Pharmaceutical Tablet Coating Machine: The Complete Buying Guide In 2025

Have you ever figured out who is behind the innovations in tablet drug delivery system? It’s not other than pharmaceutical tablet coating machine. This beneficial equipment holds a key role in modern pharma industry by establishing quality, efficacy and shelf life of tablets.

As a buyer, when you observe for a profitable investment, you cannot deny the advantageous role of this machine. This topic is designed to educate you about all the knowledge, necessary for buying a pharmaceutical tablet coating machine in order to be a part of your wise investment.

1.How to define pharmaceutical tablet coating machine?

Tablet With Thin Layer Of Coating

Pharmaceutical tablet coating machine is well-known equipment, specially designed to apply a layer of coating material to tablets for several purposes like protection, taste masking, drug release or branding. This machine is considered as fundamental part of pharma industry and playing role in delivering life-saving medicines.

As a purchaser, this machine would be a great choice to invest, as tablets are consumed very often, for mild reasons like headache, heart burn etc.

2.How profitable is pharmaceutical tablet coating machine to medicine industry?

Pharmaceutical tablet coating machine owns vital place in medicine industry for increasing the efficacy, quality and durability of tablets. This equipment is intended to use on large-scale to deliver product of promised quality. It proves to be very beneficial to industry sector, as discussed below:

High productivity:

High Productivity-Picture Courtesy: Rheonics

Pharmaceutical tablet coating machine offers consistent operation, which decreases the downtime and robursts the productivity. Coating process is carried out automatically, which results in low labor cost and top quality product.

Enhanced quality product:

Enhanced Quality Product

Pharmaceutical tablet coating machine works efficiently, provides precise coating on tablet which in turn boosts up the efficacy and presentation of it. It minimizes the chances of coating defects like cracking, chipping, or irregular coating leads to little defected products.

Cost effectiveness:

Cost Effectiveness-Picture Courtesy: SpendEdge

Efficient processing of pharmaceutical tablet coating machine ensures a quality product with less rejected items. This minimizes the cost of whole operation and saves the material from being wasted. It also decreases the utilization of more active ingredients, keeping tablet production low cost.

Compliant to regulatory standards:

Pharmaceutical Tablets Coating Machine Follows GMP

Whole operation is carried out by following good manufacturing practices (GMP) and standard regulations. Ultra-modern machine assures that furnished product is free of any contamination and possesses good quality.

Promotes specialized drug composition:

Enteric Coated Tablets

Innovation in tablet drug delivery system has brought to you by the aid of this amazing machine. It reinforces enteric, sustained-release and controlled release coatings, ensuring the delivery of drug in efficient way. Biodegradable and nano-technology based coatings are also enabled by this machine.

Advances branding:

Makes Tablets Attractive And Recognizable-Picture Courtesy: The Health Master

It gives attractive coating to tablets to make them appealing to costumers and recognizable among different brands. This strategy advances the branding of product.

Fulfills the global call:

Fulfills The Global Call-Picture Courtesy: Meghmani Dyes

This high productive machine supports the medicine industry to fulfill the global demand of quality products and aids in export of these products under regulatory standards.

3.What other industries require a pharmaceutical tablet coating machine?

Pharmaceutical tablet coating machine is first and foremost used in medicine industry, but to your surprise, it does have its role in other industries too. This fact highlights its importance in daily life. Below industries utilize this amazing equipment for some of their productions:

| Industries | Role of pharmaceutical tablet coating machine |

| Food industry:

Coated Candies |

This machine is used to coat chewing gums, candies and other food product with sugar, chocolate or other desirable coatings |

| Nutraceutical industry:

Sugar Coated Iron Supplement-Picture Courtesy: Meds For All |

This machine has its significant role in coating nutraceutical tablets like vitamin, herbal supplements to enhance their ability, external surface and ease of swallowing. |

| Cosmetic industry:

Film Coated Tablets For Acne-Picture Courtesy: Skin Care Solution |

This machine is useful for applying coatings to cosmetic powders, pressed tablets, or other solid cosmetic products to establish the stability and shelf life. |

| Chemical industry:

Chemical Fertilizers-Picture Courtesy: Vecteezy |

Pharmaceutical tablet coating machine is used to apply coating on fertilizers, pesticides and catalyst tablets. This coating helps to protect them from chemical and physical reactions and control their release characteristics. |

4.What variety of pharmaceutical tablet coating machine is available in market?

Pharmaceutical tablet coating machine has a significant value in medicine industry. As a purchaser, you must have enough knowledge about types of this machine to make well-informed decision. Three fundamental types of pharmaceutical tablet coating machine are discussed below:

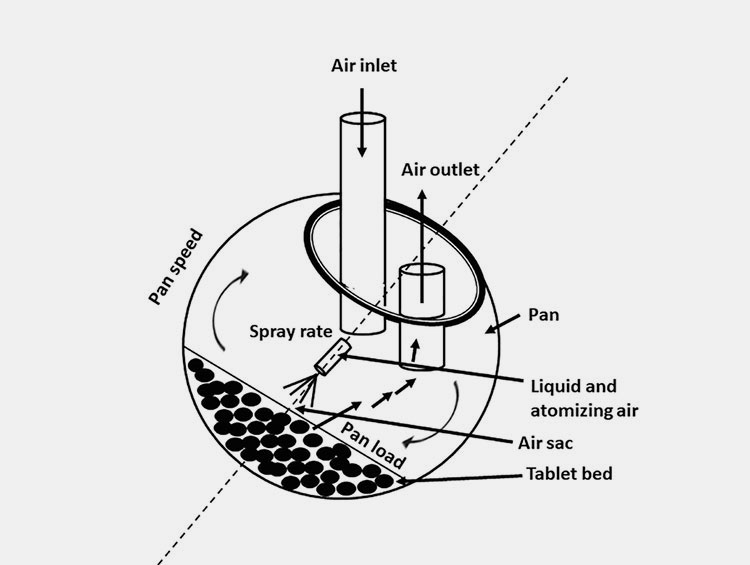

Standard coating pan:

Standard Coating Pan

A standard coating pan is traditionally used pharmaceutical tablet coating machine widely used in pharmaceutical industries to coat tablets uniformly. It comprises of rotating circular pan, which is tilted at an angle. Whole equipment is made of stainless steel to avoid any contamination and prolong shelf life of machine.

Process starts with loading of tablets in coating pan. Pan rotates, facilitating the tablets to tumble and mix as coating solution is sprayed upon tablets by the help of spraying system. Heated air is applied to dry the coating of tablets. Whole process is repeated until you get a uniform coating of tablets.

Standard Pan Coating Process

Drying system can be of three types, like immersion sword, baffled pan and diffuser and immersion tube system. Immersion sword works by distributing drying air with the help of a metal sword submerged in tablet bed. Baffled fan and diffuser provides drying air to surface of tablets consistently. Immersion tube system functions with the help of a tube immersed in tablet bed that distributes drying air by spraying nozzle over the surface of tablets.

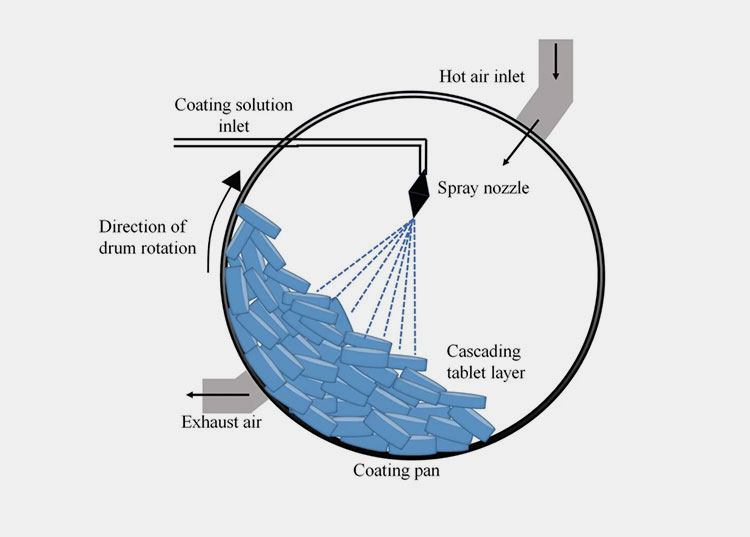

Perforated pan:

AIPAK Perforated Pan

This type of pharmaceutical tablet coating machine consists of partially or fully perforated drum, which applies coating on tablets rotating on its horizontal axis in an enclosed setup. This equipment utilizes spraying nozzles to apply coating on tablets uniformly.

The enclosed setup is constructed with sprays guns inside the drum, to provide even distribution of coating solutions. This system ensures flawless drying process and huge coating capacity as compared to other systems.

Perforated Pan Coating Process

Perforated pan comes with various designs which offer efficient drying methods.

Accela-cota has simple design; a perforated drum is used in which drying air is introduced from outside and ejected out by using a suction shoe present at bottom of machine.

Hi-coater has same design as of accela cota, air is introduced in perforated drum from outside then passes through the tablet bed and expelled by perforations present beneath the tablet bed.

Driacoater consists of hollow perforated ribs placed on inner side of drum to provide drying air for tablets. As the coating pan spins, drying air is distributed by perforated ribs over the tablet bed then air flows upward to expel outside the drum.

Glatt coater is designed by using fully perforated drum and many rapid speed spraying nozzles which has quick drying process and less processing time of the tablets. Drying air is introduced in perforated drum which passed over the tablet bed and expelled out by suction shoe.

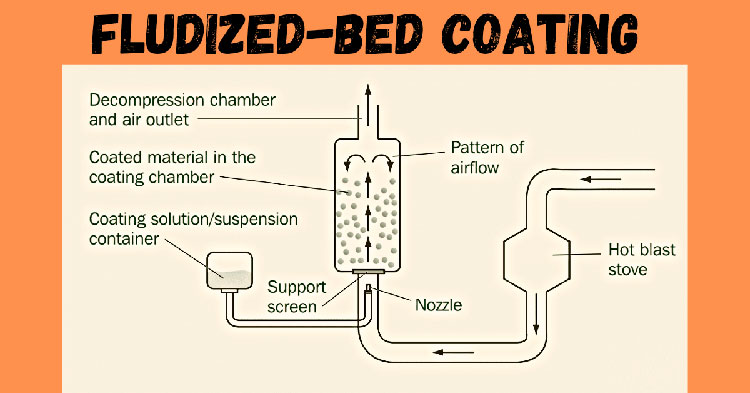

Fluidized bed or air suspension system:

Fluidized Bed Coating Machine-Picture Courtesy: Umang Pharmatech

This type of pharmaceutical tablet coating machine performs efficiently to yield good quality product. It is used to coat tablets by suspending them in an air stream, meantime applying the coating solution by the help of spray nozzle. It consists of a vertical cylinder.

Process starts when tablets are loaded and a high pressure air stream suspends the tablets, creating a fluid like motion. Coating solution is sprayed by spray nozzles on to the fluidized tablets. For drying hot air is introduced which evaporates the solvent, leads to even coating. Fluidized bed coating machine is available in three designs.

Top-spray coating machine uses technique of spraying coating solution from the top of cylinder. Usually it is used for taste masking, moisture or color protection.

Bottom-spray coating machine sprays coating solution onto tablets from bottom of the cylinder. This technique is used for control-release or enteric coated tablets.

Tangential –spray coating machine has arrangement of spray nozzles at an angle, which provides swirling effect of motion. This results in consistent coating and proper layering. This machine is used for sustained-release tablets.

Fluidized bed coating process

Pan coating machines are suitable for large size tablets, meanwhile fluidized bed coating machine is ideal for small size tablets. Above information about types of pharmaceutical tablet coating machines will guide to make right choice.

5.What shapes and sizes of tablet can be handled by pharmaceutical tablet coating machine?

Pharmaceutical tablet coating machine is versatile equipment. It can deal with different shapes and sizes of tablet, which is explained below:

Shapes of tablet:

| Tablet shape | Appearance |

| Round: this shape is used as standard in tablets, commonly used and can be easily coated evenly. |

Picture Courtesy:Chiropractic Moves |

| Oval: this shape has no edge so easily gets coated. |

Picture Courtesy: Pngtree |

| Capsule-shaped: this shape demands extra care for coating in order to avoid chipping. |  |

| Oblong: this is similar to oval but elongated. It is typically used for larger doses. |

Picture courtesy: comfort recovery LLC |

| Triangular/square/pentagonal:

Less common shape and demands specialized coating techniques. |

|

| Unique shapes:

Unique shapes are made for branding or on manufacturer’s requirement. These shapes need customize system for coating. |

Picture Courtesy: Brighter World |

Sizes of tablet:

Different Sizes Of Tablet-Picture Courtesy: European Pharmaceutical Manufacturers

Tablets are available in different sizes, based on need of formulation or compliance of patient. Pharmaceutical tablet coating machine can handle following sizes:

| Size of tablet | Application |

| Small ( less than or equal to mm) | Usually for mini-doses or pediatric use |

| Medium (between 5-12mm) | Standard size of coating tablets |

| Large (between 2-20) | It demands accurate coating measurements to prevent defects. |

| Extra-large (greater than or equal to 20) | Not common, demands advance coating techniques. |

6.What coating methods are reinforced in pharmaceutical tablet coating machine?

Pharmaceutical tablet coating machine supports various coating methods. This is the reason. It is widely used in pharma industry. In this topic, brief knowledge of different types coating methods is delivered to you. This information will be profitable for you during buying of tablet coating machine.

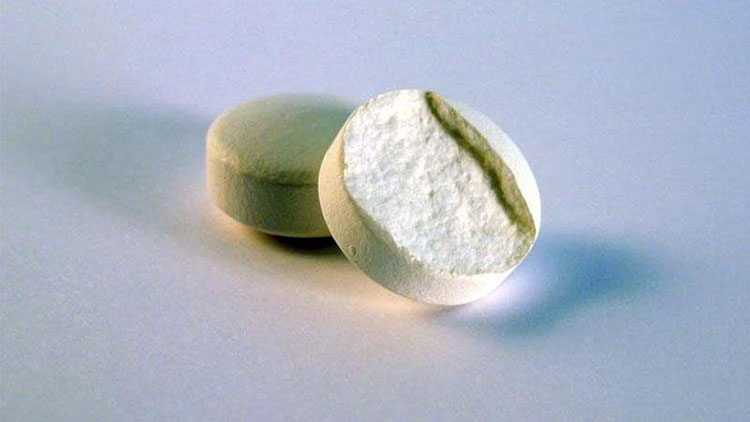

Film coating:

Film Coated Tablets

A polymer based film is applied on the surface of tablets. Materials used in coating are polymers like hydroxypropyl, methyl cellulose, plasticizers, colorants.

Good thing in this method is that, it is fast method and less weight is acquired by tablet due to thin layer. Coating offers better appearance and good taste masking.

This coating can be aqueous or non-aqueous. In aqueous coating, water- based coating solution is applied so it is safer and nature-friendly. Other one is non-aqueous coating, which is based on organic solvent, it dries faster but solvent recovery is necessary.

Sugar coating:

Sugar Coated Tablets-Picture Courtesy: iPharmachine

Many layers of sugar based solution are applied on surface of tablet. This method is carried out step by step, like sealing, sub-coating, smoothing, coloring, and polishing.

This type of coating provides glossy appearance and good taste masking. But it’s so time-taken and tablet gains much weight.

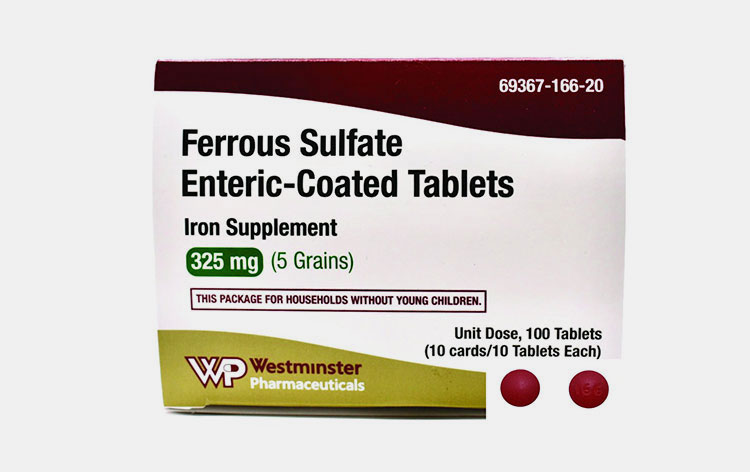

Enteric coating:

Enteric coated tablets

A specialized polymer layer is coated on tablet to protect it from stomach acid and make it dissolve in intestine. Materials used in this coating are cellulose acetate phthalate, methacrylate copolymers.

It helps in protection of active ingredients from gastric acid, minimizes gastric irritation and offers safe targeted release of drug.

Controlled or sustained release coating:

Controlled/Sustained Release Tablets

A layer of polymer based coating is applied on tablet to change the release of drug over time. Materials that are used for coating are ethylcellulose and polyvinyl acetate.

It makes patient compliance better, decreases frequency of doses and allow release of drug at optimum time.

7.How to define steps of processing of pharmaceutical tablet coating machine?

Tablet Coating Process-Picture Courtesy: Syntegon

Tablet coating is a delicate process and demands precise methods to achieve good outcome. This topic tells you about steps involve in coating of a tablet, in order to educate you about right process.

|  Steps | Function |

| Introduction of tablets in coating machine: | Tablets are introduced into the coating pan or drum of machine.

The pan spins consistently to assure even exposure of all tablets. |

| Preheating of tablets: | Dry air is introduced to preheat the tablets in order to facilitate the adhesion of coating solution on surface of tablet. |

| Spraying of coating solution: | Coating solution consists of polymer, colorant, plasticizer is sprayed upon the rotating tablets by the help of spraying guns.

Atomized solution makes a thin and even layer on tablets. |

| Drying of tablets: | Drying air is introduced through the tablet bed to evaporate solvent.

Proper drying aids in creating uniform layer on tablets. |

| Repeating the coating process: | Spraying and drying step is repeated until desirable coating on tablet is achieved. |

| Cooling and unloading of tablets: | Coated tablets are cooled to avoid cracking.

When coating process is accomplished, tablets are unloaded. |

| Quality control: | Coated tablets are checked for their thickness, uniformity and defects like cracking, peeling.

Weight of tablet is inspected to ensure that the right amount of coating is applied on tablet. |

8.What are the main parts of pharmaceutical tablet coating machine?

Uniform Coating Of Tablets-Picture Courtesy: European Pharmaceutical Manufacturer

A pharmaceutical tablet coating machine comprises of many important parts, that function together to establish uniform coating of tablets. As being a buyer, you should have knowledge about main parts, so that you would not get into trouble at time of purchase. For proper processing of this machine, every part is integral.

| Main parts of pharmaceutical tablet coating machine | Information |

| Coating pan: | A rotating pan or drum is one the most important part of pharmaceutical tablet coating machine.

In coating pan, tablets are placed for coating; it is sometimes perforated for optimal air flow or can be solid in traditional tablet coating machines. |

| Spray system: | This system helps to spray the coating solution onto the tablets. It can be adjusted for flow rate and nozzle size as per need.

It facilitates homogenous distribution of sugar, film or enteric coating. |

| Drying system: | This system provides heated air to dry the coating of tablets faster.

This system functions with exhaust system to keep temperature and humidity with in limit. |

| Solution tank and pump: | Solution tank is used to store coating solution and pump is intended to supply coating solution to the spray nozzles at controlled rate. |

| Baffles: | These are constructed inside the coating pan, aids to mix and tumble the tablets.

It prevents clumping and provides good exposure to spraying solution. |

| Control panel: | It is used to control important functions of machine like airflow, speed of rotation, spray rate and temperature. |

| Drive motor and gear system: | This system gives power to coating pan for rotation at controlled speed and optimizes the tablet coating process. |

9.What kind of spray system technology is used in pharmaceutical tablet coating machine?

Spraying System In Tablet Coating Machine-Picture Courtesy: Coating Systems International

Spray system technology plays a vital role in establishing uniform coating on surface of tablet. Different methods of spraying are applied to achieve the desirable coating of tablet.

| Spray systems | Information |

| Peristaltic pump system: | It allows distribution of measured flow coating solution to spray guns.

It helps in applying uniform coating and minimizes wastage. |

| Spray guns (atomization technology) | Liquid coating is converted into fine droplets by help of this technology.

This offers smooth and uniform coating. Typically it has 3 times: Airless spray guns that do not contain air and use high pressure to function. Pneumatic spray guns use compressed air to atomize liquid coating. Ultrasonic spray guns use ultrasonic vibrations to atomize liquid coating. |

10.How favorable is pharmaceutical tablet coating machine to the society?

Painkiller For Toothache Is Coated By Pharmaceutical Tablet Coating Machine-Picture Courtesy: Dafra Pharma

The painkiller, you had taken to subside your toothache, is coated by the help of pharmaceutical tablet coating machine, in order to ensure that the right amount of drug reaches the right site of absorption. Who can deny the fact that this coating machine doing wonders for our society? Patients, manufacturers and whole healthcare system are benefiting with this amazing equipment.

Improves efficacy:

Enteric Coating Avoids Gastric Irritation-Picture Courtesy: WPRX

Profound effects of medicine are seen when drug’s active ingredients release at right time in the body. Coating enables to control release of drug to get better therapeutic effects.

Enteric coating helps to avoid gastric irritation and facilitates drug to dissolve in intestine instead of stomach.

Establish patient compliance:

Sugar Coating Masks The Bitter Taste And Unpleasant Smell-Picture Courtesy: Biogrund

Coatings mask the bitterness and unpleasant smell of drugs, making them easier to swallow. Different colors coating helps in identifying the correct medicine.

Guarding the drug:

Coating Provides Shield To Tablets-Picture Courtesy: Thomus Processing

Coating provides shield to tablets from light, moisture and air, avoid their deformation and increases shelf life.

It also can avoid mechanical damage like chipping, breaking which commonly happens during packaging and transportation.

Helps in mass production:

Mass Production Of Tablets-Picture Courtesy: Pexels

Ultra-modern pharmaceutical tablet coating machine helps in coping up the needs of medicine by working efficiently and providing uniform coating with rapid speed.

Brings innovation in drug delivery:

Innovation In Drug Delivery-Picture Courtesy: Gastrointestinal Society

Modernization is seen in coating technology like nanocoatings, smart coatings and biopolymer coatings that supports delivery of drug to its target. Oral disintegrating tablets aid patients to take medicine without experiencing swallowing problems.

Enhances marketing:

Coating Helps In Differentiating Between Brands-Picture Courtesy Pharma Excipients

Different manufacturers apply coatings to tablets to make their product identical among different brands. Other benefit of coating to manufacturers is that when they provide high quality product, consumers grow their trust in medicine industries.

11.What attributes are important to consider for pharmaceutical tablet coating machine?

Coated Tablets-Picture Courtesy: Poison Control

There are some features you need to be attentive about them before buying a pharmaceutical tablet coating machine. In this topic we will highlight such attributes to help you in choosing the right equipment.

| Attributes | Information |

| Air capacity: | Air capacity is a main factor to look for.

The amount of air passes through the tablet bed, the amount of water or any other solvent will evaporates during drying process. |

| Composition of coating: | Coating consists of ingredients dissolved in a solvent.

After applying the coating on to the tablet, drying air is passed to remove solvent as solvent is a carrier of ingredients. This point must be focused to evaporate such amount of solvent which is present initially in the coating solution by passing enough drying air. |

| Surface area of tablet: | Surface area of tablets decides how much coating will apply on it.

It is easy to weigh the batch of tablet before loading, but the actual thing that has its influence is surface area. So it must be keenly look after so that uniform coating is produced. |

| Efficiency of coating machine: | Coating pans are traditional but slower, demands skilled operation.

Perforated pan is suitable for large size tablets, has efficient drying system. Fluidized bed is appropriate for small size tablets. Spray system must be efficient for accurate results. Machine must be made of stainless steel to avoid corrosion and other reactions. Coating machine must be versatile enough to handle different shapes, sizes and amounts of tablet. Automation and control system must be there to ensure high productivity with good quality and low cost. Cleaning must be easy and downtime is less. Also supports quick replacement of parts if needed. Regulatory standards must be followed during operation. Low energy expenditure must be seen in coating machine by having good drying system that also ensures reduce waste production. |

12.What are the effective ways to maintain pharmaceutical tablet coating machine?

Maintaining a pharmaceutical tablet coating machine is crucial to yield a good outcome and increase the functionality and durability of machine. This topic sheds some light on effective ways to maintain this equipment.

Deep cleaning and sanitation:

Empty Machine With Care-Picture Courtesy: Coating Systems International

On daily basis, clean every part which comes in contact with product by an appropriate cleaning agent.

Proper cleaning of pan or drum, spray nozzles and exhaust system must be carried out.

Remember to empty machine with care so that no remaining portion of coating will be left. This will cause contamination in product and jamming in the machine.

Inspection of coating machine parts:

Pharmaceutical Tablet Coating-Picture Courtesy: iPharmachine

Inspection of all vital parts is very necessary. Check spraying system for choking, disarrangement, and wear or tear. Replace as per need. Check coating pan for abrasion, cracks or scratches. Inspect air handling system about blockages and good flow. Check for leaks and replace the seal where it is necessary. Inspect gear boxes, belts and motors for proper functioning. Monitor temperature and humidity and control according to needs of operation.

Lubrication:

Lubrication Of Moving Part-Picture Courtesy: www.sesamemotor.com

Lubrication of moving parts of pharmaceutical tablet coating machine must be carried out by good quality lubricant to avoid friction and attain smooth operation.

Maintenance of electrical system and other systems:

Emergency Stop Button-Picture Courtesy: Machinery Safety 101

Check wiring and connections to ensure proper working of electrical system. System’s software must be updated. Emergency stop buttons and alarms must work properly.

Follow schedule of maintenance:

Follow Schedule Of Maintenance-Picture Courtesy: Linkedin

Follow the schedule of maintenance provided by manufacturer. And keep spare parts to replace when it is required.

13.What defects can be encountered in pharmaceutical tablet coating machine and how you correct them?

As like any other machine, pharmaceutical tablet coating machine also encounters some defects. In this topic, we will discuss the expecting defects and their solution to avoid any trouble in future.

Twinning of tablets:

Twinning Of Tablets-Picture Courtesy: Pharmapproach.Com

Excessive wetting of tablets is seen due to increased spray rate and in adequate drying process. Sometimes it results in stickiness of tablets together or stickiness of tablets to tablet bed.

This problem can be corrected by optimizing rate of the spray and calibrate the air flow to make adequate drying process. Check pan speed for proper tablet movement.

Orange peel effect:

Orange Peel Effect-Picture Courtesy:iPharmachine

Rough surface of tablet is witnessed due to inadequate atomization; reduce spray rate and excessive drying process and low quality coating solution.

This issue is solved by calibrating atomization, monitoring drying process and spray rates and utilizing good quality plasticizer.

Flaking and peeling:

Flaking Of Tablet-Picture Courtesy: Freeman Technology

Flakes are formed on the surface of tablet due to poor adhesion of coating solution. Another reason could be high moisture content and increased coating thickness.

Solution to this problem is to enhance coating solution with strong adhesion properties. Preheat tablets before coating to facilitate good adhesion. Upgrade the number of coating layers.

Chipping and cracking:

Cracking-Picture Courtesy: Colorcon

Breakage of tablet is seen due to excessive mechanical stress during coating process. Other reasons could be presence of excess plasticizer and over drying of coating.

Solution of this issue is to lower the speed of pan and mechanical effect. Use plasticizer in suitable amount and upgrade drying process.

Color variation:

Color Variation-Picture Courtesy: Pharmfdainfo

Light and dark shades of color or two different colors are seen on surface of tablet. This is due to inaccurate spray distribution, inadequate mixing of coating solution and improper drying process.

This defect can be corrected by optimizing spray system to apply uniform coating, mixing of coating solution must be precise and enhance drying system.

Conclusion:

Pharmaceutical tablet coating machine ensures the protective, aesthetic and functional coating of tablets. It proves to be beneficial for patients, manufacturers and complete healthcare system. Its advantages role makes it an integral part of medicine industry and our society. Few defects have seen due to poor maintenance but all over it’s a versatile, well-equipped and easy to use machine, making our lives easy too. For any query, you can contact AIPAK anytime.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine