Tube Filling Machine:The Complete Importing Guide in 2020

Have you ever thought of how is your cosmetic cream made to that plastic tube?

Yes,it is a kind of packaging device called tube filling machine,that helps in filling the various liquids,semi-liquid,paste or viscosity fluid into that perfect tube packaging material,and make them be sealed and code printed.

Some of you may think of outsourcing,although there is nothing wrong with outsourcing,you may meet planning, dialogue, transport and delivery times and other unforeseen variables.While filling tubes, it can cooperate with your employees directly from production to packaging.

That’s you need a tube filling and sealing machine to save your turnaround time.

In this tube filling machine complete importing guide,I going to introduce everything including:benefits,applications,classifications,working principle and FAQ ,you will get the the most comprehensive knowledge forever about this machinery and choose the most suitable equipment for your business.

Let's get started.

1.What is a tube filling machine?

A tube filling machine is a kind of packaging device that you will use to fill a various range of products such as cosmetic creams,toothpaste,lotion,shampoo,adhesives,ointment,shoe cream and some other pharmaceuticals in all sorts of tubes like plastic tube,aluminium tube and laminated tube.

AIPAK NF-60 tube filling machine

And since the property of the products to be filled up has determined it’s hard for you to simply pack them quickly and effectively.

Various products in tubes

Thus, this is where the importance of the machine becomes apparent as you will use it to fill the various nature of products into various of tubes.

2.What is the design option of tube filling machine?

Normally, the tube filling machine refers to the filling of products under aseptic condition,and

when the products are filled under aseptic, the aseptic state of the products can be maintained.

Therefore, on one hand,it is unnecessary for you to add preservatives to the products to meet the requirements of product safety, such as the taste and color of drinks.

Due to the tube filling machine, the products produced have tended to be sterile, delicate and diversified, and the high-capacity product types tends to few, many types of small amount of products are becoming the mainstream.

Now in the trend of environmental change, the tube filling machine has become more versatile, so it is used for various packaging materials.

That is,on the other hand,the tube filling machine not only accelerates the pace of driving technical innovation, but also make the filling and sealing more perfect based on the introduction of new technology and integrated intelligence and automation.

3.Where is a tube filling machine used?

The invention of tube filling machine will improve the performance, efficiency and bring convenience to the manufacturing process.

It will fill a wide range of liquid into various types of tubes no matter what its viscosity is.

So it is not hard for you to envision that tube filling machine is actually a common device in many industries,now I will list them as below:

.Pharmaceutical Industry

Why is an tube filling machine an indispensable equipment for medical products?

Let me take a simple example to give you a detailed explaination:

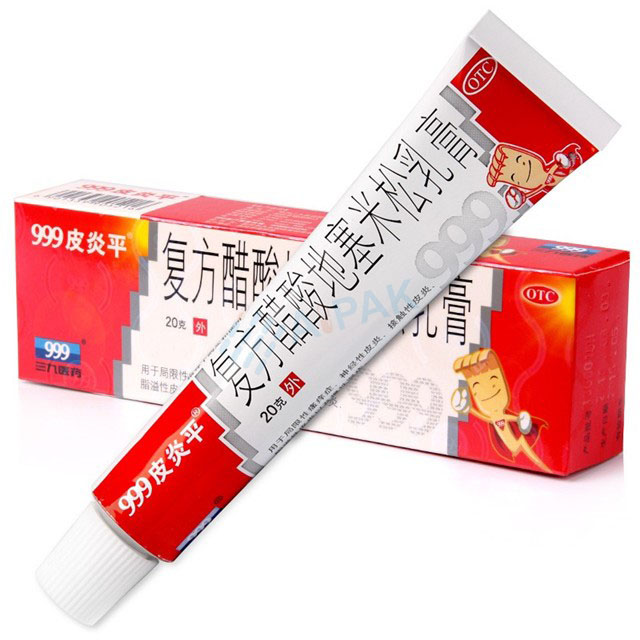

The change of seasons is a kind of pain for people with allergic constitution. Such as the rampant catkins in the past few years,that many people are allergic to it.Catkins are easily inhaled into the nasal cavity, causing strong irritation, runny nose, cough, asthma and other reactions. Allergic reactions can also occur on the skin, such as skin itching. Once itching will be very painful, the doctor will prescribe a variety of ointment.

As for the packaging of ointment, the tube filling machine is indispensable.

Cream

Besides,tube filling machine in filling up medical products also include creams and liquid medicines and syrups.

And you will find the versatility of tube filling machine in pharmaceutical industry as you can not only use it to fill,but also seal or assort your drugs when packing.

That is why nowadays,you can hardly find one pharmaceutical factory lack of this kind of machine.

.Cosmetic industry

The application of tube filling machine in cosmetic industry has great significance since cosmetic has been the largest segment market in the world now.People nowadays are inseparable of it,as it will give them confidence and make them more energetic.

The most commonly products in cosmetic industry that tube filling machine is used include:

creams,lotions, facial masks, lipsticks,liquid foundations.

Various cosmetics

Surely,tube filling machine in cosmetic industry can be used not only to fill tubes but also other kinds of similar containers such as composite pipe.

And we know cosmetic is a large industry as its products are countless,therefore,tube filling machine used are customized according to different products requirements.

While,the sealing of tube filling machine to cosmetic products also act on labelling and packaging.

.Food industry

Food is very important for people's survival. Of course, the diversity of food also enriches people's taste buds and life.

