Pharmaceutical Vial Filling Machine: The Complete Buying Guide In 2025

Have you ever noticed the parenteral medicine you received last time, was firstly packed in pharmaceutical vial? For numerous sterile drugs that are mainly administered parenterally, pharmaceutical vial is crucial. Pharmaceutical vial filling machine is utilized for filling these vials with sterile or sensitive drugs and it secures the similar importance.

When you are looking for some advantageous and smart investment, you should consider pharmaceutical vial filling machine. From your childhood to your adulthood, you have witnessed the massive use of pharmaceutical vial and drug manufacturing is incomplete without this useful machine. This guide is designed to facilitate you in buying pharmaceutical vial filling machine.

1.What do you know about pharmaceutical vial filling machine?

Sterile Drugs Are Filled In Vial By Pharmaceutical Vial Filling Machine-Picture Courtesy: MWI Animal Health

Pharmaceutical vial filling machine is specially designed to fill liquid or powdered medication in sterilized vials with great precision and safety. Vials can be made of plastic or glass material and controlled environment is maintained during whole process of filling. Parenteral antibiotics, vaccines, biotech drugs, hormones or ophthalmic solutions are filled in vials to keep them stable during shelf life.

2.What is the significance of pharmaceutical vial filling machine in pharma industry?

Pharmaceutical vial filling holds a vast importance in drug manufacturing and who can deny this fact? This topic sheds light upon its advantageous role in pharma industry to keep you informed about the noteworthiness of machine and making it convenient for you to make a wise decision.

Uniform dosing:

Pharmaceutical Vial Filling Machine Ensures Uniform Dosing

Pharmaceutical vial filling machine offers uniform and precise dosing of sterile and sensitive drugs. This machine fills the exact amount in vial and there is no chance of excess or less filling.

Offers aseptic environment:

Aseptic Environment-Picture Courtesy: Packaging Strategies

Who is not aware of the importance of aseptic environment during drug manufacturing? The drug which is responsible of treating your disease must not contain contaminants within itself. Pharmaceutical vial filling machine performs its function by keeping aseptic environment like use of laminar flow, heating to sterilize and minimizes the chances of contamination.

Highly efficient:

Pharmaceutical Vial Filling Machine Can Fill Massive Vials In An Hour-Picture Courtesy: European Pharmaceutical Review

Automated pharmaceutical vial filling machine functions rapidly and considers perfect for large scale production. Massive numbers of vials are filled in an hour and in this way productivity increases.

Versatile:

Pharmaceutical Vial Filling Machine Is Versatile-Picture Courtesy: Science

Pharmaceutical vial filling machine is versatile equipment. Vials of different sizes and material can be filled by it. Moreover different formulations like liquid, powder or suspension are filled in vials by help of this machine. Some machines can be customized according to needs as they have capability to make changes in them.

Low waste production:

Consistent Filling Helps To Produce Less Waste-Picture Courtesy: Northeastern Global News

Pharmaceutical vial filling machine fills vial every time with same consistency and this features helps to produce less waste and expensive and valuable drug product is kept save from being thrown away.

Cost effective:

High Productivity Of Pharmaceutical Vial Filling Machine Proves It Cost Effective-Picture Courtesy: Africa CDC

Pharmaceutical vial filling machine installation can be high priced but it is fast and highly efficient. You will find it as great investment when you will get high productivity and reduce problems while using it. This feature makes it cost effective on long term basis. In simple words, the investment can be initially more but consistent results with low labor cost will prove it profitable investment.

Incorporation with other processes:

Capping Is Done By Pharmaceutical Vial Filling Machine-Picture Courtesy: The New York Times

Pharmaceutical vial filling machine has its incorporation with other processes like washing, sterilizing, stoppering, capping, labeling and inspecting. It offers a complete setup for precise and safe filling of drug products that makes it an ideal choice for investment.

Competence with regulatory standards:

Pharmaceutical Vial Filling Machine Meets Regulatory Standards & Ensures A High Quality Product-Picture Courtesy: Reuters

Pharmaceutical vial filling machine ensures good manufacturing practice (GMP) during whole process. In this way it shows complete compliance to regulatory standard which is also demanded by drug products that are intended to be filled by this machine.

3.Do you know about the types of pharmaceutical vial filling machine?

Before making an investment, you must have knowledge about the types of machine so that you could choose according to your needs. Let’s discuss about the types of pharmaceutical vial filling machine in order to keep you updated for making a profitable investment.

Pharmaceutical vial filling machine is classified according to automation and method of operation.

Types on the basis of automation:

There are three types of pharmaceutical vial filling machine on the basis of automation:

Manual pharmaceutical vial filling machine:

Manual Pharmaceutical Vial Filling Machine-Picture Courtesy: Berkshire Sterile Manufacuting

This pharmaceutical vial filling machine is completely operated by human. It is suitable for small scale production and convenient to be utilized. It has low expenses but not as efficient as other two machines. There is high risk of contamination due to human interference.

Semi-automated pharmaceutical vial filling machine:

Semi-Automatic Pharmaceutical Vial Filling Machine-Picture Courtesy: Berkshire Sterile Manufacturing

This pharmaceutical vial filling machine performs some steps that are automated completely like filling of vial and some of steps are operated by a human like stoppering of vial, that’s why it is semi-automated. It has more accuracy and less chances of contamination than manually operated machine. It is considered suitable for medium-scale production but not for high-speed manufacturing.

Fully automated pharmaceutical vial filling machine:

Fully Automated Pharmaceutical Vial Filling Machine: Syntegon

As name indicates, all steps of this pharmaceutical vial filling machine are performed automatically. This type is demanded most due to high efficiency and rapid speed. Chances of contamination are diminished due to zero interference of human during process and keeping aseptic environment throughout the production. This machine is ideal for large production but needs trained staff and proper maintenance.

Types on the basis of method of operation:

Pharmaceutical vial filling machine is classified on the basis of method of operation as liquid and lyophilized powder drug products are filled in vials. Both types of drug products have slightly different method of operation.

Pharmaceutical vial filling machine for lyophilized powder:

Aipak Pharmaceutical Vial Filling Machine For Lyophilized Powders

This pharmaceutical vial filling machine is highly demanded as it offers precise dosing with safety and stability. It is suitable for such sterile drug products that are needed to convert in dry powder (lyophilized form) to keep them stable during shelf life.

This filling machine is incorporated with other processes, making it an ideal choice for high efficiency production.

This machine consists of ultrasonic bottle washing machine, sterilization dryer, filling and stoppering station, and capping machine.

It is easy to clean and offers a contamination free environment. Energy consumption is also not extensive and productivity is very high.

Pharmaceutical vial filling machine for liquid:

Aipak Pharmaceutical Vial Filling Machine For Liquid

This pharmaceutical vial filling machine is a crucial part of pharma industry as it ensures an accurate filling of liquid sterile drug products into vials.

Same as above machine, this machine is also attached with other processes, making the method of filling more fine and quick as well.

This filling machine comprises of ultrasonic bottle washing machine, sterilization dryer, filling and stoppering station and capping machine.

It is easy to maintain and provides aseptic environment for production.

4.What are the key components of pharmaceutical vial filling machine?

A pharmaceutical vial filling machine is highly equipped machine that secures the precise dosing of sterile drug products. It fills the drug in contamination free environment with great efficiency. There are key components of this filling machine that contributes in seamless functioning of it.

Vial supplying system:

Vial Supplying System-Picture Courtesy: Berkshire Sterile Manufacturing

For proper filling, position of vial must be correct. This system consists of conveyor and vial unscrambler. Conveyor has the role of supplying empty vial to the machine while unscrambler ensures the fine alignment of vial for uniform positioning.

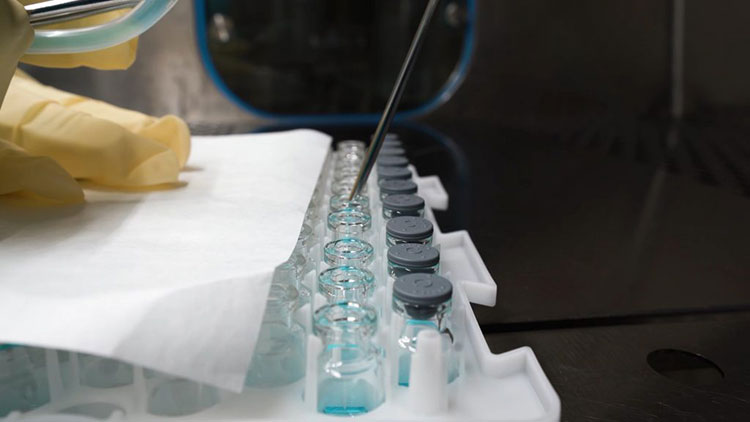

Washing and sterilization system:

Washed & Sterilized Vials-Picture Courtesy: Berkshire Sterile Manufacturing

This system is very crucial for machine and sterile drug products must require aseptic environment for filling. Washing station often uses water for injection for washing vials while sterilization unit utilizes heat or ultrasonic waves to perform sterilization of vials before forwarding them for filling.

Filling and stoppering station:

Filling System In Pharmaceutical Vial Filling Machine

There are nozzles of different sizes and required size nozzle is placed to fill the vial with great precision. Mechanism of filling can be piston, peristaltic pump or pressure-applied. It depends on which kind of drug product is subjected to filling. After precise filling, vials are moved to stoppering unit, where stoppers are placed upon the vial.

Capping system:

Capping System-Picture Courtesy: Steriline

This machine ensures proper sealing by placing aluminum seals or flip-off caps with uniform pressure. Then printed label is applied on vials, which contains important information like batch number, expiration etc.

5.What procedure is followed by pharmaceutical vial filling machine?

Before buying any machine, you must get enough information about how the machine works? This topic provides you knowledge regarding the whole process pharmaceutical vial filling machine follows.

Preparation of vials for filling:

Preparation Of Vials For Filling-Picture Courtesy: Acorn Industries

Vials are washed to remove particles present in it. Water for injection is used to wash vials so that chances of contamination reduce.

After washing, vials are sterilized by using heat or ultrasonic waves in an autoclave.

Supplying of vial:

Sterilized Vial Moving Towards Filling Station-Picture Courtesy: Vetter Pharma

Sterilized vials are moved to filling station with the help of conveyor. Vials are positioned properly by using vial unscrambler.

Filling of vial:

Filling Station-picture Courtesy: PharmaTech Industries

Filling station contains nozzles that work on different mechanisms according to need of drug product. Each vial is filled with accurate dose of sterile drug. Multiple filling heads may be added to fasten the filling process.

Stoppering of vial:

Stoppering Of Vials-Picture Courtesy: Packaging Strategies

After precise filling, vials are moved to stoppering unit. Rubber stopper is partially or completely inserted into the vial by the help of vacuum or mechanical system.

Sealing of vial:

Vial Is Sealed By Aluminum Caps-Picture Courtesy: Catster

Vials are sealed by using aluminum caps. Seal must be reliable to avoid chances of contamination. Aluminum caps are crimped tightly upon the rubber stoppers to keep the vial air-tight.

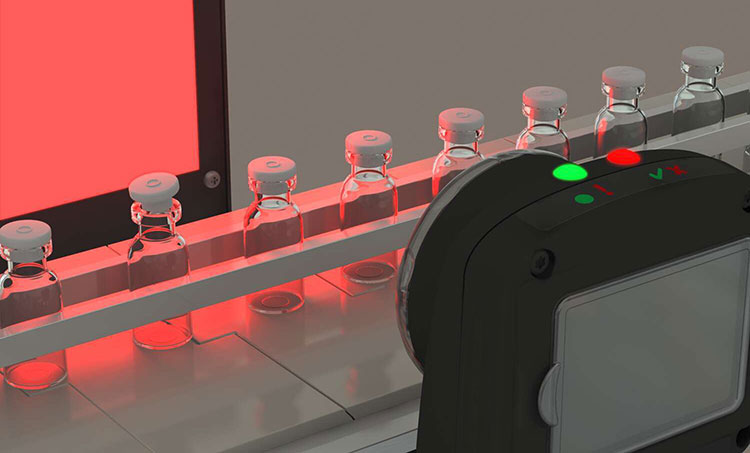

Inspection of vial:

Inspection-picture courtesy: PharmaGuideHub

Vials are inspected after filling and sealing process to ensure a high quality product. Inspection is done for looking filling volume, proper sealing and particulate matter presence in formulation. This can be done manually or by automated machine.

Labeling and packaging:

Vial Is Packed In Boxes For Storage-Picture Courtesy: Farm Progress

Printed labels are applied on finalized vials that contain batch number, expiration date etc. vials are packaged in boxes or trays for storage.

6.What kinds of drug products are packaged by using pharmaceutical vial filling machine?

Pharmaceutical vial filling machine secures great importance in drug manufacturing. It has gained popularity due to its versatility and high productivity. It offers the packaging of certain drug products that are sterile formulations or sensitive in nature and demands aseptic environment.

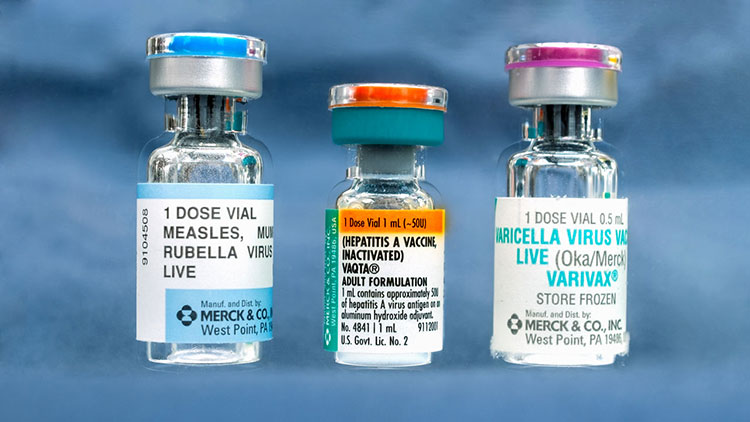

Liquid drug products:

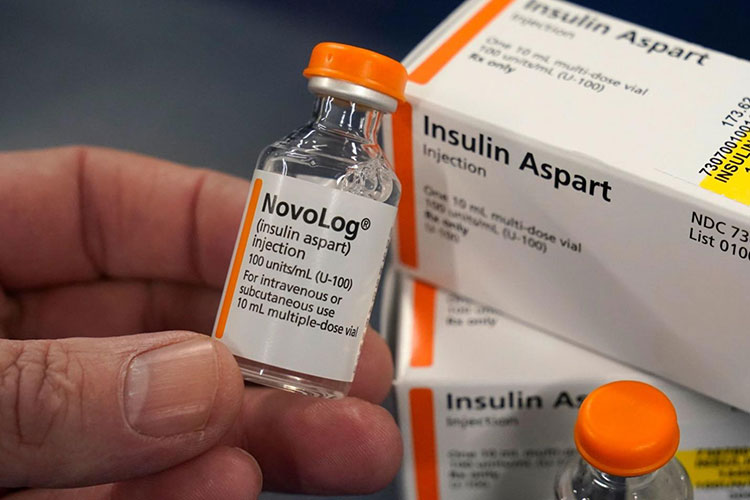

Insulin Is Filled By Using Pharmaceutical Vial Filling Machine

Injectable those are administered parenterally, are filled and sealed by using pharmaceutical vial filling machine. For example: vaccines, insulin etc.

Biologics like monoclonal antibodies or recombinant protein need this machine for accurate filling and sealing.

Intravenous solutions like saline, glucose, electrolyte solutions are filled by using this machine

Anesthetics like propofol are filled in vial by the help of this filling machine.

Hormones are filled in vial by utilizing this machine. For example growth hormones or erythropoietin.

Lyophilized drug products:

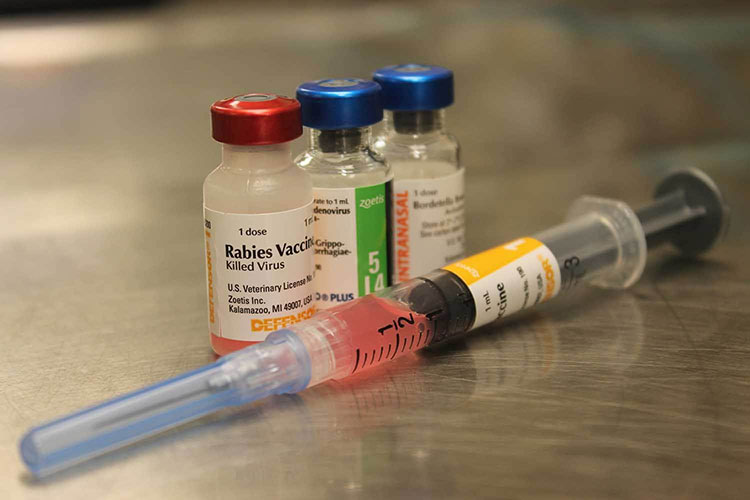

Rabies Vaccine Is Filled By Using Pharmaceutical Vial Filling Machine-Picture Courtesy: Low Cost Spay Neuter

Some drugs are changed in to freeze dried form because they remain unstable in liquid form. Such drugs need to be reconstituted before use by adding sterile diluent. Pharmaceutical vial filling machine provides precise filling of lyophilized drug products like vaccines, biologics, few antibiotics (e.g. vancomycin).

Powder drug products:

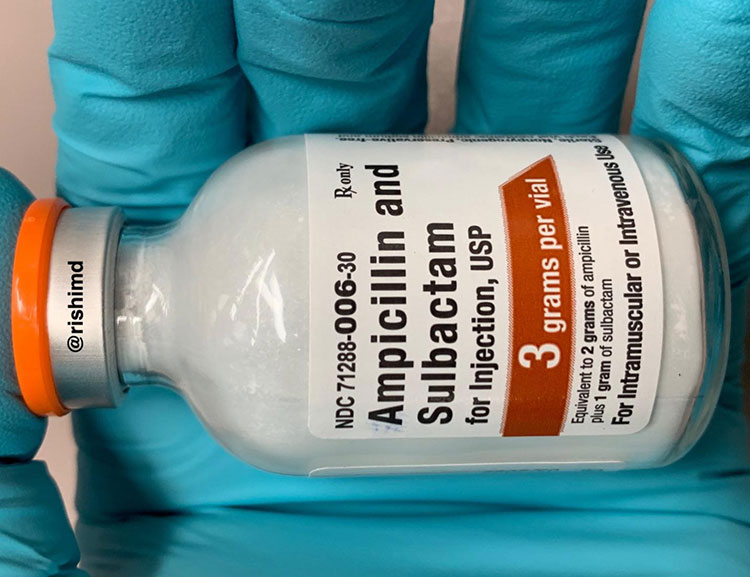

Ampicillin Powder Filled By The Help Of Pharmaceutical Vial Filling Machine

Some drugs are filled in the form of powder form by utilizing pharmaceutical vial filling machine and require reconstitution before administration to the body.

Such drugs include: chemotherapy drugs, antibiotics like ampicillin, and hormonal products.

7.What aspects must be considered while buying a pharmaceutical vial filling machine?

Making an investment in pharmaceutical vial filling machine is wise decision but some important aspects should be considered to get utmost benefits from your decision.

Regulatory compliance:

GMP Is Mandatory For The Process Involved Sterile Drug Products

Pharmaceutical vial filling machine is used to fill sterile drug products so competency to regulatory standards is mandatory. All process must match the requirements of good manufacturing practices (GMP) for maintaining the clean and safe environment for production.

Capacity of machine:

Capacity Of Pharmaceutical Vial Filling Machine-Picture Courtesy: Micron HVAC Pvt Ltd

Many important things define the capacity of a machine. First you look for its filling range; it must be according to your product requirements that how much volume you need to get filled in vial. Choose that filling mechanism that is suitable for your drug product like we choose vacuum filling for powders.

Production speed must be according to the scalability, like how vials per min can be filled by this machine. Filling accuracy must be high as to ensure exact filling of desired dose. Check the ability of machine to hold various sizes or materials of vial.

Sterility:

Restricted Access Barrier System-Picture Courtesy: Telstar

Quality control is foremost part of filling process of sterile product. Look for aseptic design that includes laminar flow, restricted access barrier systems (RABS) or isolators.

Machine must possess CIP (clean in place) and SIP (steam in place) capabilities so that maintenance and sterilization would become easier.

Automation and incorporation:

Capping Machine Is Incorporated In Pharmaceutical Vial Filling Machine-Picture Courtesy: Nbc News

Look for machine that is applicable for your scale of production. Large scale production demands for fully automated equipment. Incorporation with other processes within the filling machine makes high productivity and reliability. Other systems including washing, sterilization, capping etc. are attached to filling and stoppering station to make process rapid.

Easy to maintain:

Easy To Maintain-Picture Courtesy: Web Fonts

Machine must be easy to maintain, must possess tool less maintenance and feature of quick disassembling. Spare parts must be easily available so that you do not face trouble in future.

Cost estimation:

Cost Estimation-Picture Courtesy: BigTime Software

Overall cost must be estimated to predict the cost over production ratio. The cost of machine and its maintenance collectively considered to figure out the profit.

Safety:

Machine Must Contain Safety Features Like Emergency Button-Picture Courtesy: Machinery Safety 101

Machine must contain safety features like guards, interlocks, emergency stops. Design of machine must be easy going and requires low operator exhaustion.

8.Can you define the strategies to maintain pharmaceutical vial filling machine?

Maintenance is utmost necessity of every machine and similarly pharmaceutical vial filling machine demands proper maintenance to meet regulatory standards and to yield high quality product.

Precautionary maintenance:

Inspecting And Lubricating Moving Parts Of Pharmaceutical Vial Filling Machine

Below measures are taken to avoid machine failure:

- Regularly check moving parts for misalignment or tear. Lubricate them on weekly basis.

- Nozzles for filling and contact surfaces must be cleaned on daily basis.

- Touch screen panels and sensors must be inspected daily.

- Tubing, valves and seals must be checked for deformation or leakage.

- On monthly basis, check filling accuracy and calibrate it again when it is required. Inspect CIP and SIP systems for proper cleaning and sterilization. Change air and fluid filters when required

Calibration:

Calibration of machine is carried out to retain the high quality product-picture courtesy: packaging digest

Calibration of pharmaceutical vial filling machine is very important to retain the efficiency of whole process. Load cells, pumps, sensors must be calibrated to avoid any trouble during functioning.

Cleaning and sanitization:

CLP Is Used To Clean Internal Surfaces Of Pipes, Vessels, Filters-Picture Courtesy: Intimac

Sterile products demand aseptic environment, for this purpose proper cleaning and sanitization is essential.

- Clean-in-place (CIP) is automated system that performs flushing of fluid paths by cleaning agents.

- Steam-in-place (SIP) is intended to sterilize the internal area with high temperature steam.

- Cleaning is also done manually for external parts.

Management of spare parts:

Filling Nozzle Is Important Part Of Pharmaceutical Filling Machine And It Must Be Stocked To Avoid Long Downtime

Important spare parts must be stocked to avoid prolonged downtime. Gaskets, sensors, nozzles, filters etc. must be available when needed.

Environmental monitoring:

HVAC System-Picture Courtesy: Brandt

Cleanroom conditions must be kept favorable to production. Temperature, humidity, particle count must be in required limit. Check HEPA filters and HVAC systems to diminish the chances of contamination.

Educating staff:

Educating Staff For Trouble Shooting Procedure, Sanitation Protocols And Safety Measures-Picture Courtesy: Sigga Technologies

Operators and maintenance personnel must be educated for troubleshooting procedure, sanitation protocols and safety measures.

9.What are the limitations of pharmaceutical vial filling machines?

Error In Positioning Of Stopper-Picture Courtesy: Banner Engineering

Pharmaceutical vial filling machine performs a very integral function in drug manufacturing but it has some limitations which are discussed below:

- Extensive initial investment is required to purchase, install and validate pharmaceutical vial filling machine. So it is not affordable for a startup or small-scale production.

- Pharmaceutical vial filling machine requires skillful personnel for maintenance, troubleshooting and calibration. Downtimes can be prolonged if internal support is deficient.

- Rapid filling speed can affect the accuracy of filling and spillage or damage to vial can be occurred. Sometimes error in positioning of stopper is also reported. Pumps used to fill precise dosage of drug also start showing variations in filling and it needs to be calibrated immediately.

- Machine must meet the good manufacturing practices (GMP) and validation standards. This demand makes the process more complexed.

- Pharmaceutical vial filling machine is installed in cleanroom to avoid contamination and to provide aseptic conditions. Addition of cleanroom in infrastructure can raise the cost of operation.

10.What are the technological advancements that can be incorporated in pharmaceutical vial filling machine?

Use Of Artificial Intelligence (AI) For Detection Of Faults-Picture Courtesy: Vistula University

Many modern innovations has been made to pharmaceutical vial filling machine in order to robust the productivity and get faultless functioning of equipment. Recent advances in this machine are stated below:

- Different sizes and materials of vials are used in pharmaceutical vial filling machine and at the same times drugs of different consistencies are subjected to fill, so this requires format change within the machine. This format change is turned fully automated to save time, increase speed and productivity and minimizes human interference to avoid contamination.

- Concurrent monitoring of process is made possible to facilitate the quick detection of changes happened during process and calibration at the same time.

- Batch recording is done by using high technology. This feature helps in fast tracing and tracking of data.

- Utilization of artificial intelligence for the detection of faults that can be encountered during the process like wrong position of stopper, crack in vial, changes in crimping quality etc.

Conclusion:

Buying an appropriate pharmaceutical vial filling machine is chief decision that affects the efficiency and compliance of production. Knowledge regarding machine capacity, sterility and maintenance, competency with mandatory standards, cost and safety must be gained before choosing this equipment. Initial investment would be high but long term benefits are far more to be noted, so investing in pharmaceutical vial filling machine is advantageous as drug manufacturing is incomplete without it. For more query, you can contact aipak anytime.

Don't forget to share this post!

Vial Filling Machine Related Posts

Vial Filling Machine Related Products

Vial Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine