High Quality

Optimal Design

Conform To Standard GMP

Want A Free Consultation

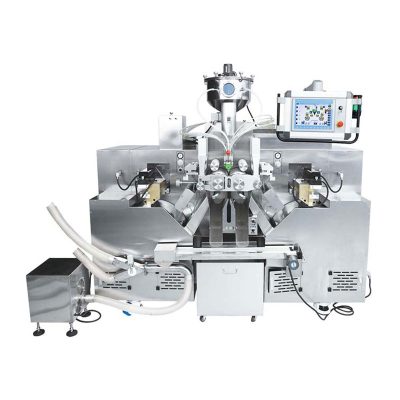

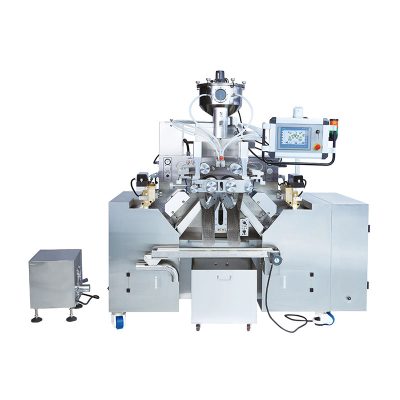

SEM-300 Softgel Encapsulation Machine

AIPAK SEM-300 softgel encapsulation machine has been widely used in medicine, health products, cosmetics and other fields,due to the advantages of softgel in the way of fast disintegration speed, easy oral administration, not easy to oxidize, easy to store and take, etc.

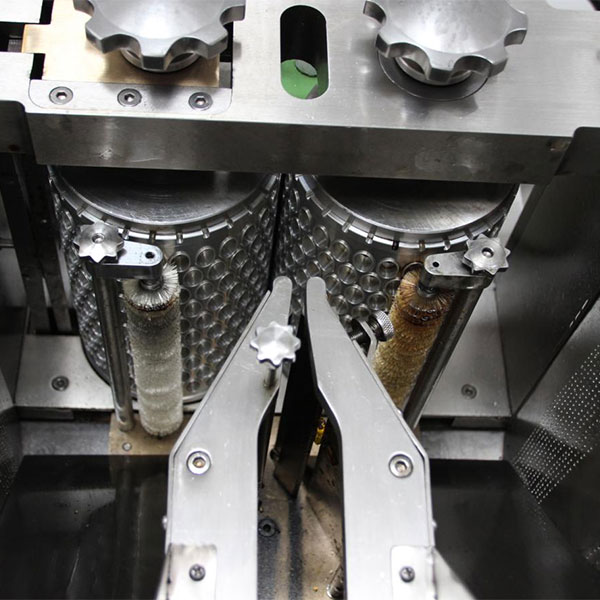

The machine adopts large-size touch screen and has fault diagnosis function, which can store various operating parameters and reserve network interface.The mold adopts aviation aluminum alloy and has a long service life. Optimized design, the number of cavities is large, and the mesh adhesive rate is low.The shaping and drying rotary cage is made of stainless steel mesh panel with no dead corners and easy to clean. An oil basin under the rotary cage ensures no oil dropping during the production.

You can customize your various shape softgel making such as cylindrical, spherical, olive, tube, pin, fish, and heart shapes.The volume of the soft capsule is the nominal volume of the soft capsule, and the unit is a drop. One drop is equal to 0.0616115ml. When the suspension is made into soft capsules, the size of the required soft capsules can be expressed by “matrix adsorption rate”. (It refers to the number of grams of liquid base needed to make 1 g of solid medicine into a capsule-filled suspension.)

Softgel Capsules Made by AIPAK SEM-300 Softgel Encapsulation Machine:

FEATURE

1. The water cooling system eliminates the dust contamination resulted from the air-cooling.

2. The gelatin is pneumatically conveyed from the thermal-insulated gelatin-storage pot through the ground, which improves the production environment.

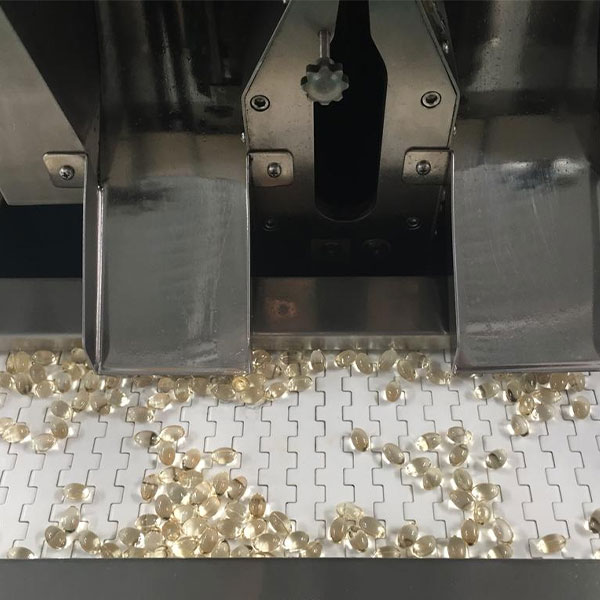

3. The food-grade conveyance belt is used for conveyance of capsule, which is non-toxic, non-sticky, and easily washable.

4. The setting-drying rotary cage is made of stainless steel expanded sheet, which is free of dead corners and easily washable.

5. All the electric elements are imported from famous manufacturers and have stable performances.

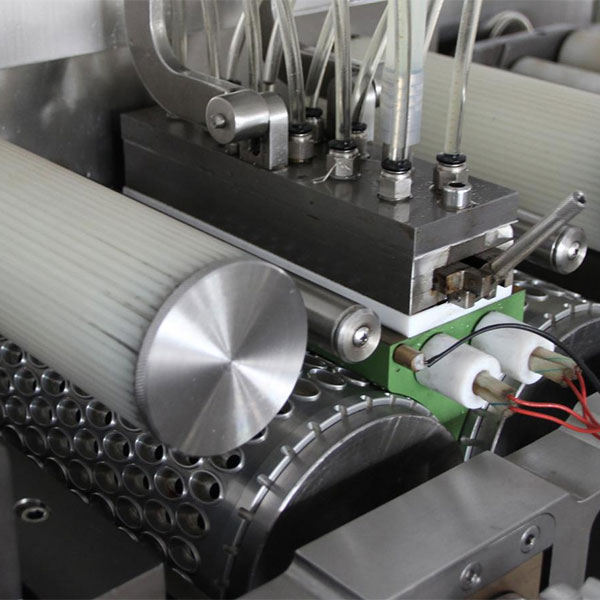

6. The optimal-designed injector extends the range of consistency of medicine solution.

7. Except that the injector, the spreading box and the rolling-mold conveyance belt are made of special materials, the parts contacting with medicine are made of 304 or 316 superior stainless steel and absolutely conform to standard GMP.

8. The capsule package rate is up to 98%.

9. High quality capsule deferent equipment adopts food conveyer belt, without poison and adhibition and easy to clean.

DATA SHEET

|

Model Name |

SEM-300 |

|

Die roll size |

150mm(Dia)X 300mm(Length) |

|

Speed |

0-5 RPM (Stepless Frequency Control) |

|

Piston number |

6 Ea |

|

Loading accuracy |

≤±0.5% |

|

Feeding amount single plunger |

0-2ml |

|

Electric Spec |

380V |

|

Required power |

11.5KW |

|

Dimension |

2,200mm * 1,275mm * 1,900mm |

|

Weight |

2189 Kg |

|

Control mode |

PLC+Touch Screen |

|

Output |

85680 pills/h |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586