Pharmaceutical Cartoning Machine: The Complete Buying Guide In 2025

How to streamline your pharmaceutical packaging process by leveraging a pharmaceutical cartoning machine? The secondary packaging of medicinal goods is way more important than primary packaging. That’s why pharmaceutical cartoning machine is an absolute solution than ever. You can pack a number of products simply with the help of this reliable option. So, this article explores the importance of the pharmaceutical cartoning machine and related content that you find really helpful. For example, benefits, types of products you can pack, how it is done, what type of machines are in the market, how it functions, etc. So, read it now!

1.How do you define a pharmaceutical cartoning machine?

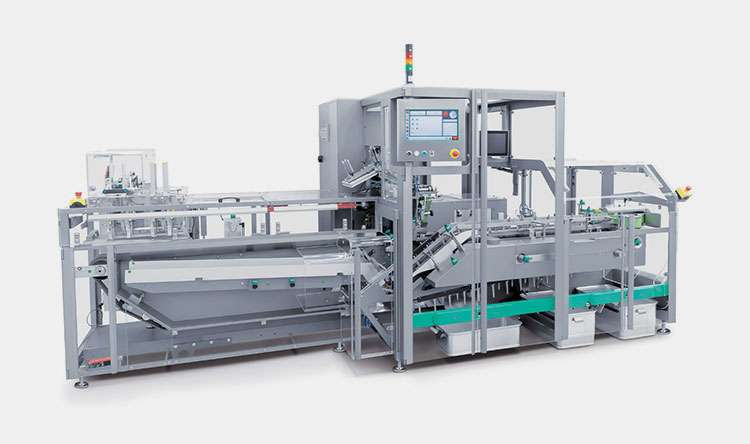

AIPAK Pharmaceutical Cartoning Machine

This machine generally belongs to a class of secondary packaging machines and is used for packing pharmaceutical products into boxes called cartons. Usually, it takes a flat piece of cardboard or paperboard and changes it into a folding carton box.

Simply, it is engineered to perform the specific task of erecting the carton sheets, filling the erected boxes with products, and finally gluing them close in an automatic series of steps. You can pack a variety of products in cartons using this equipment by customizing it to create boxes of diverse shapes and sizes.

2.What is the major purpose of using a pharmaceutical cartoning machine?

Did you ever think about how items are placed in the cartons? Well, a pharmaceutical cartoning machine is usually used for this purpose.

Why this equipment is an all-important component of the packaging line? This machine has a broad array of advantages that increase its demand in every industrial sector. Let’s have a read about its major purpose in your packaging processes:

Quick Speed Packaging

Quick Packaging

Whether you’re using semi-automatic equipment or completely automated models, a pharmaceutical cartoning machine is well-known for its quick-speed packaging. There is no doubt that it can pack way more cartons than hand filling. With this machine, you can easily complete your cartoning process in just a few moments.

Moreover, because it is automated, a cartoner is best for handling large batches of products.

Accuracy and Evenness in Product Boxing

Uniformity in cartoning

Errors and mistakes can’t be avoided in manual packaging even if you take extreme care. But if you install a pharmaceutical cartoning machine, you’ll be certain that your product is packed according to the highest possible quality standards.

With its fault-detecting sensors and process monitoring controls, you can easily prevent undesired errors and irregularities. With precision in packaging, you are able to reduce product wastage.

Customized designing

Customized designing- Picture courtesy: Korber Pharma

Are you handling products that vary in size, shape, and composition? Then rest assured a pharmaceutical cartoning machine is phenomenal in this aspect. You can easily change its settings to accommodate box cartons of varying shapes and sizes.

Besides this, you can have different cartoning speeds by tweaking its controls. Yes, it is the best tool to have on hand when you’re managing diverse packaging tasks.

Low Packaging Expenses

Low Packaging Expenses- Picture courtesy: CPHI online

Many people say that a pharmaceutical cartoning machine is quite an investment. However, do you know that this equipment justifies its cost in the long run? For instance, owing to its automation, it performs the job of many laborers. This means that you can replace workers with this machine and save a significant number of payments every year.

Protective Role

Protective Role- Picture Courtesy: Korber Pharma

Unboxed products have more chance of spoilage, damage, and theft than boxed ones. Therefore, a pharmaceutical cartoning machine protects the products by cartoning them. In this way, you’re ensured that your product will reach customers safe and sound.

It will not have any kind of contamination, tampering, dampness, denting, or scratching on arriving at its destination.

3.What is the structural design of a pharmaceutical cartoning machine?

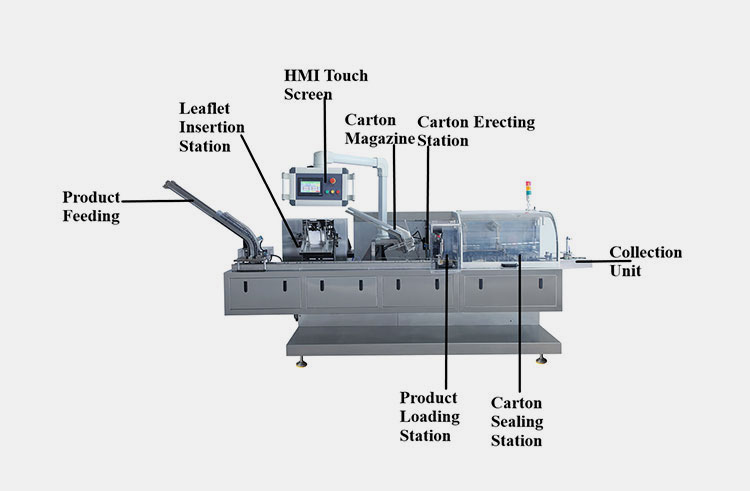

Knowledge about the structural design of a pharmaceutical cartoning machine is a must to resolve any trouble that arises later on in the equipment. Hence, for your information, we’re penning some basic parts of this machine in the section below:

Parts of the AIPAK Pharmaceutical Cartoning Machine

| Product Feeding Station | You’ll find this station at the front end of a pharmaceutical cartoning machine. And it is where products are first loaded on the machine. |

| Leaflet Insertion Unit | Leaflets are the instruction manual for effectively using the product. These leaflets are placed on the products via a leaflet insertion unit. Mechanical arms are present at this part which continuously put the leaflets for packaging. It saves you from the trouble of manually filling the boxes. |

| HMI Touch Screen | It is an intuitive touchscreen by which you can control the whole cartoning process. You can modify parameters by changing the machine setting shown on the interface. Moreover, you can also examine the progress of the packaging process and troubleshoot this machine in case of failure. |

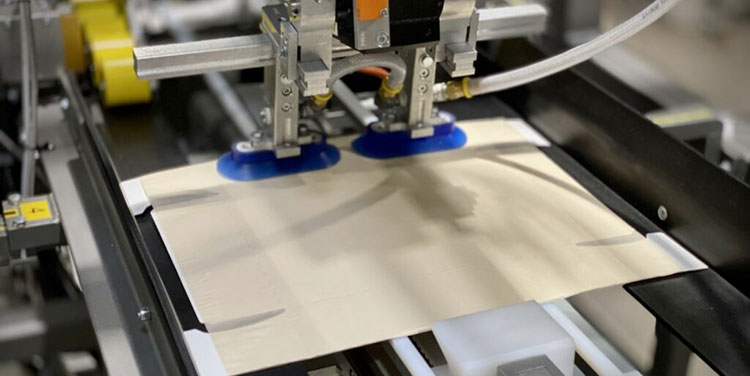

| Carton Magazine | You’ll store the stacks of flat carton sheets in the carton magazine. Afterward, the gripper picks these sheets one by one and transfers them to the carton erecting unit. |

| Carton Erecting Station | This station is the component that changes a flat sheet into an erected carton. It does so by folding the flaps and tucking the sides. |

| Product Loading Station | The products should be safely closed in their boxes for ultimate production. This part of the equipment quickly and efficiently inserts the products inside the cartons. Hence, by this, you’re assuring your customers that products are of great quality. |

| Carton Sealing Station | Cartons are securely sealed and it only happens with the help of a carton sealing station. It makes airtight and protected sealing by gluing carton sides or tucking in the flaps. Sometimes, it also applies tamper-evident tapes on your packed cartons to ensure that they are not tampered with in any shape or form. |

| Packed Carton Collection Unit | Now well-packed cartons are led towards the discharging point present at the other end of the equipment. The end cartons are collected at this unit from where you can easily pick them up and move them to the storage area. |

4.What are the operating steps of a pharmaceutical cartoning machine?

Besides learning about parts of a pharmaceutical cartoning machine, experts recommended that you must have a full understanding of the working steps of this machine. Do you want to know why?

After getting all the information about this cartoning machine, you will be able to effectively handle and operate your machine. For this, you’re invited to read the below section.

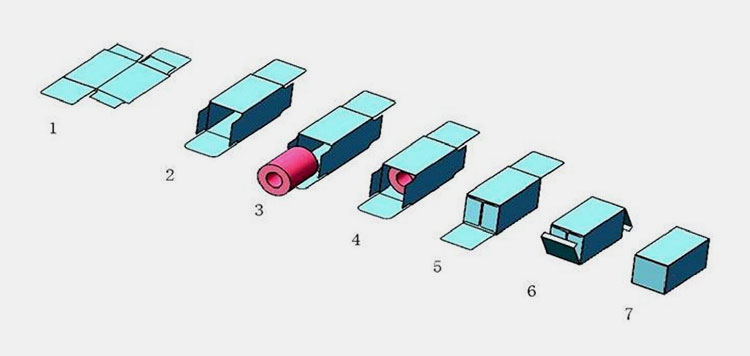

Working Step of Pharmaceutical Cartoning Machine

| Step: 1 Carton Blank Positioning | Before starting the operation, you must place a stack of blank carton sheets in the carton magazine. At the same time, the products are deposited on the cartoning conveyor either by interconnected machines or the operators. |

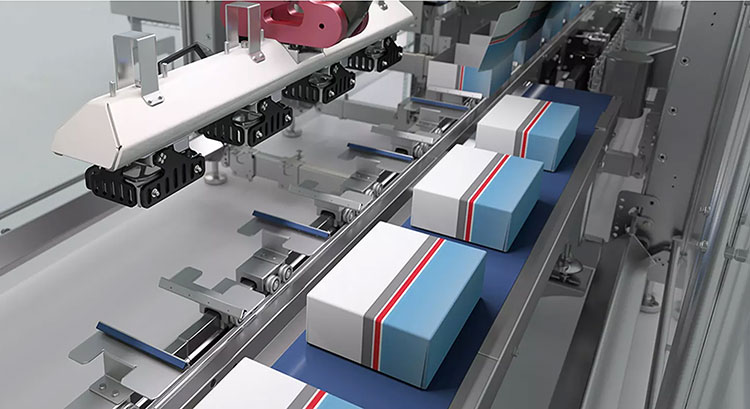

| Step 2: Carton Assembly | At this stage, you’ll observe a transformation of pre-cut flat sheets into sturdy and usable cartons. The machine shapes the flat materials into three-dimensional upright cartons by folding their flaps. Their one flap end is left open to insert the product. |

| Step 3: Carton and Product Feeding | Now, you can see the products automatically moving along the machine conveyor. Whereas blank cartons are gripped by mechanical arms using vacuum suction cups and are transferred to cartons erecting one by one for box production. |

| Step 4: Product Positioning | Now that boxes are ready for packaging, your products are placed one by one into the formed carton. Normally, depending upon the equipment type, you’ll perform this step manually or the machine will carry out this stage using a servo-driven inserter. The product dispensation can occur either from the top, side, or end. |

| Step 5: Carton Flipping | The folding of the carton edges takes place to form a proper shape for further processing. |

| Step 6: Carton Sealing | Once the products are loaded, it’s time to close the cartons. This stage is proceeded with the assistance of a flap tucker or glue applicator. Flap tucker automatically tucks the open flap. Or top glue is applied on the box to firmly close them. This process ensures that your products are completely safe from any kind of damage. |

| Step 7: Carton Discharging | Finally, in the end, you’ll notice that sealed cartons that meet quality standards checks are moving to the discharge unit, from where they are gathered manually or transferred via conveyor to subsequent packaging machines. |

5.Do you know the application spectrum of a pharmaceutical cartoning machine in other industries?

Cartons are major packaging materials for storing and transporting products. As a result, you’ll realize that a pharmaceutical cartoning machine is indispensable in every manufacturing sector. Some of the major applications of this machine are penned below:

Pharmaceutical Industry

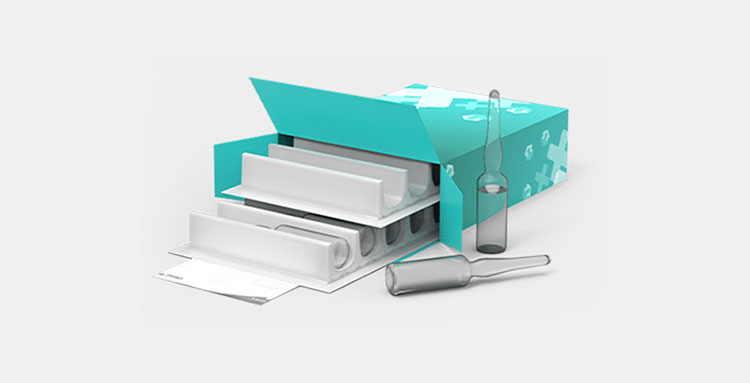

Pharmaceutical Industry

There are stacks upon stacks of pharmaceutical cartons on the shelves of pharmacies. And this is possible due to a pharmaceutical cartoning machine. It inserts various kinds of syringes, creams, blister packs, ampoules, vials, bottles, and many more in sturdy boxes. This machine is quite valuable in this sector because of its accuracy and efficiency. With this machine, you can deliver top-quality medicinal items to the market.

Food Industry

Food Industry

You've probably gotten your favorite cereal in a box, right? Ever thought about how these cereals, tea bags, coffee pods, chocolate bars, bottled drinks, and other snacks get into carton boxes? These are packed hygienically in boxes with a pharmaceutical cartoning machine. For food applications, this machine comes with food-grade components to avoid contamination risks.

Cosmetic Industry

Cosmetic Industry

In the cosmetic section of your grocery store or boutique, you’ll be attracted by all shapes and forms of cartons. These shiny, sparkly, chic, or luxurious boxes that created by a pharmaceutical cartoning machine. With this machine, cosmetic brands boost their brand image which appeals to a large customer base.

Medical and Health Care Industry

Medical and Health Care Industry

You can’t ignore the importance of carton boxes in the medical industry. By packaging diverse medical products in boxes, you’re assuring your clients the purity of products. And yes, the pharmaceutical industry is quite popular in the medical sector due to its role in sterile box packaging. It works in contamination-free environments to comply with strict regulations associated with healthcare manufacturing.

Electronic Industry

Electronic Industry

As you are probably aware electric products are very fragile and could get broken if left unpacked during their transportation and retailing. Hence, electronic manufacturers make use of a pharmaceutical cartoning machine to dispense their products in theft-proof boxes. And ensure the protection of their products all the way to their patrons.

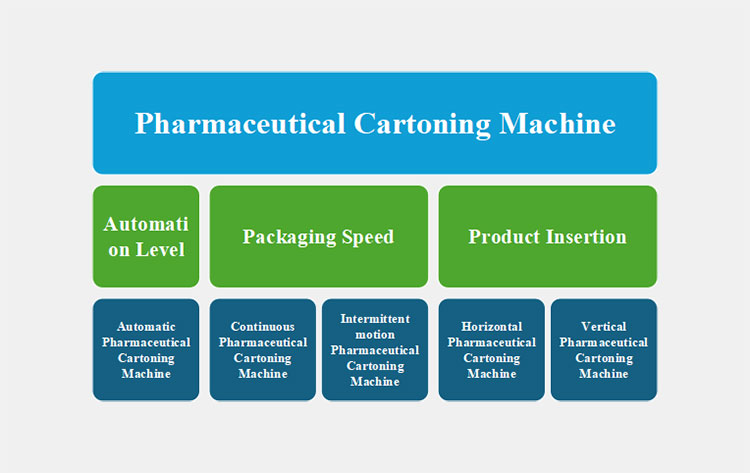

6.What are the primary categories of a pharmaceutical cartoning machine?

You’ll see a bunch of categories of a pharmaceutical cartoning machine in the market. This equipment is not only classified on the level of automation, but you may discover its different models based on packaging speed and product placement process.

So, let’s have an insight into diverse kinds of a pharmaceutical cartoning machine:

According to Automation Level

Automatic Pharmaceutical Cartoning Machine

Automatic pharmaceutical cartoning machine doesn’t require too much human assistance. It is connected to other packaging machines via conveyors that make product loading and carton ejection to next-in-line instruments very easy.

From carton feeding to carton sealing, every step in between is swiftly performed by this device, and thus it is capable of delivering large orders.

According to Packaging Speed

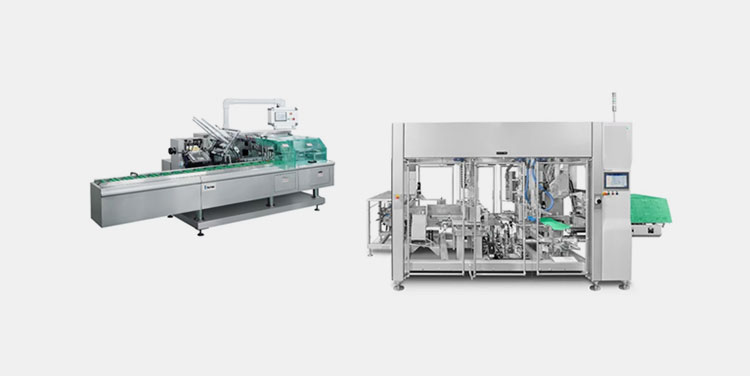

Continuous Pharmaceutical Cartoning Machine

Continuous Pharmaceutical Cartoning Machine- Picture Courtesy: Merchesini

It is a high-speed machine. Why? Simply it works without stopping. It moves cartons and products throughout the device without taking any breaks. It has in-sync carton-picking systems, product-feeding components, and conveyors.

However, it is not suited for processing products with differing sizes.

Intermittent Motion Pharmaceutical Cartoning Machine

Intermittent Motion Pharmaceutical Cartoning Machine- Picture Courtesy: Gloex

It operates more slowly. Because it runs in a step-by-step manner. It shortly stops at each step to completely execute it and then proceed to the next stage. This machine is more compatible with medium-sized productions.

Although it has moderate cartoning speed still it is well-received by numerous manufacturers due to its potential to handle products of varied shapes and sizes.

According to Product Insertion

Horizontal Pharmaceutical Cartoning Machine

Horizontal Pharmaceutical Cartoning Machine

You would have also known horizontal pharmaceutical cartoning machine by another name- end-load cartoner. It is named in this way because it pushes or inserts one or many products horizontally into an erected carton through an open side end. Usually, you use pre-formed cartons with this machine.

It has less packaging speed than its counterpart but easily handles products of irregular shapes. It packs tubes, sachets, blisters, and strip packs.

Vertical Pharmaceutical Cartoning Machine

Vertical Pharmaceutical Cartoning Machine

As the name suggests, this machine fills products in a vertical orientation. Normally, the products are placed from the top and then cartons are secured. It is more suited to the packaging of delicate products with consistent sizes and sizes.

With this machine, you can fill jars, pouches, cans, and bottles. It comes with a small conveying system. It packs products at relatively high speeds and thus is excellent for your high-speed productions.

7.What types of products can be packed by a pharmaceutical cartoning machine?

Carton boxes are beautifully and precisely arranged on the aisles. But have you ever been curious how they get that way? It is all because of a pharmaceutical cartoning machine. It packs all kinds of items under the sun. So, let’s have an insight about these diverse product groups.

Blister Packs

Blister Packs

There are numerous types of pharmaceuticals that you can load in blister packs, for instance, tablets, capsules, softgel, oral disintegration films, and others. All these blisters are inserted into cartons by a pharmaceutical cartoning machine for ease of dispensing and accounting.

Bottle

Bottles

You surely would have bought many medicinal bottles in cartons. A pharmaceutical cartoning machine is highly sought after in the pharmaceutical industry for its box packaging that keeps the bottles of eyedrops, nasal sprays, inhalers, liquid syrups, supplement containers, and, gastric emulsions from breakage and leakage.

Ampoules

Ampoules- Picture courtesy: Halcon Packaging

A pharmaceutical cartoning machine offers ampoules, lyophilized vials, vaccine vials, and other injectable drugs in hygienic sterile packaging to your customers. Also, you can include a combination of these products in one carton like a vial, syringe, and leaflet.

Sachets

Sachets

The different types of medicinal sachets, for instance, oral rehydration salt, powdered medications, single-use creams, etc are also filled in cartons. This is a sure way to stop the spoilage of contents by humidity and contamination. These cartons are popular because they support both unit-dose and bulk packaging.

Tubes & Ontinments

Tubes & Ontinments

You may also dispense your tubes, like topical creams, ointments, gels, toothpaste, pastes, and oral care products in boxes via a pharmaceutical cartoning machine. This helps to avert the deformation of tubes and allows pharmacists to easily stack boxes on shelves.

Medical Devices

Safe And Sound Health

Different kinds of syringes, insulin pens, test strips, diagnostic kits, marks, bandages, dressings, gloves, and other medical items are loaded in cartons for safe transportation and retailing display, A pharmaceutical cartoning machine also put accessory items like an instruction manual and alcohol swab in these medical cartons.

8.Do you know the difference between a pharmaceutical cartoning machine and a case packaging machine?

Both pharmaceutical cartoning machine and case packaging machine are included in the category of packaging instruments, but they serve vastly varying functions. To clear any confusion between these two pieces of equipment, here are some of the main differences between them:

Pharmaceutical Cartoning Machine and A Case Packaging Machine- Picture Courtesy: Eliter Packaging and Syntegon

| Features | Pharmaceutical Cartoning Machine | Case Packaging Machine |

| Definition | You will probably know that this equipment is designed to create, fill, and seal various carton boxes. | This machine places numerous cartons or bulk products into bigger and sturdy corrugated shipping containers or crafts. |

| Packaging Level | It is usually included under the category of primary or secondary packaging machine. | It is mostly categorized in the class of secondary or tertiary packaging equipment. |

| Products | It packs a variety of pharmaceutical items, such as blisters, ampoules, syringes, sachets, etc. | It packages shipping trays or cartons. |

| Printing/ Labeling | With this machine, you can print batch or serialization numbers on cartons. | You can label cases with tracking labels with this device. |

| Closing | It has various closing approaches, like glue, tuck-in, and tamper-proof tape. | It mostly performs strap sealing on shipment boxes. |

9.What are the major challenges you face with a pharmaceutical cartoning machine? How to deal with them?

Many things could go wrong with a pharmaceutical cartoning machine. These disturbances not only halt production but are also a source of serious concern for manufacturers.

However, rest assured, you can easily resolve these problems with some training and guidance. To aid you in this quest, we’re detailing some major issues in a pharmaceutical cartoning machine and how to deal with them.

Difficulty in forming cartons

There could be several reasons behind this issue, for instance, cartons are not correctly placed on the magazine or vacuum pressure is not sufficient to pick cartons.

Remedy

This issue is easily fixed by first examining the settings of alignment sensors. If not, then set them accurately to have proper carton feeding. Secondly, you could check the vacuum pressure inputs and adjust them accordingly.

Jamming of Carton Boxes

Jamming of cartons

It is a main concern when you’re operating equipment at higher speeds. The cartons are jammed on the conveyor or at the folding stage. And this will put a pause on the entire production. The major causes of this problem are associated with the thickness or hardness of the carton. Sometimes, the presence of foreign objects on a conveyor or damaged mechanical part also hinders cartons from moving smoothly on the machine.

Remedy

First and foremost, you should select the carton material with great consideration. It should have a moderate thickness so that it will be compatible with machine parts. Also, make it part of your routine to check parts for wear and tear. Clean and lubricate them, especially moving components like conveyors and robotic arms.

Carton Sealing Malfunctions

Carton sealing malfunction

Have you ever seen an improperly closed carton? This will lead to box content falling out. It completely destroys the product quality. This issue arises when there are temperature fluctuations in glue applicators and also because of the inexpensive adhesive or jamming of the glue spraying nozzle.

Remedy

To fix this error, you should check the temperature of the gluing component and ensure that it is not either too high or too low. Use the glues or adhesives that bond with higher binding strength to your carton sheets. And finally, always keep an eye on glue-spraying guns and clean them daily. Because with repeated use that might get clogged.

Products are not Moving Smoothly

Products are not Moving Smoothly- Picture courtesy: Rotzinger group

During cartoning, product feeding into the carton is a vital step. If it is off, then you’ll observe the jamming of products on the conveyor or they’re skipping the cartons entirely. This trouble can stem from malfunctions in product loading, variations in product sizes, or issues in sensors.

Remedy

You must begin by thoroughly checking the product feeding system. First, you should ensure there is no hindrance on a conveyor. And there is no malfunctioning in the operation of the chute. After that, tweak the feeder to accommodate any unusual-shaped products. If sensors are acting abnormally, then you should identify the defect and calibrate them in a timely manner.

Carton Folding Irregularities

Carton Folding Irregularities- Picture Courtesy: Wayne Automation

Sometimes, it happens that the carton gets improperly folded, which messes up its whole appeal. Rarely you’ll note that carton boxes are crushed during erecting or folding. This issue typically occurs because of improper alignment of guide rails or material having an inaccurate thickness, which impacts its folding by machine components.

Remedy

This issue is easily rectified by frequent calibration of guide rails. You should align them on a regular basis so that they will match the dimensions of cartons. Also, you should choose a carton material of suitable thickness. It is essential to modify folding pressure so that your cartons don’t get crushed or have poor folding arrangements.

10.What are the important quality standards that a pharmaceutical cartoning machine should be compliant with?

Quality Standards Of Pharmaceutical Cartoning Machine- Picture courtesy: News-Medical

A pharmaceutical cartoning machine must produce standard goods in order to win customer trust and prevent the risk of product rejection. Therefore, it must abide by strict quality protocols. Some of these quality standards are written below for your information:

| Good Manufacturing Practices

|

This standard is vital for sterile and clean packaging without any contamination. You’ll have to properly document and validate each step in a pharmaceutical cartoning machine. It is necessary to clean and maintain the machine on a daily basis to earn this certification. By doing this, you’ll ensure your customers about the safety and quality of your supplies. |

| FDA 21 CFR Part 11

|

This quality standard is essential for the safety and security of your machine. It prevents unauthorized tampering with digital controls, such as unpermitted changes in program settings. You can adhere to this standard by auditing every action on the machine and implementing user authentication controls on HMI. |

| CE Marking

|

If you’re selling or buying a pharmaceutical cartoning machine in the European Market, then your machine should have this CE marking. With this certification, you are certain that the machine fulfills every safety, health, and, environmental regulation in Europe. |

| ISO 9001:2015

|

If your potential machine meets ISO 9001:2015 quality standards then it is safe to say that it is manufactured according to quality guidelines. Manufacturers conform to this quality standard by adhering to standardized manufacturing protocols and performing routine quality inspections and auditing. |

11.What should be important factors before deciding on a pharmaceutical cartoning machine?

As you are probably aware investing in a pharmaceutical cartoning machine requires a huge capital. Usually, you when buy it you want it to serve for numerous decades. To ensure a long-term operation, you should consider several aspects before making your decision.

So, let’s discuss some major factors that should be at the forefront of your mind when buying this machine:

Type of Product

Types of products- Picture courtesy: Tishma Technology

It is pertinent that you should take into account the type of product you’re packaging. Like you’re boxing ampoules, blisters, or vials. The nature of products (shape, size, fragility, and quantity) helps you to decide whether to buy a horizontal type or vertical kind of pharmaceutical cartoning machine.

Machine Speed

Rotary pharmaceutical cartoning machine

Another factor that makes or breaks your operation is machine speed. Hence, before buying, you must ask your vendor how quickly the machine boxes and what is its working capacity per day. if looking for more precision, select linear pharmaceutical cartoning machine, for more production go for rotary cartoning machine.

Type of Sealing

Type of Sealing- Picture Courtesy: Korber

You’ll notice that there is a wide range of sealing methods for cartons from glue to tuck, from tape or stable in the pharmaceutical cartoning machine. This selection decision usually depends on your liking. For example, glues are more durable and tamperproof, whereas tuck-in flaps are a simple sealing method and very cost-effective for smaller and lightweight cartons.

Conclusion

A pharmaceutical cartoning machine has a central place in pharmaceutical industries because of its fast-processing speed and its effect on product stability. With this tool, you can safely, precisely, and, smoothly store your products in boxes. It creates an attractive product display without compromising the quality of inner content in any way. Hopefully, after reading this guide, you’ll be well-versed in all aspects of a pharmaceutical cartoning machine. Are you still undecided about which type of cartoner to buy? Then, we invite you to contact our customer care. Because we, AIPAK will guide you in picking the perfect equipment for your facilities.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours