Liquid Capsule Filling Machine

Fast & Stable

Easy Operation & Low Maintenance

Want A Free Consultation

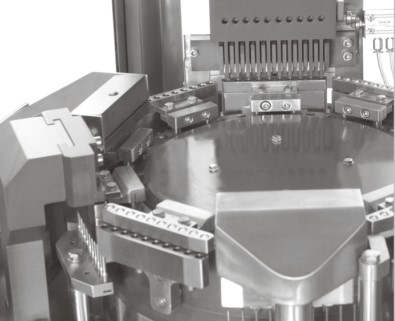

NJYF-300C Automatic Hard Capsule Liquid Filling and Sealing Machine production line

AIPAK NJYF-300C automatic hard-capsule liquid filling machine and sealing linkage line equipment are the first in-line equipment of our company based on our own multi-year capsule filling technology, self-developed design and production of hard capsule filling liquid and sealing. And exclusive proprietary intellectual property rights and a number of technical invention patents, the device can complete the filling of hard capsules (solution, suspension, microemulsion or hot solution) and sealing the capsule cap joint to make the capsule The contents are sealed in the process of packaging, transportation and use, which improves the stability and safety of the product. It can provide new modes of administration, improve the drug delivery problems of many drugs, and fill the domestic and foreign pharmaceutical and health care. The blank of hard capsule filling liquid and sealing technology in the product industry is also the gospel of many pharmaceutical companies and health care products factories for the development of some (highly active drugs, poorly soluble drugs) preparation products.

FEATURE

- The equipment adopts man-machine interface control system, which automatically lacks capsules and lacks material alarm.

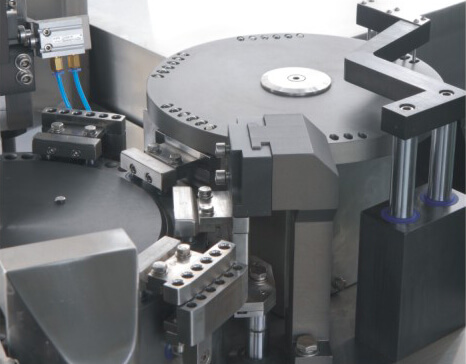

- The capsule feeding machine has a vacuum positioning and separating mechanism, so that the probability of the capsule is over 99%.

- The fiber is automatically detected, and the capsule is missing in the upper and lower mold holes.

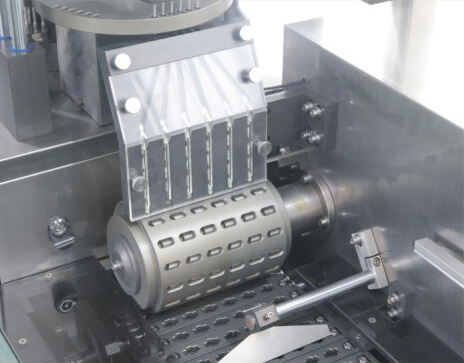

- High-precision ceramic pump and servo motor dosing system are adopted to control the difference of the loading amount to about ±2%, and the dosage is accurate.

- The sealing mechanism adopts the servo motor lifting device, which can be used to jog and fine-tune the rubber wheel to achieve the best effect of the sealing layer.

- The sealing liquid tank is designed as a sealing structure, and is equipped with a heating and heat preservation system to ensure the viscosity of the glue liquid and effectively extend the glue liquid period.

- The finished dry curing mold adopts hanging type and free rotation structure, which effectively improves the disassembly and unloading cleaning time.

DATA SHEET

|

Model |

NJYF-300C |

|

Yield |

18,000 capsules / hour |

|

Sealable capsule filling |

Solution, suspension, microemulsion |

|

Mold hole number |

6 holes |

|

Applicable capsule |

00-4# gelatin, plant capsule |

|

Environmental requirements |

Room temperature around 20C, humidity 40% -55% |

|

voltage |

Three-phase 380V/220V 50Hz |

|

Total power |

9KW |

|

Compressed air |

0.6Mpa |

|

Total weight |

2300KG |

|

Dimensions |

3800*900*1900MM (length × width × height) |

|

NJYF--300C Automatic hard capsule liquid filling and sealing machine linkage line Main electrical accessories, configuration list |

|||

|

Name |

Model |

Qty |

Brand |

|

touch screen |

6AV6 648-0CE11-3AX0 |

1 |

Siemens |

|

PLC programming controller |

6ES7288-IST60-0AA0 6ES7288-2DT16-0AA0 |

1 |

Siemens |

|

Frequency converter |

6SL32105BE215UV0 |

2 |

Siemens |

|

servo motor |

1FL6034-2AF21-1AA1 |

3 |

Siemens |

|

driver |

6SL3210-5FB10-4UA1 |

3 |

Siemens |

|

AC contactor |

3TB4322-0X 3RT6016-1AN21 |

4 |

Siemens |

|

Thermal overload relay |

3RU6116-1FBO |

3 |

Siemens |

|

Relay |

RXM2LB2BD |

13 |

Schneider |

|

switch |

ABL2REM24D65K |

1 |

Schneider |

|

Main motor |

S47 DRS80M4 |

2 |

SEW (Germany) |

|

Vacuum pump (dry) |

KRX5--P--V--03 |

1 |

Hollywang (Japan) |

|

cutting machine |

RU--83DS10 |

1 |

Daojin,Taiwan |

|

Detection fiber |

FD--33G |

12 |

Panasonic (Japan) |

|

Ceramic pump |

TC--01 |

6 |

Jiangsu Wuxi |

|

Linear Bearings |

LM10UU LM12UU LM20UU |

90 |

IKO (Japan) |

|

vacuum cleaner |

XCJ Series |

1 |

The company produces |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586