Automatic refueling cup

Double layers can be pressed

Adjustable filling thickness

Want A Free Consultation

ZP-33 glass mosaic tablet press machine

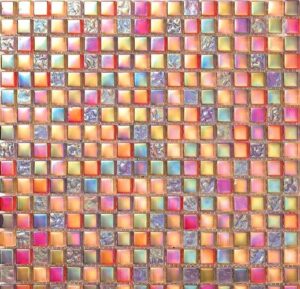

AIPAK ZP-33 glass mosaic tablet press machine is used to compress various granular materials into flakes. It is a basic equipment suitable for mass production. The speed of the turntable, the filling depth of the material and the thickness of the tablet can be adjusted during tableting.

Single-sided tableting is used. The mechanical buffer device on the machine can avoid mechanical damage caused by overload.

This glass mosaic tablet press machine is used to press the glass powder into a specific (customer-designated) block shape, automatically sorting the pieces and pushing the pieces to the sintered plate through the matching conveying block device, and adopts a forced feeding method to ensure uniform feeding each time.

The glass mosaic tablet press machine is based on the original tablet press of our company in response to market needs and customer requirements. It meets the customer’s production needs and is equipped with a conveying device. The fully automatic process of pushing the film solves the problem of mosaic falling off and damage caused by hand in the production process, which greatly improves the production efficiency.

FEATURE

- This machine is suitable for the pressing of conventional mosaics.

- The largest mosaic piece suitable for pressing is square 15*15mm.

- Common specifications include 12*12mm shallow arc, deep arc, 15*15 shallow arc, deep arc, and round. And polygonal tablets.

DATA SHEET

|

Number of die (paid) |

33 |

|

Maximum tablet pressure (kN) |

40 |

|

Maximum tablet diameter (mm) |

16.5*16.5 |

|

Maximum filling depth (mm) |

15 |

|

Maximum tablet thickness (mm) |

6 |

|

Turntable speed (rev/min) |

11-28 |

|

Production capacity (pieces/hour) |

17000-43000 |

|

Electric motor (kw) |

3 |

|

Dimensions (mm) |

950×960×1600 |

|

Host weight (kg) |

850 |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586