Pharmaceutical Carton Design: The Complete FAQ Guide In 2025

When you walk into the pharmacy, your eyes draw to a particular box on the pharmacy shelf. You need pharmaceutical products for relief, healing and recovery but you faced multiple choices with same benefits in the pharmacy, which one will you choose? Of course the carton that has clear readability, eye-catchy and durability. And this can only be possible by pharmaceutical carton design. Just like the well packed and elegant cosmetic looks premium, clean and clear pharmaceutical carton design grab the attention of buyer.

Before the patient reads leaflet and taking pharmaceutical products, their trust developed by the design of pharmaceutical carton has. An attractive carton not only pack your products but also increasing your customers trust. But how pharmaceutical cartons design? How to make great pharmaceutical carton? Let’s discover the elements that help in understanding pharmaceutical carton design that can build the trust of your customers so let’s start!

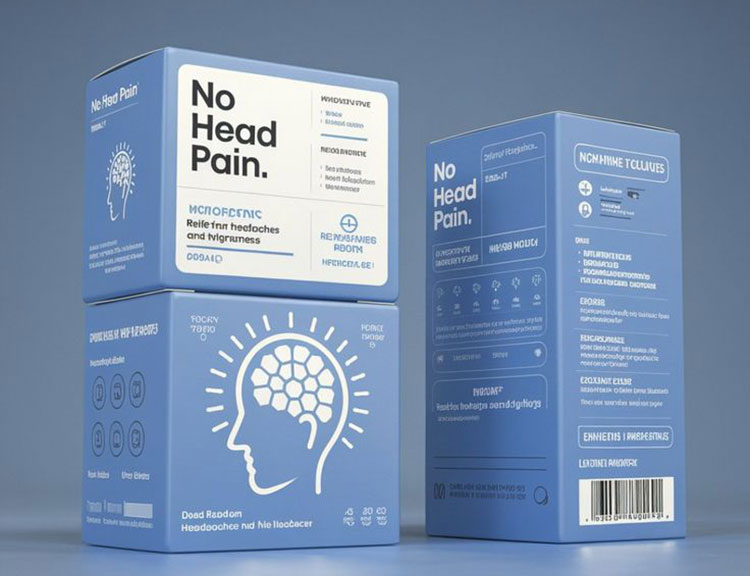

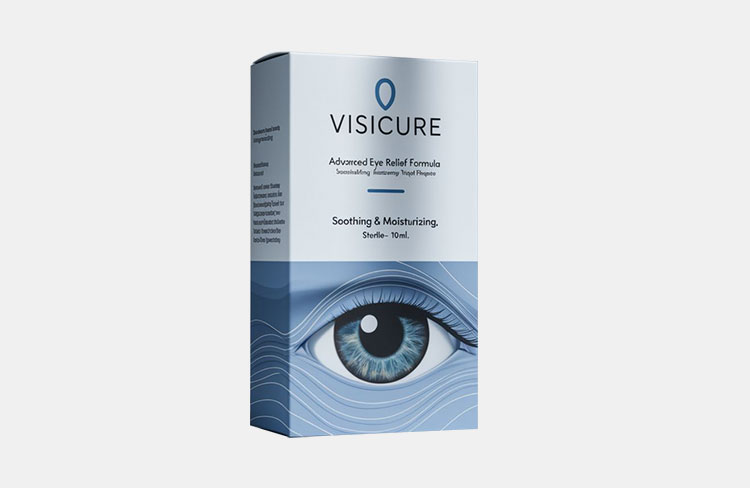

1.What is pharmaceutical carton design?

Pharmaceutical carton design

Pharmaceutical carton design refers to the process of creation and packaging of pharmaceutical and healthcare products, in the form of boxes or cartons. These cartons accommodate and protect healthcare products and medical instruments. They have labelling about the product like drug name, its ingredients, QR code and safety warnings.

The pharmaceutical carton design not only care about the safety of patients but also protecting the product from external factors like contamination and moisture etc. And also to use sustainable materials in cartons make the planet safe for the people as well as for other creation in the world. The unique carton design make a brand widely-recognizable.

2.What are the benefits of pharmaceutical cartons design?

You often go to pharmacy and wondered how beautifully the products are protected in these cartons! It’s not just a box, it’s the customers cure, safety and appealing to them. Let’s explore more benefits of pharmaceutical carton design!

Safeguard the healthcare products

Safeguard the healthcare products

The main objective of pharmaceutical industries and companies is patient health, care, safety and their happiness. The healthcare products are properly sealed so, whenever your customers will buy drugs, they’ll always look for a sealed one. This will ensure their safety.

You also know that some of the products in pharmacies are also very sensitive either it is to the shock or heat. So, pharmaceutical cartons are designed in a unique way. During shipping, they remain protected from shock and external heat and you can shipped your desired product in a safe way.

Clear and accurate information

Clear and accurate information

Clear and accurate information plays an important role in pharmaceutical carton design. Whenever you purchase the medicine or other medical equipment, the first thing you do is reading the information printed on the boxes. The pharmaceutical cartons has cleared instructions regarding the product inside them.

For example, the dosage of product is clearly mentioned (4ml, 500mg). Dosage instructions like take with food, warnings like keep out of reach of children, and also have expiratory date and batch mark. In this way, it ensures the consumer safety.

Traceability

Tracing of medicine- Picture courtesy: Opuspac.com

You can easily trace the information regarding the product. Pharmaceutical carton have printed bar codes and QR codes which allow the users to collect information of the product. And also it allows you to trace your items to ensure that your products reached to your desired destination. In this way, the cartons provide trust to everyone due to transparency and accountability.

Sustainability

Sustainability

Everyone wants to live healthy lifestyle in healthy environment. It can be possible by using environment-friendly cartons. But some people wondering how can it be possible? It is of primary concern of pharmaceutical industries to protect the products and also to protect the planet.

Pharmaceutical carton designs can protect both product as well as the environment where you live. It can use environment-friendly material instead of plastics.

It also used less materials without compromising the quality of the product which can reduce the weight of the packaging. In this way, it can reduce the usage of fuel during transportation of your medicinal and pharmaceutical products.

Multi-compartment design

Multi-Compartment design

Are you looking for the carton design which has many separate sections because you are on strict follow-up treatment? You have this option available as well. Pharmaceutical industries can also design multi-compartment boxes or cartons. The purpose of creation of such kind of design is to take right medicine on the right day if your customers are using several medicine in a day. In this way, they’ll not mix-up the medicines and reduce their anxiety.

Box with labelled day and time

The boxes are designed in such a manner that it divided into different sections and each section is labelled with day and time (morning, afternoon and night). Your customers can now use their medication without worrying to mix-up.

Branding and marketing

Branding and marketing-Picture courtesy: medd-design.com

Everyone wants to care about their products safety as well as wants to gaining trust of their customers. Many pharmaceutical industries make carton designs in a unique way. You need to design boxes of drug in such a manner that it has eye-catchy visual aids, QR code, proper layout, dosage, proper instruction, quantity and proper sealing of cartons.

In this way, you can grab the attention of customers by ensuring their safety. A strong brand creates a sense of professionalism so, you must have to design the cartons in a unique and proper way.

3.What are the types of pharmaceutical carton design?

You often visit pharmacy and look at the shelf. Are the medicine boxes look the same? Recall your previous visit to pharmacy, didn’t the boxes different? You must also noticed the diversity of medicinal and medical items over there, encased in different styled boxes. Thanks to pharmaceutical carton design that created boxes appealing to the consumers. Let’s talk about various cartons that you encountered with!

Straight Tuck-End Carton

Straight tuck-end carton

You come across the packaging in which top and bottom flaps fold in the same direction. Do you know why is it designed in this way? Because this type of cartons looks neat, clean and simple to make. It also provide convenience in opening and closing of the box. You must be thinking about its holding strength. So, let me tell you it is perfectly designed for lightweight items such as sachets, blister packs and tablets.

Reversed tuck end carton

Reversed tuck-end carton

You must came across the cartons in which the top and bottom flap folded in the opposite direction to each other. Did you ever think, what the purpose of this type of packaging? This design is easy to pack the products inside the box and is economical. And this carton is suitable for small bottles and blister strips.

Auto-lock bottom carton

Auto lock bottom carton-Picture courtesy: bulbapp.com

You noticed that the bottom of some of the box automatically closed by own. This is auto lock bottom carton. It doesn’t need your effort to fold it. Instead it automatically come to its position if you try to open it.

The bottom of carton is strong enough to carry heavy items like tubes of ointment and syrup bottles.

Sleeve carton

Sleeve carton-Picture courtesy: Fastprinting.com

You encountered a beautifully designed packaging which is not a full box, instead it is a sleeve that slides over another compartment, tray or container. You must be thinking what is the purpose for designing such carton? Well, the main purpose is not to carry the product directly, instead it is used for eye-catching, aesthetic and for good presentation of items. You can pack trial kits in sleeve cartons, which looked appealing and more organized.

Window carton

Window carton

You often visit pharmacy and your eyes remain on the packaging in which the product is visible. You must have thought in your mind, why other products are not having this type of packaging? Window carton is designed in which transparent sheet cover the product. The main objective is customer satisfaction about the product. It can build your trust and you can view the product without opening it.

Partitioned or compartment carton

Partitioned carton-Picture courtesy: Webscientific.com

This carton has multiple sections or compartments, suitable for organizing multiple items in a single carton. It is perfect for multi-dose packs. The benefit you can get from this carton is that you’ll find your items organize in it.

Child resistant carton

Child-resistant carton-Picture courtesy: Webpackaging.com

Some of the products are harmful for children. What if they accidently touched them or swallowed them? For this purpose, pharmaceutical industries design a carton that has locking featured or it has proper way of opening it. This ensures the safety of your children.

Temper- resistant carton

Temper-resistant carton-Picture courtesy: Weber-marking.com

Everyone want a sealed medicine, tubes or blister packs. Temper-resistant carton is designed in such a manner that if someone has tried to open it then you’ll know about it. The carton may have tear glue or perforation when tempered with. It is used for most regulated pharmaceutical products to ensure its safety.

4.How pharmaceutical cartons design are manufactured?

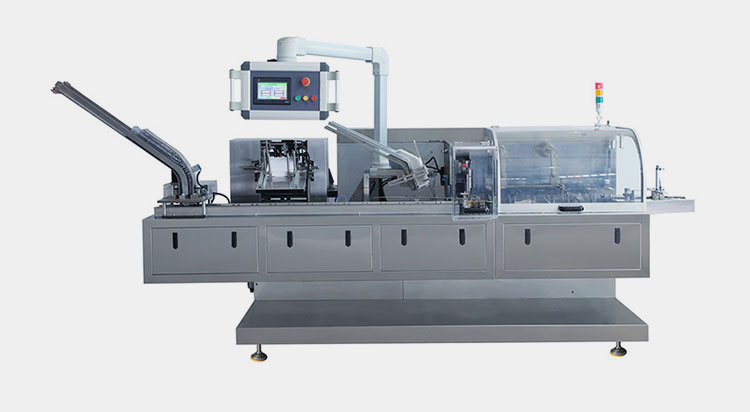

Synthesis of pharmaceutical carton design

For the synthesis of pharmaceutical carton design, you can use pharmaceutical cartoning machine. There are different types of cartoning machines are available but the working principle is almost same for everyone. Let’s start to explore how these machines manufactured pharmaceutical carton design:

| Feeding of blank flat carton into the machine | In the first step, you have to put stack of flat blank carton into the carton magazine. Carton magazine automatically eliminate pre-cut or damaged carton and the smooth and un-damaged cartons are transferred for carton production. |

| Carton erection | In the second step, these flat cartons will lift by grippers in the suction pump and convert them into 3-Dimension upright cartons by folding the flaps. The one side of carton will sealed by glue while the other one remains open for product insertion.

The carton transport lugs can ensure that every carton is completely sealed, if the sealing is open then it will stop the machine. This ensures that the carton is in intact position and ready for encapsulating the product. |

| Product and leaflet insertion | Once the cartons are ready for product packaging, you need to perform this job manually by placing the carton for product insertion or may be automatically perform by machine. This task depends upon the type of machine you are using.

The placing of products might be from side and top, depends upon the machine you are using. At the same time leaflet is also inserted into the carton. |

| Carton flipping and sealing | Then the flipping of carton occur and then will seal the carton either by glue, locking mechanism or tape sealing. This will ensure the safety of your product and for resonating and enhancing popularity of your products in the market. |

| Carton discharging and storage | In the final step, the machine will discharge the desired product and its box outside the machine. Now, you can collect and store it. The stored cartons are now ready for transportation and your products are ready to impress and satisfy the consumers. |

5.What are the machines used for manufacturing of pharmaceutical carton design?

For the manufacturing of pharmaceutical carton design, modern technology has revolutionized the world. Various machines used for manufacturing appealing boxes for your products are as follows:

Based on the automation

Some machines perform and handle the whole manufacturing process by self. According to the automation, the main machine used for pharmaceutical cartooning design is as follows:

Automatic pharmaceutical cartoning machine

AIPAK automatic pharmaceutical cartoning machine

If you doesn’t want an operator to operate the function then you have to go for automatic cartoning machine. This machine able to perform each and every step by itself. You will get your desired boxes in less time.

The benefit of this machine is the production of huge packaging in short time and is human-error free.

Based on the speed of packaging

Some machine package materials continuously without stopping and others package the items in stop-go manner. According to the speed of packaging, they are divided into two categories:

Continuous pharmaceutical cartoning machine

Continuous pharmaceutical cartoning machine- Picture courtesy: Linermachinery

Continuous pharmaceutical cartoning machine works in continuous manner. It doesn’t require break between various steps occurring in the machine. From flat carton insertion to final sealing and discharging of boxes occur in non-stop manner.

Intermittent pharmaceutical cartoning machine

Intermittent cartoning machine-Picture Courtesy: utmostusa

Intermittent pharmaceutical cartoning machine work in sequential manner or you can say, it stops at every step to ensure every step is carefully handle. It works best for all sized cartons.

According to product insertion into the cartons

Products can be inserted into the cartons according to their shape. In some machines, products are inserted from sidewise while others from the top into the cartons. Based on product insertion into the cartons, they are categorized into two main types:

Horizontal pharmaceutical cartoning machine

AIPAK horizontal pharmaceutical cartoning machine

In horizontal pharmaceutical cartoning machine, products are inserted horizontally into the cartons. The carton may wrap around the product or may encased the product in U-shaped packaging or you can say, it manufactures sleeve-type cartons to ensure the visibility of the products.

It is also suitable for irregular shaped products like vials.

Vertical pharmaceutical cartoning machine

Vertical pharmaceutical cartoning machine- Picture courtesy: saintyco

In vertical pharmaceutical cartoning machine, carton remain stationary and the products are inserted into the cartons vertically.

This machine is suitable for packaging of tubes and blister packs. It also suitable for irregular shaped products like vials.

6.What materials can be used in pharmaceutical carton design?

For the designing of pharmaceutical cartons, various materials used for the packaging. They are as follows:

Paper board ( Folding Box Board )

Folding box board

Paper board is thick material used for packaging of pharmaceutical items. It is made up of virgin bleached wood pulp so, 100% plant- derived paper is used in this packaging. The front side is of off-white color and inner is also uncoated white color. When tear it, you will see the pulp as a light yellow in color.

For pharmaceutical items, its cleanliness is the major concern. As paperboard has high purity and cleanliness, so it makes it a good option for packaging and designing of pharmaceutical apparatus. Due to its production from nature, it is also eco-friendly.

Due to its lightweight and flexible nature, you can easily cut and fold it and make design of your respected value. It is less-suitable for high quality printing so it can be coated to enhance the printing quality.

Solid bleached sulfate paperboard

Solid bleached sulfated paperboard

It is made from 100% plant wood pulp so excellent choice for your product as well as for the nature. You must come across white color of carton, which is bright milky white on both sides. That is solid bleached sulfate paperboard carton.

When you touched such carton, it gives you smooth sensation and this property makes is superior for sharp graphics, visual aids and good quality printing.

This carton is mostly used in blister pack outer boxes, medical device packaging and diagnostic kit cartons in pharmaceutical industries.

Kraft paperboard

Kraft paperboard

Kraft paperboard is also formed from wood pulp. The layers of wood pulp are compressed by Kraft process and result into strong and compact carton. It is available in both unbleached (brown) and bleached (white) form. You must be confused about the difference between Kraft paperboard and other paperboard.

Well, it is also paperboard but is stronger than other paperboard. Due to this property, it is used for bulk medicines or in shipping boxes for pharmacies. For better printing, this carton is coated and results in gloss finish and water resistant.

Clay-coated paperboard

Clay-coated paperboard

Clay coated paper is made from recyclable components so it is 100% recyclable. The front side is coated and appears white in color. The back layer is uncoated and appears grey or brown in color. When tear it, you’ll see grey or brown color pulp. Due to its plant derived components, it is recyclable carton. Due to its coating, the outer layer appears smooth and suitable for high quality printing. The carton is rigid and suitable for cutting and folding. These cartons are available in various thickness so suitable for different sized and weight materials.

Black ply special paper

Black-ply special paper- Picture courtesy: Unicopacking.com

It is also made from wood pulp which is 100% recyclable. The outer covering is coated black in color while the inner is uncoated greyish black in color. This make such carton aesthetic appealing to the consumers. Due to its rigidity, it can be cut and fold into customized boxes. It support embossing which is suitable for luxury pharmaceutical gifts like skincare and anti-aging products.

Corrugated cardboard

Corrugated cardboard-Picture courtesy: Holidaypac.com

Corrugated cardboard is multilayered packaging design. The outer layer is smooth, the middle layer is corrugated (wavy) and the inner layer is also flat and smooth. The sandwiching of corrugated layer between two flat surfaces has also an aim. The aim of wavy layer is absorb the shock during the packaging of product or during shipping. You can easily cut, fold and can make various carton designs. It is suitable for shipping of bulk drug containers.

7.What is the usage of pharmaceutical carton design in various industries?

The carton designs used in pharmaceutical industries are very flexible so they can be cut, fold and mold into customized designs. Due to its flexible ability, many industries get benefit from it. Some of the industries that use pharmaceutical carton designs are as follows:

Food and beverage industry:

Food and beverage industry

Food and beverage safety is major concern of everyone. Food industry pack snacks, chocolates and many other food with specially designed cartons for your food safety. The introduction of vibrant colors, visual aids and logos make them appealing for your customers.

If you are transporting glass beverage, then you must have to use strong and durable carton to ensure its safety.

Partitioned cartons are used for powders and teas. You can also use plastic material for carton designing for food and beverage packaging but make sure to use sustainable and eco-friendly plastic material.

Hospitality industry:

Hospitality industry

The hospitality industry manufacture various types of items like food (snacks), guest kits, washroom items and hygienic items. By designing different cartons for packaging of these items, by customization of packaging with colorful color and logos increase your product rate in market. Due to compact packaging, it ensures its safety and premium presentation.

Multi-compartment cartons are used for various baby kit products etc. Sleeve style cartons are used for coffee or tea kits.

Cosmetic and personal care industry:

Cosmetic industry

Cosmetic and personal care industry package skincare products, makeup kits, makeup brushes, fragrances, hair care, brushes and many more in various cartons. They provide safety for such delicate objects. Beside its safety, the aesthetic and eye-catchy visual aids and full detail of the product on the cartons make them in-demand for customers in the market.

Window cartons are typically used in skincare products and compact cartons are used for the packaging of perfumes.

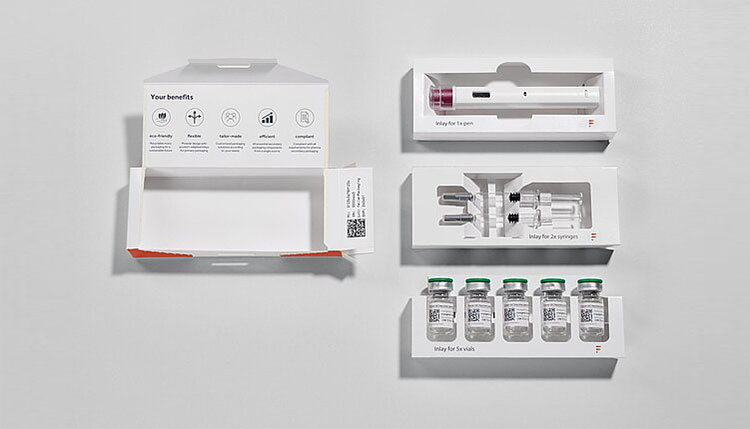

Pharmaceutical and medical industry:

Pharmaceutical and medical industry-Picture courtesy: Faller-packaging.com

Pharmaceutical and medical industry package medicines, blister pack, syringes, vaccines and operation devices in various cartons. The visual aids, traceability, and proper instruction on the cartons gain your customer trust and their safety.

The child-resistant cartons make sure that child are safe and away from medicines. Compartment carton is used for packaging of vials and many more carton designs are used for packaging of pharmaceutical items.

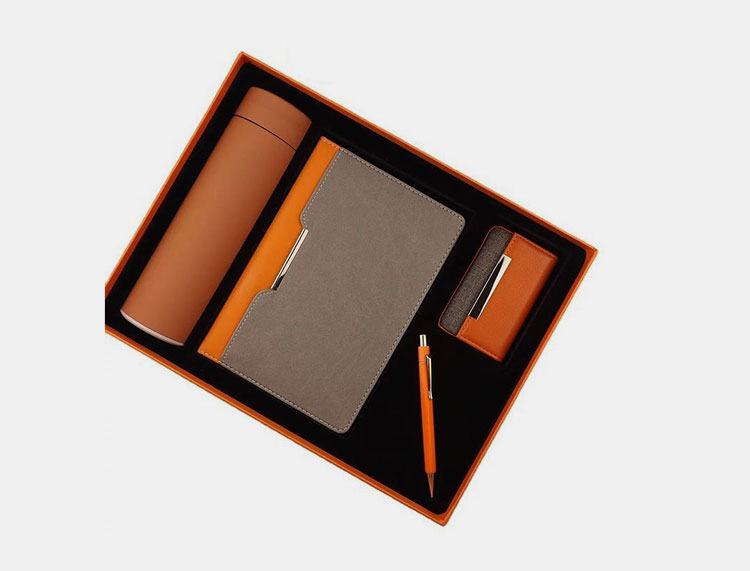

Stationary and paper industry:

Stationary and paper industry

Stationary and paper industry packaging pens, pencils, color markers, notebooks and gift stationary in different cartons. The cartons ensures damage-free and organize display of items.

The cartons used in the packaging of pens and marker is tuck-end cartons. Stationary sets are packaged in window-type cartons and compartment-style cartons are used for packaging of gift boxes.

Chemical industry:

Chemical industry-Picture courtesy: thecoindustries.com

Chemical industry package various chemicals, ampoules and chemical bottles in various cartons to ensure its safety and chemical integrity. The labelling on cartons make them easy to manage and safe transportation of glassware and chemicals to labs.

Partitioned cartons are used for the packaging of bottles and ampoules. Eco-friendly plastic material is used for packaging of chemicals like ethanol etc.

Home and decor industry:

Home and décor industry- Picture courtesy: Sitesgoogle.com

Home and decor industry used cartons for the packaging of decoration apparatus of home, glassware and bulky furnishing in various cartons to ensure its safety during transportation from industry to the market. By adding aesthetic visual aids resonate your products in the market.

As the glassware needs extra protection during transportation and storage in shop, corrugated cartons does its amazing job in protecting such delicate items.

8.How to make great pharmaceutical carton design?

Before designing the pharmaceutical carton design, you must have ideas in your mind that can safe your energy and time and can also elevate the popularity of your brand worldwide.

Understand the product and its requirement

Understand the product and its requirement

Before designing a carton, you must have complete information regarding the product need to package. You must be known about what type of material you want to package. Either is it tablet, ointment, injection or medical apparatus. Then you must know about the target user for this. Either it is wanting for elderly person, children, and adults or for hospital.

By knowing the information regarding the product to be package, one can get your carton in spectacular way.

Prioritize safety and functionality

Prioritize safety

By prioritize safety, you can build trust of consumer and also can meet industrial standard. You must have to label ingredients, visual aids, dosage, serial number, barcode, QR code and temper-proof labels to easily track and know about sealed product. You must also use locking mechanism in your cartons to ensure children safety.

Follow regulatory requirements

Follow regulatory requirement

In pharmaceutical industry packaging, strict regulation is the major concern. You must make sure to clearly label name, dosage, suitable for what age person, ingredients, storage, QR code, expiry date and visual aids on the carton.

This feature makes your products well-known and market- leader.

Add user-friendly features

Visual aid on packaging

User-friendly aspect is one of the major benefit of pharmaceutical carton designs. It is easy to handle and can use by all users. The packaging can be done as it can easily open by user without applying too much force.

The cartons also have visual aids that create a sense of understanding to those users who are having limited literacy or language barrier. Some cartons have also printed dosage taking schedule, which can reduce the error during treatment. In this way, every consumer can access to your products.

Integrate smart packaging designs

Integration of temperature-sensors-Picture courtesy: Yankodesign.com

You must be worried about the vaccines and biologics at your pharmacy that are temperature sensitive. Modern science technology is surprising you in this regard. Temperature-sensors are designed on the packaging which alert you when the product is exposed to unsafe temperature. You have to must integrate temperature-sensors to your cartons.

Pharmacy companies are getting benefit from smart packaging of tracking. You can track your medicine to ensure that your drugs reached the patients safely.

Choose the right carton type

Choosing of carton

For designing pharmaceutical carton, you must have to select eco-friendly and correct size and type of carton. For example for blister pack, use folding cartons, for combo-packs, use sleeve- cartons and many more.

9.What should you care about while making pharmaceutical cartons design?

While manufacturing pharmaceutical carton design, you must care about few of the things that you must be considered while making cartons. These are as follows:

Type of product to be packaged:

Pharmaceutical products

First and foremost aspect of pharmaceutical carton designing is you need to know about the dosage form to be packaged. Is it tablets, ampoules, syringes or ointment and cream? You need to flip the carton accordingly.

Blister cartons should be tuck-end carton. Bottles need space to avoid leakage and damaging and ointment need narrow cartons.

Production capacity

You must know about the production scale, need low-volume production or high-volume. By this, you can select right choice of machine and this will save your time and energy.

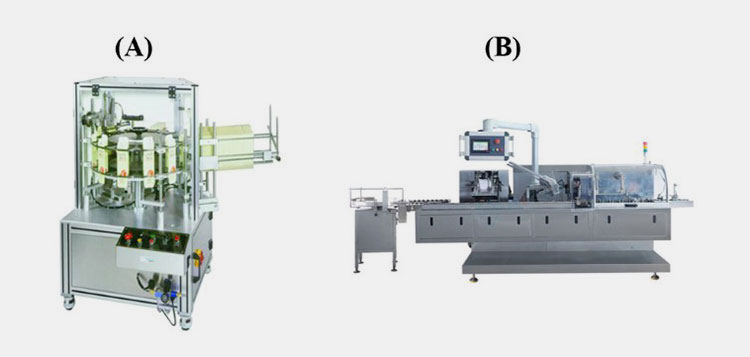

Semi-automatic cartoning machine (B) Fully automatic cartoning machine

For small scale production, you can use semi-automatic cartoning machine while for large-scale production, use fully automatic cartoning machine.

Budget planning

Budget planning

You should must consider your budge before designing pharmaceutical cartons. You can manage basic and premium paperboard selection, digital or flexographic printing, embossing and foil stamping furnishing accordingly.

Regulatory compliance and safety

Regulatory compliance and safety

Your product boxes must have all compulsory information of the product to be packed. It must imprint with drug name, expiry date and QR code etc. ensure leaflet is inserted into the box. Ensure child-proof and temper-evident features.

Material and sustainability

Sustainability

You must consider to use eco-friendly and sustainable cartons for packaging. Ensure that the carton is moisture-proof and coated for neat and clean printing.

Conclusion:

In summary, it is concluded that pharmaceutical carton design play an important role in consumer safety, their trust and brand recognition in market. Proper labelling, eco-friendly, child-proof and temper-resistant cartons not only protect the product but also resonate your brand in the market. You must know about the material to be package, type of carton used and then select right machine for packaging of the product. This will save your time and increase your brand popularity worldwide. If you have still any query, feel free to contact AIPAK.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine