All Sizes of Capsule Available

High Productivity & Fully Automatic

High Efficient & GMP Standard

Want A Free Consultation

NJP-7500C Fully Automatic Capsule Filling Machine

NJP-7500C Fully automatic capsule filling machine is our company after years of careful research, independent research and development of a new hard capsule sealing equipment, and has independent intellectual property rights and a number of invention patents. The equipment can be used for sealing hard capsules filled (liquid, granule, powder, etc.) with glue, so that the products are always in a sealed state in the process of packaging.

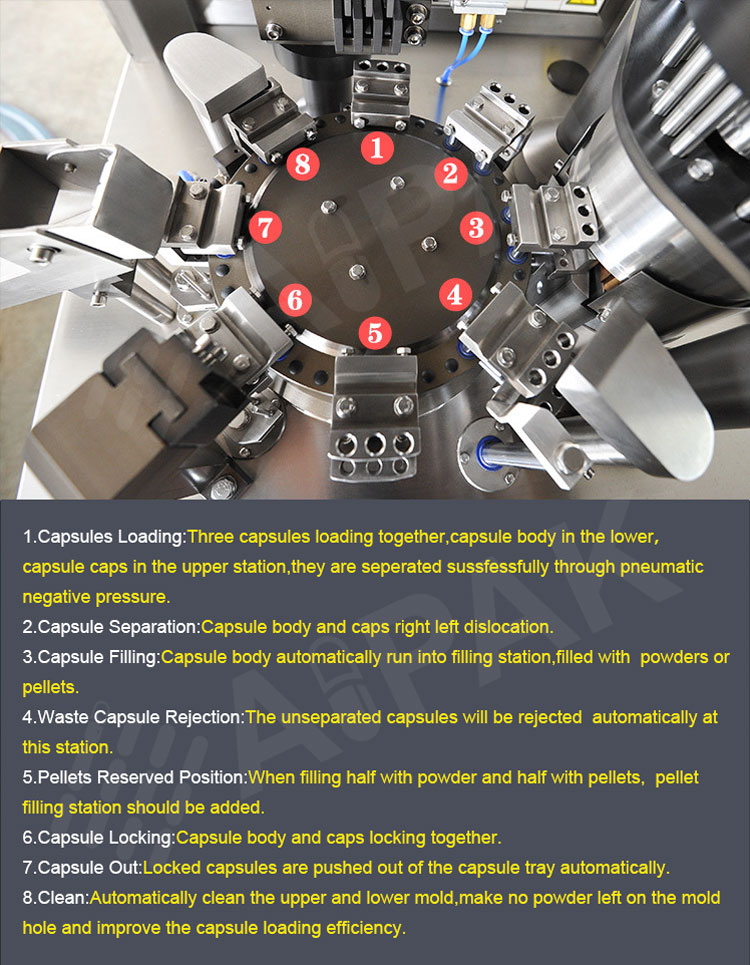

1.Automatic Capsule Filling Machine Working Principle

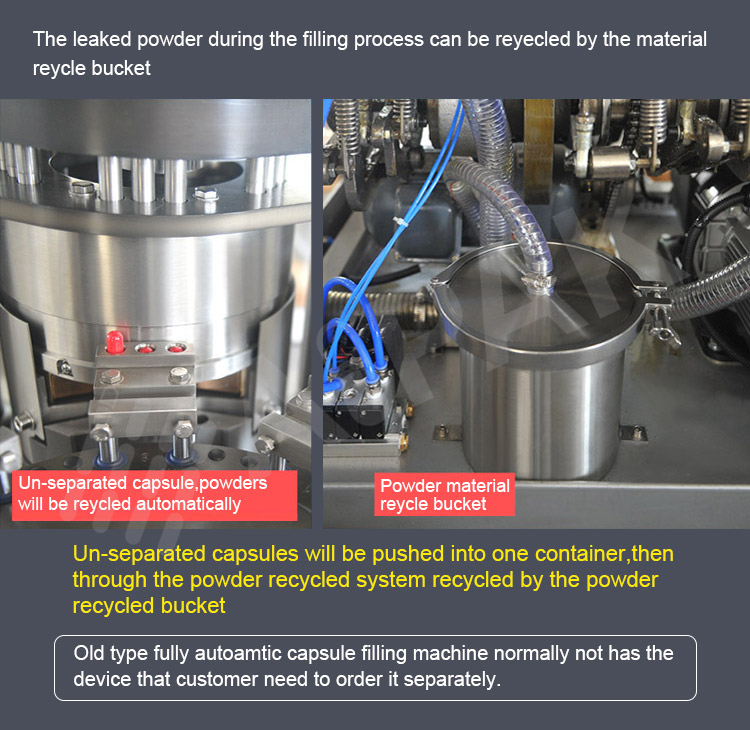

2.Automatic Capsule Filling Station

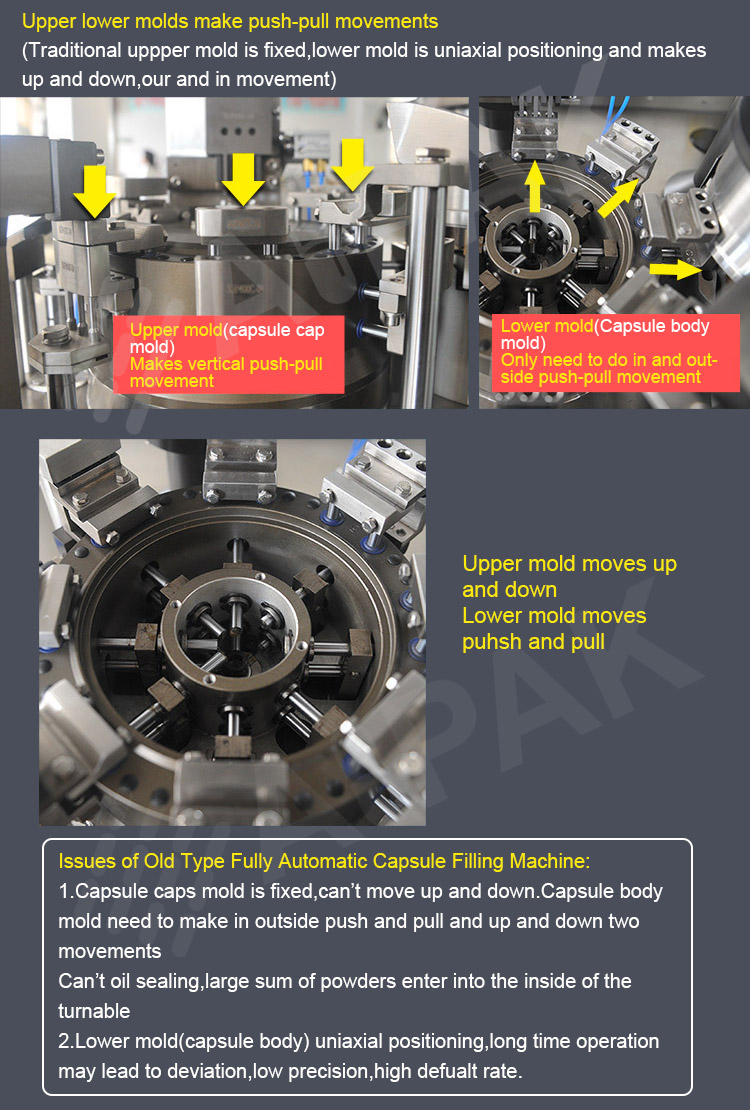

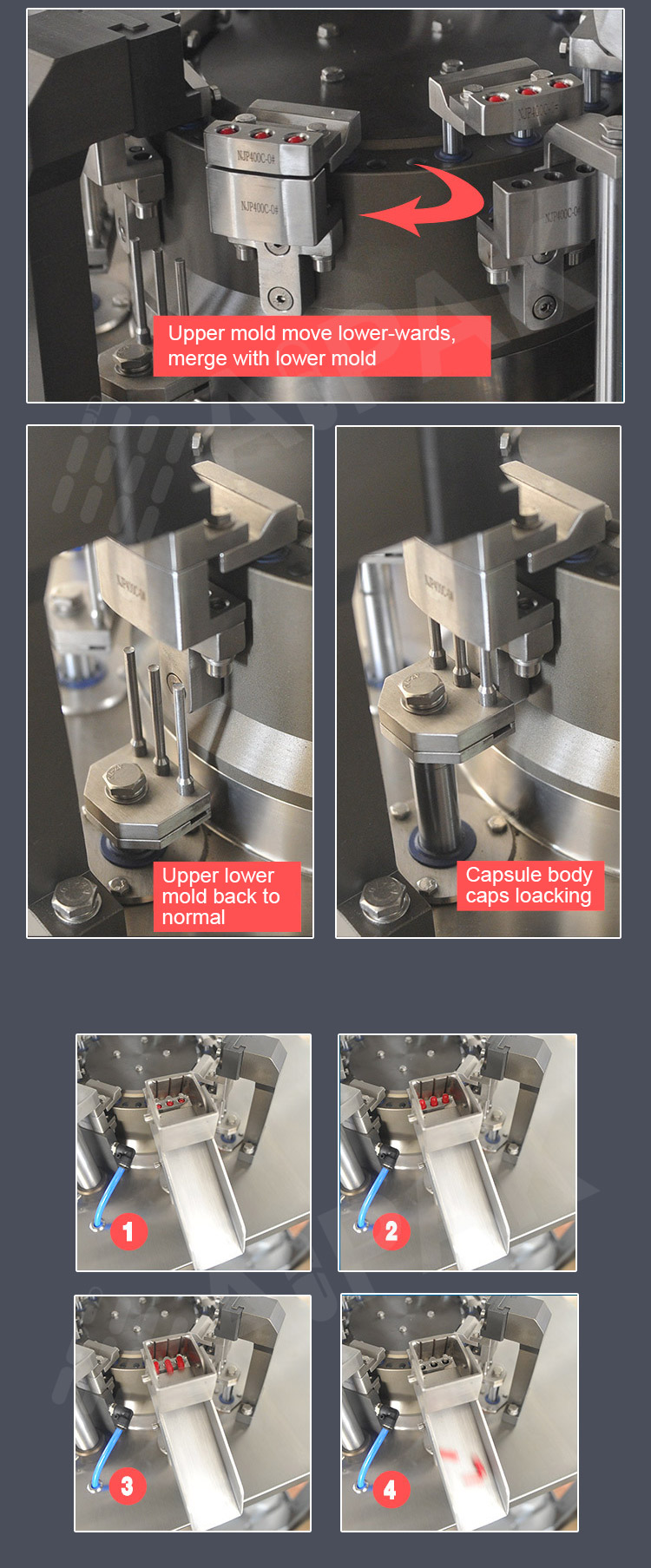

3.Upper Mold Movement

4.Double Shaft Double Oil Sealing

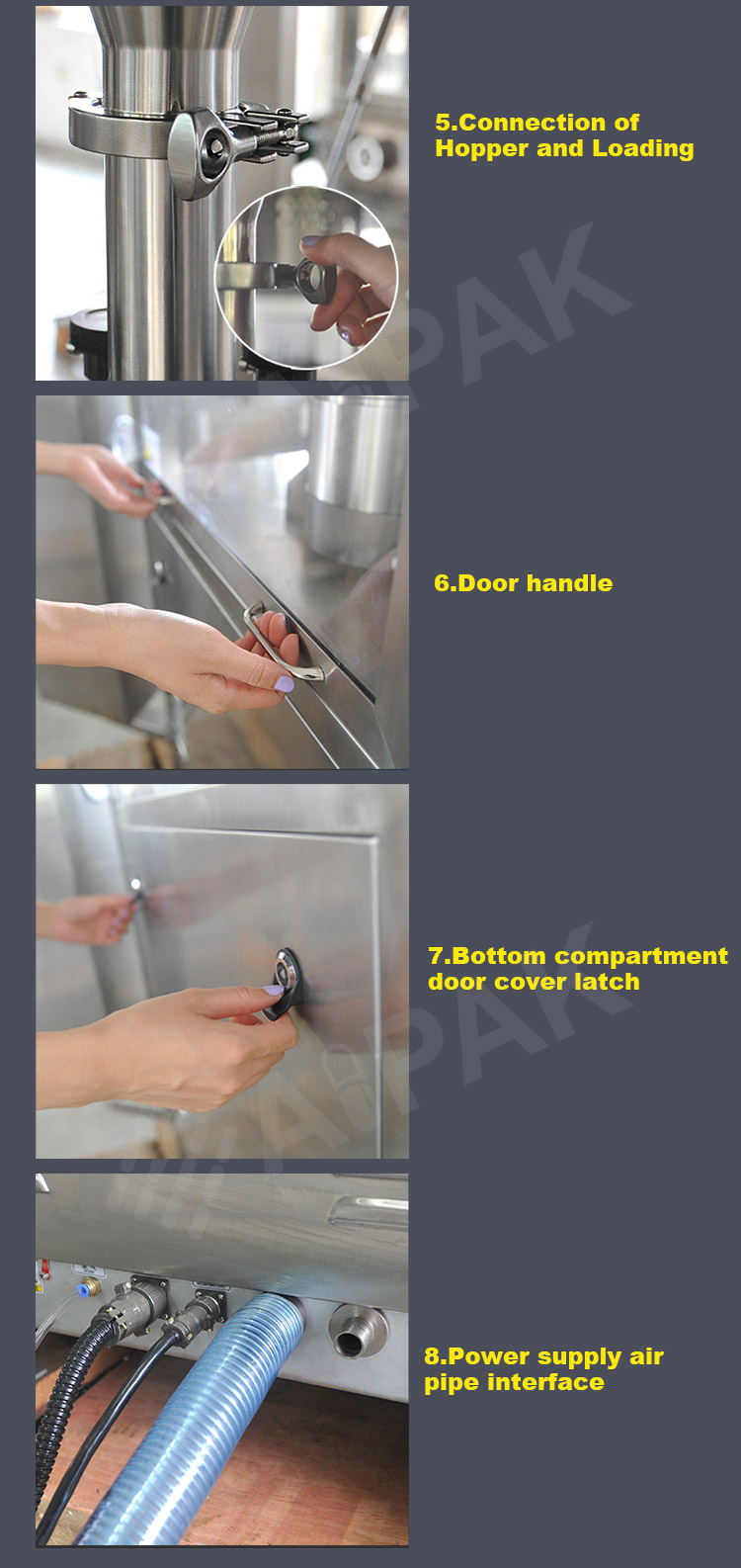

5.Loading Valve

6.Aviation Material

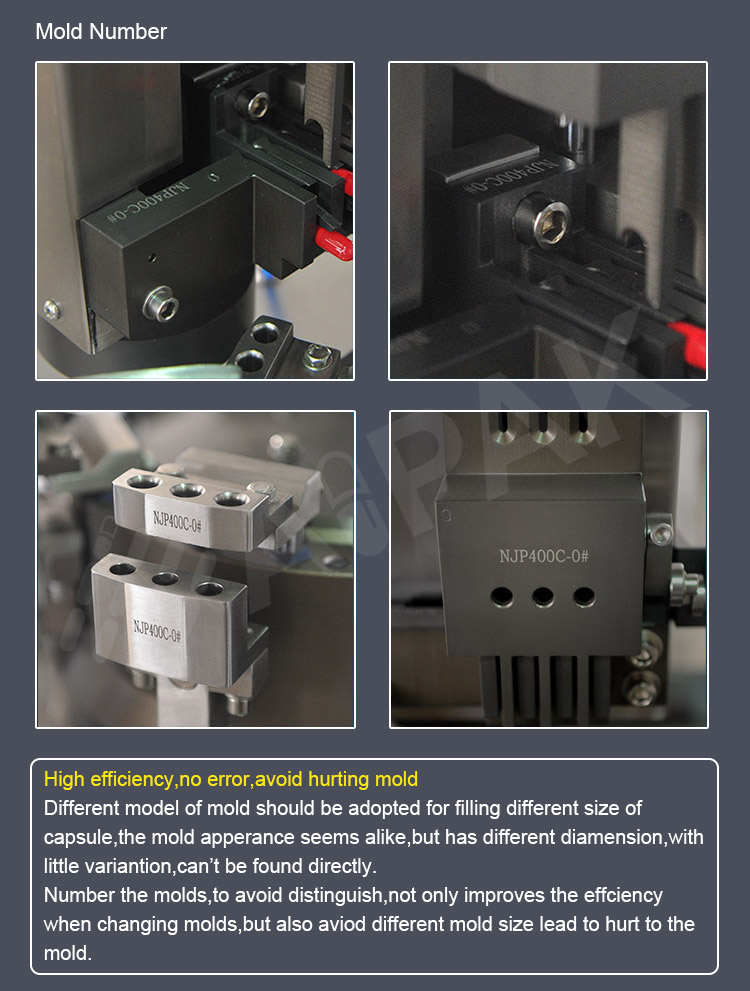

7.Mold No.

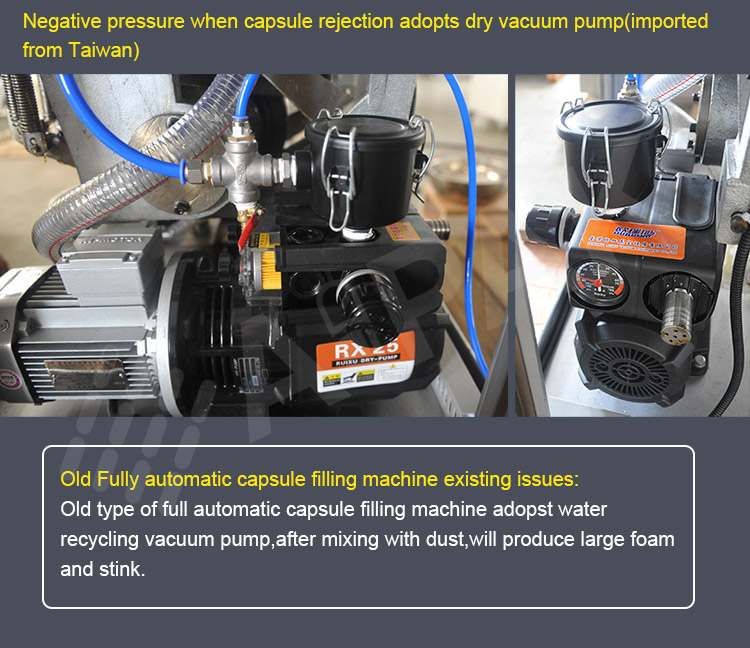

8.Dry Vacuum Pump

9.Safety

10.Specific Details

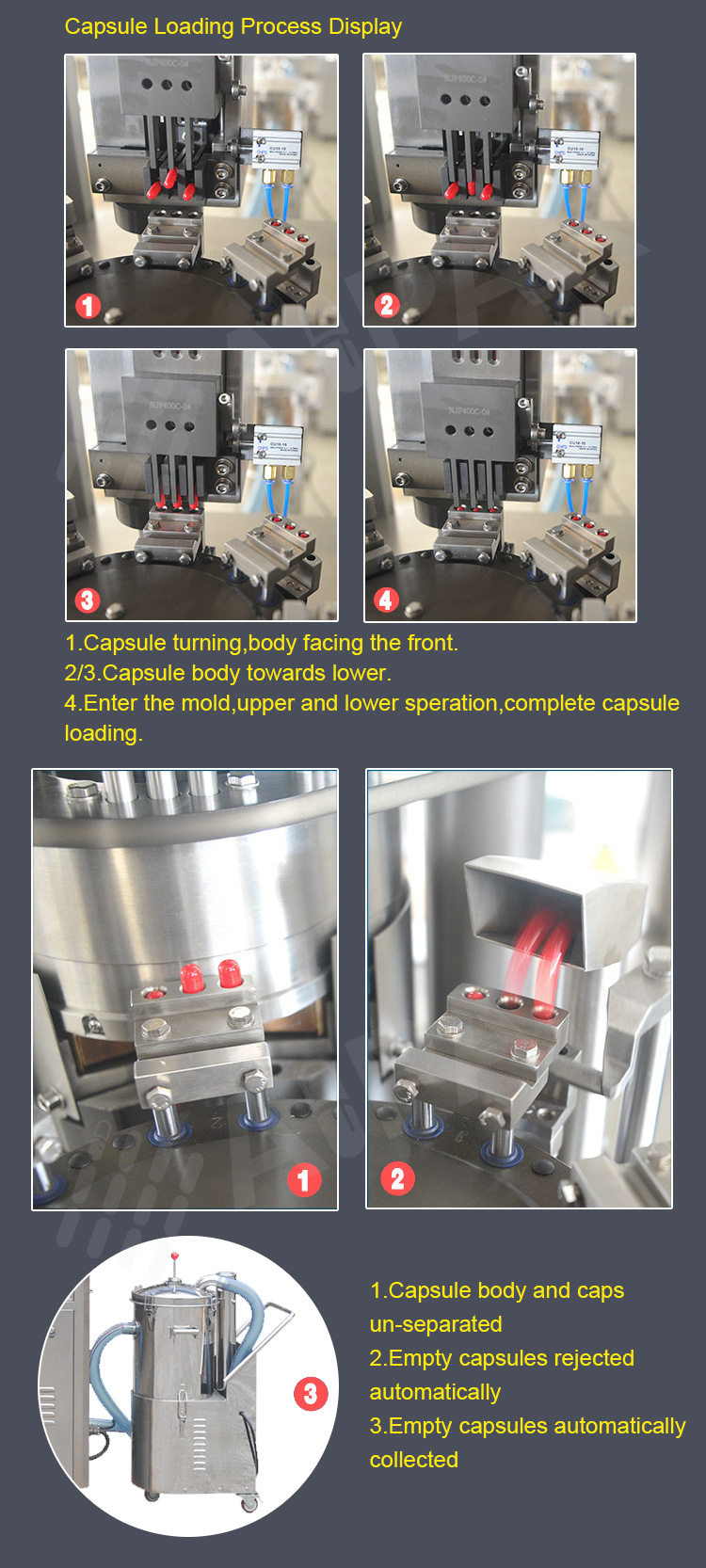

11.Capsule Filling Complete Process

12.Pellet Filling

13.What AIPAK Automatic Capsule Filling Machine Can

FEATURE

1. NJP-7500C is the equipment with the highest output in China;

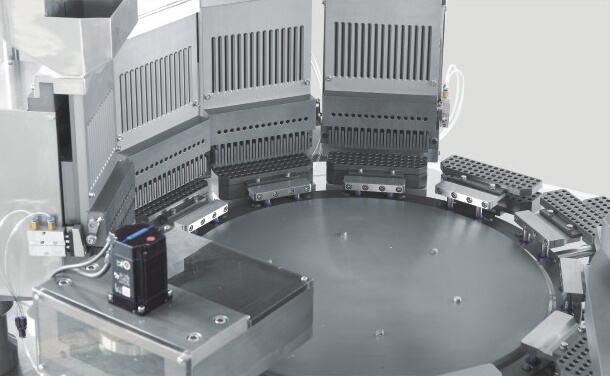

2. The equipment is fully enclosed, with 12 workers' rotary table and flling module arranged with 58 holes in four rows;

3. The whole machine is equipped with the automatic stop system of gate control and alarm, which can realize the function of electronic signature printing and industrial Ethernet connection;

4. The lower module has one-way movement with two shafts, and the imported polyurethane sealing ring prevents dust from entering the rotary plate;

5. The main engine is equipped with intelligent remote control,inching, test, easy to operate, to ensure personnel safety;

6. Automatic vacuum feeding and vacuum capsule can be installed,and the control system is operated by touch screen.

DATA SHEET

|

Model |

NJP-7500C |

|

Output |

46800 Granule/Hour |

|

Machine Weight |

3500Kg |

|

Machine Dimensions |

1450x1920x2400mm |

|

Power Supply |

380/220V 50Hz |

|

Motor Power |

14Kw |

|

No.of segment bores |

58holes |

|

Vacuum |

0.4-0.6Mpa |

|

Dust |

24.5Kpa 210m3/h |

|

Nosie |

<75DB(A) |

|

Making rate |

Empty capsule 99.9% Full capsule over 99.8% |

|

Suitable for capsule |

00#-5# |

|

Filling error |

±3%±4% |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586