Running in a high automatization and intellectualization

No bottle no labeling

High efficiency&fast speed

Want A Free Consultation

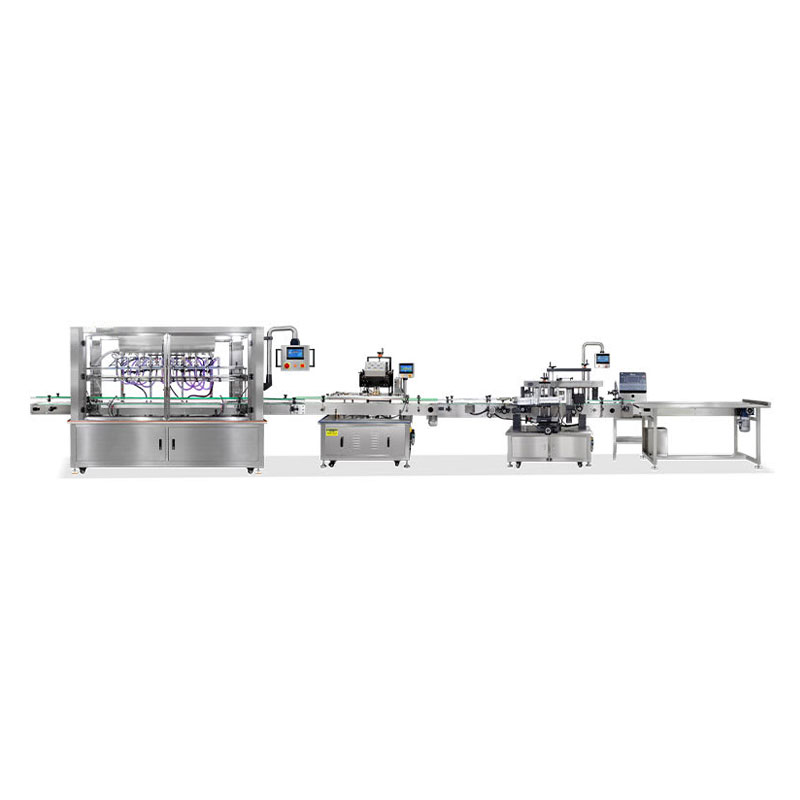

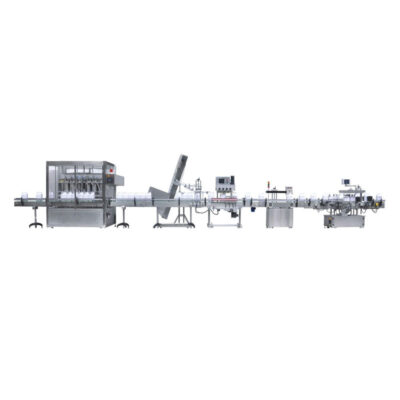

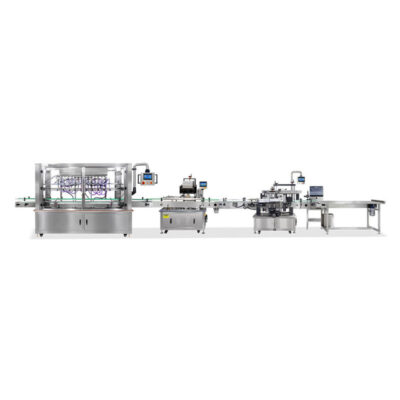

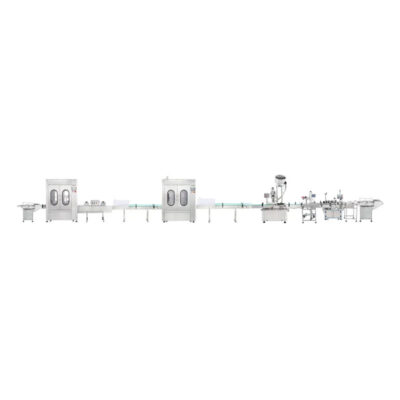

Anti Corrosion Chemical Insecticide Solvent Filling Machine Automatic liquid filling line

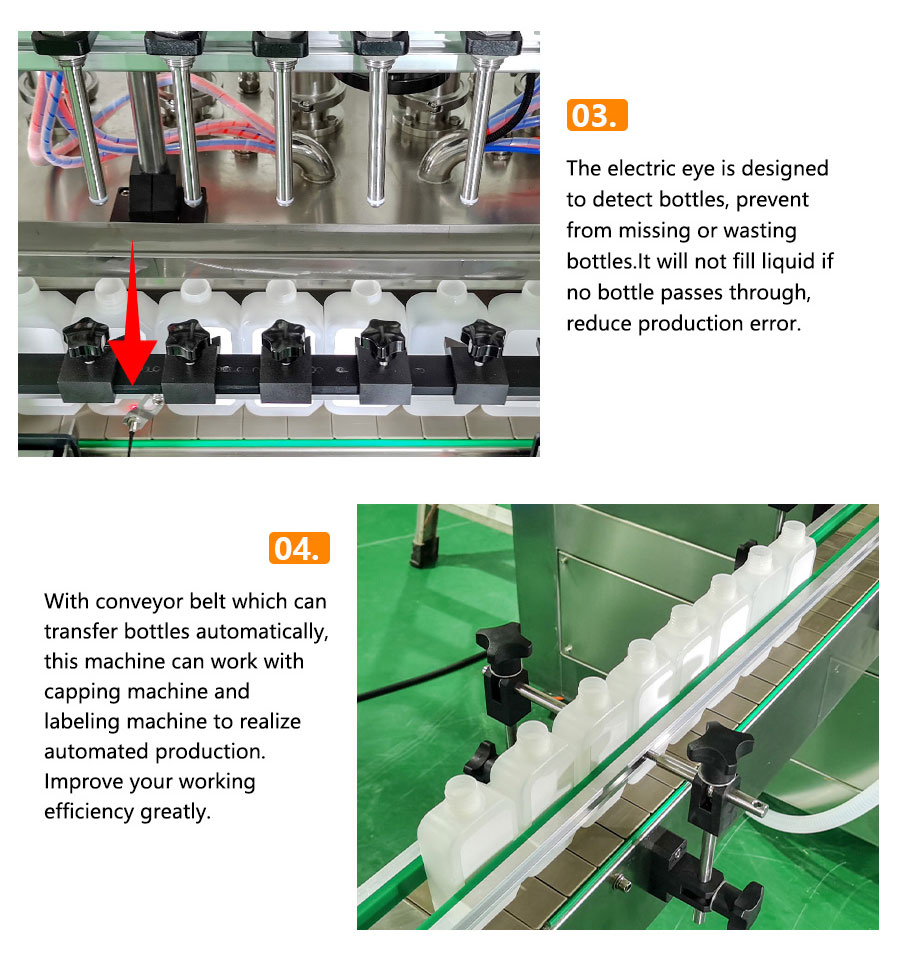

AIPAK solvent filling machine automatic liquid filling line is developed wholly in corrosion standard. It is a high-tech filling equipment which is a combination of microcomputer (PLC) controlled photoelectric sensor and pneumatic actuator.It is specially used for high corrosive liquid, such as solvent,bleach liquid, 84 disinfection liquid, toilet clean fluid, Bleach liquid and so on. can be used to fill corrosive liquid both with sticky or not, can fill round bottle or any other bottles(e.g: angle neck bottle). With features, such as precise filling volume, no drip, photoelectric detection, no filling when without bottle.

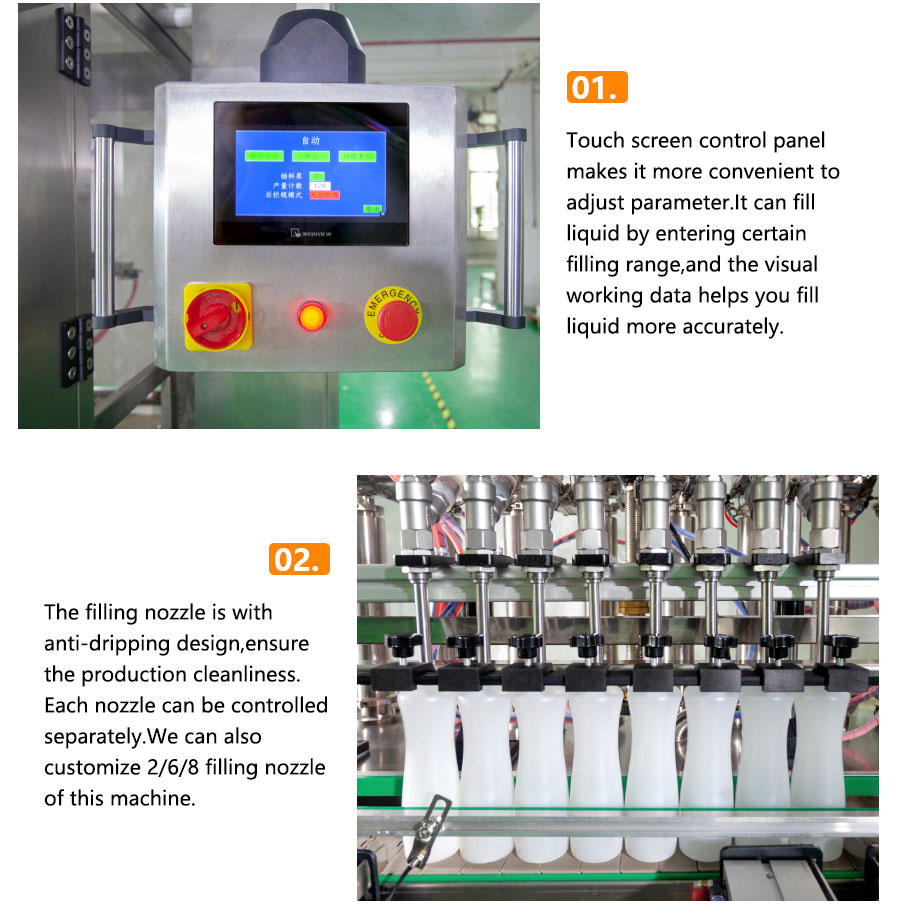

AIPAK Solvent Filling Machine Details:

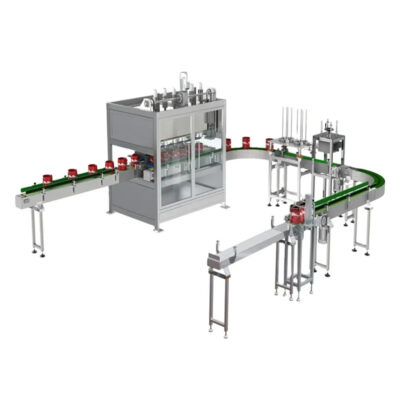

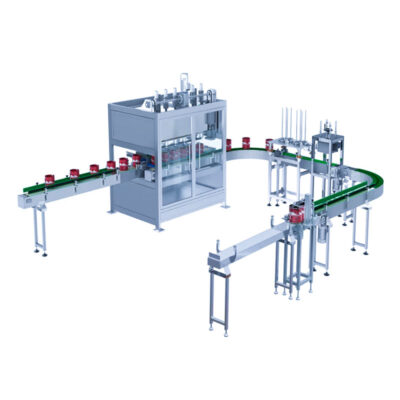

AIPAK Solvent Filling Machine Working Process:

AIPAK Solvent Filling Machine Products:

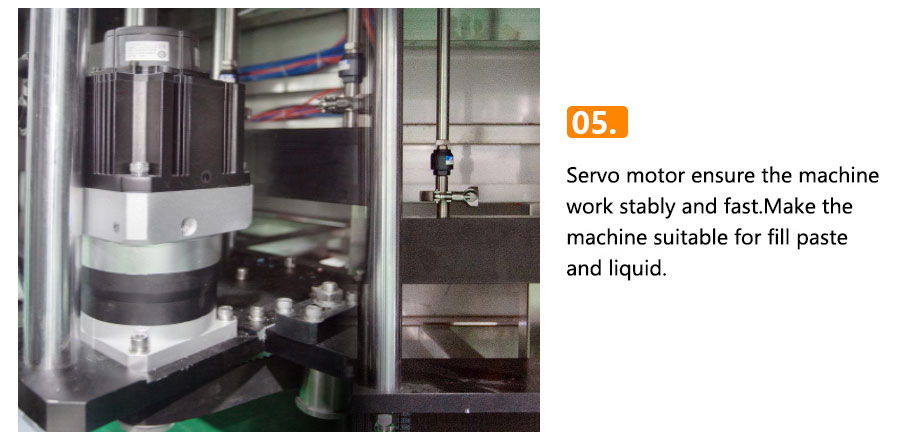

FEATURE

- The main machine adopts anti-corrosive PP material, pesistant and durable.

- The feeding pipe is made of PTFE with high strength and strong corrosion resistance.

- Independent anti-corrosive appliance control cabinet, safe and reliable.

- The conveyor belt is made of anti-corrosion materials PP or PVC;

- Pneumatic executive control valve, high efficiency and safety;

- Adopts international first-class electric and pneumatic configuration;

DATA SHEET

|

Nozzle Number |

PCS |

4 |

6 |

8 |

10 |

12 |

|

Production capacity |

Bottle/h |

600-800 |

750-1200 |

1100-1500 |

1200-1800 |

1400-2200 |

|

Quantitative error |

% |

≤±0.5% |

||||

|

Source voltage |

V |

Three-phase four-wire system AC220V 380V ±10% |

||||

|

Consumed power |

KW |

1.8 |

2.2 |

2.5 |

2.8 |

3 |

|

Gas supply pressure |

MPA |

0.55-0.8 |

||||

|

Air consumption |

M3/min |

0.8 |

1 |

1.2 |

1.2 |

1.8 |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586