Pill Making Machine: The Complete FAQ Guide In 2025

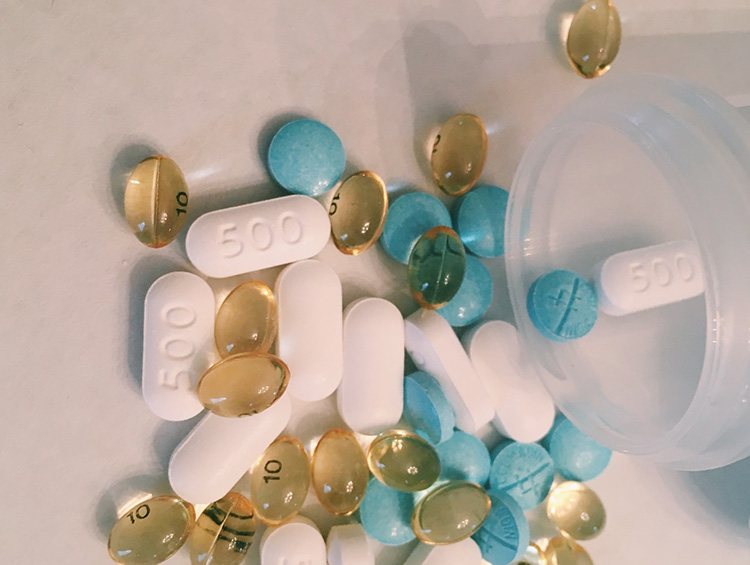

Pills are an optimized way of delivering the medication requires to treat the patient with the best possible outcomes. In addition, these are produced in many colors, shapes, and sizes, to improve the user’s sense of accepting them.

Pharmaceutical engineering produces new technologies and advancements that ease pill making job. Pill Making Machine: The Complete FAQ Guide in 2023 aims to provide all possible FAQs ones has in mind when purchasing the machine. Let Read!

1.What Exactly Pills Are?

Today, in pharmaceutics, the word pill is loosely used for any solid dosage form to be a swallow, for instance, tablet, capsule, caplet, etc., but it was exactly referred to ‘round object’. In modern terminology, any flat shape medicine is correctly known as a ‘tablet’.

The pill is derived from the word ‘Katapotia’ means ‘something to swallow’, this term was used by ancient Greece, who used to make small round shape balls. A roman Scholar ‘ Pliny’ was the first who coined ‘ Pilula’ in 23-79 AD.

These pills were a mixture of powdered plant with other ingredients to make them down in the body easily with a less bitter taste. For that, a plant slimy layer was used as a coating agent.

There are various types of pills today; that’s why it is important to have knowledge of the differences among them to select a medication option for you.

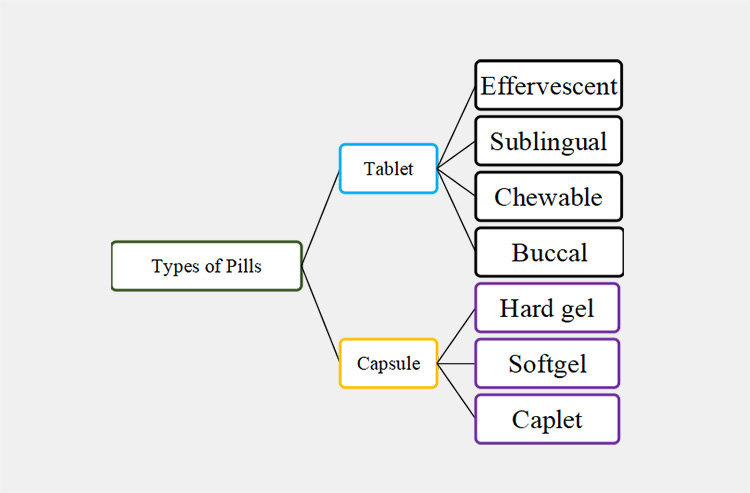

2.What are the Types of Pills?

As mentioned earlier, pills were identified as small rounded balls in ancient times. But modern time has converted this logic into a broad spectrum; mean any oral solid dosage form that are meant to swallow i.e., tablet or capsule, and more

With so many types of pill, each of them somewhat demonstrated with different physiologically response. Indeed, all of them shows the same safety goal with high potency but they’re different in term of preparation or inducing their own action. For example:

Tablet: effervescent tablet, sub-lingual tablet, chewable tablet, buccal tablet and so on.

Capsule: hardgel capsule, softgel capsule, sprinkle capsule, and so on.

3.What is a Pill Making Machine?

A pill making machine is mechanical equipment that ensures the production of a drug in a compressed pill of evenly distributed particles of active ingredients and excipients.

This machine shows a broad array of classifications where one can produce tablet pill making machine, capsules pill making machine , softgel pill making machine, etc.

A measured granulated powder is always used to make pills, that can be metered into molding cavities such as die-cavity for compression and acquiring shape.

A great force must be pressed to bind the powder mixture into a compressed pill. The following pressed drug is the combination of the active drug with other components such as binders, glidants, diluents, etc.,

This machine not only helps in transforming powdered content into firm bonded pills but supports the bilayer to multilayer colored pill production.

4.What is the History of Pill Making Machine?

Before the emergence of pharmaceutical companies for making medicines, drug dispensing was considered a difficult and complicated task. At that time, pill machine was a unique tool of chemist collection.

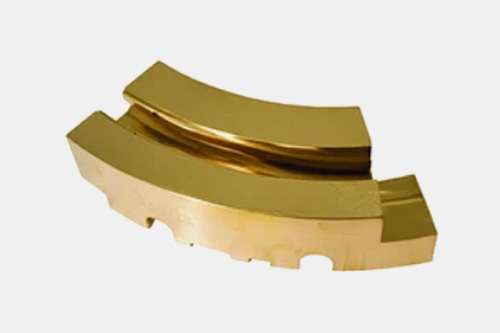

Pill making machine was introduced in the mid-1700s; soon it became a staple of the Victorian chemist’s shop. The ingredients of pill powder were mixed using binding agents and rolled with a hand roller over a pipe on the tile presented at the back of the machine. Then it was subjected to a grooved brass plate and divided equally using the corresponding side of the roller.

Previously, pills were cut with the help of sharp knife by taking measurement on a ceramic tile. Moreover, after cutting pills were finely rounded and coated with a sugar crust. For prestigious consumers, makers even used silver or gold leaves and packed them in cylindrical pill boxes. Today, pill making machine is presented with various excellent ranges that ensure small to large batch production up to customer demand.

5.Why Do You Need Pill Making Machine?

Before pill, drugs were taken in divided powder form that was featured with mixing of active ingredients with excipient like taste masking agents. This mode of medication was indeed a non-compliant method of drug administration especially in case of taking bitter extracts.

Pills are compact formulation that holds your drug in an effective manner. Means, pill making machine helps in conversion of granulated powders into pill of uniform size, shapes and attractive colors. Moreover, pills making machine ensuring evenly distribution of active ingredient. That’s the reason, pill making machine is broadly accepted in huge production companies where basic working principle are followed to get correct solid dosage form.

6.What is the Importance of Pill Making Machine?

Pill making machine is popular extensively in production sector due to following reasons:

Offering Various Shapes and Sizes of Pills

The pill making machine helps in development of required pills in various shapes and sizes depending upon assembling various die cavities and mold.

Limited to Unlimited Production Capacity

A highly efficient pill making machine is capable enough to deal with small, moderate to large batch size pill production, hence it is an ideal solution for R&D, clinical, and large production activities.

Robust Design- No Risk for Contamination

The body make up of pill making machine is of stainless steel that ensure productivity with no chances of contamination. Moreover, they’re presented with robust designs that are suitable for medium to large laboratory spaces.

Cost Effective

Pill making machine is capable of generating hundred to thousands pill per hour including bilayers tablets. So, you won’t need much time to stand in order to get required capacity.Additionally, emergence of automatic features has lowers cost expenditure, i.e. less labor, time- effective, etc.,

Minimize Errors-Proficient Outcome

Pill making machine has solved the problem for providing highly efficient results with effective pill formation including defined pill designs, layers, shape, etc.,

7.What are the Applications of Pill Making Machines?

Pill making machine has several industrial applications; some of which are mentioned below:

Pharmaceutical Industry

There are thousands of medications produced in every independent pharmaceutical industry.

Each medicine must be properly blended, pressed, and packed. Pill making machine is the most popular and reliable part of this industry as it produces effective medication with lesser wastage of ingredient of the pill.

Chemical Industry

Pill making machine play a significant role in the preparation of chemicals where different types of ingredients are pressed firmly and prepared. Such as buffer salt, acidic and basic compounds. This machine can help user to obtain chemical compounds without any contact hence ensuring 100% product and user safety.

Food Industry

Food industries deal with the manufacturing of various edibles that requires pill making machine. For instance, confectionery items like chocolates, biscuits, candies, soda tablets, sweetener pills, etc

Cosmetic Industry

A pill making machine is a reliable device that can be used in making cosmetics items to provide the best skincare and self-care products in accurate bar form. Such as face cleansing pellets, or bars.

Nutraceutical Industry

Pill making machine is used in making nutraceutical items worldwide. This is robust equipment that ensures 100% hygienic production of nutraceutical items with less contact with the product. For e.g. vitamins tablets, protein serum supplements, calcium tablets, etc.,

8.What Is the Working Principle of Pill Making Machine?

The working principle of different pill making machines is quite different. For your understanding the main operational principle of some basic types of pill making machines is given below:

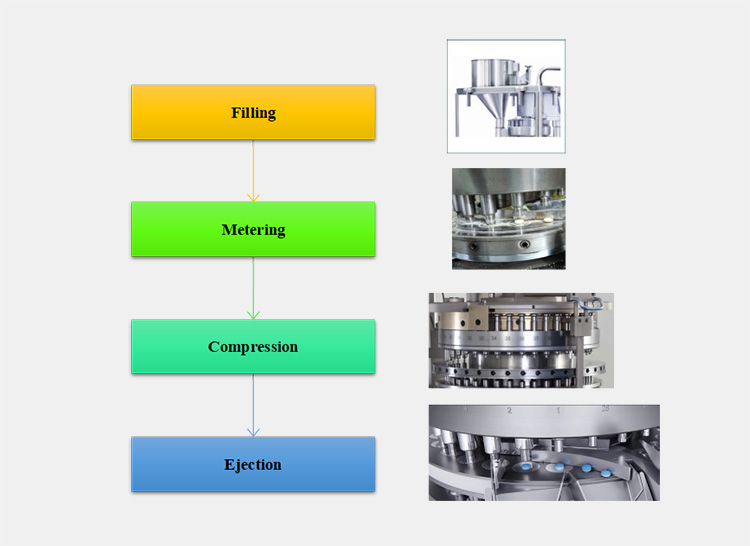

Working Of Tablet Pill Making Machine

Filling

The granular materials are placed inside the hopper. The lower punch is moved down to create the passageway for the flow of granules towards the die cavity.

Metering

For removing excess granular powder from the machine, lower pouch is slightly lifted which then pushes the surplus material outside and this material is removed from die table using scrapper.

Compression

The downward movement of upper punch and upward motion of lower punch exert hydraulic pression for compression of granular powder into tablet pills within die cavity.

Ejection

At this stage, upper punch is raised upward while lower punch is also lifted to expel tablet pill from the die tooling. The scrapper then moves tablet pill in the collecting bin.

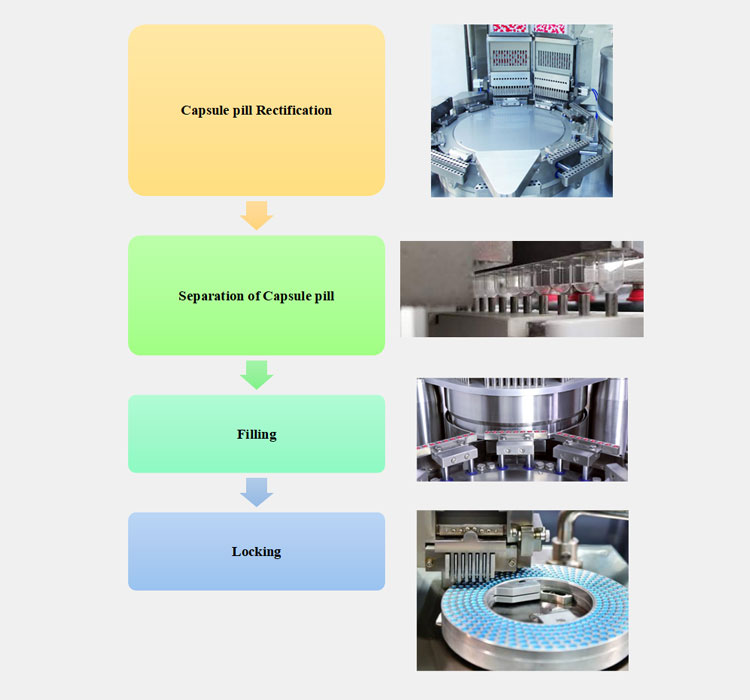

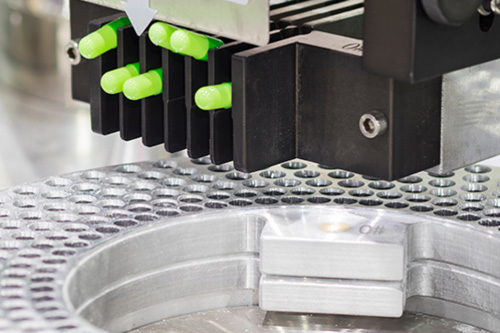

Working Of Capsule Pill Making Machine

Basic principle of capsule pill filling machines is detailed below:

Capsule Pill Rectification

Capsule pills from hopper are randomly placed inside the capsule pill delivery plate. Springs fixed at bottom of these plate move to and fro so that these capsule pills move one by one to circular tube one by one. Vertical forks rotate the capsule pills so that head of capsule pill are in upward direction.

Separation of Capsule pill

Air suction force due to vacuum system separate cap and body from each other. The head of capsule pill is moved towards upper capsule segment while the bodies of capsule pill will remain present in lower capsule pill segment

Filling

After separation, capsule pill body is moved to filling station where these are filled with a drug mixture by various dosing systems.

Empty capsule pill bodies or unseparated capsule pills are expelled from the capsule pill filling machine by the rejection unit. These faulty capsule pills drop into rejection bins.

Locking

At the locking stage, the upper tray holding capsule pill caps and lower trays containing filled capsule pill bodies are rotated simultaneously resulting in their overlap. In this way, caps and bodies are locked together using pin plates.

Capsule Pill Ejection

Filled capsule pills are expelled from the machine via a pin. The pin present in the ejection unit forces the fully formed capsule pills towards the capsule collecting tray.

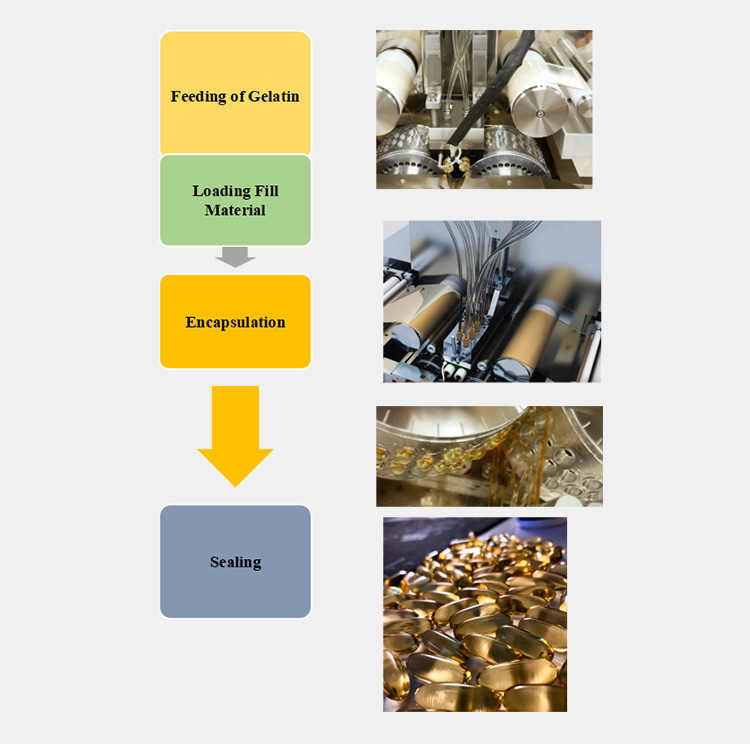

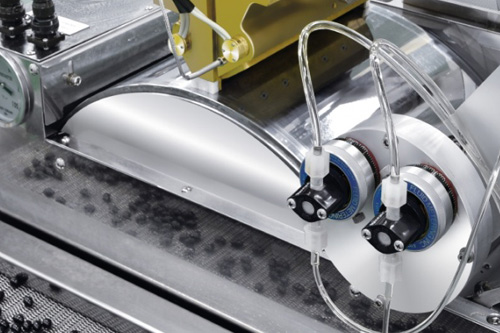

Working Principle of SoftGel Encapsulation Machine

The main operational principle of softgel capsule filling machines is discussed below:

Feeding of Gelatin

At initial stage, the gelatin is liquid form is pumped into machines and spreader box are used for producing thin ribbon like layer of gelatin on both sides of the machine.

Loading of fill ingredients

The liquid or paste fill materials are placed in hopper from where these move to injection wedges.

Encapsulation

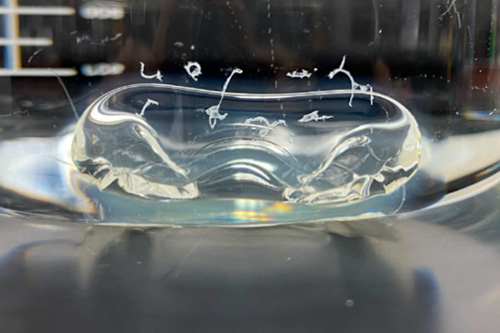

The gelatin ribbon goes over the rollers while the fill materials are pushed inside these ribbons. Afterwards, the ribbons are moved to die pockets where by the rotation of die rollers, the ribbons converge with encapsulated substances present inside.

Sealing

These partially formed soft gels are moved to the sealing station where hermetically sealing of softgel capsule pills take place at a temperature of 37-40° C.

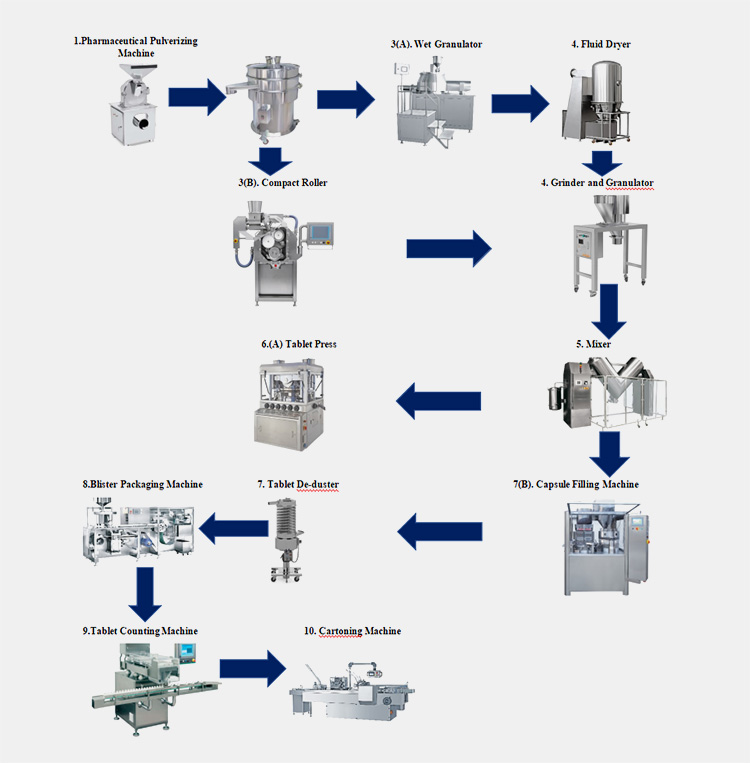

9.What Other Machines Are Involved with Pill Making Machines?

Pill making machines are often integrated with other equipments in production line for autonomous, efficient, high-speed, and accurate pill manufacturing. These machines are:

1.Pharmaceutical Pulverizing Machine

This equipment performs the process of grinding and crushing to reduce particle size of pharmaceutical ingredients and powders. These machines use hammer to press materials into soft fine powders.

2.Vibro Sifter

It is a spinning vibrational machine that is employed in pill making production line to filtering and sorting oversized residues from fine particles to ascertain the quality of pill manufacturing.

3(A). Wet Granulator

It is a mechanical device which is employed for binding of various powder particles using liquids adhesives for form granules. It is usually used for particle enlargement.

3(B). Compact Roller

These machines are used in pharmaceutical industry during tablet and capsule pill manufacturing to agglomerate active ingredients as well as excipients for making even sized granules.

4.Fluid Dryer

It is the machine used routinely for decreasing water content of raw materials or granules. Hot air is used for removing excess water for wet granules in fluid bed dryer.

5.Grinding and Granulator

These machines are used for crushing or slicing materials into smaller sized particles using rotating cutter and sieve mesh. They are used of milling, resizing, and regranulation purposes during pill making.

6.Pharmaceutical Mixer

For uniform and homogenous mixing of drug materials either in granular or powders, pharmaceutical mixers are employed in pill production line.

7(A). Tablet Press Machine

It is an electromechanical system which compacts or compresses granules to uniform sized tablets. It is the main equipment in pill production that uses hydraulic pressure for making constant shaped tablets.

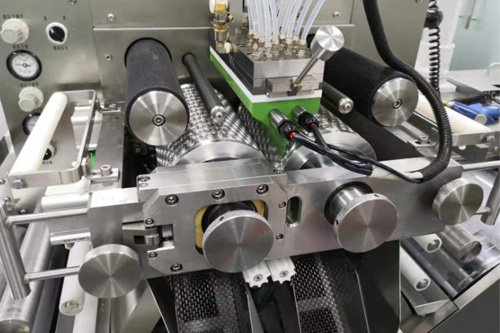

7(B). Capsule Filling Machine

These are also known as encapsulation machines used for encapsulating soft or hard gelatin capsules with different kinds of ingredients such as powders, granules, pellets, tablets, and liquids.

8.Tablet De-duster

It is a pharmaceutical instrument that is used for removing dust from the surface of pills by means of vibration motion.

9.Blister Packaging Machine

It is also referred to as blister packer. It is a machine used for packaging capsule or tablet pill in cavity using heat and pressure. These pockets are created using sheet of plastic or aluminum film.

10.Tablet Counting Machine

This is a system which uses camera-based technology for detection of artifacts in pills as well as for counting their number.

11.Cartoning Machine

It is tertiary packaging system, employed in pharmaceutical industry which form and erect cartons, and fill these with pills. It is often utilized for securing pills and preventing their tampering.

10.What Are the Components of Pill Making Machine?

Pill making machines are furbished with several parts that work in synchronization to accomplished efficient and trouble-free pill production.

Some basic parts of each pill making machine types are discussed below:

Components of Tablet pill Press Machine

| Hopper

It is the top part of machines that holds the granular powder mixture and this part of machine moves the powder to feeder system. These are available in various shapes and sizes. |

|

| Feeder System

These parts have feeder peddles and feeder housing systems which are employed for filling precise and consistent amount of material into die cavity. |

|

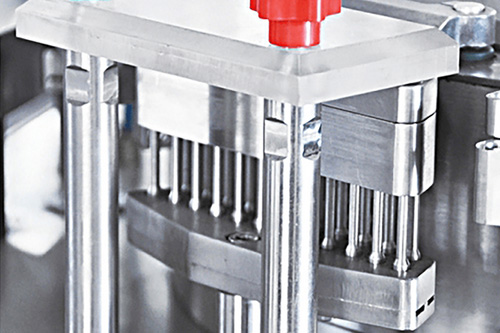

| Punches

There are two set of punches-upper and lower which brings about the tablet pill compression. These exert high compression pressure on granules to compact them into tablet pills. |

|

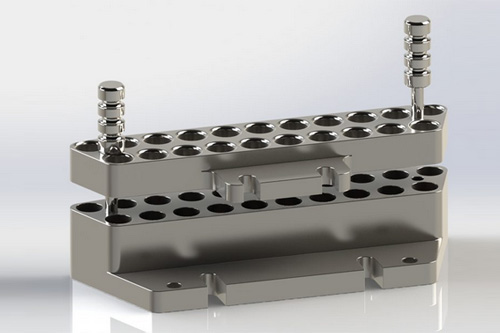

| Die Cavity

The size and design of tablet pills is usually depended upon die cavity. From feeder, material move to die where it is compressed into tablet pills of required shape and diameter. |

|

| Turret

Upper and lower punches are housed in the turret. It is the heart of tablet pill press which ascertains right elevation of die bore. |

|

| Cam Tracks

Two upper and lower cam tracks direct the up and down motion of punches. Cam tracks are integral in efficient compression process. |

|

| Compression Rollers

There are two types of compression rollers-precompression rollers and main compression rollers. These two provide exact compression pressure for tablet pill compression. These are also employed for removing trapped air between granule particles. |

|

| Ejection Cam

It directs the movement of lower punch for expulsion of tablet pill from die cavity. |

|

| Tablet Pill Scrapper

This is also called take-off blade and is employed for brushing of tablet pill from die tablet pill into the discharge chute. |

|

Components of Hardgel Capsule pill Filling Machine

Some parts of hardgel capsule filling machines are penned below:

| Capsule Pill Hopper

It is the part where empty capsule pills are loaded for filling. It is equipped with two sensors which control the number of empty capsule pills in hopper. |

|

| Powder Hopper

It is made of stainless steel and the fill materials are filled in this hooper prior to capsule pill filling. |

|

| Dosing Disc

This part employs tampering pins which oscillates in upward and downward direction within a powder bed for transporting required amount of powder to dosing disc. |

|

| Separation System

It is composed of upper and lower segments. When capsule pills are separated by means of vacuum, upper segment holds the cap part of capsule pill while the body of capsule pill is stored in lower segment. |

|

| Capsule Pill Fork

It rotates the capsule pill by 90° and force the capsule pill out of magazine into mold bore. |

|

| Locking System

This part is used for joining of two halves of capsules that are cap and body after filing. |

|

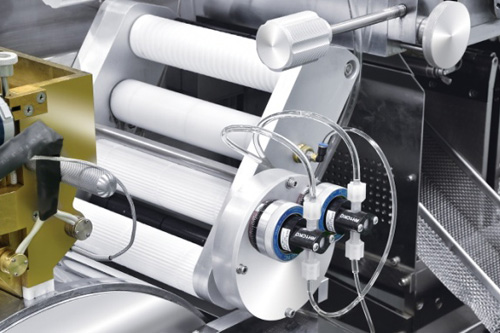

Components of Softgel Encapsulation Machine

Few components of softgel encapsulation machines are detailed below:

| Spreader Box

Its function is to spread gelatin in order to create thin layer for softgel formation. |

|

| Injection Wedge

This part of machine is used for elevating temperature of gelatin via steam or electric heating system. |

|

| Die Rollers

These parts play a significant role in determining shape and diameter of softgel. These rollers are generally used for pressing molds. |

|

| Lubrication Rollers

These rollers are vital in preventing damage to gelatin. These are used for gelatin lubrication and tighten it for appropriate softgel manufacturing. |

|

| Cooling Drum

This part consists of fan or water operated device for decreasing the temperature of gelatin shell. |

|

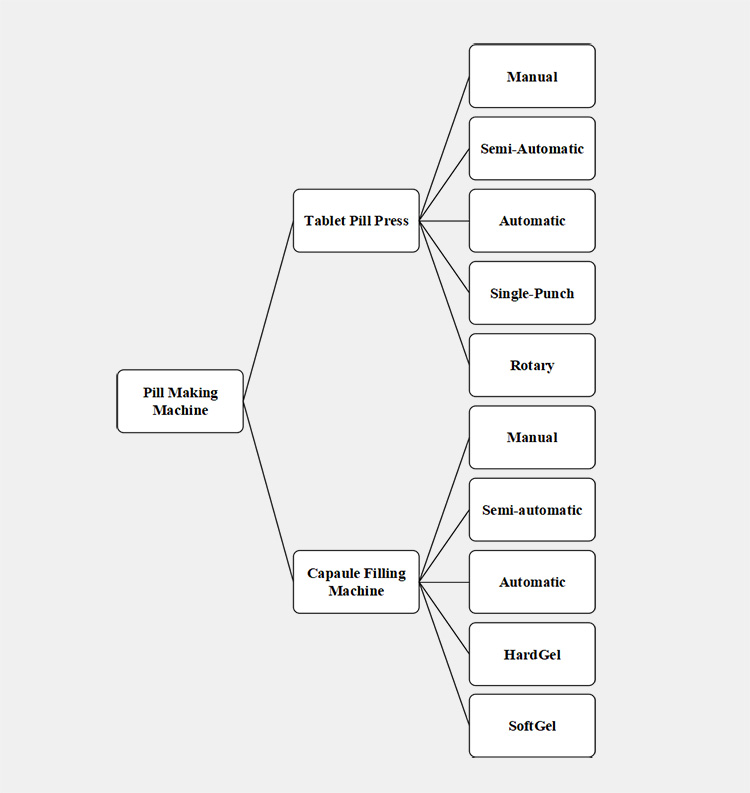

11.What Are the Different Types of Pill Making Machines?

Pill making machines are classified into two main types.

- Tablet Pill Press Machine

- Capsule Pill Filling Machine

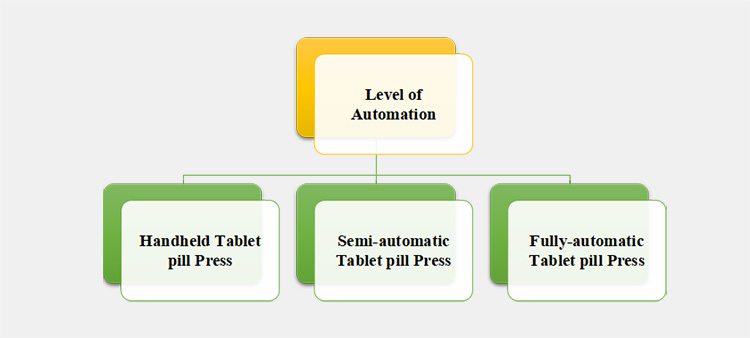

Classification of Tablet pill Press on the Basis of Automation

There are three kinds of tablet pill press machine on the basis of automation level.

Handheld Tablet Pill Press

It is simple, portable tablet pill press in which material loading, compression, and tablet pill removal is performed manually. It is cost-effective machine and is usually employed in small scale pharmacies and laboratories setting. These machines make small number of tablet pills at a time.

Semi-Automatic Tablet Pill Press

These machines usually consist of one set of punches and die with desktop construction. They are easier to operate with machine performing compression itself. While loading of granules and removal of tablet pills is carried out by working personnel. They are low-budget machines effectively used in small hospital setting and business

Fully-Automatic Tablet Pill Press

These are completely autonomous machines with advanced components, each working seamlessly to carry out tablet pill compression. These are high-speed machines customized with HMI that minimizes the amount of human intervention. These are routinely employed in large scale pharmaceutical plants.

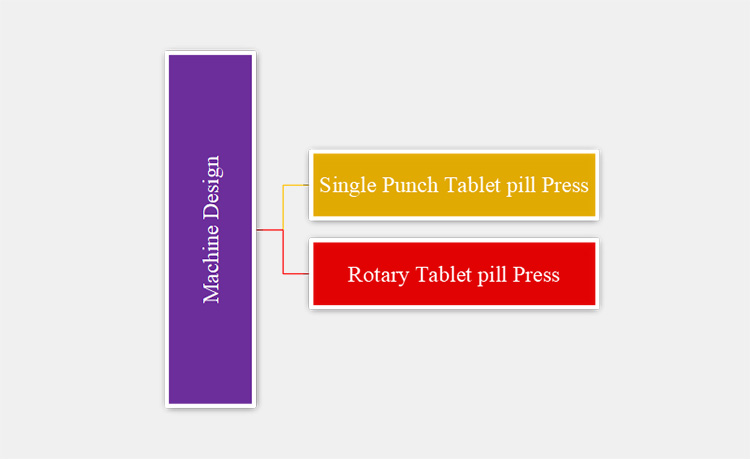

Classification of Tablet pill Press on the Basis of Design

There are two kinds of tablet pill press on the basis of design.

Single Punch Tablet Pill Press

As the name indicate, these machines have pair of punches and a single die. The tablet pill compression in this equipment is because the movement of upper punch. The lower punch in this machine remains immobile. This machine uses high compression force to lower the number of tablet pill variants. Moreover, it has small foot-space thus can be easily moved around.

Rotary Tablet Pill Press

These are also known as multi-station tablet pill press and consists of multiple set of toolings thus can manufacture multiple pills in short time. In this machine, both punches move to compress tablet pills. These machines are furbished with automated systems that results in high pill accuracy.

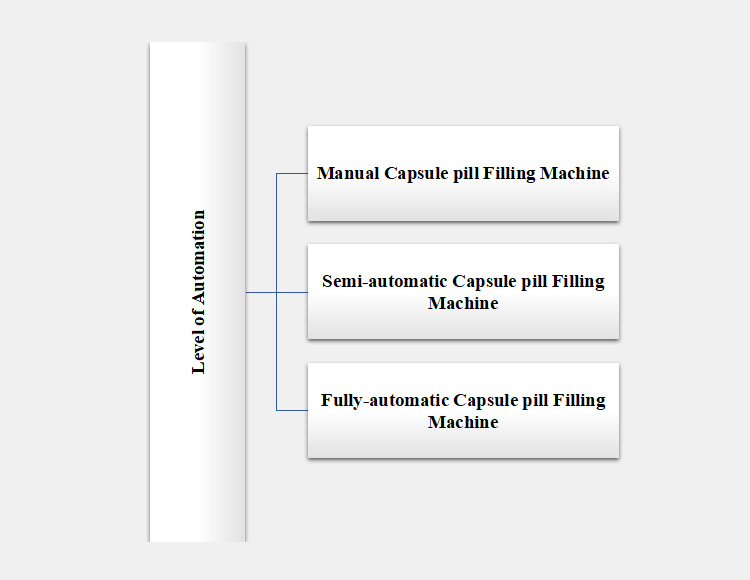

Classification Of Capsule Pill Filling Machine

Types on the Basis of Production Level

On the basis of production level capsule pill filling machines are categorized in three categories:

Manual Capsule Pill Filling Machine

It is the hand-operated capsule pill filling machine that is routinely used in small scale production such as in pharmacies, small clinics, home-based settings, and laboratories. Manual capsule pill filling machines are cost-effective and in these machines every step-from capsule pill loading to filling is carried out by operators themselves.

Semi-Automatic Capsule Pill Filling Machine

In semi-automatic capsule pill filling machine, both operational capabilities-manual and automatic- are combined. Loading of capsule pills is done manually while filling process is these machines is automatic and is performed using auger or pneumatic filling systems. Semi-automatic machines are equipped with dosing disks for accurate capsule pill filling.

Fully-Automatic Capsule Pill Filling Machine

These are the advanced machines comprising of stainless-steel assembly and high-tech electromechanical systems for precise and high-speed capsule pill filling. Every encapsulation process whether capsule pill loading, rectification, filling, and ejection is executed by these machines autonomously. It is easily integrated into production line to achieve best possible capsule pill production.

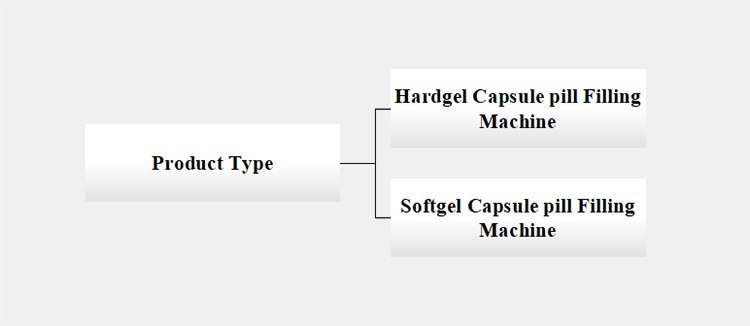

Classification on the Basis of Product Type

There are two main types of capsule pill filling machines on the basis of product type.

Hardgel Capsule Pill Filling Machine

It is a machine that is designed for filling materials such as granules, pellets, powders, and liquids inside empty two-piece hard gelatin capsule.

Softgel Capsule Encapsulating Machine

These machines are used for softgel capsule manufacturing from gelatin and encapsulate them with different materials in semisolid or liquid form.

12.What Kind of Products Are Made by Pill Making Machines?

Pill making machines are used in pharmaceutical, nutraceutical, and chemical industry for making different kinds of products such as:

- Tablets-Standard tablets, mini-tablets, herbal tablet pills

- Capsules-hardgel capsules pills, softgel capsule pill, nutraceutical capsule pills

- Chemical-Dish washing pills, chlorine pills, detergent pills,

- Cosmetic-Bath bombs, dermal pills

- Food-biscuits, cereal bar

13.What Component of Pill Making Machine Define Shape and Size of Pill?

Tablet pills and softgel pills are available in various shapes and sizes while hardgel capsules pills differ only in their size.

Tooling part consisting of punches and die define the shape and size of tablet pills. Punch and die have different design such as round-shaped, capsule-shaped, geometric-design, irregular-design (animal, fruit, lock) and oval-shaped.

Dip coated pins defines the size of hardgel capsule pill in hardgel pill making machine.

Die rollers in softgel capsules comes in different sizes and cavity. This part imparts different sizes and shapes such as round, oval, oblong, tube, fish, etc. to the softgel capsules pills.

14.What are Common Problems and Solutions of Pill Making Machine?

Numerous problems arise in pill making machines that can lead of downtimes, lengthy repairs, and costly replacements. However, these problems are easily solved by following some guidelines.

Here are some problems of pill making machines.

| Problem | Root Cause | Remedy |

Buildup of Sticky Formulation During Capsule Pill Filling |

High humidity

Inadequate temperature during formulation and filling High rate of condensation in compressed air High speed of capsule filling machine Improper gap between dosing disk and tampering pin |

Maintain 35-45% relative humidity during filling

The temperature should be around 60-70°F to minimize stickiness of formulation Put in air dryer or water separator system to remove excess water from compressed air. Lower the speed of capsule filling machine Increase the gap between dosing disk and tampering pin to about 0.015 inch. |

| Granules Sticking to Punch

|

Small amount of lubricant in granules

High quantity of binder Presence of moisture in granules. Inadequate compression force Scratched or damaged punch head Oily feed materials |

Add sufficient and effective lubricant

Use appropriate binder according to formulation Fully dry the granules before compression process Apply proper amount of compression force Polish or replace punch face Alter mixing method and incorporate absorbent in formulation

|

| Inadequate Fill Material Flow

|

Fluffy or lightweight powders

Granular powder bridging due to particle interlocking with each other High moisture content in granules |

Use hopper with feedle paddle

Use angled wall hopper for proper flow of powder Employ adequate drying for removing excess moisture |

Weight Variation in Tablet Pills |

Shallow fill cam resulting in inadequate filling of Die bore

Lower fluidity of granules in die cavity Variation in granules particle size High speed of tablet press or reduce filling time |

Install appropriate length fill cam in tablet pill press

Use angled hopper or paddle to improve fluidity of granules Use sieve to achieve uniform granule particle Decrease speed of tablet press or extend filling time |

Tablet Pill Abrasion |

Large particles of granules break apart on high compression force

Trapped air between particle leads to breakage of tablet pills High ejection force cause splintering of pills Decreased compression force leads to poor particle binding |

Increase cohesivity of powders by adding binding agents

Extend dwell time by decreasing speed of tablet press Lower ejection force Inspect die tooling for wear and tear |

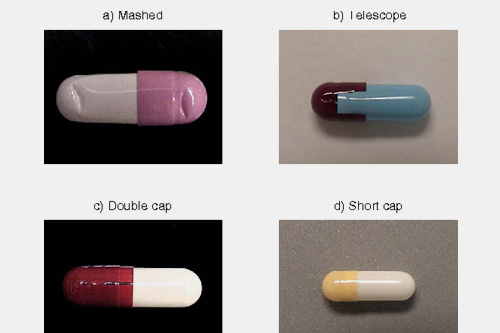

Improper Capsule pill Rectification |

Use of plastic container to load capsules cause development of electrostatic charges

Improper setting of stroke or finger length |

Employ stainless steel scoops for loading capsules in hopper

Adjust setting of stroke or finger length as per length of locked capsule pills. |

Capsule Pill Fails to Separate |

Faulty setting of vacuum for capsule pill separation

Large gap between upper and lower segment |

Gauge reading for maintaining proper vacuum should be between 15-18 inches of mercury

Reduce the gap between upper and lower segment |

Popping of Capsule Pills |

High locking pressure leads to capsule pill opening after filling

Overfilling of capsule pill also causes popping |

Replace or repair locking system

Properly fill capsule pill as specified by supplier |

Capsule pill Brittleness |

Lose of moisture from capsule pill shell

Use of hygroscopic active ingredient or excipient |

Maintain optimum threshold of 12.5% moisture during storage

Reformulate the capsule pill fill materials |

Conclusion

With the advancement in technology, different types of pills such as tablets, capsules, caplets are manufactured to increase patient compliance. Pill making machines have an integral role in pharmaceutical, herbal and nutraceutical industry. These equipments are easily integrated with other pharmaceutical machines to increase efficiency of pill product. Moreover, these systems are equipped with advance, high-tech and specialized parts to increase pill production output. AIPAK Pharmaceutical is a technological hub of manufacturing advance and robust machine used in pill making process. Whether tablet press, or encapsulation, our expert offers solutions of every procedure in economical way. Please Contact Us Now!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours