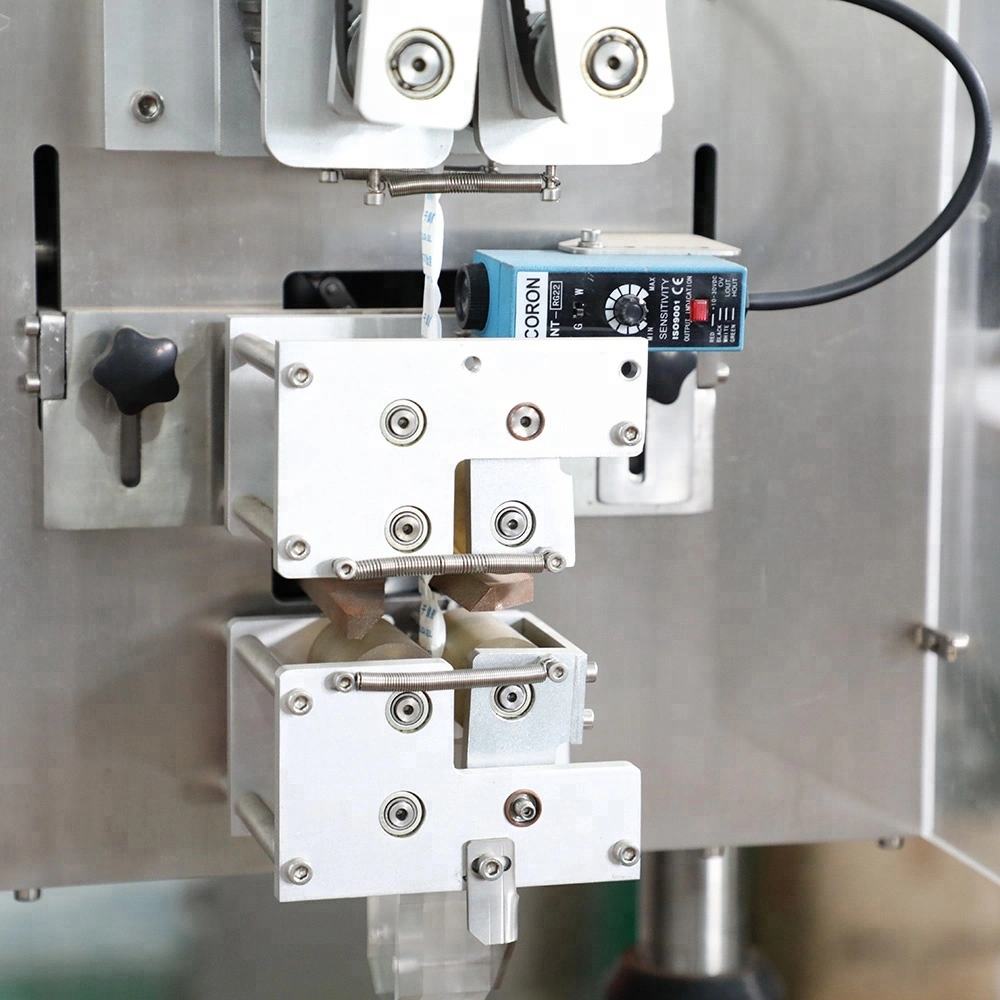

ZP25 effervescent rotary tablet press machine for Pharmacy

ZP25 effervescent rotary tablet press machine is a latest rotary tablet press developed by our company,used to press granular raw materials into tablets.It is the only professional effervescent tablet press in china.It is mainly used for tablet production of effervescent tablets,aromatic tablets,washing blocks and other tablets with difficult mold release.

FEATURE

- The peripheral housing is fully closed.The peripherals and internal tablet surface are made of 304 stainless steel to maintain luster on the surface and avoid cross contamination,conforming to GMP requirements.

- The tablet punching machine working chamber is fully closed by organic glass.The transparent protective covers enable the machine operation status to be clearly observed.In addition,they can be opened to make cleaning and maintenance easy.

- With mechanical and electrical integration,variable frequency speed adjustment is adopted.

- The machine is provided with a dust collector to thoroughly collect the dust in the tablet pressing chamber.

DATA SHEET

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586

The Buyer's Guide

Effervescent Tablet Press: The Complete Buying Guide in 2025

Effervescent tablets are more than fizzy tablets. These tablets also offer nutritional benefits. Effervescent tablet press plays a prime role in fabricating these tablets. These machines are widely popular throughout the world and are used in wide ranging business such as confectionary, food, etc. the design and structure is appropriate for low cost production of effervescent tablets.

Read through this guide if you are curious about effervescent tablet press. This detailed blog will provide you information about various types, benefits, uses, maintenance and much more about effervescent tablet press.

Let’s have a deeper look!

1.What is effervescent tablet press?

Effervescent tablet press is a type of tableting machine also known as effervescent compress machine, is a mechanical device that is used to compress granular powders blends of active ingredients and excipients (alkali or acidic components) into fizzy and bubbly effervescent pills.

Effervescent press machine manufacture tablets of uniform size and shape. Effervescent table press usually produces large sized tablets having the diameter of 35-40 mm and the maximum pressure force used by these effervescent tablet press machine is about 120 KN.

2.Can you tell about the industrial usages of effervescent tablet press?

Applications of effervescent tablet press are in wide variety of industry such as

Pharmaceutical Industry

Effervescent tablet press is important component of pharmaceutical industry. These machines manufacture high quality effervescent tablets that are used for treating coughs, reducing pain, curing indigestion, and cleansing gastrointestinal tract.

Nutraceutical Industry

Effervescent tablet press is utilized in nutraceutical industry for manufacturing of nutritional effervescent tablets used to treat deficiencies of minerals and vitamin like vitamin C, calcium, potassium, etc.

Agricultural Industry

These machines have found their application in the agriculture industry for formulating effervescent tablets which are used as fertilizers, pesticides, nutrients, growth promoter, etc.

Chemical Industry

Effervescent press is used in chemical industry for producing effervescent cleanser tablets which are utilized as detergents, for cleaning kitchen grease, and for disinfecting swimming pools.

Hygiene Industry

Effervescent tablet press is also employed in hygiene industry for manufacturing of bathing salts.

Veterinary Industry

These machines have their usage in veterinary industry for fabricating effervescent tablets which serve as nutritional supplements for pets as well as used to disinfect animals.

3.Effervescent tablet press-Benefits?

Investing in effervescent machine is extremely profitable for your manufacturing line as this innovative machine boasts huge benefits such as:

Manufacturing Capacity

Effervescent tablet press has high manufacturing capability up to 2500 to 3000 effervescent tablets per minutes; which translates into high amount of your products in market ultimately increasing your profits and sales.

Cost

These machines are automated which decreases the amount of labor required to manage the machine, thus lowering your production cost.

Moreover, as there is no human intervention in operating the machine so it also reduces the waste of tablets further cutting down the cost.

Hygienic Design

The manufacturing of effervescent tablets is quite a dusty process but hygienic design of effervescent tablet press prevents the contamination of product from dust by ventilating the system environment through holes in die.

Trouble-Free Operation

The entire operation of effervescent press machine is controlled through display screen interface which lowers the stress on working personnel.

4.How will you classify effervescent tablet press?

Effervescent tablet press machine is divided into two main categories.

Single Punch Effervescent Tablet Press

It is known as single station effervescent tablet press, is the simplest machine for manufacturing effervescent tablets and consist of a single die, upper and lower punches.

Compaction pressure is exerted only by the upper punch while the lower punch remains stationary.

These machines can be operated by hand or by power. It is portable, lightweight and generally used for small scale manufacturing line like hospitals and research institutions.

Muti-Punch Effervescent Press

It is also referred as multi-station effervescent press or rotary press and has a number of tooling devices which moves to compress powder to effervescent tablets.

It uses double-sided compression provided by accordion like movement of both punches. The output capability depends upon the speed of turret and number of toolings devices on the machine.

This machine is extremely useful in increasing the production volume and is used in large scale production businesses.

5.Can you tell about different parts of effervescent tablet press?

The important components of effervescent tablet press are described below:

Hopper

This part of machine is filled with the raw material or powders either manually or automatically and then this channel passes the material to die.

Punches

The purpose of punches is to compress powders into compact shape. There are two kinds of punches in effervescent press machine: upper and lower punch.

In single punch effervescent press, upper punches moves vertically in and out of die bore while the lower punch remains stationary.

In rotary press effervescent press both the punches move to compress the powders.

Die Cavity

Die part of machine receives the raw material from feeder; compress the powder into tablets of various shapes and sizes.

Cam tracks

These components direct the motion of punches at different stages of tablet compression.

Compression Turret

This ensures the proper alignment of upper and lower punch and the production capacity of machine can be increased by rotating turret.

Feeding Unit

This channel controls the movement of powder between hopper and die.

Take-off Blade

This is present in front of feeding unit and moves the effervescent tablets to discharge chute.

Discharge Shaft

This is the part where ejected tablets are collected after compression.

6.What is the working principle of effervescent tablet press?

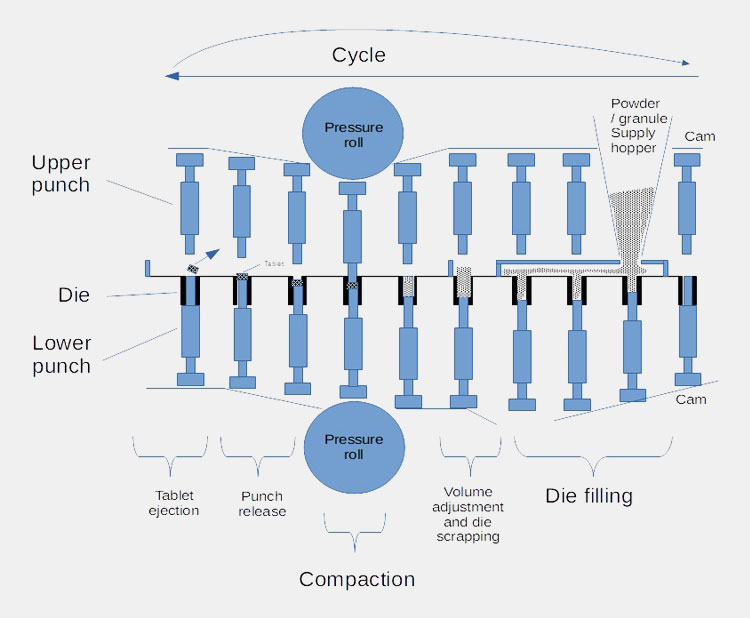

The working principle of rotary effervescent tablet press machine is broadly is based on the movement of punches in the die. The high pressure or force exerted by both the punch results in the compaction of powder into effervescent tablets.

The working of effervescent tablet press is as follows:

- First, the powder or raw martial goes from hopper to the die cavity.

- Adjustment of lower punch is done to measure the accurate volume of powder. Scrapper is used to get rid of excess material.

- The upper punch moves and applies the high force on powder resulting in compression.

- The upper punch is raised which causes removal of pressure force.

- The lower punch is moved upward to eject the tablet which is moved to discharge chute. The lower punch is moved downward to next cycle.

7.What are expected failures of effervescent tablet press? How will you solve them?

Troubleshooting is an integral part of manufacturing process. It is very essential that you know various kinds of problems that occur during production of effervescent tablet and how can you solve them.

Some common failure and their solution are derailed below:

Ⅰ.Non-uniform sized Tablets

Sometimes the effervescent tablets have issues in their compactness. These tablets are of various sizes which causes the rejection of effervescent tablets and their wastage.

Causes

This issue is caused by abnormal motion of punches.

Solution

You can resolve this problem by

Setting the punches to accurate punch depth

Checking whether effervescent press toolings have the right size.

Inspecting the working condition of the toolings

Replacing the old tooling system

Ⅱ.Reduced Material Flow

There is low power flow in die channel which causes decrease in compaction and wastage of products.

Causes

This problem is posed due to

Misalignments of parts and usage of old parts.

Solution

This problem is fixed by

Increasing the powder flow and raising the level of feeder.

Increasing the rate of feeder speed.

Always use the powder that has uniform particle size.

Ⅲ.Spilling of Powder

Sometimes the powder falls or spill from the main body of the machine.

Cause

This predicament is caused by different factors such as

Rapid flow of materials inside the feeder

Improper level of frame

High speed of feeder unit

Solution

This problem of spillage is solved by

Fixing the speed of feeder

Decreasing the rate at which material is flowed into the feeder.

Fixing the level of frame

Ⅳ.Freezing of Lower Punches

Sometimes the lower punches get struck and you have to use some effort to move them.

Causes

Failure to properly maintain cleaning schedule causes sticking of lower punches.

Solution

To resolve this problem

You should thoroughly clean the tip and socket area of punches. This will remove the upsurge of material.

You should always properly follow the cleaning schedule to ascertain that your machine is in proper working condition.

Ⅴ.Abnormal Vibration

Sometimes you hear abnormal ticking sounds or feel uncharacteristic vibrations coming from your machines. These abnormal sounds disrupt the manufacturing process.

Causes

These strange noises or vibrations are because of wobbly working parts.

Solution

This issue is fixed by

Fastening the loose nuts and screws

Greasing the components of machines

Checking mis-align parts and then properly align them.

Ⅵ.Capping

Capping is the breakage of effervescent tablets and removal of top or bottom part. The air trapped between powder particles causes decreasing in bonding capability and tensile strength of effervescent tablets that result in capping.

Causes

This problem arises due to

High punch penetration

Fast rotation of turret

Solution

This issue is solved by

Reducing punch penetration which allow decrease in air flow

Decreasing turret speed

8.What are buying considerations of effervescent tablet press?

Effervescent tablet press machine is important component of your production. If you are interested in buying this machine, here are few important tips for you that will aid you in selection process.

Speed

Speed is the important parameter of production line which determines the quantity of material produced during shift, is depended upon the level of automation of machine.

Fully automatic machines produce effervescent tablets at much faster rate than semi-automated machines.

Layout

Always choose machine which is suitable to your production space. Size of the machine impacts the production capacity of effervescent tablets. So it is necessary that you should choose that tablet press of suitable size that meets your production requirements.

Easy Handling

Choose effervescent tablet presses are equipped with HMI as this feature ensures safe operation and easy maintenance of machine.

Compatibility

Select those effervescent tablets press machine that are compatible with your existing instruments to ensure maximum output of effervescent tablets.

Power Consumption

It is very important to check the power consumption capacity of effervescent tablet press. Decrease power consumption by machine will translate in reduced power expenditure.

Material

Always look for stainless steel machine as it provides hygiene and avoid contamination.

Manufacturing Company

You should always go for effervescent tablet press from the trustworthy manufacturing company because they provide a warranty period which certifies the operational durability of the machine.

Conclusion

Effervescent tablet press is useful inventions especially for the pharmaceutical and nutraceutical industry. These machines increase your production capacity and save your money. We hope you’ve found this informative review useful and worth considering before you shop for effervescent tablet press. Happy Shopping!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling MachineCartoning Buyer's

Tell us your material or budget,we'll reply you ASAP within 24 hours