Your Leading Protein Powder Filling Machine Manufacturer

- Various Protein Powder Filling Available

- High Filling Accuracy

- Automatically Complete Measuring Filling

AIPAK Protein Powder Filling Machine

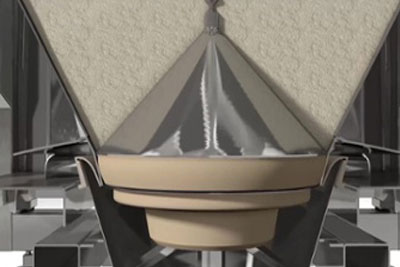

AIPAK protein powder filling machine is usually used for volumetric measurement of bulk materials like powder or granular materials. The machine uses a rotating screw to convey and dispense materials from the container through a doser, and use a funnel to guide it to the packaging process. Gravimetric and volumetric screw conveyors provide a simple and affordable solution for continuous metering or batching. In addition, the metering equipment can be converted into a new product easily and quickly.AIPAK protein powder filling machine complies with modern standards to ensure reliable, economical and accurate filling. The auger filling technology is most commonly used in applications that require the distribution and distribution of powders, spices, coffee powder, chemicals, flour, salt, baking mixes and other products with similar characteristics. All AIPAK protein powder filling machines ares designed to accurately dispense your product using a customized screw that will indicate how many turns are needed to reach the required weight.

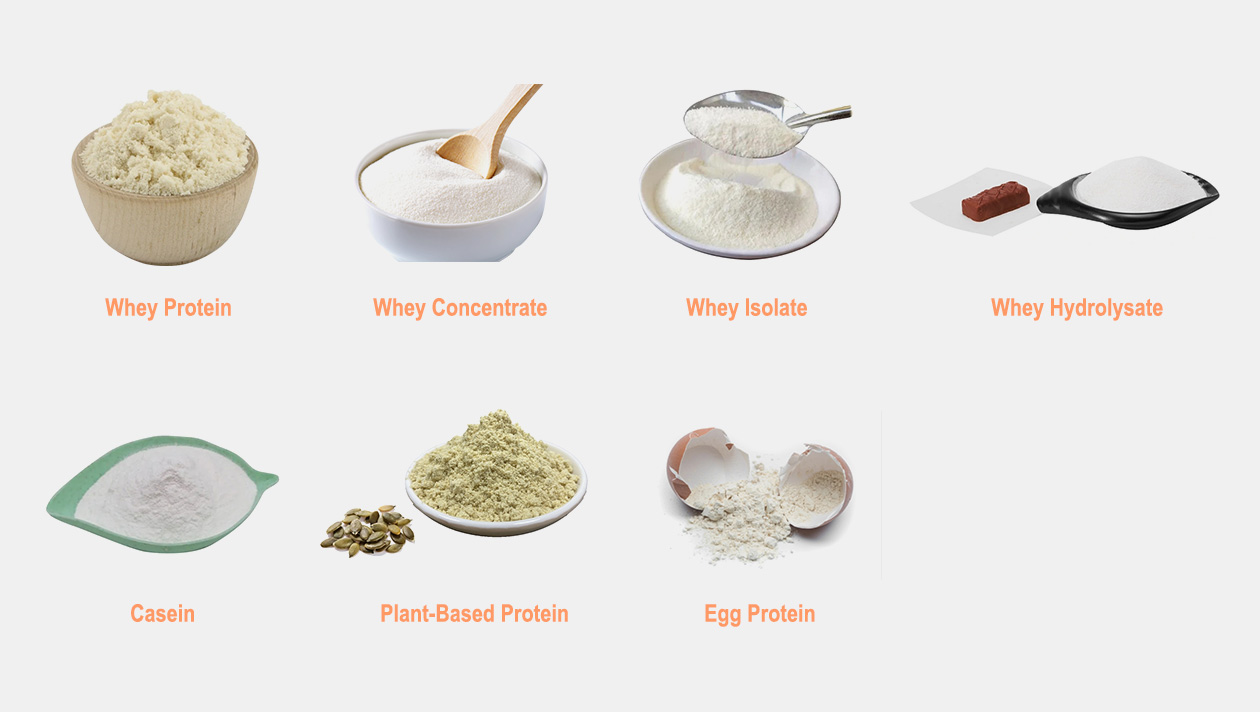

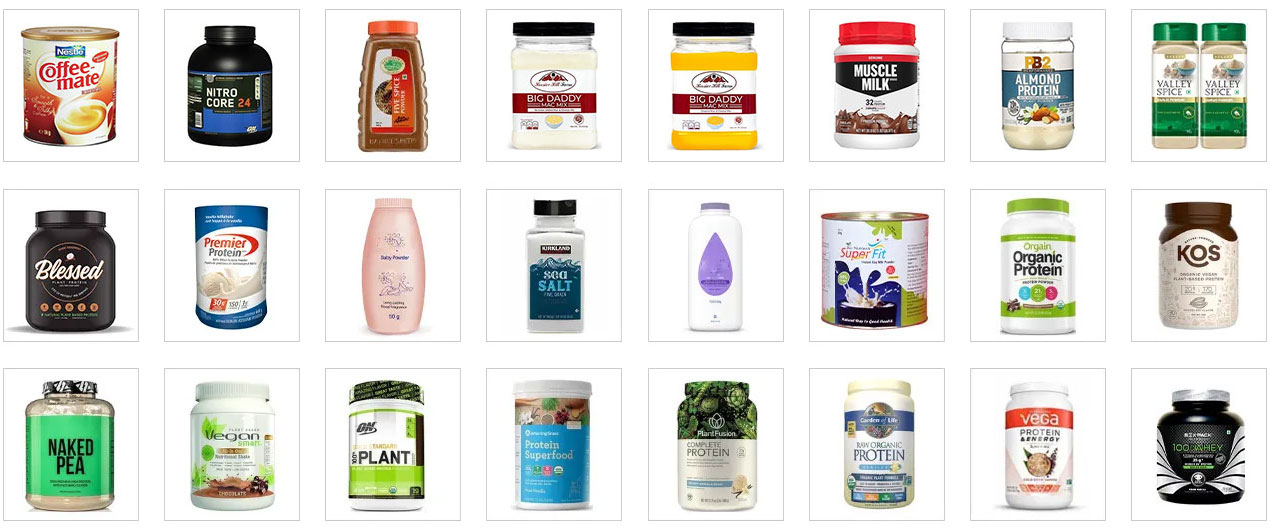

Different Types Of Protein Powders

Various Protein Powder Packaging Types

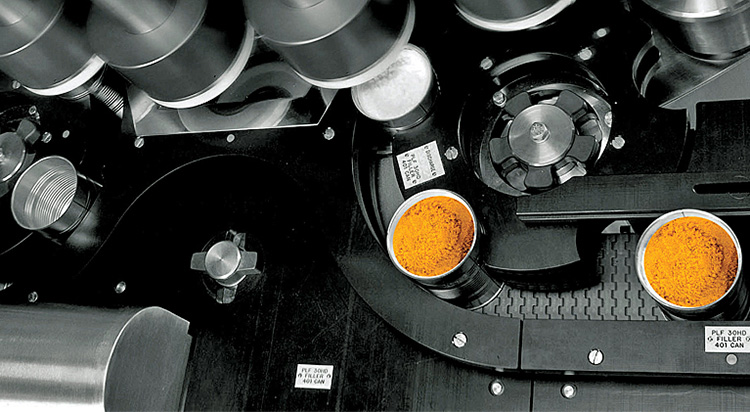

Protein Powder In Can/Jar

Protein Powder In Tin

Protein Powder In Stand Up Pouch

Protein Powder In Flat Bottom Bag

Protein Powder In Three-side Sealed Bag

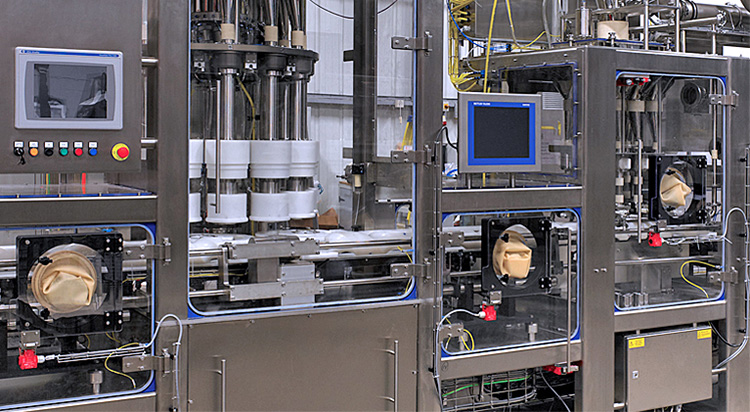

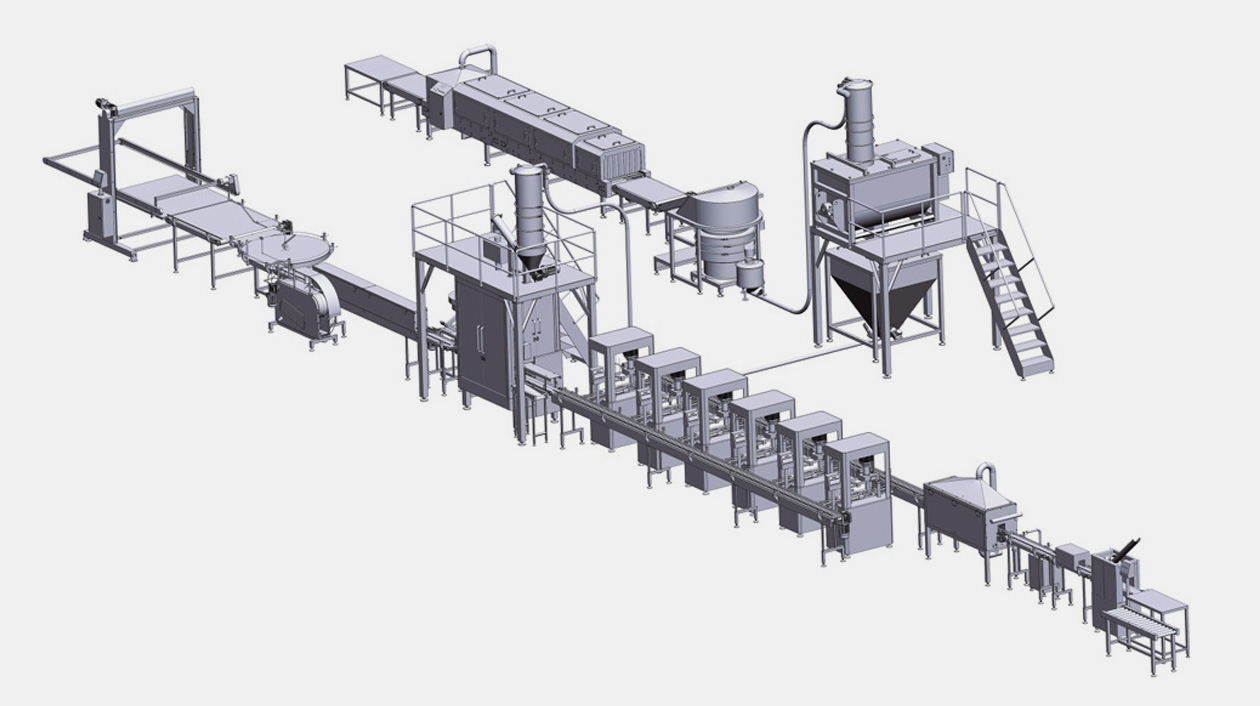

AIPAK Protein Powder Filling Line

AIPAK Protein Powder Filling Machine Sample Display

The Buyer's Guide

Protein Powder Filling Machine: The Complete FAQ Guide In 2025

Do you know how to preserve the nutritional value of protein powder? Yes, protein powder filling machine is exactly performing the job that every manufacturing company look for. Moreover, this is the machine that is capable of catering filling and packaging issues in no time. In today’s fast and busy life, protein powder filling machine has gained popularity as it helps you in convenience filling of protein powder with no chance’s errors. For skyrocketing business, a protein powder filling machine is a one stop solution you must add.

Without further ado, let us now start with our discussion.

1.What is a protein powder filling machine?

Protein Powder Filling Machine

A protein powder filling machine is a handy equipment that fills bulk amounts of protein powders into different containers, such as bottles, pouches, jars, and cans. To preserve the quality of protein powders from storage till shipment, a protein powder filling machine has a significant role. It is essential in containing the protein powders which keep them from getting damaged and rotting.

With the help of different kinds of dosing systems, this machine fills exact quantities of powders in different containers. Moreover, the protein powder filling machine is ergonomic and is used for filling both free-flowing as well as non-free-flowing powders.

2.Where can you use the protein powder filling machine?

A protein powder filling machine is an ideal automated solution for production lines where powder packaging is done. Due to its contamination-free packaging, different industrial sectors prefer to have this machine in their plants.

Here is the list of industrial uses of this machine.

Nutraceutical and Herbal Industry

Protein Powder Filling Machine in Nutraceutical Industry

A protein powder filling machine is the need of nutraceutical and herbal industry. Various kinds of powder supplements such as protein, fibers, probiotics, amino acids, lactose-free milk formula, sport-boosting powders, and electrolyte supplements are packed by the protein powder filling machine to provide health, endurance, and recovery benefits to customers.

Pharmaceutical Industry

Protein Powder Filling Machine in Pharmaceutical Industry- Picture Courtesy: Pharma Excipient

This machine is integral in pharmaceutical powder packaging production. This innovative equipment is perfect for accurately and precisely filling powders inside bottles, pouches, as well as sachets. This machine has specialized barrier components that aid in the processing of delicate powders such as penicillin and cephalosporin.

Food Industry

Protein Powder Filling Machine in Food Industry- Picture Courtesy: The Coffee Wholesalers

In the food industry, the protein powders filling machine is equipped with auger technology and vacuum systems that aid in weight checking before filling food powders. A wide range of food powders like flour, spices, sugars, milk powders, tea, coffee, pulses, cereals, seasoning flavors, etc. are filled inside a variety of packaging by this equipment.

Cosmetic Industry

Protein Powder Filling Machine in Cosmetic Industry

You will be surprised to know that protein powder filling machine is also employed in the cosmetic industry for dispensing diverse type of beauty powders, such as masks, foundation, face powders, blushes, and eye shadows in different kinds of jars and bottles to protect them from moistures and other environmental elements.

Chemical Industry

Protein Powder Filling Machine in Chemical Industry

For achieving the highest level of safety and security in packaging, a protein powder filling machine is utilized in the chemical industry for the filling of different grainy and fine powders such as detergents, adhesives, cleaning agents, fire extinguishers, etc.

Construction Industry

Protein Powder Filling Machine in Construction Industry

Yes, large quantities of construction materials such as cement, metals, gypsum, limestone, plaster, talc, ash, and other mineral powders are packed inside big bags by the protein powder filling machine. This equipment efficiently and precisely processes construction powders with automatic weight checking.

3.What are the advantages of a protein powder filling machine?

It is part of various industrial lines due to its versatile capabilities. This machine offers innovative packaging catering to the needs of different industries.

Some important advantages of protein powder filling machine are:

No batch-to-batch Variation

Protein Powder Filling- Picture Courtesy: JBT Corporation

Are you tired of overfilling or underfilling in protein powders? Then invest in a protein powder filling machine. This machine has sensors that monitor the filling weight of the product. This lowers the error rate in protein powder filling, consequently producing consistency in every batch.

Hygiene Filling

Hygiene Fill by Protein Powder Filling Machine- Picture Courtesy: Design Crowd

With a protein powder filling machine, safe and hygienic filling is guaranteed. Protein powder filling is an extremely delicate and sensitive process, hence, minimal cross-contamination can deteriorate the quality of protein powders. This machine has a sanitary design made from stainless steel and various other sanitary features that reduce the chance of contamination during protein powder filling.

Efficiency is Everything

Efficiency of Protein Powder Filling Machine- Picture Courtesy: JBT Corporation

Manual filling is quite slow and burdensome therefore, the workforce often requires breaks from work. However, the protein powder filling machine is very efficient and has a higher filling output. This equipment fills thousands of containers in a limited time.

Flexibility is Way to Future

Flexibility of Protein Powder Packaging- Picture Courtesy: Dieline

This machine can process a variety of powders whether nutritional powders or food products. It can handle powders with fine particles, tiny grains, and powders varying in density powders and fluidity. This flexibility of the protein powder filling machine is key to processing different powders and packaging.

Brand Building

Brand Building- Picture Courtesy: Generation Nutra

To have success in retail stores, protein powders must look good and appeal to end-users. Therefore, the protein powder filling machine fills protein powders in beautiful customized packaging that captivates and magnetizes customers. Simple and minimal protein powder packaging is a way to build brand identity and image.

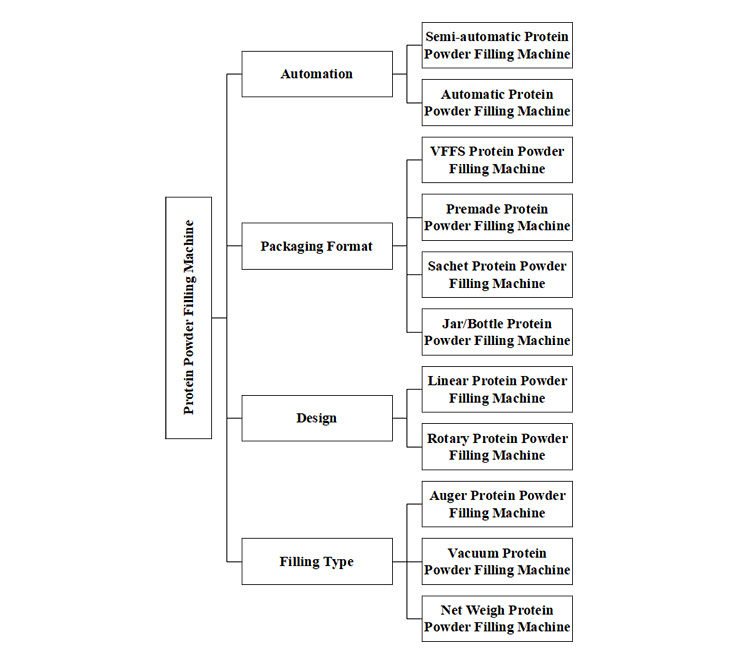

4.What is the classification of a protein powder filling machine?

Since its invention, there has been a lot of innovation in protein powder filling machines. It has evolved from an old simple manual protein powder filling machine to an advanced sophisticated unit handling large batches at once. Here is a detailed classification list of protein powder filling machine.

Classification Based on Automation

There are two different kinds of protein powder filling machines when classified depending upon automation.

Semi-automatic Protein Powder Filling Machine

Semi-automatic Protein Powder Filling Machine- Picture Courtesy: Jetpack

It is the simplest form of protein powder filling machine available in the market. It is a primitive and compact form with an easy filling process that includes programming settings on the machine PLC unit, however, operators have to place packaging containers under the auger hopper and after filling remove them manually. Its production capacity is slow because it only fills one container at a time.

Working Principle

It has simple working steps. The bulk amount of protein powder is loaded inside the machine hopper and containers are placed manually by the operator. Filling starts after the detection of the container under the filling head. After filling, this container is removed from the machine.

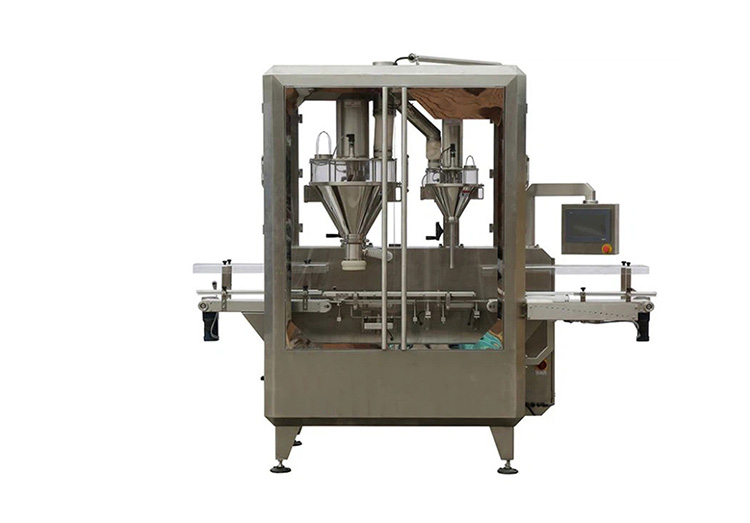

Automatic Protein Powder Filling Machine

Automatic Protein Powder Filling Machine

It is a stand-alone unit that works autonomously and carries out different filling steps like weighing, handling, filling, and sensing containers. With the help of a PLC unit and advanced sensors, the machine efficiently processes different filling steps. It has a modular build requiring more space in production.

Working Principle

The movement of conveyors, rotary star wheels, and filling heads is coordinated and linked in the automatic protein powder filling machine. The bulk amount of protein powder and containers are loaded on the conveyors before the start of batch processing. On sensing the container, the filling initiates, through auger devices and filling nozzles, an accurate amount of protein powder is dispensed inside the filling container.

Classification Based on Packaging Format

Based on packaging format, there are four kinds of protein powder filling machines.

VFFS Protein Powder Filling Machine

VFFS Protein Powder Filling Machine- Picture Courtesy: Smartweightpack

This type of protein powder filling machine forms pouches from the film roll, packs them with protein powders, and finally hermetically seals them using sealing bars. The packaging operation occurs in the vertical direction in this equipment since protein powders are delicate items, consequently, they fall into pouches under the influence of gravity. This machine is ideal for production as it is fast and has little footprint thus needs little space for installation.

Working Principle

Rollers and unwinding disk keep the film under tension as it unwinds. The film after passing over the roller moves to a cone-shaped forcing tube present on the top. Once, the pouch is formed by the combined action of forming collar and sealing jaws, the PLC system starts the signaling of protein powder filling. Finally, the horizontal jaws completely fuse the top edges and the cutting knife separates the joined pouches.

Premade Protein Powder Filling Machine

Premade Pouch Packaging Machine- Picture Courtesy: LENIS MACHINE INC.

This machine uses ready-made pouches for filling the protein powders. It is an independent unit. It has a higher output rate than its counterpart it does not require pouch fabrication. However, premade pouches are more costly than film rolls.

Working Principle

First, the stack of empty pouches is placed in a bag magazine and grippers pick individual pouches and carry them to the inflating area where bags are inflated by air. Next, the filling device fills the required amount of protein powders and in the end sealing element seals the pouch.

Sachet Protein Powder Filling Machine

Sachet Protein Powder Filling Machine- Picture Courtesy: LENIS MACHINE INC.

This equipment has a similar working principle as that of the VFFS machine, conversely, it packs protein powders in a much smaller sachet, typically having quantity for single-serving. Normally, it makes 3 and 4-sided sachets. It is cost-effective in the sense that it uses little packaging material.

Working Principle

After placing the film on the film holder it is unwounded by the rotation of the disk. Then this film is cut into two halves and passed to forming tube where it is designed into the small pack-like sachets. Protein powders are loaded inside the packed by the fillers such as auger filler. Then, sealing jaws seal and glue the topside of the sachets.

Jar/Bottle Protein Powder Filling Machine

Jar/Bottle Protein Powder Filling Machine- Picture Courtesy: FILLING AND SEAMING MACHINE

This machine packs protein powders in jars and bottles. It is available both in linear and rotary configurations and has a conveyor, hopper, and filling device. It is a versatile machine as it can handle jars and bottles of varying sizes.

Working Principle

Initially, the jars or bottles are placed on the conveyors at fixed intervals. They go to the filling area one by one. On the command of the PLC station, the filling nozzle fills a predetermined amount of protein powders inside the containers. After successful filling, the containers are then conveyed to the capping or lidding area.

Classification Based on Design

Depending upon size, there are two types of protein powder filling machines.

Linear Protein Powder Filling Machine

Linear Protein Powder Filling Machine- Picture Courtesy: Vtops

This machine is designed in Z or L or straight-line configuration. The filling heads are fitted in the sequence in this machine type. It has a conveyor system and one or more filling heads for rapid filling. It has a low filling output. But can be easily upgraded by installing more filling heads.

Working Principle

In a linear protein powder filling machine, containers pass one by one under the filling head and once the filling starts, the movement of the container stops. After filling, a preset amount of protein powders, these containers move down the line for further processing.

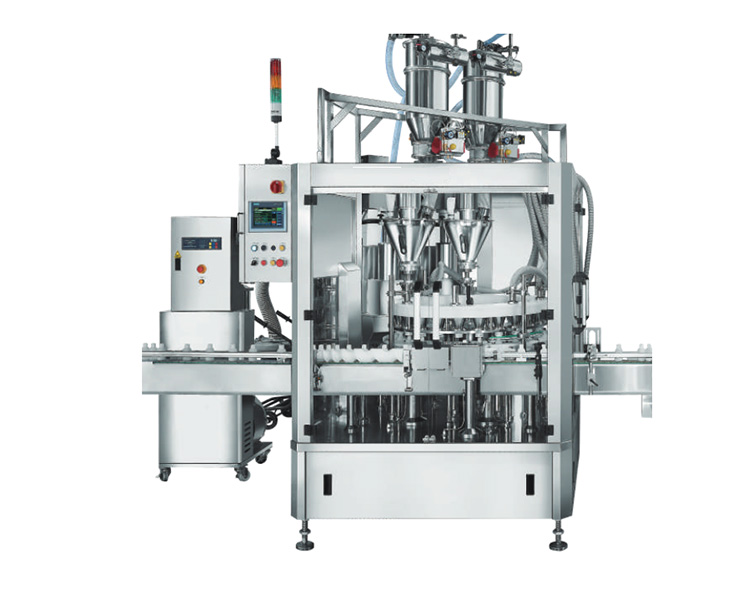

Rotary Protein Powder Filling Machine

Rotary Protein Powder Filling Machine- Picture Courtesy: CVC Technologies

This equipment opts circular configuration due to the presence of a star wheel or turntable. A turntable has multiple filling heads; therefore, this machine can fill more than one container at a time without having to pause. So, in this way, a rotary protein powder filling machine can process larger batches in a short period.

Working Principle

The conveyor systems transport containers to the rotary star wheel. The packaging is gripped by grippers or holders and different filling nozzles carry out simultaneous filling and sealing of multiple pouches or jars.

Classification Based on Filling Type

There are three classes of protein powder filling machines when classified depending upon the type of filling.

Auger Protein Powder Filling Machine

Auger Protein Powder Filling Machine- Picture Courtesy: SED Pharma

It is one of the most popular types of protein powder filling machines based on its filling method. It is an auger device, a stirrer, and a hopper. The hopper present on the top transfers protein powders to an auger device which by the rotating of screws loads products inside the container. It is used for precise volumetric filling.

Working Principle

When pouches or jars reach under the filling nozzles of the auger system, the gripper keeps the container under a firm grip to prevent spillage. The fixed quantity of protein powders passes through the auger plate by rotating screws. These powders gradually trickle down to containers via filling nozzles. Once filling is complete, these containers go to the sealing station for permanent sealing.

Vacuum Protein Powder Filling Machine

Vacuum Protein Powder Filling Machine- Picture Courtesy: JBT Corporation

This machine uses vacuum pumps for delicate protein powder filling instead of an agitator and stirrer. The advantage of using this machine is that there is no powder dust production. Moreover, it preserves the structural integrity of protein powders.

Working Principle

Conveyor systems transport containers to the filling area where the vacuum system creates a suction pressure for drawing protein powders inside the filling nozzles. Sensors detect and control the volume of filling volume inside the containers. After filling, capping heads or sealing elements seal the containers.

Net Weigh Protein Powder Filling Machine

Net Weigh Protein Powder Filling Machine- Picture Courtesy: Accutek Equipment Packaging

For filling accurate weight of protein powders, a net weigh protein powder filling machine is used. It has weighed cell and weight check devices that estimate the weight of protein powders before filling. It processes granular powders and irregularly shaped powder particles. Since it uses weight instead of volume, it does not have inconsistency when filling powders.

Working Principle

When bottles or jars go under the filling nozzle, a weight-checking plate measures the weight of the container and next protein powders are moved from the hopper to the load cell. These load cell measures and weighs the precise amount of powders and transfer them to filling nozzles.

5.What kinds of containers can be used by the protein powder filling machine?

Protein Powder Packaging- Picture Courtesy: Dieline

A protein powder filling machine is a multifaceted machine that can accommodate a wide range of packaging with simple changes in parts. This machine can process different packaging both flexible and rigid. These packaging kinds are discussed in detail below:

BASED ON FORMAT

Pouch

Due to its cost-effectiveness, customization, and processivity, pouch packaging for protein powders is widely popular and is available in quite different styles. These packaging styles are discussed one by one below:

| Stand Up Pouch

Due to the bottom gusset and stable base, this pouch can stand upright on store shelves and is the best option for marketability. It has a rectangular shape and is the most popular option for filling protein powders. This pouch also comes with a tear-off top and has a resealing zip-lock option. |

Standup Pouch- Picture Courtesy: Food Packaging |

| Quad-Seal Pouch

It has side gussets that provide stability and allow it to expand when filled with protein powders. This filled product aids in standing upright. It is manufactured with a fold-over seal at the bottom therefore, the base of this pouch is not completely leveled. |

Quad seal Pouch- Picture Courtesy: Poucheurope |

| Flat Bottom Pouch

It is also called a block bottom pouch as it has a box-like look. It can pack more quantity because of the large space at the bottom. The flat bottom pouch has a side gusset and flat base that give it a classy and sophisticated look and also reinforce the design style. |

Flat Bottom Pouch- Picture Courtesy: Guoshengli |

| Flat Pouch

This pouch has a much simpler design and is square-shaped. It usually lays on the back as it has an unstable base. Therefore, it is also known as a flat-lay pouch. Moreover, it does not have a side gusset. It is sealed on 3 sides, has a tear-away seal on the top, and usually packs a single-serve quantity of protein powders. |

Flat Pouch- Picture Courtesy: Revival Supplements |

Bottle

Protein Powder Bottle Packaging- Picture Courtesy: Business Insider

It is a round or cylindrical container with a larger diameter and a narrow opening. It is employed for packaging bulk amounts of protein powders. It is made with rigid plastic or glass and is sealed with re-closable caps.

Jar

Protein Powder Jar Packaging

It is a round, square, cylindrical, or hexagonal-shaped container available in different formats. Protein powder jars are often straight-sided jars that do not have any neck. This design aids in the easier removal of protein powders. Moreover, it has a large area for labeling, thus can achieve maximum marketability.

6.How do you ensure product quality by protein powder filling machine?

A protein powder filling machine fills exceptional quality protein products as the health of individuals is dependent upon it. Different kinds of leakage tests and machines are incorporated into the protein filling machine to ensure that there is no leakage or scratching on the pouch. Therefore, there are some methods to ensure product quality.

Water Bath Leakage Test

Water Bath Leakage Test- Picture Courtesy: Industry Plaza

In the water bath leakage test, trace gas is not employed instead the container is immersed in a water bath. The air is removed from above the water level via a venturi nozzle. The protein powder pouch contracts underwater because of the absence of air. If bubbles are seen rising above the water, it shows that there is leakage in the pouch and the air is fleeing from a minute hole or loose sealing.

Trace Gas Leakage Test

Trace Gas Leakage Test- Picture Courtesy: Cleatech

This test uses trace gases such as helium, hydrogen, or carbon dioxide. It is a stringent test that can detect even tiny leakage in the hermetically sealed protein powder pouch. Sometimes for conducting this test, trace gas is introduced inside the pouch while other times this test is done using already present carbon dioxide in the pouch.

The package is put inside a vacuum chamber and if there is leakage in the packaging then trace gas escape is ascertained using senor due to pressure difference created by seepage of trace gas. This test is conducted to detect the cause of leakage such as a loose seal or tear in a pouch. Moreover, it can also find a position of leak.

7.What is the difference between single and double-head protein powder filling machines?

Both these machines are used for auger filling of protein powder, still, there are significant differences between these types. Some of these differences are discussed below:

| Single Head Protein Powder Filling Machine | Double Head Protein Powder Filling Machine |

Single head protein powder filling machine- Picture Courtesy: aat.pack.com |

Double head protein powder filling machine- Picture Courtesy: Spec Enterprises |

| Single-head protein powder filling machine has only one auger filling unit. | Double head protein powder filling machine contains two auger filling units. |

| It has slower processivity due to the presence of one filling head. It fills 20-40 per minute with protein powders. | It fills a greater number of containers because of its two powder-filling heads. It can fill 30-80 bottles per minute. |

| Single-head protein filling machine has limited versatility. | It can fill two different kinds of protein powders in the same container therefore, it is more versatile than its single-head counterpart. |

| It has a smaller footprint and is perfect for small businesses. | It requires more space and is ideal for medium-scale productions. |

8.What are the common challenges and solutions of a protein powder filling machine?

The protein powder filling machine is an exceptional unit, increasing the production capacity of businesses by tons. It can work without needing to stop, however, occasionally this equipment can face some problems that could be resolved by following some guidelines.

