High-quality stainless steel frames

International famous brand electrical components

Easily controlled by computer

Want A Free Consultation

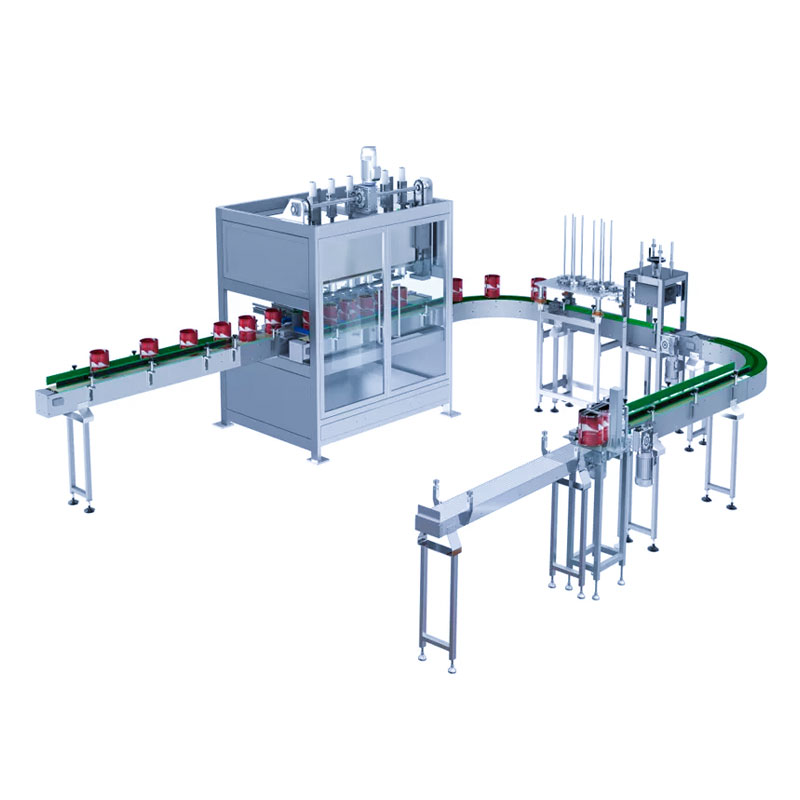

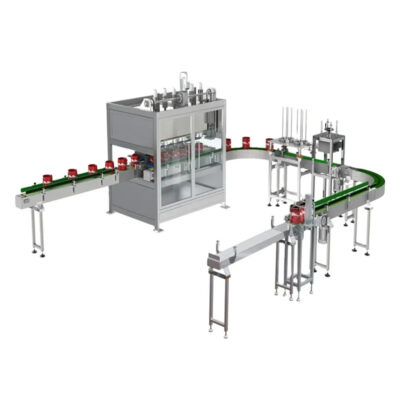

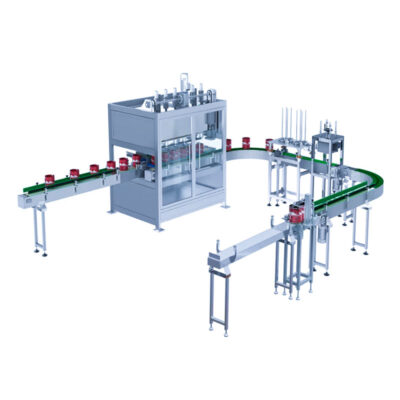

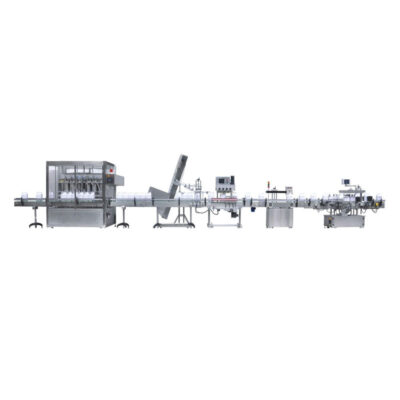

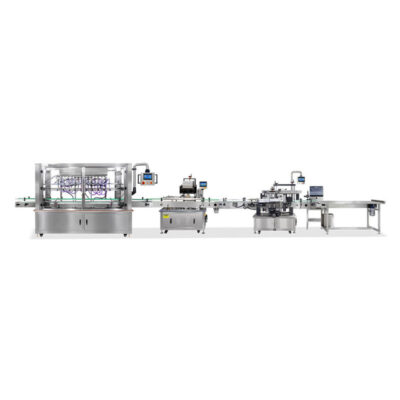

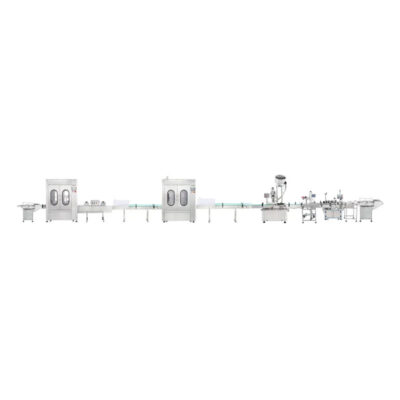

Liquid/Engine Oil/Paint Filling Machine For Cans/Buckets/Pails Automatic liquid filling line

AIPAK paint filling machine automatic liquid filling line is widely used in food and chemical industries.The paint filling machine ranges from simple single head units to high speed multi-head machines with cappers to suit. Built to the highest industry standards and used by many major companies world-wide, these machines can cater for a wide range of viscosities from paint to inks, water to mayonnaise, soft-gels, creams, oils etc.This automatic liquid filling line contains semi automatic, automatic in-line, pneumatic and electric servo drive volumetric fillers, weigh fillers and drum/IBC fillers. They are fast, accurate, reliable and flexible, and we can provide bespoke innovative filling solutions for special applications.

FEATURE

1.This paint filling machine automatic liquid filling line is specially made for bottles/jars/cans/buckets/jerry cans/drums filling of different products like juice,wine,spirit,soybean sauce,water,vinegar,edible oil,liquid fertilizer,lubricant oil,toilet cleaner,medium liquids,liquid drinks,other chemical and biology liquids in food,cosmetic, chemical industries.

2.The whole filling production line is consist of filling machines, capping machines, labeling machines. Bottle unscrambler machine, filling machine,capping machine,labeling machine, ink coding machine and packaging machine can be added as an option and combine freely.

3.The whole liquid filling production line is a full automatic system, PLC control, 7 inch touch screen operator, Simens, Schneider, Airtac, Omron world famous electric and pneumatic components.

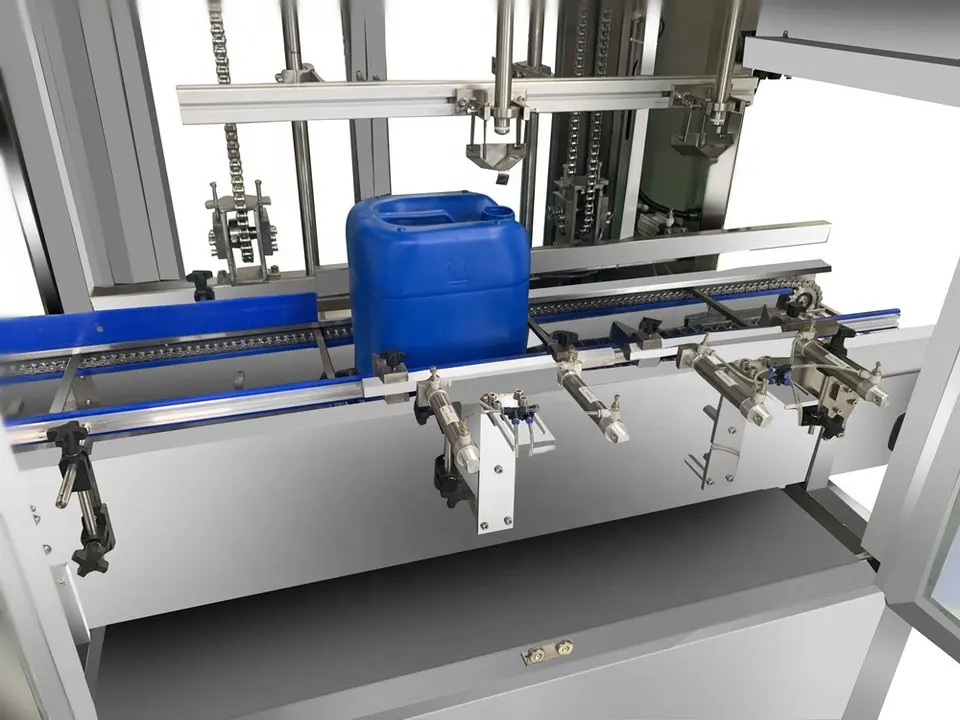

4.All the machines are made of good quality 304/316 stainless steel and alloy aluminum. If for corrosive products, anti-corrosion machines by PVC PP material can be customized.

5.Filling volumes can be adjusted easily in the touch screen. We use quick and fast joints for building the machines which is easy for dismentling the machines and maintenance,and convenient for cleaning.

6.The machines are with automatic liquid level control system for feeding, which is very high automation.

7.The filling nozzles are specially made for anti-drips with years of experience which prevent the products dripping on the bottles while filling.

8.Filling nozzles are customized depends on your capacity required,2 nozzles,4 nozzles,6 nozzles,8 nozzles,10 nozzles,12 nozzles are available.

9.Weighing filling, volumetric filling,gravity filling, flow meter filling available depends on different products.

- Capping machine can be adjusted for different sizes of caps, jerry cans, buckets, jars. Capping torque adjustable of magnetism.

DATA SHEET

|

Number of filling heads |

6 heads |

|

Filling capacity |

100-1000ml |

|

Filling form |

Multiple heads into bottle bottom fast or slow filling |

|

Filling speed |

16-35 bottles/hour based on 1L |

|

Filling accuracy |

±1% |

|

Cap putting form |

Elevator cap sorter feeding |

|

Capping form |

Servo grab and screw cap |

|

Capping speed |

50-60 bottles/minute |

|

Total power |

3KW, AC220V/380V, 50/60Hz |

|

Program control |

PLC+ touch screen |

|

Net weight |

600KG |

|

Materials of liquid contacting parts such as filling nozzle and chute: 316L # stainless steel and PVC pipe. |

|

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586