With the development of economy and the continuous improvement of people's living standards, people begin to pay attention to and pursue what they eat.

Many food must be processed, packaged and transported to different places, so the diversity of food also determines the diversity of food packaging machines.

Condensed milk

However,the variety of tube filling machine have adapted to the variety of food,with the aid of tube filling machine,all production processes like feeding, metering, filling and bagging, printing date and product outputting can be completely automatically,which bring great convenience and save a lot of labor.

Of course,tube filling machine helps in filling up and sealing food,like peanut butter,condensed milk,chocolate,laminated food.

.Daily chemical products industry

As to daily chemical industry,you may think of toothpaste,a necessity in our daily life.

Tube filling machine is a professional equipment for the filling and packaging of such kind of products,and use of the machine has avoided the defect of insecure sealing caused by the foreign matters on the pipe wall, and the sealing is beautiful.

Various toothpaste

Other daily used products such as shampoo, liquid soap, foot bath liquid,body and hair lotions,tint are also with the help of tube filling machine.

4.Why you need a tube filling machine?

Everyone knows packaging is very critical to the business,a good packaging or not will determine the completion of sales of a product as we are visual,we will judge the product from the appearance.

That’s a product with attractive appearance will attach to the eyes and undoubtedly a good way to enhance the sales.

Therefore,there is every reason that you need a tube filling machine.

AIPAK NF-80 tube filling machine

So I will conclude some points that why you need to invest on such a perfect tube filling machine.

1.Reducing labor cost

Compared with the traditional way of packaging,you will need not that much labors as either the filling or sealing process can be completed automatically.

You can image how many people you will need if you still use human labor to fill up the tubes and then transit for the other side of human labor to seal the tubes.

With a tube filling machine you will only need one operator to guarantee the normal working of every parts of the machine.

That is to say,it will save your money spend in compensating your labors for the work they have done for you,which is what matters the most to you.

Besides,the reduced labor cost will make your profit turnover exclude to the efficiency and convenience it will bring to you.

2.Improving efficiency

You must have known the most constraint factors to the production output for a factory is the production speed.

That is you must speed up to get more profit from your production process.

And the speed of filling ,sealing and bringing your products to the market also play a critical role in determining the success of your business.

However,using a tube filling machine will assist you in filling and sealing your various kinds of products in the right tube within the shortest time possible.

The reason is that your thin liquids and high viscous substance can be quickly filled and sealed in its respective tubes in a cycle.

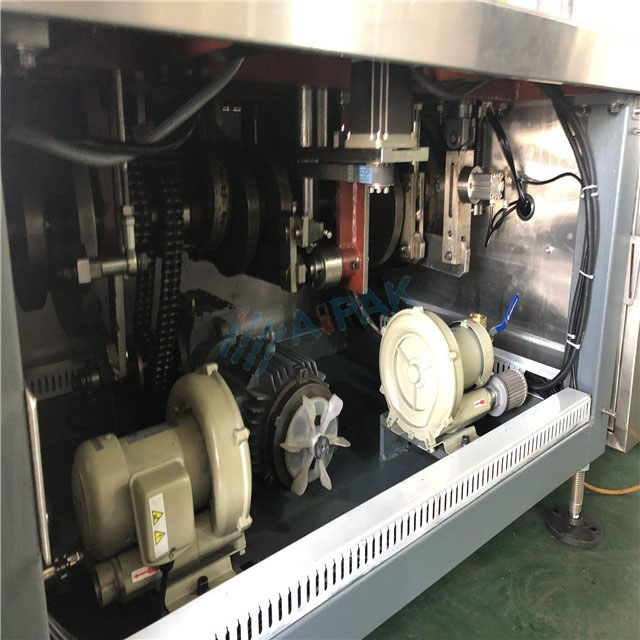

Below you will find one part of the tube filling machine to better understand why it is effective.

3.Providing reliability and consistency

There are variances when you are filling your products into the tubes,but of course,there is some devices that will help you reduce the variances.

However,have you ever thought of the time that you will spend on these devices,totally,it will affect your whole production process.

But with the help of tube filling machine,it is just one machine that gather malfunctions of reliable filling units and consistent working.

Parts of tube filling machine

Moreover,the tube filling machine will not be affected whatever the filling is on the basis of weight,volume or any other measurement unit.

4.Versatility ability

If your company has a wide range of products that needs to be packages in various tubes,then you still no need to worry about it.As the tube filling machine has the versatility ability that will provide you with multitask solutions.

And one tube filling machine is designed not only for one simple product or tube,it will allow you to fill different size or shapes of tube,containers.

Different size of tubes

And it can also fill different nature of products whatever it is thin or viscous.

So most critically,using the tube filling machine will help you save the equipment cost and enhance the manufacturing efficiency.

5.Reducing waste

Another crucial point that you need a tube filling machine is that it is surely the most effectively way of reducing waste of your products.

Since the filling and sealing of the machine are quite precise,you only need set the required units to be filled,the machine will automatically counts the exact amount of products so that the waste is avoided.

Part of aluminium filling machine

6.Providing opportunate for upgrading

It may not easy for you to image this machine has such a further implication.In fact,it surely is.

Since initially,you may use a tube filling machine with a few filling heads like four,six or eight.But as the time went by,with the increasing of your production,that number of heads may not meet your manufacturing requirements,then you may upgrade with more filling heads like eighteen or more.

However,your upgraded tube filling machine with more heads will also allow more tubes or containers to be filled at the same time in a cycle.

Surely,the production efficiency and speed also determined by the tube size,shape or the nature of the products.

Can be upgraded parts of tube filling machine

That is ,in a simple word,you will get more sophistical skills by using a machine from the basic to the complex.

5.What types of tube is right for you?

Apart from selecting a most tube filling and sealing machine,it is also critical for you to choose either the right empty tube material, the right “tight” fitting cap or the most suitable and efficient filling and sealing systems.

That is ,first of all,you must consider every product detail including its formula, viscosity, its type and use, but also, its aesthetic.

Then let's start to talk the basic kinds of tubes that can be considered which include plastic tubes,aluminum tubes and laminate tubes.

Plastic tubes

First you need at least get familiar with the basic idea about plastic tubes which consist of three grades of polyethylene,include low density polyethylene,medium density polyethylene and high density polyethylene.

Products in plastic tubes

Generally,these kinds of tubes are suitable for skin care products,such as creams,lotions,shampoos and conditioners,as they can be built with a barrier coating for the additional protection to the product.

Aluminum tubes

Aluminum tubes are well known for offering the best barrier protection for your formula.

Compared with the plastic tubes,aluminum tubes will provide better protection to your products as they are materials of heavy gauge.

Products in aluminum tubes

Besides,you can use a variety of colors to enhance or cover the aluminum to make them more fit with your aesthetic.

More interesting,when you evacuate the aluminum tubes,the body of the tubes may look like out of shape,while they will recovery in use.

Laminated Tubes

Laminated tubes can also be polyethylene but have an extra laminated coating which will make you benefit from their serving functions.

First, you will benefit from laminate tubes as they will provide extra barrier protection for more volatile or irritant ingredient products.

Secondly, the laminate layer allows you to make mor complex art.

Toothpaste with laminated tubes

However,there is a drawback of the laminated tube as the laminated material is produced flat,that will not allow you to make 360-degree art on them.

Laminate tubes are generally used for products such toothpastes, sun blocks, acne products or hair products .

6.How many types of tube filling machines are there?

Believing the various reasons from above may convincing you to purchase a tube filling machine,but before choosing the best suitable machine,you need to know the types of equipment in the market now .

As all types of tube filling machine in the market now are designed to attract different purpose.

You need to realize the varieties of efficiency and performance between types of machine to determine the most suitable for your own.

Generally,the most common types of tube fillers can be list below:

.Fully automatic tube filling machine

.Semi automatic tube filling machine

.Ultrasonic tube filling machine

.Rotary tube filling machine

.Filling and sealing machine

I will try my best to explain the detailed information about these types to you.

1.Fully automatic tube filling machine

It is just as its name indicates,all of its performance functions are programmed,which is 100% automatic,that makes it an ideal device for large scale of filling multi specifications and large caliber tubes.

It is widely used for filling and sealing of plastic pipe and aluminum plastic composite pipe in medicine, food, cosmetics, daily chemical products industries.

AIPAK full automatic tube filling machine

Besides,you will find the more benefits of fully automatic tube filling machine,namely:

1.It can inject all kinds of mushy, paste, viscosity fluid and other materials into the hose smoothly and accurately, and complete the heating of hot air in the pipe, sealing and marking batch number, production date, etc.

2.Fully automatic tube filling machine is designed with compact structure with automatic tube loading, fully closed transmission part.

3.The all programmed operation system make it can complete the whole process of tube supply, tube washing, marking, filling, hot dissolving, sealing, coding, trimming and finished products outputting.

Parts of fully automatic tube filling machine

4.There is pneumatic way to supply and wash tubes, which action is accurate and reliable.

5.Its rotary pipe mould is equipped with an electric eye to control the central positioning device of the tube, and the automatic positioning is completed by photoelectric induction.

6.You will be easy to adjust and disassemble the machine.

7.The intelligent temperature control and cooling system makes the operation simple and the sealing reliable.

8.The contact part of the product is made of 316L stainless steel, which is clean, sanitary and in full compliance with GMP specifications.

9.The machine speed can be controlled and adjusted by frequency converter.

Products by fully automatic tube filling machine

10.Its height of the turntable can be adjusted directly ,thus makes it so convenient.

11.You can adjust the filling volume by adjusting the hand wheel,which is convenient and quick.

12.Fully automatic tube filling machine is equipment with safety device,you can open the door and stop the machine directly,and it will not work if there is no pipe,that makes a double protection to the machine.

2.Semi automatic tube filling machine

Compared with fully automatic tube filling machine,the semi is a kind of machine that need manually place the tube,and manually seal the tube,which need some manually assists,and a little slower than that of the fully automatic.

But it is still a common tube filling machine in many industries to fill various products like creams,lotion,adhesive,paste.

It is the best option for small scale manufacturing,and it is comparatively small in size,however,it is simple to operate.

AIPAK NF-30 semi automatic tube filling machine

Still,you will find there are many different sizes,shapes,capacities and design of semi automatic tube filling machine in the market.And their price varies as different cost performance.

Though they are semi automatic,they can still to some extent to increase your production capacity.

You can choose it as the backup of the fully automatic tube filling machine.

Besides,there is digital temperature control system for the semi automatic tube filling machine,which will be easy for you to maintain the power supply.

And there is sensor on the semi automatic tube filling machine,who will detect the level of the substance you need to fill for the following procedure.

Last from the appearance,you may not hard to understand,though it needs human assist but not too much,just one operator,when you set up all the items,it will perform the other process automatically.

3.Ultrasonic tube filling machine

From the name,it implies it is an advanced euqipment for the sealing of platsic soft tubes.

Ultrasonic tube filling and sealing machine-Photo credits:Upmach

As it uses ultrasonic wave to make the sealing place of the plastic tube produce high impact heat and melt to glue quickly through ultrasonic friction, it doesn't need to add any auxiliary products.

Its sealing speed is fast, the quality is good, appearance is beautiful.

The biggest advantages of an ultrasonic tube filling and sealing machine is that it will have little influence on the chemical agent ,you will no need to worry about the surface pollution. And it has solved the shortcomings of using adhesive or hot fusion welding to seal.

And its intelligent digital ultrasonic welding has made it avoid the causes of weak welding that lead by foreign matter adhering to the walls.

It is a perfect device for sealing of toothpaste, cosmetics, oils, drugs, food, industrial supplies and other kinds of soft pipes.

4.Rotary tube filling machine

This is an ideal sealing machine for plastic tube and composite pipe in medicine, daily chemicals, food and special industries.

It comes both in fully and semi automatic,that makes it easy for you to choose the most suitable to meet your various production requirements.

AIPAK NF-120 ratary tube filling machine

Rotary tube filling machine uses the technology and principle of heating, to make the sealing surface of plastic tubes under the heating condition and with high pressure fusing both sides of the tube to avoid some defects of poor sealing due to the foreign matters on the pipe wall.

The versatile characteristic determines that you can use this machine either to fill your products or sealing as well as crimping,batch no code,ejecting in one cycle.

Besides,its sealing system makes it work stable and reliable and you can use it specially for filling plastic tubes or laminated tubes.

And it is easy to operate and you can easily adjust it to get your desired filling dosage.

The machine is equipped with quantitative memory that will save your time for the next process and quantitative shutdown device for your easy maintaining.

More importantly,a rotary tube filling machine will help you enhance your production process and save your cost.

5.Filling and sealing machine

The filling and sealing machine adopts closed and semi closed form to fill paste and liquid, with no leakage sealing, has good consistency in filling weight and capacity.

And it can do one-time completion of filling, sealing and printing, suitable for product packaging in the fields of medicine, daily chemicals, food, chemical industry, etc. For example: filling and sealing of materials such as dermatitis flat, ointment, hair dye, toothpaste, shoe oil, adhesive, AB adhesive, epoxy adhesive, neoprene adhesive, etc.

AIPAK fully automatic tube filling and sealing machine

It is an ideal, practical and economical filling equipment for pharmaceutical, daily chemical, fine chemical and other industries.

Now have known the various types of tube filling machine in the market now,you may have at least have a little idea about what you want to buy.

Therefore,it will be more important for you to know the significant components of this machine.

7.What are the main components of a tube filling machine?

First,you need to understand that the machine is made by different assembling parts and components and that every parts or components are integrated to play various specific roles through elaborate design.

In other words,every parts and components are indispensable to the operation,efficiency and performance of the machine.

Now let’s talk about the main parts:

1.Frame

Frame is the outer structure system of the machine ,it is made of robust material and is the backbone of the tube filling machine to supports all the other parts and guarantee the normal running of all the components of the machine.

Both the inner parts and the outer parts are well assembled inside the frame.

With firm material ,the frame to the tube filling machine can prevent corrosion,humid conditions and resist to physical destruction.

2.Electric motor

Everyone knows,all machines are driven by energy, the electric motor I want to introduce is to convert electrical energy to mechanical energy to ensure the normal running,effective performance of the machine.

And the capacity of the electric motor may vary according to different workloads the tube filling machine will drive.

You may need to learn the kind of knowledge of motors to get the most suitable one for longterm production needs,since the model of the electric motor may vary from numerous factors.

Last, you need to remember,the larger your production output is,the bigger capacity of the electric motor should be.

3.Tank

The tank is a container that is to hold the product needs to be filled up.

Normally,the tank is designed higher than the frame as it will be more easy to make the product flow into the tubes during the filling process.

And you will find the tank is made of stainless as it must be resistant to corrosion and have high resistance and have to bear different temperature variations.

4.Control panel

The control is undoubting the most sensitive part of the tube filling machine.

It is a touchscreen interface that you can use it to adjust the production speed,motor speed,temperature setting and all other parameters of the machine as it has contained all the elements that you can manage the various parameters of the machine.

And you will also find there are some buttons included in the control panel,which is also the same purpose for your adjustment.

To summarize,a control panel like the brain of machine that make you in charge of the whole production process till the finished product outputting.

5.Safety mechanism

All operations should guarantee safety,the tube filling machine is not an exceptional,as its safety mechanism contains all the elements that may have effect to the safety.

It safeguard your operator from any malfunctions or immediate emergency that need special attentions.

Besides,the safety mechanism will also warn you of any situations that may lead to the damage of the machine.

You can regulate the safety mechanism by the buttons it includes and then the special situations will be controlled through severe measures.

6.Electronic box

The electronic box is made of four parts,namely,the protecting circuit air switch,the wiring board,relay carrier and the PLC switch that makes order to the machine.

This is a box where all the electrical connections of the machine including electricity and its related are gathered here.

Of course,you need to know there are other electrical components for the machine,such as drive,solenoids vale and transformer.

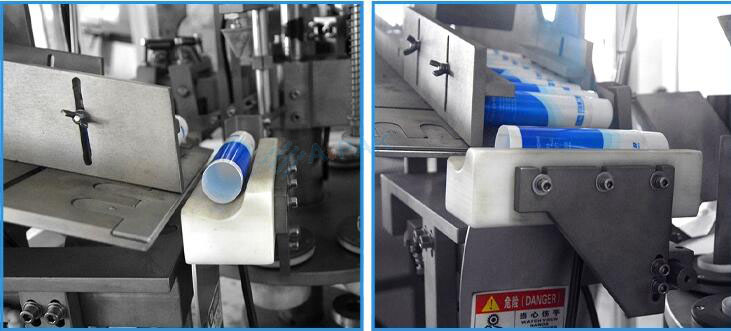

7.Tube storage and feeding

Tube storage place

Tube feeding

It is an automatic feeding device,that when you put the tubes to be filled in order on its storage place,then the tubes will be automatically inserted into the positioning die.

And this automatic device will also place the messy tubes in order automatically that to some extent save your time putting these tubes in order.

8.Feeding pump

The feeding pump is to pump your product into steam,water or gas flow through precise flow rate.

It has various methods that make your product flowing into the containers or tubes in accurate volume.

In other words,the feeding pump attains the ability to change the flowing rate.

It works as sucking a measured quantity of products that you will fill up into a chamber and inject them into the above tank.

Last,you need to know the feeding pump is powered by the electric motor,though the out controlling system and the outer pump controlling you can make it controlled.

Feeding pump

9.Filling nozzles

The filling nozzles are the crucial parts that determines the efficiency and performance of the tube filling machine.

Filling nozzles

It is the part that controls the flowing direction of the liquid into the tubes or containers and it is connected with the product supply device.

Surely,the filling nozzles are available in various designs,you may choose a special that suitable as your actual production needs.

Besides,the size of the nozzles varies,like large filling volume will of course need large size of nozzles.And some are suitable for common flow speed liquid and some are fit for low tension liquids.

But there is something I need to prompt,it is not that the bigger the nozzles,the better,if the nozzles size are too bigg,you will meet with surrounding dripping such kinds of issues.

Last,you need to know the size of the filling nozzle will determine the filling speed .

10.Tube holders

It is basically the components that are used to hold up the tubes when they are filled up.

The amount of tube holders vary ,as it is determined by the tubes or containers that the machine can fill in every cycle.

Tube holders must rotate in conform with the filling speed comes from the discharge,and also have to be in a comparatively high speed to keep pace with normal running.

Surely,the tube holders are running automatically,you will be easy to regulate them during your production process.

More interestingly,the tube holders will hold the tubes tightly when injection but transfer them to the next procedure in quite a well order.

However,it is the rotating and transferring consistency that guarantee the uniform of filling of the tubes.

11.Discharge item

This is the part that starting the filling process,as it is to take the material out from the tank and make the material go into the tubes or containers.

Surely ,it is the place the determines the amount of materials eject from the machine to fill the tubes.

It is an important part for the machine as you will be easy to measure the precise quantity of the material .

And it is adjustable,you can adjust it to meet your necessary quantity needs since both the speed and the amount of material that the discharge item taking from the tank can be controlled.

Now getting all the points about this tubeing filling machine ,it may be more easy for you to understand how it works.

Let's go to the next chapter directly.

8.What is the working principle of tube filling machine?

Video

Firstly,you will need to put the tubes on tubes storage room,then this part will place the tubes in order automatically for the next procedure to be inserted into the tube holder sequentially.

Secondly, the tube holder will start to rotate with the turntable,and then the tubes will be placed at it corresponding positions.

Here,you must have all parameters well set on the control panel to make the machine perform all its possible function in an regulated sequence.

Thirdly,the machine will start the filling,sealing and tail cutting until the final batch number printing process automatically.

The most important thing for the whole process is that you need to monitor the whole progress and adjust the parameters from the control section.

Of course,it is crucial for all the process that you need to well adjust the filling volume and production speed.

9.What are the advantges of tube filling machine?

Now, you may see the the tube filling machine has a very important position in the field of packaging.

Its transmission part is closed in the lower channels, which is pollution-free, safe and reliable. And the filling and sealing parts are installed on the channels, and the external frame can be seen on the cover, without semi closed static electricity.

In addition, the tube filling machine adopts storage inclined lifting tube and upper tube organization, and equipped with vacuum device, which make sure the filling is automatic and accurate.

The nozzle of the equipment is also equipped with materials to ensure the filling quality, the glue is heated in the tube, and the external equipment is cooled.

Besides,the machine will alarm, and even if there is no alarm, the door will open, or close due to overload, etc.

The application of tube filling machine not only simplifies the shape and packaging structure, but also greatly reduces the production and sales process of various wastes due to its economic and reasonable characteristics, methods and related equipment.

Moreover, the tube filling machine eliminates many unstable factors, so improve the overall efficiency and finally show the general direction of professional technical innovation in the long run.

Thus,tube filling machine meets the use requirements of environmental protection packaging.

10.What are the specifications of AIPAK tube filling machines?

Above all questions may have given you a good understanding of the tube filling machine,now in order to help you choose the precise or ideal type of machine,I would like to list the detailed specifications.

To begin,I would like you know,AIPAK Pharmacy is one of the leading manufacturers in the world supplying all kinds of pharmaceutical equipments to the global,that’s surely including the high quality tube filling machine.

1.NF-30 Semi-automatic plastic/laminated tube filling machine

This equipment is widely used in industry of toothpaste, cosmetic, drugs and food etc., it is applicable for various plastic tube and plastic-laminated-tube. It can fill-pack all kinds of cream, latex, lotion, oil etc.

It can automatically fill, seal, stamp batch numbers and exit tubes(with 8 tube position) .

All the channels can be unloaded fast and agilely.

The material-valve can be rotated, it can be clean out easily, so there’s no place for the dirty. Fixing organization can fix position precisely and firmly.

The position-turning part can change speed by using different-frequency. Customers can adjust the working speed themselves.

The detailed specification is

1.Power Supply:~220V±10%

2.Power:350W×2(inside heating) 250W×2(outside heating)

3.Filling Range:plastic/laminated tube 5~250(ml)

4.Operation Speed:10-30/min

5.Suitable tube length:plastic/laminated tube 50~210(mm)

6.Suitable tube diameter:plastic/laminated tube 13~50(mm)

7.Whole Machine:about 1100X800X1600(㎜)

8.Weight:about 280kg

9.Working Pressure:>0.4Mpa

10.Control type:Button

2.NF-60/80 Automatic plastic/laminated tube filling machine

NF-60/80 Automatic tube filling machine adopts imported foreign advanced technique,specially designed according to technology of cosmetics, ointment cream products,machine include automatic tube feeding,heating,sealing,pretreatment system,and adopt mechanical piston, electrical control system and operation platform filling system.

NF-60

NF-80

3.NF-100/120 Automatic plastic/laminated tube filling machine

NF-100/120 Automatic plastic/laminated tube filling machine are a high-tech product which successfully developed and designed by adopting advanced technology from abroad and strictly meet GMP requirement.

PLC controller and color touch screen are applied and made it possible for programmable control of the machine.

They can perform the filling for ointment, cream jellies or viscosity material, hot sealing, batch number embossing (include manufacture date) automatically.

They are ideal equipment for plastic tube and laminated tube filling and sealing for cosmetic, pharmacy, foodstuff and bond industries.

NF-100

NF-120

Feature

■ The Product has 40 locations and matching with manipulator, the machine is able to meet different type of sealing requirements of plastic tube and laminated tubes.

■ Tube feeding, eye marking, material filling, sealing , batch number printing, finished products discharging can be performed automatically (the whole procedure).

■ With external reversal feeding system, makes tube charging more convenient and tidy.

■ The mechanical linkage photo sensor precision tolerance is less than 0.2mm. The chromatic aberration scope between tube and eye mark is reduced.

■ Photo-electronic, electric, pneumatic integrative control is applied with the machine. No tube, no filling. It gives an alarm when low pressure occurs. The machine stops automatically if tube error or open the safety door.

| Model | NF-60 | NF-80 | NF-100 | NF-120 |

| Use | Plastic tube,aluminium tube,laminated tube | |||

| Speed | 30-60 tubes/min | 50-80tubes/min | 80-95tubes/minute | 80-120tubes/minute |

| Filling volume | 5-250ml | 5-250ml | 5-250ml | 5-250ml |

| Filling accuracy | ±1% | ±1% | ±1% | ±1% |

| Tube diameter | 10-50mm | 10-50mm | 10-50mm | 10-50mm |

| Tube length | 50-210mm | 50-210mm | 50-210mm | 50-210mm |

| Air pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa |

| Motor power | 1.1kw | 1.5kw | 1.5kw | 2.2kw |

| Heat seal | 3kw | 3kw | 6kw | 6kw |

| Overall dimensions(LxWxH) | 1800x850x1980mm | 2200x1220x2080mm | 2300x1350x1800mm | 2950x1310x2300mm |

| Weight | 850kgs | 1200kgs | 1500kgs | 3000kgs |

11.What should pharmaceutical manufacturers do to better protect their medicines by tube filling ?

Nowadays,more and more pharmaceutical manufacturers are aware of consumers and patients tend to prefer the more convenient tubes as they are easier to dispense the medicine without any sudden release or splash.

However,the pharmaceutical brand owners should more realize that they should make sure that no air enters the tubes,since air and moisture can affect and change the composition of the formulation of their medications.

Thus,in order to overcome this,pharmaceutical manufacturers should add preservatives and other compounds,but which can be expensive or lead to side effects.

In fact, a simple solution is to use airless tubes.

Tube airless refers to a new airless tube packaging that is specifically developed for packaging pharmaceutical creams and pastes and ensures that air does not easily enter the tube.

Airless tube-Photo Credits:Quadpack

It is made of small plastic pouch and an air chamber sealed inside the flexible tube.

The airless tubes are more cost effective than piston pumps for pharmaceutical manufacturers as piston pump have so many parts while tube ariless tube only has three.

Besides,tube airless tubes are more environmentally friendly as they use less plastic.

And the tube airless tubes are easier for your use as they will make controlled dispensing of cream or gel possible.

Last but not the least,tube airless will make the patients more compliant to their treatment.

As often patients do not follow the medicine instructions because of dispensing difficulties or difficulties in evacuating the entire gel or cream.

With these difficulties removed and better protection for the cream or gel, they tend to be more compliant.

12.What is the difference between a tube filling machine and a sealing machine?

As tube filling machine is sometimes also called tube filling and sealing machine by some people,so when it comes with the sealing function,many people will begin to wonder is there is any difference between the tube filling machine and the sealing machine.

Sealing machine

In fact,the difference can be concluded in some aspects,they are:

1.In terms of sealing function

Tube filling machine are used for sealing tubes.

Sealing machine is used to seal some films and plastic bags.

Products by sealing machine

2.In terms of function

There are generally three types of tube sealing machines, one is only tail sealing, the other is filling and tail sealing, the other is automatic tube filling and automatic tail sealing and one-time molding with date printing.

While there are generally three kinds of sealing machine, one is foot sealing machine, one is continuous sealing machine, and the other is pneumatic sealing machine. They are all sealed plastic bags, such as film plastic bags, aluminum foil bags, vacuum bags, composite plastic bags, PP / PE bags, etc.

13.Which aspects you need to consider when purchasing a tube filling machine?

Until now,you may have gotten the basic idea about this tube filling machine,but as to buy one,there are also some aspects you need consider.

1.Material and structure

The material that makes the machine is surely one of the most important factor you need to consider first.

As high quality and firm structure will determine if the completion of the filling or sealing tasks or not.

From the tube filling machine main components,you may have know the material must prevent the machine from corrosion,bad weather and resist to some physical conditions.

Most of time,you will see many manufacturers adopt stainless steel,that’s because this kind of material has good properties and can bear all bad conditions that the machine is subjected to.

And you also know that the machine is vibrating most of time when running,so it will be trick for you if the structure is not firm.

Therefore,merely a high quality material is not enough to guarantee the machine,you need also consider if the structure meets the standard requirement.

2.Size

Nowadays,with the progress of technology,the machine has grown to be more compact and effective from the original large and heavy one.

But that is not mean you can choose the machine size at will,you still need to check the exact size to meet your actual production needs.

And you also need to consider your workshop space as it doesn’t mean the bigger of the machine,the better performance it will be.

You need to make plan for your expected capacity then determine the best size of the machine to buy.

3.Capacity of production

You will find the capacity of production is normally one of the most important factors that many people pay attention to when purchasing a tubing filling machine.

Yes,it’s true the capacity is crucial as it’s the production ability of the machine producing a certain quantity of products within a certain time,which matters with your whole manufacturing efficiency.

And you will find the capacity of the tube filling machines can be various,however,whatever it is,you will always find the most suitable machines for your own.

Therefore,what you need to do is to confirm your production needs,that is,if you are a large factory,it is often quite common that a large capacity tube filling machine may most suitable for you.

4.Machine model

As to the model,you may think of NO.,it’s true there are various model no in the market now

since nowadays the packaging industry is growing and technology is improving,various manufacturers are joining in this team and try their best to meet the growing demands.

But in fact,the model of the tube filling machine that you buy is more important than you have ever thought.

AIPAK NF-100 Tube filling machine

First of all, you need to determine the products to be filled by the machine as you may have many kinds of products.

And when purchasing the tube filling machine, you may hope that one machine can pack all kinds of these products.

In fact, the filling effect of special model is better than that of compatible model.

Of course,this is for reference only. You can coordinate with the manufacturer.

In addition, the filling range is different and the price is different. If the filling range is different, the products should be filled separately.

5.Quality and safety

Quality and safety should always be the most important factors that you need to take notes whether they meet the standard requirements whatever what kinds of machine you purchase,like if the machine meet with GMP requirements,get CE approval or have SGS,ISO certifications.

Surely,most of the manufacturers must the get the approval from specific regulatory before making their machines sell in the market,then can these machines are called ideal equipment for using.

In fact,a high qualified and safe equipment will not only bring you quality performance,efficient production,convenience to your production process but also give you confidence that the products produced by the machine meet the basis safety standards and make you feel at ease for safety production.

You should as far as possible choose the famous brand suppliers with a long history, the quality is guaranteed.

And mature technology and stable quality models will make the packaging faster and more stable, low energy consumption, low manual and low scrap rate.

And the tube filling machine is a talent consuming machine. If you buy low-quality machines, you will accumulated waste of packaging film in your daily production in the future, which is also not a small number.

6.After-sales service

In terms of after-sales service, try to choose the suppliers with a good reputation.

Timely after-sales service is particularly important for food processing enterprises. Such as beverage enterprises, summer is the peak period of production, if the machine in production problems can not be solved immediately, the loss can be imagined.

And If there are field visits, you should pay attention to major aspects, but also to small details, which often determine the quality of the whole machine.

Test machine with samples as much as possible.

14.How to troubleshooting common problems of tube filling machine?

You will get the best results from the production process of each products when you have purchased the most suitable machine through taking the above aspects into consideration.

Below I will explain some of the common problems that excluding the problems caused by the low quality of the machine itself.

First of all, before analyzing the specific problems, you need to check the equipment as follows:

- Check whether the actual operation speed of the tube filling machine is the same as that of the initial commissioning of specification.

- Check whether the heater is on the position.

- Check whether the compressed air supply pressure of the equipment meets the pressure requirements during normal operation.

- Check whether the cooling water flows smoothly and whether the temperature of the cooling water is within the range required by the equipment.

- Check whether there is any dropping of paste in the tube filling machine, especially ensure that the paste is not stuck on the upper part of the inner surface wall of the tube.

- The inner surface of the tube shall not contact with anything, so as to avoid contamination.

- Check whether the air intake of the heater is normal.

- Check whether the temperature detector inside the heater is in the correct position.

- Check whether the suction device of heating head works normally.

Then after the above initial inspection, I will analyze some of the phenomenons:

Phenomenon 1: Some of the problems may caused by too high temperature.

At this time, it is necessary for you to check whether the actual temperature is the temperature required for the normal operation of the tube.

That’s the actual temperature on the temperature display should be relatively stable at the set temperature (the normal deviation range is between 1 ℃ and 3 ℃).

Phenomenon 2: There are ears on one side.

First you shall check whether the heating head is correctly placed in the heating head nest. Then check the perpendicularity between the heating head and the lower tube.

Another possible reason for the phenomenon of ears on one side is the deviation of the parallelism of the two tailboards.

And it can be detected by a gasket between 0.2 and 0.3 mm.

Phenomenon 3: The tail sealing begins to crack from the middle of the tube.

This phenomenon occurs because the size of the heating head is not enough.

You will need to replace a larger heating head.

The standard for judging the size of the heating head is to insert the heating head inside the tube, and then pull it out. When pulling out, it feels a slight suction.

Phenomenon 4: "Eye bag" appears under the explosion-proof line of the tail sealing.

The height of the heating head air outlet of is incorrect.

Phenomenon 5: The middle of the tube cutting tail end depressed.

This problem is usually caused by the wrong size of the tube cup, and the hose is too tightly clamped in the tube cup.

There are standard judgment for you to check the size of the tube cup: the tube should be fully stuck in the tube cup, but when the tail is clamped, the tube cup should not affect the natural change of the shape of the tube.

15.How to maintain fully atomatic tube filling machine?

Remember that only when the preparatory work is done well, can the filling and sealing machine improve the production efficiency and get twice the result with half the effort.

Apart from ensuring the integrity and good operation of the equipment when using the fully automatic tube filling machine, you will need also maintain the equipment regularly.

This includes:

- Clean the circuit of the electric control box, and sweep the chemicals in the electric control box.

- Check whether the contact terminal and wire heads of all electrical components of the machine are in good condition, and whether the ground wire is in good condition without leakage.

- Check whether the motor bearing is abnormal and measure the insulation of the motor.

- Check whether the operation mechanism is flexible, whether the scissors and shaft sleeve are worn and whether the fasteners are loose.

- For the liquid level adjustment of the machine: before the filling in each shift, first lift the liquid level probe rod on the material tank and put it at the original height position (the position cannot be changed), then open the main feeding valve (keep the valve in the same position basically).

The minimum liquid level of the material box shall not be lower than the feed outlet of the material box, and it can meet the requirements of batch filling.

If it is necessary to increase the liquid level of the material tank, you should raise the probe rod to a proper height.

The pressure of the level controller can also be adjusted.

6.The main feeding valve of the machine must be closed before work.

16.How to clean the basic components of automatic filling and sealing machine?

At the same time,getting the idea of how to clean the basic components of the machine will also in the long-term stable working of your machine.

First all of ,you need to know the surface, bottom plate, lower mold slide plate, groove, upper mold inner pressing plate and positioning rod should be cleaned regularly with the power turning off and the normal temperature restoring.

And the lower die slide plate, strut bearing, eccentric wheel, guide post, guide rail and other transmission parts are regularly butted to ensure the performance of the machine.

Then you will get the cleaning method of toothed cutter:

First plug two drain holes of the lower die with cotton ball, pour boiling water into the groove of the lower die until it is full.

Then push the sliding plate of the lower die to a proper position, press the upper die down to the lowest point, let the toothed cutter soak for several minutes until it is clean, and repeat several times.

During the maintenance, dismantle and clean the piston, and dismantle the fixing screw at the same time, so as to avoid affecting the technical requirements of the other piston when disassembling the first piston.

Then you shall take out the remaining products in the machine, and fill the barrel with soft cleaning liquid.

As the cylinder has been lubricated in the factory,you shall not open or add any lubricating oil to ensure the surface of the tail sealer is clean and tidy.

17.Is there any innovations in the tube filling industry?

As we are going to the end of the article, I am going to tell you that as more and more cosmetics and food product manufacturers are showing greater interest in tubes as their packaging material as they are less expensive to make and transport,more importantly,greener.

In fact,there are various innovations in the the tube filling industry that will make your products better standing out on the shelves and become as must for the marketers.

Now,I will introduce three of them.

One is we have completed the heteromorphic sealing project.

That means that in the future,you will have your heteromorphic tubes sealed by our tube filling machine.

Aonother is there will be change on the packaging material.

Nowadays,you will find more and more people are becoming more conscious of protecting the environment and tend to purchase products that contains less plastic which is not easy to dissolve and produce some pollutions,so more sustainable materials are becoming more and more popular among them.

Eco-friendly cosmetic packaging-Photo credits:TWP

As a result of which,many manufacturers are now focusing on eco-friendly materials to package their products like cardboard,metal or glass container.

And according to statistics based on data that only 9.5% of plastic was recycled in 2014,thus the green packaging concepts should be strongly promoted among all manufacturers.

Below I have list some green package types,you can take them for your future package taget as it will keen to the customers now.

.Cardboard/paper for outside packaging and boxes

.Paper-carton tubes for lotions and creams

.Glass bottles for liquids and creams

.Metal tubes for lotions, creams, and other cosmetics

.Bamboo for brushes and make-up pallets