Pouch Cartoning Machine: The Complete Buying Guide In 2025

Thinking to buy pouch cartoning machine? But confused which one? In revolutionizing world, manufacturers are seeking innovative solution to robust their operational processes, reduce labor cost and enhance productivity. One machine that one-stop solution for all concerns is pouch cartoning machine.

This machine is designed to efficiently packed pouches in carton with precision and speed. Whether food items, pharmaceutical or personal care product, it provides quality and consistency in each batch making good choice for manufacturer. But with many options and configurations available in market, choosing right for your business is daunting task.

This comprehensive “Pouch cartoning machine: the complete buying guide 2025” article is packed with expert’s advices and experience which help you to select pouch cartoning machine which is best fit for your business demand.

1.What Do You Know About Pouch Cartoning Machine?

Pouch cartoning machine is highly automatic equipment which packs pouches containing product like food, pharmaceutical product or personal care product in cartons with precision and efficiency. It has become a crucial component of packaging streamline as it performs multiple step in single process including folding cartons sheets into shape of carton, inserting pouches, sealing cartons and labelling.

Pouch cartoning machine is highly advanced equipment which can easily configured to handle different types of product pouches from solid to liquid or powder. Other than that it provides tamper-evident seals and batch coding making a one stop solution for packaging unit large scale production capacity.

This equipment greatly enhances packaging efficiency by reduce manual labor, increasing productivity and efficiency.

2.What are Beneficial Aspects of Pouch Cartoning Machine?

Pouch cartoning machine has some great benefits that can be reduce labor cost, increase efficiency, versatility and list goes on. Let’s learn some benefitting aspect of this equipment in this segment.

Increasing production output

Increase Production Output

Pouch cartoning machine is an advanced equipment which can pack pouches in cartons at very high speed. With continuous operation and reduced downtime, it can efficiently pack large batches of pouches in carton enable manufacturer to meet increasing market demand.

Reducing labor cost

Reducing Labor Cost- Picture Courtesy: Tekpak Automation

Pouch cartoning machine is highly automated equipment which work efficiently without need of manual intervention. In this way, it has greatly reduced manual labor and eventually reducing overall cost of packaging operation. It is a great investment for any manufacturer.

Maintaining accuracy and consistency

Maintaining Accuracy and Consistency- Picture Courtesy: Jochamp

This equipment with automated operation greatly reduce error encounter with manual packaging. It ensures precise and accurate filling of pouches in carton and sealing. This equipment eradicated error like misalignment or improper packaging of cartons.

Handling different sizes

Handling Different Sizes

Pouch cartoning machine can handle different shapes and sizes of pouches making it versatile. Due its easy configuration, can easily adaptable in various industries like food industry, pharmaceutical industry or personal care industry.

Enhancing product safety

Enhancing Product Safety-Picture Courtesy: CECLE Machine

Pouch cartoning machine packed pouches in carton which enhance safety of product during handling, transportation and storage. This equipment also come with tamper evident sealing option which make it best fit for manufacturer.

Customizable

Customizable

Pouch cartoning machine comes with different option like multi pouch insertion, modified labelling and easy integration with other equipment in streamline process. This ease of customization enables manufacturer to customize according to needs.

3.Elaborate Application in Different Industries of Pouch Cartoning Machine.

Pouch cartoning machine has versatile implementation in many industries. Other industries also use this equipment to increase overall production and reduces operational expenses. In this topic, you will learn about some major industries which are incorporating pouch cartoning machine in their packaging line.

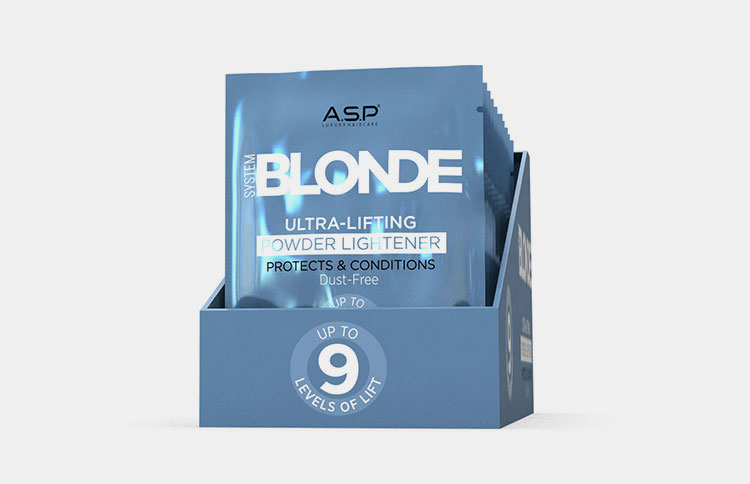

Cosmetic industry

Cosmetic Industry- Picture Courtesy: ESP Expert Haircare

There is vast application of pouch cartoning machine in cosmetic industry. If you have ever use face masks, shampoo, conditioner pouches, all comes in small card board boxes and all these pouches packed in boxes using pouch cartoning machine.

Pharmaceutical industry

Pharmaceutical Industry- Picture Courtesy: DVAGO

Pharmaceutical industry need safety, precision and hygiene due to strict regulatory compliance which is ensure by using pouch cartoning machine. Many pharmaceutical ingredients like medicated powders, gel, lotions or diagnostic kit packed in pouch are placed in carton by using this equipment.

Personal care and cosmetic industry

Personal Care and Cosmetic Industry- Picture Courtesy: Skin Nutrient

Pouch cartoning machine is crucial in cosmetic and personal care industry as it gives hygienic and appealing look to product. This equipment automated the process of placing cosmetic and personal care product pouches in carton with upholding efficiency and consistency of product.

Pet food industry

Pet Food Industry- Picture Courtesy: B2K Pet

Pet food industry has gained so much popularity after pet lovers looking for hygienic and safe food option for their pet. This requirement is filed by pouch cartoning machine by placing pet food pouches in carton with accuracy and speed. This machine efficiently packed wet food pouches, treat pouches r multivitamin pouches in carton efficiently.

Agriculture industry

Agricultural Industry- Picture Courtesy: Natura Market

Many agricultural products like pesticides, seeds and fertilizer all comes in secure sealed pouches to maintain high level quality. These pouches are efficiently placed in cartons by using pouch cartoning machine which can enhance safety of product during handling and transportation.

4.What is the Working Principle of Pouch Cartoning Machine?

This pouch cartoning machine must look simple but in real it includes series of process which combine to create effective filling of pouches in carton. Let’s learn about their processes.

Carton sheet feeding and folding

Carton Sheet Feeding and Folding- Picture Courtesy: Bhagwati Pharma

In first step, carton sheets are suck by vacuum suction cup and leading these flat carton sheets to folding station where carton sheet is folded in desired shape and size of boxes according to manufacturer instruction or demand.

Pouch alignment

Pouch alignment- Picture Courtesy: WePack

In the second step, pre filled pouches are aligned in machine through conveyer belt. Due to advanced features of pouch cartoning machine, it may handle multiple pouches or arrange them in specific mentioned orientation.

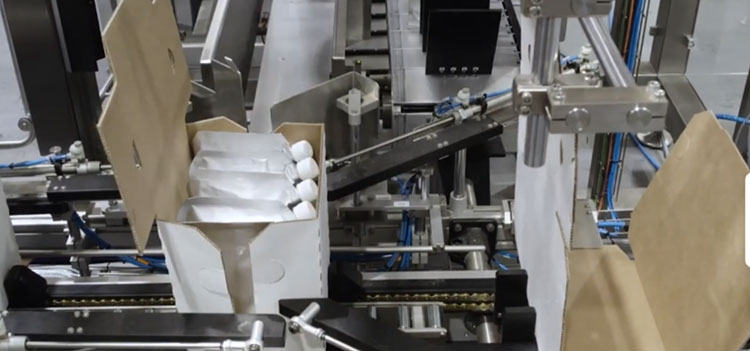

Pouch feeding in carton

Pouch Feeding in Carton- Picture Courtesy: Tekpak Automation

After carton folding and pouches alignment, pouches are precisely and securely placed in cartons with the help of gripper or pusher to ensure proper alignment without damaging product.

Inserting information leaflet

Inserting Information Leaflet-Picture Courtesy: Direct Industry

This step is optional, as it depends on operation requirement. In this step instruction leaflet like, product handling guide, storage condition specification or warranty card (in case machinery) is inserted in the cartons.

Sealing of cartons

Sealing of Cartons

After placing pouches in carton, they are forwarded to sealing station. At this point, cartons are securely sealed by tuck in folding method without using glue or sealed with glue or carton tapes depending on the shape and type of carton.

Labeling and coding

Labeling and Coding- Picture Courtesy: VKPAK

Some pouch cartoning machines are integrated with advanced labeling and coding option where carton after secure sealing are labeled to add product information, expiry, batch number and etc.

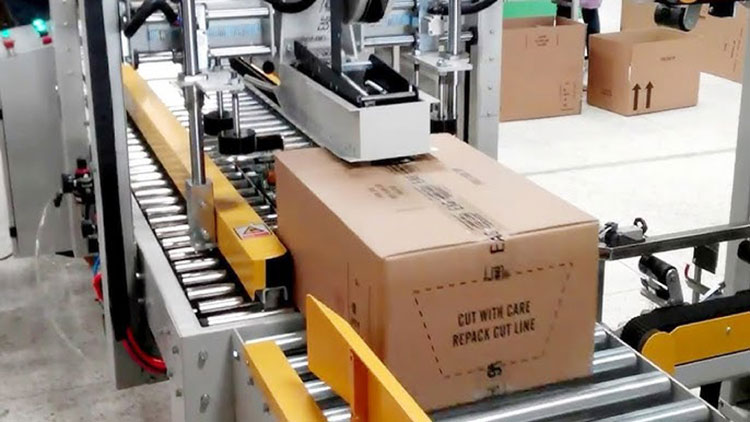

Discharging cartons

Discharging Cartons- Picture Courtesy: Justdial

After secure and safe sealing and labelling, cartons are discharge from outer conveyer belt of pouch cartoning machine proceed to final quality check stages.

5.What are Different Types of Pouch Cartoning Machine Available in Market?

Pouch cartoning machine comes with different variation depending on the requirement of manufacturer. It also depends on level of automation or modification. Let’s discuss each of it separately for your understanding.

On the basis of level of automation

Semi-automatic pouch cartoning machine

Semi-automatic Pouch Cartoning Machine- Picture Courtesy: Azone Machinery

As the name suggest, in this type of cartoning machine interference of manual labor is required at different steps like loading flat carton sheet or flip sheets. The semi-automatic pouch cartoning may require manual labor to operate but it is quite cheaper than other automated version and suitable for small scale manufacturing unit.

Automatic pouch cartoning machine

Automatic Pouch Cartoning Machine

Automatic pouch cartoning machine is highly advanced equipment which can perform whole cartoning process without manual intervention. This equipment automates several step like carton alignment, pouch insertion, sealing and labelling without manual efforts. You will find it convenient to operate.

On the basis of structural modification

Vertical pouch cartoning machine

Vertical Pouch Cartoning Machine- Picture Courtesy: Best Supplier

In vertical pouch cartoning machine, pouches are introduced vertically in the carton. This equipment is suitable where keeping pouches in upright position is needed. It is preferred for small space due to compact design. It is used to pack personal care product and small animal treat pouches.

Horizontal pouch cartoning machine

Horizontal Pouch Cartoning Machine- Picture Courtesy: Liner Machinery

Horizontal pouch cartoning machine is highly automated equipment which packed pouches in carton in horizontal orientation with precision and accuracy. It can perform multiple task in single step without any manual intervention. This machine is widely used in food, pharmaceutical, beverages, cosmetic and pet food industry due to its efficiency and quality. This machine has become staple equipment for large scale manufacturer.

6.What are the Main Components of Pouch Cartoning Machine?

There are some major components of pouch cartoning machine through which pouch being inserted in the carton. Several components involve together that performs the whole process smoothly.

PLC Control panel

PLC Control Panel

This control panel has different specification which also work automatically but need some instruction as per the work requirements. It must control through manual adjustment in order to prevent any error.

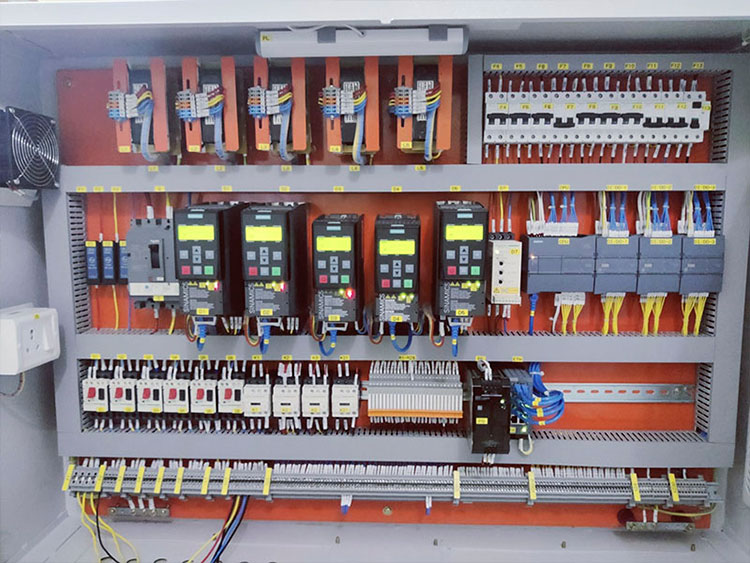

Electrical panel

Electrical Panel

Electric panel is considered crucial component in pouch cartoning machine. It controls and coordinate all automated equipment process. This electric panel ensure automation, power distribution, safety and overall performance.

Carton tooling and feeding system

This tool is an essential component which help in precise sizing and shaping which you entered through control panel and make proper alignment and sizing. This tooling system ensure that carton sheets are properly aligned and pouches are accurately filled in the carton.

Carton sealant system

Carton Sealant System- Picture Courtesy: IPG

The sealing system sealed the carton after filling the pouches in the box and sealing must ensure that the carton is properly packed and pouches must be save for handling and distribution. There is different sealing method are used depending on requirement like adhesive glue sealing, or adhesive tape sealing

Ink printer jet

Ink Printer Jet- Picture Courtesy: Tradeindia

It acts as printing station for cartons. It can print information product name, quantity, batch number or any detail related to product. This system enhances traceability, compliance and identification of product.

Sensors and alarms

Pouch cartoning machine is equipped with sensors which detect any malfunction before any serious damage. These sensor beep sent alarm so that problem is solved immediately.

Conveyer belt and guide rails

Conveyer Belt and Guide Rail – Picture Courtesy: Packaging Digest

This system consists of conveyer belt and guide rail use to move pouches or cartons to different station. It is critical system because a set speed is required so that each step is perform smoothly.

7.How Different Factors Effect Efficiency of Pouch Cartoning Machine?

The efficiency of pouch cartoning machine is greatly impact speed, production capacity and overall quality of product. There are many factor which influence efficiency of pouch cartoning. Let’s discuss some important factors that impact pouch cartoning machine.

Packaging material

Packaging Material- Picture Courtesy: CRB

It is really important to use good quality of carton material in pouch cartoning machine. If material is too coarse it can result in improper folding and misalignment of cartons or if material is too thin it can easily have torn off during process.

Speed of machine

Speed of Machine

The well-equipped machine with proper speed maintain the proper production with quality products and with average production on time will balance the production of product. Over speeding equipment can lead to carton jamming, misalignment od pouches and improper sealing. To avoid these situations, use optimal speed which can align with equipment.

Temperature

Temperature

This is also the important factors which effect machine efficiency because due to temperature minimal changes may also effects the pouch quality and also the condition of carton therefore must ensure to maintain temperature result good end product.

Lack of maintenance of components

Lack of Maintenance of Components- Picture Courtesy: Global Electronic Services

Due to continuous processing and production, equipment part worn out or damage which can slow down process and effect production outcome. Always schedule periodic maintenance, clean and replace damage part timely.

Malfunctioning in sensors

Malfunction in Sensors- Picture Courtesy: Zarpac

Faulty and defected sensor greatly influenced the performance of pouch cartoning machine. Timely maintenance and checking all sensor and alarm before starting operation reduces chances of error and waste of product.

8.What are Important Key Factors You Need to Consider Before Buying Pouch Cartoning Machine?

There is numerous key factor must be considering while buying any pouch cartoning machine

and listed some important factors that you must consider.

Machine capacity for production

Machine Capacity for Production

You must consider the pouch cartoning machine capacity which include the production speed because it is primarily important that how much quantity packed at specific speed which might beneficial for the production side.

Compatibility

Compatibility- Picture Courtesy: Food Engineering

You must ensure that machine may adjust as per the requirement of pouches and must be handle easily without getting any inconvenience. On the other hand, it can be compatible with other equipment in production unit.

Cost effective

Cost Effective

This is the major key factors in production and must be calculate the cost of pouch cartoning machine till to the installation. This is usually the biggest factor to be consider before buying an equipment

Maintenance

Maintenance - Picture Courtesy: Polar Bear N.Y

This is also another important key factor before buying a machine that all parts of machine are available easily and the machine is easy to maintain without any wastage of time.

Safety measures

Ensure that all safety measures equipped in machine and safe to use. It must have emergency sensors without going any life threatening situation and the machine meet all safety standard.

Conclusion

Pouch cartoning machine is crucial and revolutionizing advancement toward effective packaging. It can enhance overall appearance of packaging and also can develop consumer satisfaction. In this article, you learned about usage, benefit and application in different. Which one is suitable for you. Still you are confused which pouch cartoning machine set with your business need? You are encouraged to contact our AIPAK service team because we are best in it.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide