Pharmaceutical Carton-A Sustainable Packaging Approach

Pharmaceutical cartoning is a part of secondary packaging that does not need a lunch break. This continuous process runs shoulder to shoulder with the production of medications. Don’t you think it offers more protection to finished products by boxing them inside? We think so!

Pharmaceutical packaging is a competitive market where each and every task is challenging. Thanks to the modern sciences that have improved a lot by stepping towards day-to-day innovation for packaging machines. Here are some interesting facts about pharmaceutical cartons for consumers’ convenience.

Table of Contents

I.Innovation in Pharmaceutical Cartons through the Years

First carton made of cardboard, was introduced in 1817 in England by the business called M.Treverton& Son. Kellogg Cereals was known for packaging of breakfast in cardboard cereal boxes.

In 1856, patent for corrugated cardboard was issued but this material was used as liner for hats. Around 1871, this corrugated cardboard material was first used for the shipment of products. The patent was issued for cardboard shipment material to Albert Jones.

In 1874, the machine was invented by G. Smyth for producing huge quantities of corrugated cardboard. Pre-cut cardboard box were first developed in 1890 by Robert Gair. In 1895, the first cardboard carton was produced in America. Afterward, corrugated cardboard boxes replace wooden boxes as the means of shipment in 1990s.

In the pharmaceutical sector, cartons are a great means of secondary packaging. You can store strip packs, blister pack, syrup bottles, drips, solutions etc. They are suitable for the transport goods from one place to another. Indeed, their demand is on high rise due to ultra protection properties of your medicines.

Pharmaceutical cartons serve as an excellent packaging needs for the following:

- Over the Counter (OTC) medicines and prescription medicines

- Nutraceuticals supplements

- Energy drinks

- Medical and Surgical devices

- Herbal medicines.

- Cosmetics

Ⅱ.Significance of Pharmaceutical Carton Packaging in Production Unit

It’s not just a box! Pharmaceutical cartoning has chief importance in the packaging of various medicinal goods. Although it looks a simple and effective way of storing and holding the products.

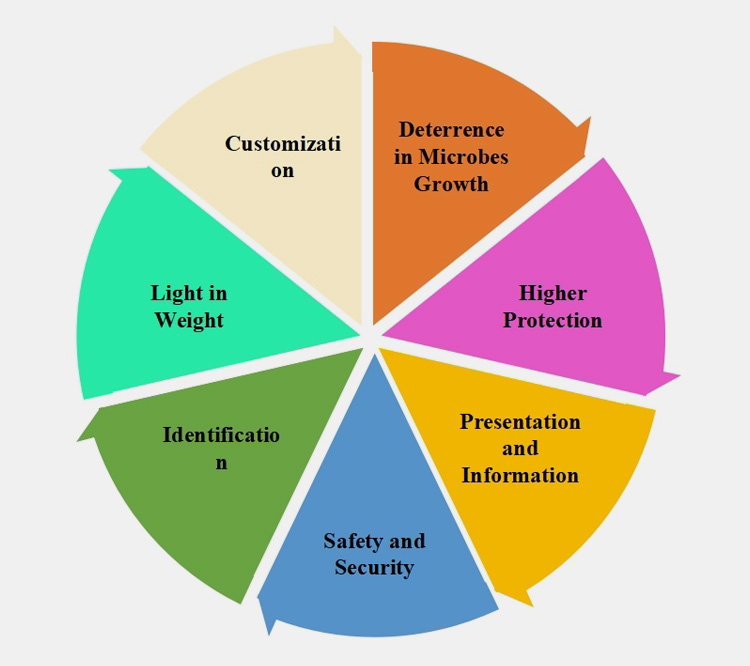

Following are the advantages of cartoning in the pharmaceutical industry:

Deterrence in Microbes Growth

Microbial growth can severely affect the potency of pharmaceutical products. High-quality cartoning has the fundamental purpose of preventing microbial contamination in products and improving the efficacy of the formulation.

Higher Protection

Pharmaceutical cartons ensure the complete protection of products after packing. They are firmly sealed and leakproof thus reducing the chances of product damage by water content, humidity, oxygen, light and mechanical strength. These are useful to maintain the quality and potency of pharmaceutical products.

Presentation and Information

All pharmaceutical products are delivered with mandatory information about medicinal products. For instance, dosage, concentration, manufacturing and expiry date, batch number, company names etc., The clearly labeled drug information consequently reduces the incidence of drug mix up. The patient and medical practitioner can easily read the information which aids easy and error-free access.

Safety and Security

Cushioning effect of cartons provides stability to items during handling and delivery consequently deterring the breakage of fragile items. Pharma cartons are made tamper-proof which hinders the chances of counterfeiting exploitation of medication and consumer items.

Identification

Colorful, graphical printed cartons facilitate in recognition of packed products by consumers. By reading packed cartons consumers especially elderly patients can identify products without need of opening them. This attractive design also has a role in patient compliance.

Light in Weight

Pharmaceutical companies are using right-sized carton packaging that use less number of raw materials in manufacturing thus making them light in weight and convenient in transportation and lower shipment charges. This also makes cartons easy to recycle due to little carbon footprint.

Customization

Pharmaceutical cartons can be customized for branding and marketing purposes. These customized cartons create brand awareness, appeal to customers and promote product purchases. Pharmaceutical companies are using customized designs with vibrant colors for advertising their goods.

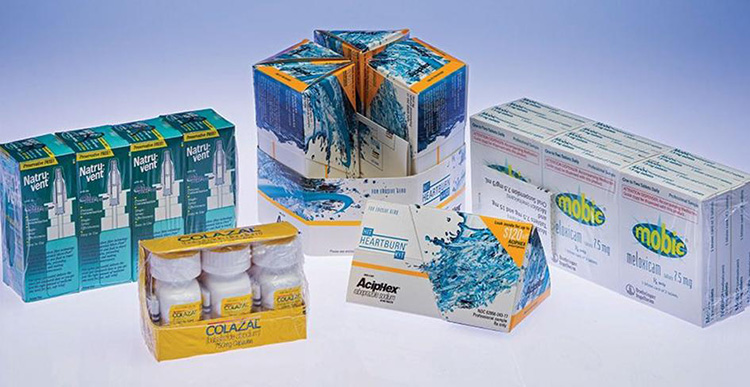

III.Various Classification of Pharmaceutical Cartons Used in Manufacturing

Pharmaceutical cartons are classified in several ways such as:

1.Based on Design

There are various types of carton design styles:

| Slotted Cartons

These cartons are formed by one piece corrugated paperboard. It is formed by glued or taped joints. These are best for shipping purposes. These are routinely used in packaging of medication bottles and blisters. |

|

| Telescopic or Rigid Cartons

Two separate top or bottom halves that fit at the top of one another form telescopic or rigid cartons. These are comprised of unglued joints. These have two parts: base and lid. These cartons are suitable for packaging blisters and strips. |

|

| Folder

It is one or more part board which has flat bottom without any joints and top half covers the product. Folder cartons are good for packing ampoules. |

|

| Dispenser Cartons

These cartons made of rigid material, have a perforated opening usually located at the center for tearing the carton. When this opening is torn, products like diarrhoea medication sachet are easily pulled out. |

|

2.Based on Material

On the basis of material, pharmaceutical cartons are categorized in to the following:

| Cardboard Cartons

Cardboard cartons are formed by single layer of thick paper material or heavy-duty pulp. These are less rigid and thick and are often used for storing various medicine packaging like ampoules, vials, bottles, syringes, etc. |

|

| Corrugated Cartons

These cartons are multilayered comprising of outside liner, inner liner, and a middle fluted layer. These are sturdy, hard, and are more resilient. These carton types come in handy when shipping and transporting bulk quantities of packed containers of drugs. |

|

| Chipboard Cartons

Chipboard cartons are made of reclaimed paper stock. These are easier to cut, bend, fold, and close. These are lightweight and are used for packaging pharmaceutical and health care products such as gloves, eye drops, plastic drug bottles, etc. |

|

| Aseptic Cartons These are multi-layered cartons suitable for packaging potent drugs and various antibiotics. The layers are composed of polyethylene, cardboard, aluminum and more plastic materials. This increases shelf-life of medication and prevents them from contaminating. These are used for packaging of powdered drugs such as antibiotics, etc. |

|

3.Based on Structure

On the basis of structure, pharmaceutical cartons are classified into the following:

| Book Style Cartons

These are used for printing information both inside and outside of cartons and are employed for packing medical items such as capsule and tablet bottles. |

|

| Gable Top Cartons This carton is erected, loaded and closed firmly. These are the best packaging of nutraceutical supplements. |

|

| Tray Cartons These cartons have one piece having an uninterrupted base with several corrugated end flaps. These are best for storing syringes and ampoules |

|

4.Based on the Folding Style

Cartons are classified in different categories according to a closing method such as:

| 1-2-3 Bottom Box This is also known as snap bottom or lock bottom carton. It requires three steps for assembly. Lower flaps are pushed inside each other for closing. It is suitable for packing heavier items like laboratory glass bottles and PET medicine bottles. |

|

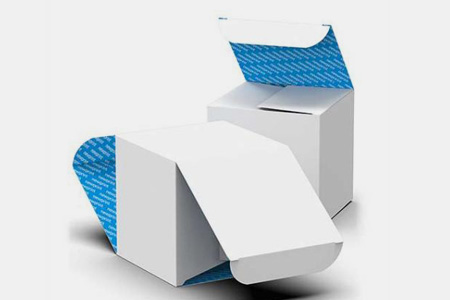

| Auto-Lock Bottom Carton These cartons have specific bottom flaps that automatically close when assemble. Top side of this carton is simply a tuck flap. These cartons are the strongest carton types and are used for packing heavier products like disposable wipes, bandages, and supplement bottles. |

|

| Straight Tuck Carton

The top and bottom closing flaps are present at the same side of the carton, assembling the box from front to back. These have end slit for holding the tuck in position. These are used for storing lightweight products like oils, blisters pack tablets or capsules bottles. |

|

| Reverse Tuck Cartons

The design of these cartons is identical to straight tuck cartons except top and bottom closing ends are present at the opposite sides of cartons thus folding occur in opposite direction. Reverse tuck cartons are pricier than straight tuck carton. Ointments, creams, and pastes are packaged in these styled cartons. |

|

| Sleeve Cartons These cartons do not have bottom or top flaps. It is two pieces with one sliding over another. This gives stability and cushioning to product. These are excellent for storing fragile items like ampoules and vials. |

|

IV.Cardboard Carton VS Corrugated Carton: Understand the Difference

In pharmaceuticals, Cardboard Carton and Corrugated Carton are both similar in their design and have same protection purpose for pharmaceutical items but there are few differences in carton types, for instance:

Material

Cardboard cartons are formed from paper or heavy-duty paper pulp. These paper or cardboard materials are utilized for making small boxes. Corrugated cartons are comprised of three layers: inner liner, outer liner, and fluted material that goes between them.

Use

Cardboard cartons provide structural support to items like clothing and delicate items such as, blister, strips, bottles, etc. Corrugated cartons are more suited for shipping of products.

Hardness

Cardboard cartons are thinner, lighter, and are brittle. Corrugated cartons are thick, have more weight, and are resilient and tough.

Versatile Design

Because of flexibility of cardboard cartons are shaped and turned into variety of designs. These are more easily shaped than corrugated cartons, sometimes, sometimes taking the shape of their packing products. It is difficult to do this with corrugated cartons because of their resilience and thickness.

Protection

When comparing protection properties, corrugated cartons offer greater protection than corrugated cartons. The former ones have weather-resistant properties while lowering shipment damage. Corrugated cartons are especially valuable in the protection and safety of drugs pack while shipped.

Ⅴ.Safety of Pharmaceutical Products in Cartons

Safety is an important concern of the pharmaceutical industry. The number of counterfeiting events of medicines has soared over the past years. Counterfeiting of medicines not only undermines sales but also endangers life of patients.

So protection of healthcare and medical products is a major objective of pharmaceutical cartoning. Some measures for ensuring the safety of medications are given below:

Tamper-Proof Cartons

Interfering of medicine can be avoided by packing them in tamper-proof cartons. This ascertains that drugs cannot be altered without opening tampering seal. So in this way, distribution of altered drug can be prevented.

Serialization of Medical Cartons

The pharmaceutical cartons are serialized by data matrix code. This is to circumvent the fraud of falsified medications. The cartons are authenticated by means of printing codes on cartons and keeping their information in the database. This helps to verify the medications.

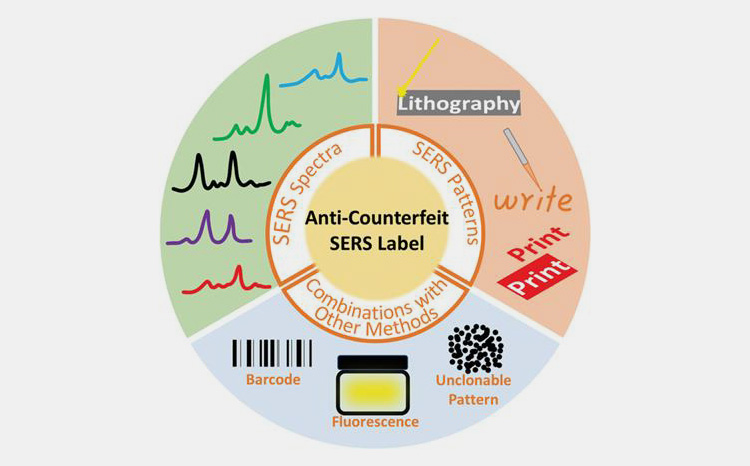

Anti-counterfeiting Procedures

Various anti-counterfeiting measures like invisible writing, thermochromic paints, encrypted codes, concealed images or geometric patterns, micro-texts, color-shift labels, security sealing are also used for creating counterfeiting-resistant cartons.

UV and infra-red inks are gaining popularity in anti-counterfeiting protection technology. Digital trademarks, Taggants, and QR codes are also highly used for measuring the authenticity of medications.

Ⅵ.Child-Resistant Carton Technology Used in Pharma

Carton packaging has evolved since its initiation. Today, child-resistant carton innovation has a special appeal. This innovation is hard to open by children but can be accessed easily by adult especially elderly persons. It lessens the chances of poisoning in children by putting off children from retrieving and consuming the product.

An ingenious technology Locked4Kids is a patented carton packaging style that is comprised of resalable cartons and a plastic tray containing medications. For retrieving products, you simply have to pull plastic tray like you are pulling drawer.

Two hooks present diagonally at sides of carton makes it difficult for children to open the cartons. These two hooks have to be pushed simultaneously for accessing inside tray containing medication. Children are unable to understand this technology and even if they do, they are still unable to push these hooks concurrently because of their small hands.

Conclusion

Pharmaceutical cartons are a versatile way of packing goods for protection and safety. This is a supporting way between the patient and the product and will always be more than a box. If you’re interested in procuring a cartoning machine or need expert consultation; Just send us a short message! Our experts are always here to serve you.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine