Pill Filling Machine:the Complete Buying Guide In 2025

Oral pharmaceutical, and nutraceutical products are consumed by lots of people across the globe every day. But have you ever wondered how they are packed in the different containers such as bottles?

Pharmaceutical pills are oral dosage forms that require special filling treatment. To improve patient compliance, safety of the product from chemical and microbial degradation, facilitation of manufacturing process you’ll require a pill filling machine.

Pill filling machine is widely used in pharmaceutical and nutraceutical industry for filling of bottles/containers with pills that include tablets, capsules and pellets. Automatic pill filling machine was first invented by John Fradenburgh, at that time it was an improvement to the existing H. Horner delivery mechanism 1942 which was approved in 1954.

Nowadays many manufacturers claim to provide best machinery in the market which proves to be difficultat times in selecting the best equipment that can cater the need of buyer or end user.

In order to facilitate the buyer or end user in selecting the best machinery we have brought “Pill Filling Machine:the Complete Buying Guide in 2021”.

At the end of the guide, you will be able to identify your needs, prepared to select the best available pill filling machine and ready for operations.

In this blog we will cover:

1.What is the pill filling machine?

AIPAK pill filling machine

Pill filling machine is a GMP compliant instrument that is used for counting and filling different shapes and size of pills with efficiency and accuracy. Some models come with advance electronics that include sensors, computer control, scans, alarm, fail-safe measures and other features that smooth filling and packaging operations. It is a perfect machine to be employed in pharmaceutical nutraceutical and food industry that need next to 100% deliverance.

2.What is the make of pill filling machine?

The main strength of pill filling machine is its compact design with sturdy built. The compact design encompasses simplicity yet advance features that enable buyer to purchase the machine at an affordable price. The main body and all materials that come into contact with the product are made up of stainless steel. Unique selling point of this machine is the smooth design devoid of joints welds that prevents cross contamination.

3.What are the different types i.e. manual, semi-automatic or fully automatic pill filling machine?

Every industry uses different types of pills filling machines according to need of their manufacturing procedure. You will find versions of pills filling machine in the market that varies from manual hand counting instrument to semi-automatic and fully automatic.

Each type has their advantages and disadvantages, where some are easy to operate and other being cost effective, though all types can cater the demands of the buyer.

These are briefly described below:

1) Manual Counting Tool

A useful hand tool for counting of pills manually. A compact tool can fit in the palm of a hand, used in research laboratories and small scale research and development and production batches. Usually made up of stainless steel or aluminum it can be designed for any size and shape of pill. Using this tool saves time and reduces errors by manual counting.

Manual hand operated counting instrument- Picture Courtesy- YouTube

2) Semi-Automatic Pill Filling Machine

A useful machine superior to manual hand operated tools cancount 1 to 250 pills and also fill the primary containers (bottles). Usually used in research and development settings and production department of pharmaceutical and food industry. Made up of stainless steel this machine can be customized to user needs. Usually it consists of a feeding hopper, a customized disc where the pills are counted and delivery chutes that direct the pills into the container.

Semi-automatic pill filling machine

3) Automatic Pill Filling Machine

AIPAK Automatic pill filling machine

The machine is used for filling and counting of pills. The operational processes from tablet induction in the hopper to the delivery of pills into the bottles are fully automatic. This machine comes with sensors that guaranteed 100% accuracy of pill filling and counting. Can be connected to other units such as unscrambler, bottle washer, inserter, capper etc. to make a fully automated pill bottling line. A detailed description of automatic pill filling machine is given below.

4.Which industries widely use pill filling machine?

Pill filling machine expedites innovative manufacturing processes of the following industrial units.

1)Pharmaceutical Industry

You might know widespread applications of pill filling machine in pharmaceutical sector.

Pharmaceutical industry broadly use pill filling machine to fill tablets, capsules, and pellets every day. Pill filling machine accelerates large scale filling process that ensures high accuracy, correct and precise volume of dispensed product. Pills filling machine offer superior automation, high consistency, robustness and reliability that ultimately benefits specific production goals and boost the demands of pharmaceutical output.

2) Nutraceutical Industry

Today, many of you prefer to approach nutraceutical drugs products rather than using a prescription drug. That’s why a high productions revenue of nutraceutical products is observed from last few decades.

Therefore, pills filling machine is of high importance to deal with high production demand of nutraceutical items such as capsules, tablets etc. This high-speed machine allows you to count and fill the desirable number of nutraceutical pills to meet the production requirement with minimum interruption.

3) Agricultural Industry

Have you ever heard about agricultural pills?

Agricultural industry manufacturers are consistently progressing with growth promoting bio-stimulants products in the forms of tablets, capsules, or small pellets. Many agricultural firms prefer to use these products to aid growth promotion, cell division and boost the vigorous crop development.

Therefore, pill filling machine is applicable to fill agricultural goods to improved production line safely and accurately.

4) Chemical Industry

Pills filling machine is one of the most versatile machines that has broad range of applications in chemical industry.

You are exposed to different hazardous conditions during manufacturing, filling, and packaging of chemical goods every day. But dealing chemicals required high vigilance, precautions, and protection because corrosive, toxic and high exposure may harm your physiology. That’s why pills filling machine play an essential and protective role to deal with counting and filling of chemical products. Hence, you do not need to physically handle such substances because pills filling machine ensures an accurate, safe and secure dispensing of manufactured goods. For instance, Sodium bicarbonate pellet, pH tablets, buffers, acidic content, etc.

5) Veterinary Industry

Veterinary industry widely use pills filling machine for high-level dispensing of veterinary oral medications used to relieving various medical pathologies in animals. For instance, antiprotozoals, anti-inflammatory, hormones or anti-inflammatory etc., are modern necessities used for therapy or prophylaxis in animals.

6) Cosmetic Industry

You definitely use skin care products everyone does! You might have come across certain products available in pills, capsules, or tablet form. Most of them are applicable for topical usage such as serums, vitamins, facial products etc. They are not meant for eating; you can directly utilize these products by opening a bottle and apply to your face. Hence, cosmetic industries preferable invest their money on pill filling machine to rationalize filling of such cosmetic items.

7) Food Industry

Whether it concerns with large or small of tablets, or capsules filling. Pills filling machine ensures advanced and quick response. In food industry, pills filling machine is ideally use for the filling of food items such as chocolate beans, coffee beans, nuts, pulses etc.

5.Can the pill filling machine be operated for both tablet filling and capsule filling?

You can use pill filling machine for counting and filling a range of dosage forms including tablets, capsules, soft gels etc. of different sizes and shapes with accuracy owing to incorporation of state of art design and electronic sensors. Pill filling machine can accurately fill 25-150 bottles per minute.

6.Does the pill filling machine meet cGMP requirements?

Yes! Pill filling machine is manufactured in a cGMP approved plant and it meets with local and international regulatory bodies standards. Some models even comply with 21CFR standards and all electronic records and signature are incorporated as part of regulatory requirements. Data is stored and available whenever required.

7.What are the technical parameters of pill filling machine?

Pill filling machine is available in different models, and the technical or parameters differ slightly between each models. All models require a power supply of 120V/60Hz. Some units are standard and cannot be customized whereas others can be altered according to customer needs. Pill filling machine is evaluated for performance and efficiency on following technical specs.

Capacityfilling (pills/min):The capacity of the machine is actually the number of pills filled in primary packaging container (bottles) in a minute. The manufacturer provides a customize range which is in between 6000-12000 pills filled in bottle per minute.

Quantity per bottle (pills/bottle): Bottles of different sizes and volume can be filled without altering any unit. Manufacturer provides a built in range of 15-9999 pills perbottle. This range is indicative of a quality machine.

Bottles specifications: A quality pill filling machine can be adjusted to accommodate bottles of different sizes. A standard unit comes with a range and can fill bottles of varying width (30-75mm) and height (40-250 mm).

Weight (Kg): A pill filling machine usually weighs between 500-1000 Kg. It is recommended to use a hoist that can handle more than a ton for transportation of machine.

Dimensions (L x W x H): Standard unithas a dimension 1600 x 2400 x 1670, however this can change based on model or requirement of buyer.

Hopper volume (L) and conveyer length (mm): Manufacturer provides astandard range of hopper volume and conveyer length which cannot be customized. The standard range of hopper volume and conveyer length is 40-80 L and 2400-3000 mm respectively.

Air pressure (M pa): Some automatic units are provided with pneumatic air unit, typically generating a pressure of 0.5 M pa.

8.What are the major parts of pill filling machine?

Pill filling machine typical comprises of a) feeder, b) counting mechanism, c) feeding system, d) cabinet and e) controlling system.

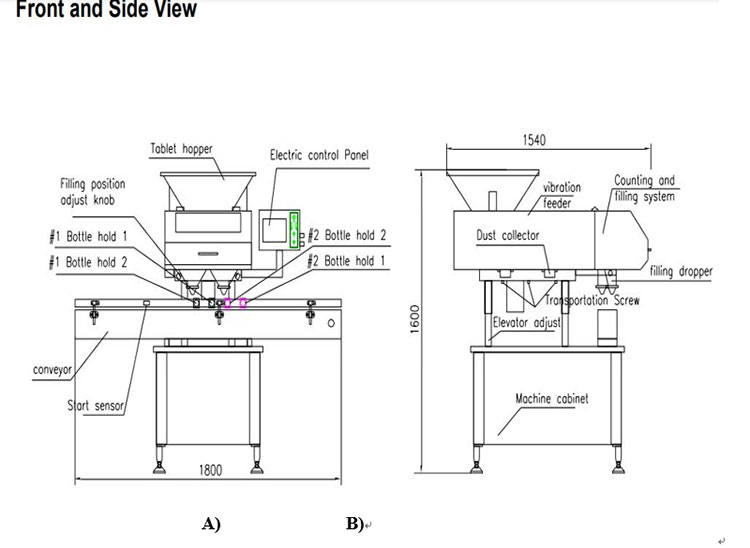

Illustration of pill filling machine A) front view and B) side view- Picture Courtesy- IMC

1.Feeder

Feeder or vibrating feederis further divided into four distinct parts namely hopper, vibrator feeding track and dust cap. Each of these parts are described below.

Hopper: Pills such as tablets and capsules are stored and held in hopper for counting purposes. At the base of the hopper near the exit an adjustable screw mechanism is present that controls the volume of the pills fed to the feeding track.Hopper is a detachable unit and can be separated from the main body for proper cleaning.

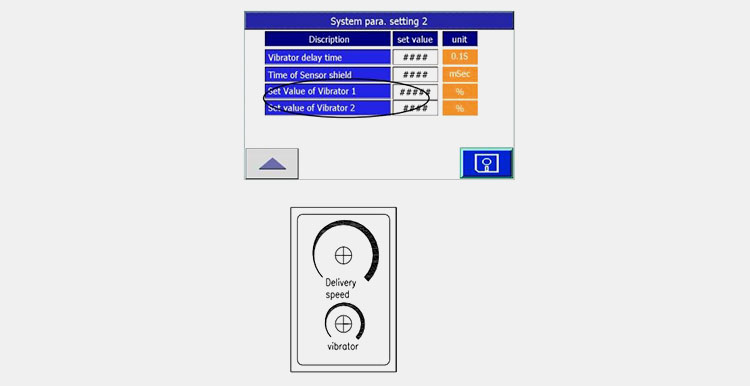

Vibrator and pill feeding track: The machine makes use of three different vibrators i.e. vibrator 1 (long corrugated board), vibrator 2 (short corrugated board) and vibrator 3 (flat board). Vibrator 3 is present near the hopper and controls the flow of pills. Vibrators 1 and 2 can be set for vibrations by changing the parameters on parameter setting page. A knob is present on the side of control panel which adjusts the speed of vibrator 3.

System parameter as seen in control panel- Picture Courtesy- IMC

A small gap about 2mm is present in front of pill feeding track. During operations dust and powder is collected into the dust collector after vibration. It is necessary to clean the collector at regular intervals.

Three vibrators sorting out pills- Picture Courtesy- CVC pharmapak

Dust cap: A dust cap made of polymethyl methacrylate (Perspex)is also present which prevents dust particles and provides a clear view of pill feeding operations.

2.Counting Mechanism

A separate dual dropper and double track conveyor is employed for operations. The counting mechanism is composed of pill guide plate, counting heads and dropper.

Pill guide plate: A customized pill guide plate is provided according to the operational specifications requested by the buyer orend user.

Counting heads: Made up of highly sensitive and accurate sensors, in this unit the number of pills are counted as they pass by and the information is displayed on the screen via signals sent to the control system.

Dropper: Based on different models two filling droppers are provided, that fill the pills after counting is completed. An adjust screw is also present that can adjust the dropper, positioning it on top of the bottle neck. The dropper should match the diameter of bottleneck.

Dropper filling bottles with pills- Picture Courtesy- CVC pharmapak

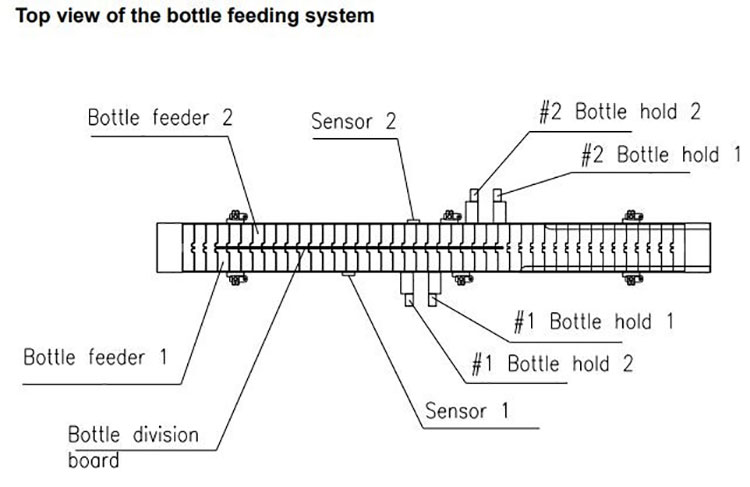

3.Feeding System: A bottle feeding system is present under the dropper, and it is composed of transmission, conveyer and railings.

Transmission: It includes a transmission shaft driven by a three phase motor.

Conveyer: The tension pulley at the beginning and end of the conveyer is linked by a chain plank. The conveyer moves the bottle in the right direction at a given speed. Based on the model of pill filling machine at the middle of the chain plank a divider is present that divides the conveyer into two parts such that two bottles can be moved at a given moment.

Railings and electromagnet: The railings on either side of the conveyer can be adjusted according to the width of the bottles. The distance between the two railings should be the same as the width of the bottle. The machine is provided with a sensor present above the conveyer. If no bottle is present on the conveyer the system will trigger an alarm and the vibrators will be stopped immediately.

Feeding line top view- Picture Courtesy- IMC

4.Cabinet

Cabinet includes a case, screws on pillar and adjustable pillar. Using the four mounting screws on the pillars the height of the machine can be adjusted and brought on the same level to facilitate attachment to other machines. Keep in mind that pill filling machine can be attached to other machines to form a tablet and capsule bottling line.

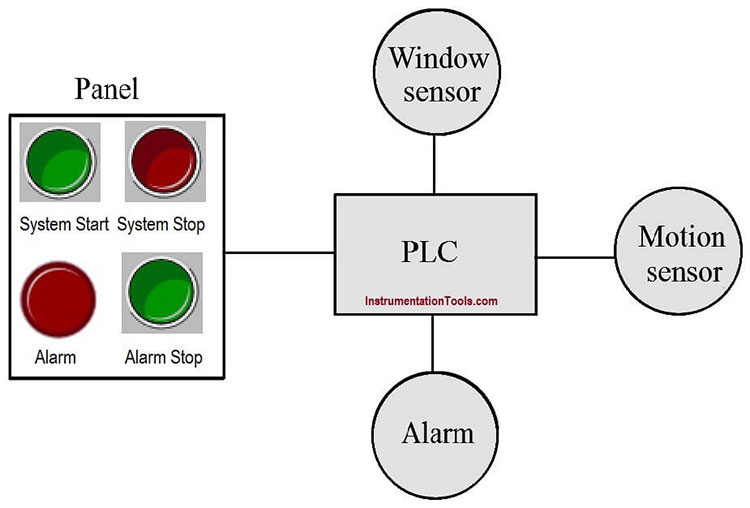

5.Controlling System

Inside the machine cabinet most of the electrical components are present and are controlled at the programmable logic controller (PLC’s). The main supply plug is present on the right hand side of the cabinet.

9.What are pre-start up points of the pill filling machine?

Before starting the pill filling machine first time after installation, necessary checks should be made in order to grasps best results and services and avoid any potential errors that may lead to time wastage and monetary losses. Pre start up points are given below.

1.Operators should be equipped with personal protective gears (PPGs) before operating the pill filling machine. Necessary PPGs include safety shoes, safety goggles, helmet and working gloves. Operators should have necessary training and experience in terms of hours in handling the pill filling machine.

2.Before starting the machine check for electrical and mechanical connections as there might be some loose connections after transportation and installation. Secure and tighten all connections.

3.Check the power supply, the machine is operated by a 220V±5V, 5Hz acmotor. The main power supply should be properly grounded.

4.Check the alignment of the pill feeding tracks and the counting tracks, both should be properly aligned. Cover with the plexiglass.

10.How to operate pill filling machine?

Following is the step-by-step guide to operate pill filling machine and extract the maximum and effective output out of your unit.

1.Fill the hopper with the pills.

2.Based on the size of the pill adjust the space between the hopper and vibrator 3 (flat board).

3.Adjust the height of the dropper and railings on both side of the conveyer according to the width of the bottles to be filled. Dropper should be exactly on top of the bottle. Use the knobs to move the dropper and fixed the railing to properly hold the bottles.

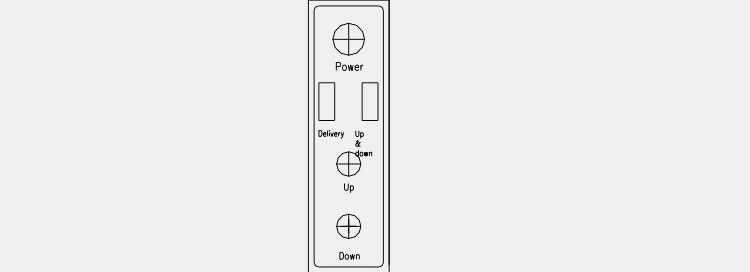

To adjust the height of the dropper push UP and DOWN buttons (light will switch ON particular button) on the controller. Keep the dropper approximately 2mm away from the neck of the bottles.

Controller for height adjustment of dropper- Picture Courtesy- IMC

To adjust the railing loosen the fixed screw on the feeding the system. Alter the distance between the two railings on conveyer according to the width of the bottles and tighten the screw.

Avoid overlapping of pills. Ensure appropriate gaps between pills on the feeding track.

The entrance to the counting passage is 1-2mm lower than the pill feeding track, in order to avoid jamming, aim the end of feeding track at the pill counting passage.

During operations ensuring certain necessary steps will increase the machine performance throughout its working life. If an alarm sounds the machine will automatically stop, remove the cause according to the user manual and restart the process. For instance if an alarm goes off and the control panel is flashing “NO BOTTLE” even though the bottles are on the conveyer system, adjust the bottle inspection sensor, it may not be on the right position.

11.Is the pill filling machine equipped with automatic rejection system and emergency stop in case of incorrect filling?

Pill filling machine comes with advanced detecting system including controller and dust compensator. The idea behind dust controller is to avoid false alarm while maintaining actual alarm functions. The sensors automatically adjust the sensitivity to offset the accumulation of dust. If the bottles are incorrectly filled due to incorrect setting, the auto-rejection system removes them from the main conveyer.

In fully automatic machine the control panel displays the rejection message, and the rejected bottles are removed from the count.

However, in semi-automatic machines after display message the machine stops and has tobe started manually. Some machines come with IR sensors and double discharged funnels that can fill double bottles at once.

Automatic removal of rejected bottles- Picture Courtesy- CVC pharmapak

12.Is the pill filling machine equipped with fail-safe features?

Pill filling machine comes with a number of fail-safe built in features that include alarm, emergency stop and automatic bottle rejection. These all add up to make a smart machine available at a low price, a win-win situation for the buyer.

13.What are safety, transport, installation and storage requirement of pill filling machine?

Safety Requirements

1.Operators should be well trained and experienced in handling the machine.

2.The installation site should be well levelled and the pill filling machine should be placed on a flat/levelled surface.

3.The main supply and all electrical connections should be properly earthed.

4.At least four feet space should be present on all four sides of the machine to provide proper view of the machine during operations and maintenance.

5.After installation and maintenance, check for any loose connections before operating machine.

6.Perform the cleaning procedure on an appropriate time. Before cleaning the main power supply should be cut and the connections disconnected. Take great care in cleaning the electric components of the machine. No cleaning liquid should get into electrical parts.

7.Avoid placing anything especially liquid on the machine top.

8.It is inadvisable to open machine during operations. This can lead to serious injury and traumatic amputation.

TransportRequirements

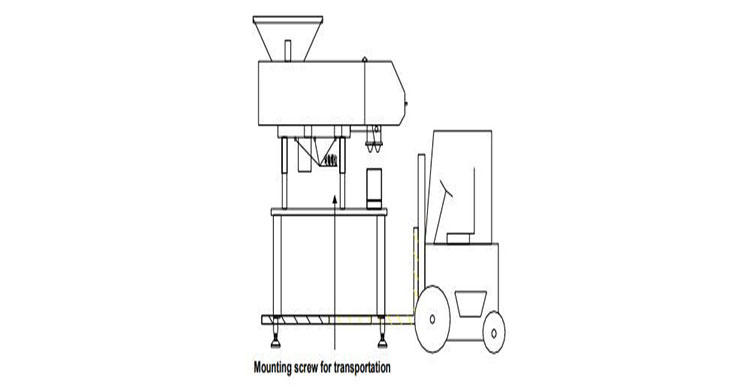

1.The pill filling machine is provided in wooden crates. Use appropriate machinery such as forkliftand hoist to transport machine to the installation site. Hoist can be used to transport the wooden case at angle greater than 15o.Take special care not to tilt the machine at any cost, it should always be in upright position.

2.It is recommended that the machine be taken out of the wooden crates at the site of installation. Remove the top of the wooden case first followed by the sides.

3.Inspect the machine properly and tick the check list provided by the manufacturer. In case of missing or damage parts immediately notify the manufacturer.

Schematic diagram of location of mounting screw- Picture Courtesy- IMC

Installation Requirements

- The machine should be installed on a smooth, hard and flat concrete floor.

- Loosen the bolt at the bottom of the wooden case. With the help of forklift lift the machine and transport it to the site of installation.

- Place the machine on the floor and adjust the height of the machine with the help of bolts.

- Hopper and control panel are provided separately, after the placement and height adjustment are performed, install the hopper and the control panel on the machine.

- Clean the surface after finishing with the installments.

- Remove the mounting screws before operating the machine. These are present just beneath the vibrator plate.

Storage Requirements

It is recommended to install the pilling filling machine upon arrival. However, if there is a delay in installation due to any reason the machine should kept in a sheltered area, free from dust, water and other factors that may influence its working.

14.How quick can you dismantle pill filling machine for clean up?

According to GMP requirements the parts of the machine that come in contact with the product should be dismantled and cleaned before operating once again. A unique feature of pill filling machine is that it is easy to dismantle and can be cleaned within minutes. The machine can be dismantled and assembled within 6 minutes for cleaning purposes without the use of tools. Also the machine is equipped with dust collector where dust produced during operations is separately collected making change over easy and operations efficient.

Pill filling machine after dismantling- Picture Courtesy- CVC pharmapak

15.What are failure solutions of pill filling machine?

Troubleshooting is integral part of operations and is unique to different machines. A number of problems may arise that can hinder the smooth flow of filling operations. Below are some solutions to commonly occurring problems during pill filling operations.

1) PillJam-Up

This problem usually arises when speed is high. Adjusting the speed of the vibrator and feeding track will resolve pill jam-up.

2) Lining Up of Bottles

It occurs mainly due to three reasons i.e. the timing of the bottles, the dropper is not aligned with the bottleneck and the space between the railings is bigger than the required width. For timing of the bottles adjust the parameter on the control panel. Align the dropper by adjusting its height and station. The space between the two railings should be adjusted according to the width of the bottles.

3) Counting and Filling Error

The most common reason for this type of error is incorrect counting and end time. Adjusting the photoelectric gate time will resolve this issue.

4) Tablet Falls Out of The Bottle

The distance between the dropper and the bottle neck is not appropriate. Adjust the dropper such that it is directly above the bottle neck and the distance between the two should be less than the diameter of the tablet or capsule intended for filling.

5) Bottles Are Not Properly Held

The opening time of the bottle hold is too long. Adjust the bottle pass time from control panel.

6) Counting Sensor Error

This problem arises when there is dust on sensor, or the sensitivity of the sensor is out. Remove the dust and adjust the knob on the circuit board will resolve the error.

7) Alarm Goes Off

There may be several reasons when an alarm is triggered. Most commonly it occurs when there are no bottles on the conveyer system or dust or the sensor is out of adjustment. Place the bottles on the conveyer belt or remove dust from the sensor or adjust the bottle inspection sensor will switch off the alarm.

16.How to perform maintenance of pill filling machine?

To increase the output in the most effective way proper maintenance and replacement of parts should be carried out at regular interval, same is true for pill filling machine. Maintenance SOP should be made according to the recommendation from the manufacturer and engineering department of the buyer. Following maintenance points should be read and understood completely before initiating the regular maintenance of pill filling machine.

- Skilled and experienced persons from the engineering department of the firm should carry out the maintenance of pill filling machine.

- Proper gears such as safety shoes, safety goggles and helmet should be provided for individuals working on repair and maintenance. No safety measures should be by-passed during maintenance of the machine.

- Before starting the maintenance cut off the main power supply and disconnect the power cable from the socket.

- Use cotton or silk fabric for cleaning the sensors.

- Regularly empty the dust collector below the vibrator.

- Keep the machine clean during and after operations.

- Avoid putting tools on feeding system and conveyer system.

- After every batch according to cGMP, clean the hopper, dropper and pill feeding track before starting the next batch of product.

Do not adjust the electric board, the board is provided after fine tuning at the manufacturing plant.

Conclusion

We hope after reading this entire blog, you must be able to realize the importance of pill filling machine to run a successful business. Thus, pill filling machine is very important as it signify your production line. Furthermore, with continuous development of industrialization and advent competition, pill filling machine is a prime tool that offers an accurate product filling, mechanization, safety, and automation that will keep up your product demand higher.

Tablet Counting Line Related Products

Tablet Counting Line Related Posts

Tablet Counting Line Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours