage to prevent human injury during operation.

3.What are the Components of a Rapid Mixer Granulator?

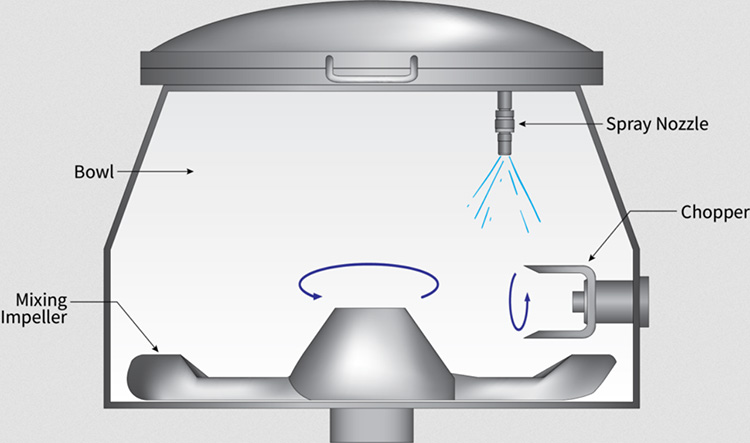

Rapid mixer granulator has a modular construction and is furbished with components that have a particular role in bringing out the perfect mixture for granulation. The basic components of these machines are discussed below for your understanding.

Hopper

On the top of the machine assembly, a hopper is located for adding binder or solvent to the mixing bowl. This hopper has a spray nozzle which is used for spraying solvent on the powder material. The spray system in the hopper sprinkles a precise amount of binder in a controlled manner over material feed to prevent the risk of over-wetting.

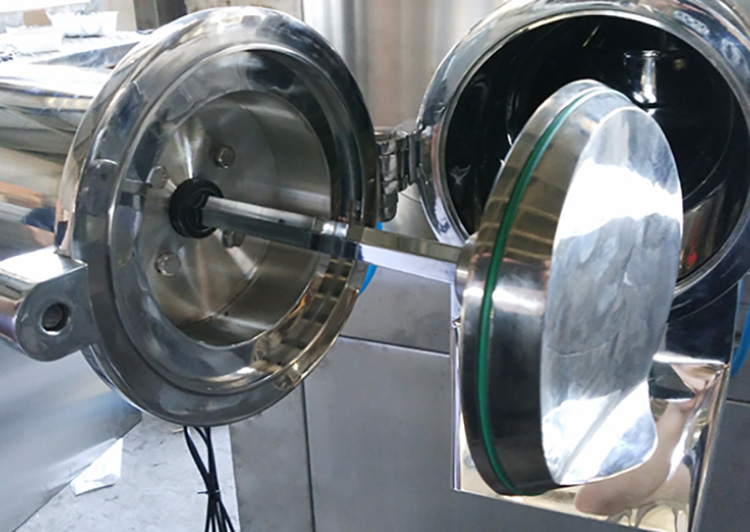

Mixing Bowl

It is the structure in which the powder mixture is loaded for homogenous mixing. The mixing bowl is made of stainless steel material and is the main part of the rapid mixer granulator which has direct exposure to starting material. It has three configurations that are conical shape, dome shape, and circle-like shape.

The size and design of the mixing bowl usually determine the mixing capacity of the rapid mixer granulator.

Impellers

Three impeller blades are usually found at the bottom of the mixing vessel. One impeller blade has full length while the other two are half the length of first one. These impellers mix the materials by slightly lifting them.

The full-length impeller pushes this lifted material back into the mixture for complete mixing. The impellers also fragment the materials into small pieces. These blades are rotated anticlockwise at different rpm by motors.

Choppers

These blades are found at the side of the mixing bowl. These blades act like a cutter as they break lumps into smaller pieces. The choppers have higher speeds than impellers and are rotated at about 1440-2880 RPM. These are powered by a separate motor and are usually employed to prevent the agglomeration of particles during mixing.

Discharge Port

This is fixed horizontally in the cone-shaped mixing bowl and has a vertical opening. The end products or granules are removed or discharged from the machine using a discharge port and are transported to the wet milling machine. The valve of this component is controlled by pneumatic systems or compressed air cylinders.

Filter Assembly

It is also called a breathing filter and has an air vent. This is present on the upper side of the machine. Its function is to decrease pressure inside the rapid mixer granulator. It is also used for discharging purging air from the machine. This purging air is generally blown inside the machine for preventing the accumulation of granules on impellers.

HMI

It is an interactive touchscreen display generally present at the side of the rapid mixer granulator. This part is employed for easy programming of operating parameters such as impeller speed, speed of chopper blade, the timing of opening and closing of discharge port valve, compressed air pressure, etc. This HMI also displays a complete operational report and shows instructions for machine diagnosis.

4.What is the Operational Principle of a Rapid Mixer Granulator?

A rapid mixer granulator is a versatile machine used for quick and efficient mixing and granulation. These machines generally employ agitation, shearing, and tumbling for mixing dry and wet mass. The impellers and choppers are the main components that assist in mixing and fragmenting materials respectively.

Some steps in the working of a rapid mixer granulator are:

Loading of Starting Material

In the first step, the materials for granulation are loaded inside the rapid mixer granulator for their premixing. These materials can be filled inside the machine manually after removing the lid or the materials can be added automatically via pneumatic systems in some advanced tech machines.

For automatically closed loading of raw feed, suction pipes are put inside the vessel containing material then by suction pressure, these substances move inside the mixing bowl of rapid mixer granulators.

Dry Mixing

After loading, the raw feed is dispersed and mixed by the rotation of impeller blades. The impeller blades are rotated at full speed for efficient dry mixing. 3-5 minutes are generally required for dry mixing of small batches.

Wet Mixing

The next step after dry mixing is the wet mixing of powders. For this purpose, the binder solvent is incorporated into the dry mixture via a binder solution hopper. The nozzles spray binder at a controlled rate for minimizing the risk of over-wetting. During binder addition, the impellers and choppers are rotated at a lower speed.

This binder solution is used for transforming powders produced during the wetting step into granules. The choppers break down larger lumps for optimum granulation. The wet mixing of small batches usually takes about 5-10 minutes in a rapid mixer granulator.

Discharging

After the formation of optimum-sized granules, these are unloaded from the rapid mixer granulators through the discharge ports. The valves of these ports are pneumatically opened for discharging of granules.

5.What Are the Industrial Uses of Rapid Mixer Granulators?

Rapid mixer granulators are needed in every industry due to their quick mixing and optimum granulation. Some important applications of rapid mixer granulators are discussed below:

Pharmaceutical Industry

In the pharmaceutical industry, rapid mixer granulators are used for the uniform mixing of drug ingredients and other excipients for producing tablets and capsules. These machines mix granulating fluids such as alcohols, water, and powders and aid in the formulation of consistent-size granules.

Nutraceutical Industry

Rapid mixer granulators are used in the nutraceutical and herbal industry for uniform blending of vitamins, minerals, proteins, and other supplements powders in various liquids for forming pellets, pills, and supplement capsules.

Chemical Industry

These machines play a vital role in the chemical industry for manufacturing dishwashing tablets, chlorine pills, detergent tablets, paints, glues, etc. Rapid mixer granulators are used for blending different chemical ingredients.

Food Industry

In the food industry, these systems are used for mixing various food powders, stabilizers, additives, preservatives, coloring agents, etc. for making sauces, dressings, spices mix, curry powder mix, confectionaries such as chocolates or candies, etc.

Cosmetic Industry

Various cosmetic powders and pigments are evenly mixed in rapid mixer granulators. These machines are often employed in the production of bath bombs, perfumes, face powders, and beauty creams.

Agriculture Industry

In the agriculture industry, different soil types, organic manure, feeds, pesticides, and insecticides are homogenously blended and granulated using a rapid mixer granulator.

6.How Is Rapid Mixer Granulator Capacity Calculated?

Working capacity is important in large batch processing. The mixing bowl of rapid mixer granulators should be filled accurately and up to the maximum holding capacity of the vessel for obtaining optimum consistency granules.

Therefore, it is very important to determine the working capacity of machines before the start of the operation. For the calculation of working capacity, first, you need to determine the bulk density of starting powders. Then multiply this density by the capacity mentioned in the manual of the machine.

For example, if working capacity of the rapid mixer granulator provided by the manufacturer is 800 liters and the working volume of equipment is 80%.

This means the working capacity is 640 considering its working volume. Now if the bulk density of your processing powder is 0.6 then the capacity of the machine in kilograms is:

640x0.6=384 kg

Thus, for an 800-liter rapid mixer granulator, you have to prepare a batch of 384 kg for achieving ideal granulation results.

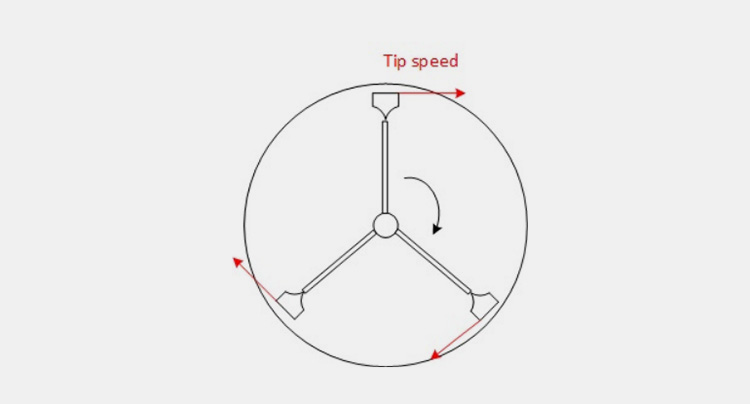

7.How Do You Calculate the Tip Speed of Rapid Mixer Granulator?

The tip speed of the rapid mixer granulator is the speed at the outer edge of the impeller. It usually tells how much further the outer tip of the impeller will travel in a given time duration.

Tip speed determines the efficiency of the rapid mixer granulators. This speed varies with the design of the impellers.

It is calculated by multiplying the diameter of impellers by pi (3.141510). Then will result in the circumference of impeller at the outer edge. Now simply, multiply this circumference by the rotational speed of impeller.

For example, a rapid mixer granulator has a 24-inch impeller that runs at 400 RPM.

First convert 24 inches is equal to 2 feet (1 foot =12 inches). Now multiply 2 feet by pi

2x3.14159=6.283

Then multiply this result by 400

6.283x400=2,513.2ft/min

8.What Is the End Point of Rapid Mixer Granulator?

The endpoint of the rapid mixer granulator is defined as the target particle size average or distribution. It is observed that once you reach the endpoint the characteristics of granules and the characteristic of succeeding tablets are the same, irrespective of performance factors of rapid mixer granulators, for instance, speed of impeller and binder spray rate.

Calculation of the endpoint is very essential for obtaining better quality granules with required physical characteristics such as average size and porosity. It is also important for maintaining the said quality when multiple batches are processed.

The endpoint of the rapid mixer granulator is determined by two methods:

Banana Breaking Method

It is the traditional method for determining the endpoint. In this method, wet granules produced by a rapid mixer granulator are squeezed in hand if there are no dry powders after breaking granules, which means the endpoint is reached.

Ampere Load Method

This method is widely used in industries for calculating endpoints. The ampere load is the power consumed by impeller and chopper while running. It is displayed on the HMI screen. It has a high value while the machine is still mixing the materials but decreases when the endpoint is attained.

9.What Is the Difference Between Rapid Mixer Granulator and Planetary Mixer?

Although both rapid mixer granulators and planetary mixers are used for mixing and granulating substances yet there are some major differences between these machines. These differences are discussed below:

| Rapid Mixer Granulator | Planetary Mixer |

|

|

| Parts | |

| This machine consists of a mixing bowl, impeller, chopper, filter, and discharge port. | It is formed by a mixing bowl, mixer or beater, scraper, and manual lifts. |

| Construction | |

| The agitators’ blades in this machine are located at the bottom of the mixing bowl. | The mixing tools are present at the top of the mixing bowl. |

| Mixing | |

| It is capable of performing both dry and wet mixing. | These systems are more suitable for wet mixing. |

| Shearing Forces | |

| These produce high shearing forces. | These machines produce low shearing forces. |

| Uses | |

| These are mainly used for tablet production | Planetary mixers are mainly used for kneading dough in bakeries. |

| Air Purging Systems | |

| It has air purging systems to decrease the stickiness of granules to machine surfaces. This system also helps in cleaning the machine. | They do not have air purging systems. |

10.What Are the Critical Process Parameters of Rapid Mixer Granulator?

Numerous process parameters influence the performance of rapid mixer granulators. A few of these parameters are discussed below:

Rotational Speed of Impeller and Chopper

The movement and mixing of materials in the mixing bowl are depended upon the speed of the impeller and chopper. If the speed of the impeller is less then granules formed as a result are smooth and have a large surface area.

The quality and size of granules are reduced by increasing the speed of the impeller. The effect of chopper speed on granulation is seen when the impeller speed is around 700 RPM.

Design

The design construction of agitators such as impellers and choppers also has a major impact on the quality of granules. This design not only affects the mixing volume of the materials but also the temperature and cohesivity of resultant granules.

Mixing Time

Wet massing or mixing time affects the final amalgamation and consolidation of granules. Kneading is an important step in working rapid mixer granulators. The mixing time should be right to prevent the formation of poor granules having unwanted density.

Binder Addition Rate

The binder should be slowly sprayed on the surface of the powder bed in a rapid mixer granulator. The slower spray rate ensures uniform liquid distribution. If liquid addition is too fast then it can increase the chance of lumping.

Properties of Starting Material

Different characteristics of raw materials such as volume, size distribution, stability, and viscosity impact the performance of rapid mixer granulators. If starting materials has lower cohesivity then end granules will have poor strength.

Nature of Granulation Solution or Suspension

The granulation in rapid mixer granulators also depends on the nature of granulating solvent such as its viscosity or surface tension. For instance, if the surface tension of a liquid solvent is low then its large quantity is required for granulation.

Furthermore, if a binder is more concentrated then its addition results in better granules. But granules are unstable if the concentration of binder is increased beyond a certain limit.

Viscosity also affects the quality and density of the granules. If the binder is highly viscous then large-sized and denser granules are formed.

11.Why Is the Capacity of a Rapid Mixer Granulator Measured in Liters?

The capacity of the rapid mixer granulator is measured in liters because of its design. The rapid mixer granulator is the instrument that holds and mixes the standard volume of starting materials. The capacity of the rapid mixer granulator is usually calculated by determining the amount of volume the mixing volume holds thus the capacity is measured in liters.

12.What Problems Arise During Operation of Rapid Mixer Granulator? How To Solve Them?

Multiple things can go wrong during the operation of rapid mixer granulators that can result in lengthy downtimes. But these problems are easily remedied by the below-mentioned tips.

| Issue | Cause | Remedy |

| Non-uniform mixing

|

The mixing bowl is not filled to the capacity

Mixing speed is not accurate The time for mixing is not sufficient Decrease the quantity of powders Separation of powders |

Load the mixing bowl according to the manufacturer's guidelines

Adjust the mixing speed Increase the mixing time Use a geometric mixing approach to achieve uniform mixing Powder particle sizes should have a limited variance to prevent segregation |

| Lumps In Mix

|

High moisture content

Sticky material High binder concentration |

Reduce the sprinkling rate

Increase the rate of airflow Use an accurate amount of binder |

| Failure in Air Filtration System

|

The sealing of filters is damaged or worn out

Broken filter sock Feed materials accumulated in filters |

Repair or replace damaged sealing

Replace filter sock Use a Teflon filter sock having a pore size of 1µm.

|

| Failure in Motor Function

|

The circuit breaker is turned off

Accumulation of particles on motor magnet

|

Turn on the circuit breaker.

Removed the particles from the magnet |

| Scratching on Mixing Bowl

|

Impeller blades scratch the surface of a mixing bowl

Chopper may scrap mixing vessel |

Tighten the nuts and screws of the impeller assembly

Tauten loose chopper bearing |

| Over-wetting

|

Excess quantity of binder is incorporated into materials

More mixing time after binder incorporation The spray rate of binder is high |

Decrease the amount of binder

Reduce kneading time after testing granules' quality Slow spraying rate of binder |

| Under-wetting

|

A lower quantity of binder is added

Less mixing time after binder addition Very slow rate of binder addition |

Increase the amount of binder after doing validation studies

Increase mixing time after binder addition Adjust the binder spray rate for even distribution |

Conclusion

Rapid mixer granulators are versatile machines that are routinely used in numerous industries for efficient mixing in less duration. Rapid mixer granulators are quick and superior granulator systems that are capable of self-cleaning, and self-discharging. These systems mix powders and solvents by agitation and tumbling. Impellers and choppers are two main components that aid in the quick dispersal of starting materials. If you need additional information regarding rapid mixer granulators you can easily contact our customer care helpline.

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machin