Below discussed are some common problems and solutions of a protein powder filling machine.

| Cause | Solution | Picture |

| Protein Powder Bridging | ||

| It can be due to the poor fluidity of powder due to variations in the shapes and sizes of protein powder particles. Powder particles bind with each other, preventing the flow of the rest of the powders. | The use of cone valves and agitators decreases the protein powder bridging. |

Protein powder bridging- Picture Courtesy: Matconibc |

| Incorrect Pouch Cutting Position | ||

| This can be due to a fault in the photoelectric sensors of machine and also due to a poorly cleaned forming tube. | Repair or replace the photoelectric sensor. Thoroughly clean forming tube. |

Poor Cutting- Picture Courtesy: Jochump |

| Inaccurate Weighing of Protein Powders | ||

| It can be due to faulty calibration of sensors, defective weight-checking systems, and due to instability in machine leveling. | Recalibrate the machine sensor to ensure it is properly working. Replace or repair the damaged weighing system. Properly adjust the machine level. |

Inaccurate Protein Powder Filling- Picture Courtesy: BellaRx |

| Leakage in Protein Powder Pouch Packaging | ||

| Poor sealing results in leakage of pouches It can happen due to inadequate sealing temperature and time. It can be due to poor working conditions of sealing jaws. Moreover, incompatibility between packaging material and machine can cause bad sealing. | Provide accurate temperature and time for the sealing process. Repair worn-out sealing system. Ensure packaging material and protein powder filling machine are compatible with each other. |

Leakage in Protein Powder Packaging- Picture Courtesy: Lowe’s |

| Generation of Dust During Protein Powder Filling | ||

| This problem might be due to the open filling of powder and the absence of a dust removal system with a machine. | Carry out filling in a closed system and install a dust removal device with a machine to prevent dust production while filling. |

Dust Generation- Picture Courtesy: Matconibc |

9.What are the buying factors that should be taken into account before buying a protein powder filling machine?

A perfect protein powder filling machine is purchased by doing some research and after weighing several options. By taking into account, different factors like quality, design, and much more, you can ensure that you have purchased the best protein powder filling machine for your production.

Automation

Automation of Protein Powder Filling Machine- Picture courtesy: JBT Corporation

It is the biggest part of production and the level of automation also determines the price of the machine. So, if you are part of a large production and want to fill thousands of pouches or other containers per minute then you should choose a protein powder filling machine that is a fully independent unit and has multiple filling heads. However, a semiautomatic protein powder filling machine with single or double filling will fulfill the needs of small and medium-sized businesses.

Ease in Use and Maintenance

Ease of Use of Protein Powder Filling Machine- Picture courtesy: Keep It Usable

The machine with simple controls and ease of use will require minimal skill of operators thus, causing fewer problems in programming filling parameters which in turn reduces the number of errors in protein powder filling. Moreover, a protein powder filling machine with easily accessible parts can aid in doing preventive and scheduled maintenance. This ease in maintenance will decrease the number of technical faults throughout the machine run.

Flexibility in Packaging Container

Flexibility in Protein Powder Filling Machine

Before selection, it is pre-eminent to check whether the protein powder filling machine you are selecting is well-aligned with your packaging type. Moreover, always go for a machine that can process packaging with differences in design, sizes, and shapes. It is a foolproof way to ensure that your selected protein powder filling machine will be able to accommodate your future packaging needs.

Versatility in Material Processing

Versatility in Protein Powder Filling Machine- Picture Courtesy: Puriiton

Today, the packaging industry is experimenting with several films, pouches, and other container materials. Businesses are always striving for innovation in their packaging material with different finishes to attract and captivate their customers. If you want to be the pioneer in using unique materials for your protein powder packaging, opt for a protein powder filling machine with a diverse material process range.

Safety

Safety in Protein Powder Filling Machine- Picture Courtesy: JBT Corporation

Last but not least, the safety of equipment is one of the biggest concerns of business. These safety features protect operators as well as production plants from accidents. Therefore, select a protein powder filling machine with a deduster or vacuum system to reduce dust production as otherwise its charge can ignite on sparking. Moreover, a machine with closed doors is best to prevent product contamination.

10.What are the future trends of protein powder filling machine?

Future Material Processing by Protein Powder Filling Machine – Picture Courtesy: Visican

Due to the health and fitness-conscious lifestyle of people, the demand for protein powders is rapidly increasing in the world. This in turn increase the demand for protein powder filling machine. To fulfill the high exigence of a protein powder filling machine, manufacturers are in a continuous struggle to innovate this machine that has higher output with a lower error rate in filling.

Modern protein powder filling machine will be state-of-the-art machine with automated systems such as robots that cut down the need for human operators and in turn, reduce contamination by humans. Moreover, it will be customized with a variety of dosing systems that will fill multiple kinds of protein powders in the same packaging.

Today, dust generation during powder filling is a challenge for protein powder filling machine. Morden protein filling machine will be equipped with degassing and vacuum systems to prevent dust generation. This futuristic machine will have a lower carbon footprint due to less fuel consumption and will process more sustainable materials that have a greater recyclability rate.

Conclusion

If you are in the business of packaging protein powders, then having a protein powder filling machine is a must. Automation, efficiency, precision, and consistency are a few of the great advantages of this machine. This equipment is ideal for your ever-changing packaging needs. If you want to buy this handy machine for your business then visit Allpack China for consultation and get an expert opinion on which protein powder machine will be suitable for you. Furthermore, at Allpack you will get high-grade machines at fair prices.

Protein Powder Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586