Drying time is short

High efficiency

Easy clean&maintenance

Want A Free Consultation

XF Series PLC Control Horizontal Fluid Bed Dryer For Desiccated Coconut

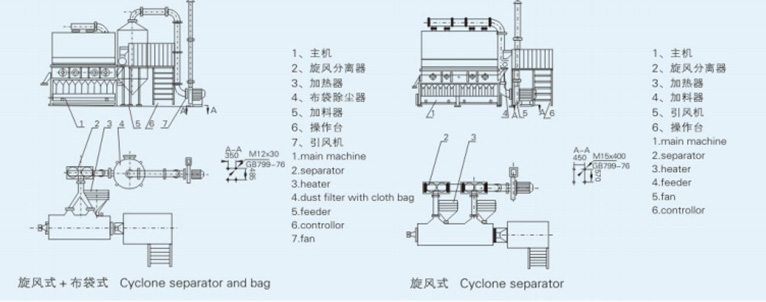

AIPAK XF series horizontal fluid bed dryer is also called fluid bed.Through operation and improvement over 30 years,it has play an active part in the fields of pharmaceutical,chemical,foodstuff,gain and so on industries.It consists of air filter,fluid bed,cyclone separator,dust collector,high-speed centrifugal fan,control cabinet and so on.Because of the difference of property from raw material,it is necessary to equip dust remover in accordance with practical needs.It may select cyclone separator and dust collector both or one of them.In general,cyclone separator can be selected if the raw material is larger and the dust collector may be selected if the raw material is light.Moreover,there is pneumatic feeding device for your selection.

XF Series Horizontal Fluid Bed Dryer Working Principle

The clean and hot air enters into fluid bed through distributor of valve plate.The wet material is fed from the feeder forms the fluid state by hot air.Because of the wide contact between hot air and raw materials,the time of drying is short.The air enters from the front of bed,fluidized in bed for several minutes,and float another side of bed.The machine’works in negative pressure.

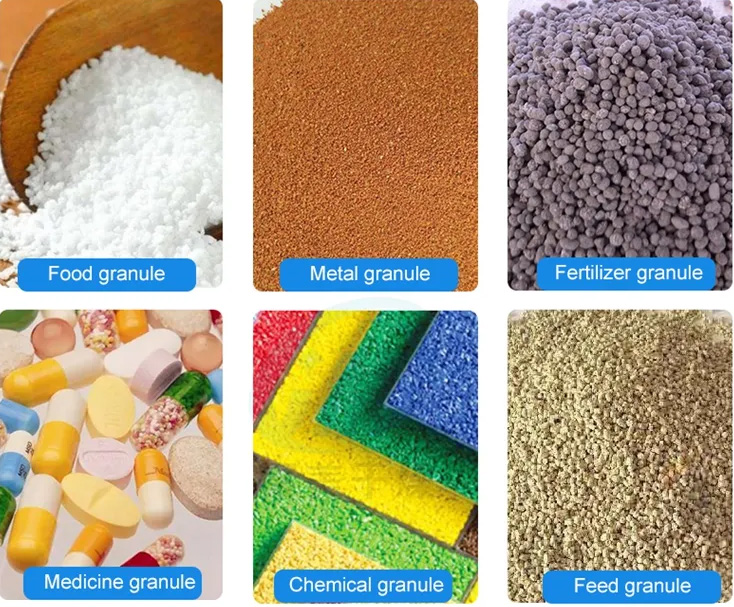

XF Series Horizontal Fluid Bed Dryer Applications

Drying process of medicines,chemical raw material,foodstuff,grain processing,feed and so on.For example,raw medicine,tablet,Chinese medicine,foodstuff of health protection,drinks,feed,resin,citric acid and other powders.The suitable diameter of raw material is normally 0.1-0.6mm.The most applicable diameter of raw material will be 0.5-3mm.

FEATURE

1.fluidized drying,heat and mass transfer fast.

2.operate under negative pressure in a closed,no dust.

3.Using antistatic filter material,safe operation.

4.Equipment has no dead ends,cleaned thoroughly,no cross-contamination,according to the special needs requirements,increase the mixer thing,vacuum feeding system.

5.meet the requirements of GMP.

6.Compared with the GFG with greater spatial streams.

DATA SHEET

| tom | unit | Spec | |||||||||

| 3 | 5 | 30 | 60 | 120 | 200 | 300 | 500 | 1000 | |||

| Container of raw material Production capacity | dim. | mm | 300 | 400 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 2200 |

| volume | L | 12 | 22 | 100 | 220 | 420 | 670 | 1000 | 1500 | 2500 | |

| Min | kg/batch | 1.5 | 4 | 15 | 30 | 80 | 100 | 150 | 250 | 500 | |

| Max | kg/batch | 4 | 6 | 36 | 72 | 140 | 240 | 360 | 600 | 1100 | |

| Consume of steam | kgbatch | 12 | 23 | 70 | 140 | 211 | 282 | 366 | 465 | 800 | |

| Amount of compressed air | m'/min | 03 | 0.3 | 0.3 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.5 | |

| Power of fan | kw | 2.2 | 4 | 5.5 | 11 | 18.5 | 22 | 30 | 45 | 75 | |

| Temperature | 'c | Adjustable from ambient to 120 | |||||||||

| Collection rate | % | >99 | |||||||||

| Time of operation | min | 15-30(Depends on materall | |||||||||

| Contot of final product | % | ~0.2(Depends on materiall) | |||||||||

| Noise | dB | ≤75 | |||||||||

| Height of main machine | mm | 2100 | 2300 | 2500 | 3000 | 3300 | 3800 | 4000 | 4800 | 6200 | |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586