High filling precision&no leak&corrosion

Long life antic corrosive filling

Touch screen operation control

Want A Free Consultation

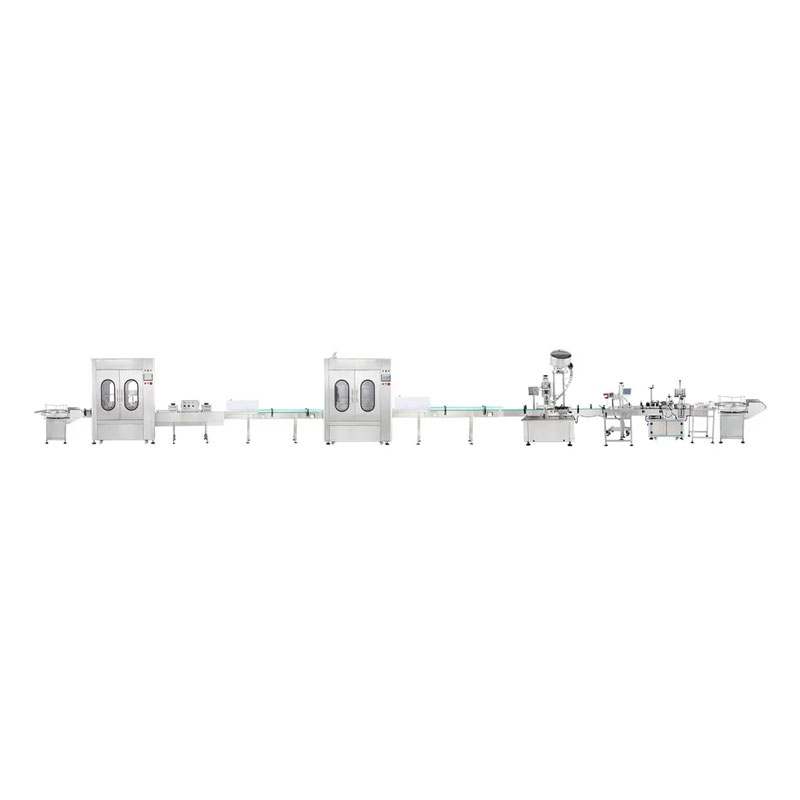

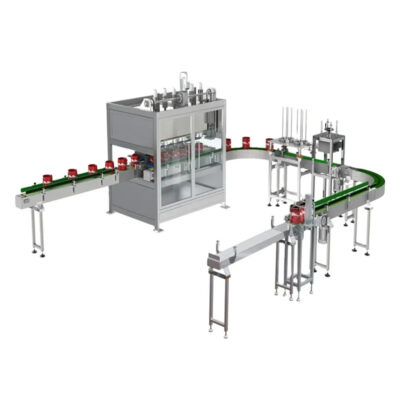

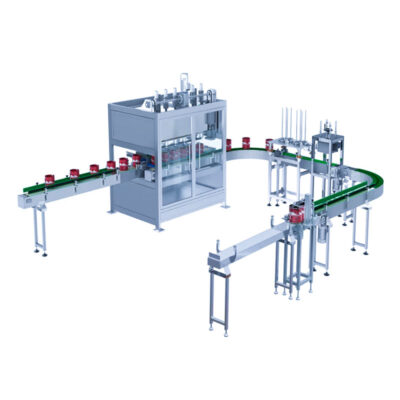

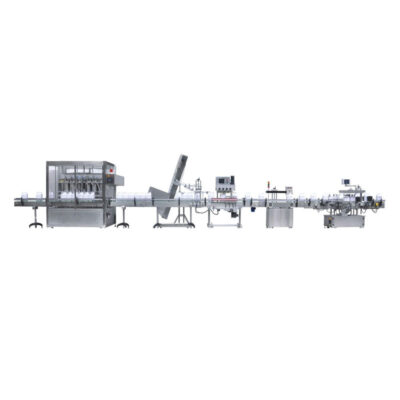

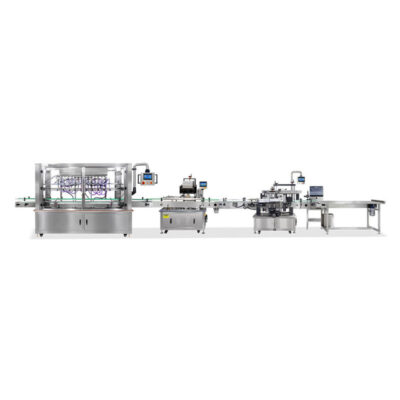

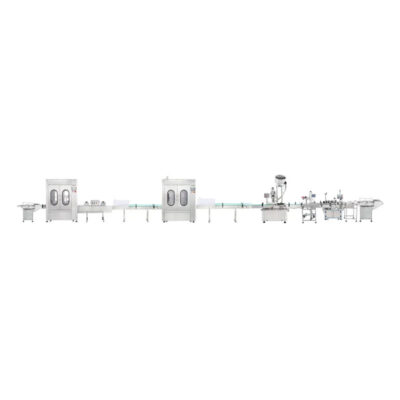

Pesticide Filling Machine Chlorine Disinfection Alcohol Bottle Filling Automatic liquid filling line

AIPAK pesticide filling machine automatic liquid filling line can be also called automatic acid filling machine,is often used for filling free-flowing,non foaming,non flammable chemicals because of low relative capital cost and flexibility of container size and geometry.This pesticide filling machine also can be used to efficiently fill both containers with small openings as well as large bulk containers with large openings.However,if the product is foamy,this pesticide filling machine may not be as efficient as the overflow filling for filling containers especially with small openings.

The pesticide filling machine is a full corrosion-protecting high-tech filler integrating in the PLC program control, photo electricity transuding and pneumatic. The machine is specially used in the liquid filling of strongly corrosion liquid and cosmetics which can’t touch the metal. The equipment’s all parts touching liquid are manufactured with the non-metallic corrosion protection material, and designed the descending filling function. Measurement accurate, there is not bubble and drool as filling.

Difference:

It integrates light, machine, electricity and gas into one body. Control feeding time is adopted to realize different metering and filling, the filling time can be controlled to one percent seconds. Filling process is under the control of the PLC program on the touch screen to complete. Imported brand filling valve, advanced technology, precision, filling and non drip phenomenon.

FEATURE

- The weighting system is from METTLER TOLEDO from Switzerland and USA, with high filling accuracy.

- The contact parts and exposed parts of the materials are made of high quality stainless steel material SUS304 & SUS316L.

- Each filling head has a weighing and feedback system that can fill each head. Filling for filling setup, adjustment and monitoring. Weighing sensors, proximity switches, etc. are all advanced sensing components, so that no barrels are not filled, the barrels are automatically stopped and alarmed.

- The anti-drip and anti-drawing filling nozzles to ensure that the liquid does not draw water and drip.

- Use PLC and human-computer touch screen control system: change specifications, filling volume adjustment, parameter setting, manual operation, etc. are evenly completed on the touch screen.

- Photoelectric sensing and pneumatic door control, lack of bottles, inverted bottles are automatically protected.

DATA SHEET

|

Filling heads

|

2

|

4

|

6

|

8

|

|

Suit to fill

|

Liquid like water or oil or semi-paste

|

|||

|

Filling range

|

1-5L/ 5-30L/ 30-200L

|

|||

|

Filling method

|

Gravity+ weighing filling

|

|||

|

Filling speed

(Bottles/ hour, based on 5L)

|

600-800

|

1200-1400

|

1600-1800

|

2000-2200

|

|

Filling error

|

±5g (Based on 5L)

|

|||

|

Power

|

220/380V 50/60Hz 1.5Kw (Can be tailor made to suit different countries)

|

|||

|

Air pressure

|

0.6-0.8Mpa

|

|||

|

Weight

|

400Kg

|

500Kg

|

600Kg

|

700Kg

|

|

Machine sid

( L*W*Hmm)

|

1800*1000*2200

|

2400*1000*2200

|

2800*1200*2200

|

3000*1200*2200

|

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586