All Sizes of Capsule Available

High Productivity & Fully Automatic

High Efficient & GMP Standard

Want A Free Consultation

NJP-400C Automatic Capsule Filling Machine

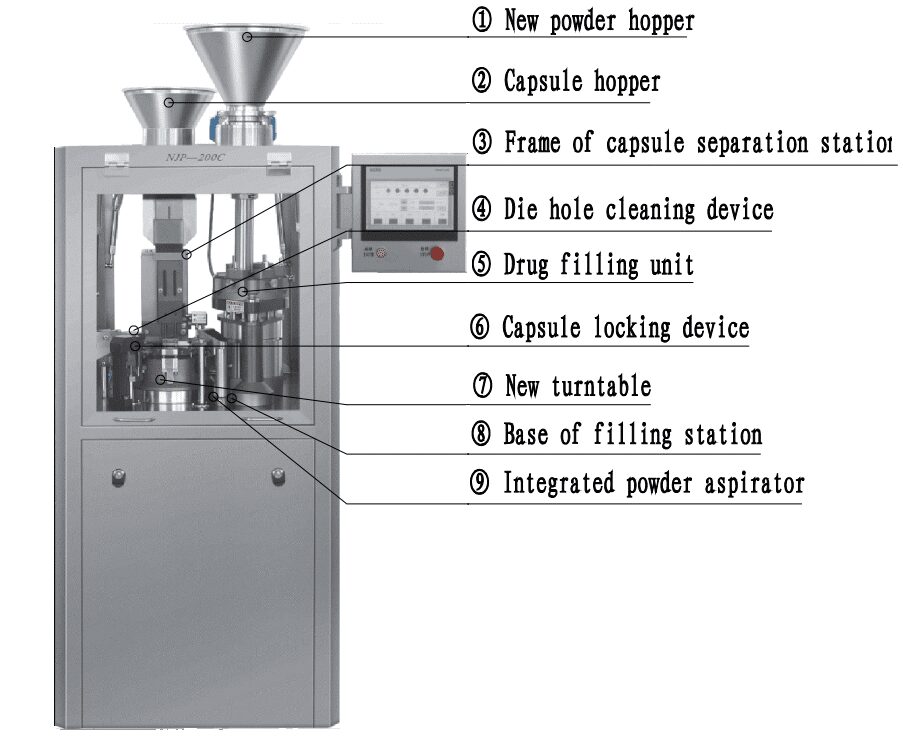

AIPAK NJP-400C automatic capsule filling machine, as a perfect upgrading alternative for semi-automatic capsule filling machine, has been widely used in hospitals, colleges, pharmaceutical research institutes and labs of big pharmaceutical enterprises.

Its new hopper adopts butterfly valve-type powder feeding, and is very suitable for drug powder with poor liquidity, including Chinese herbal medicine and Chinese patent drug, due to that its vibration unit equipped will force the powder to run down, which has solved problem of failing to feed in powder that often happens in the traditional screw feeding device because of the poor liquidity of powder.

The loading condition can be seen via the observation holes. When capsules are used up, the machine will sound an alarm and stop automatically.

Its newly designed frame of capsule separation station uses transmission of guide rail, enjoying higher precision and longer service life. Its closed design can prevent the defective capsule and dust from entering, ensuring a rapid and orderly capsule separation, as well as accurate capsule orienting.

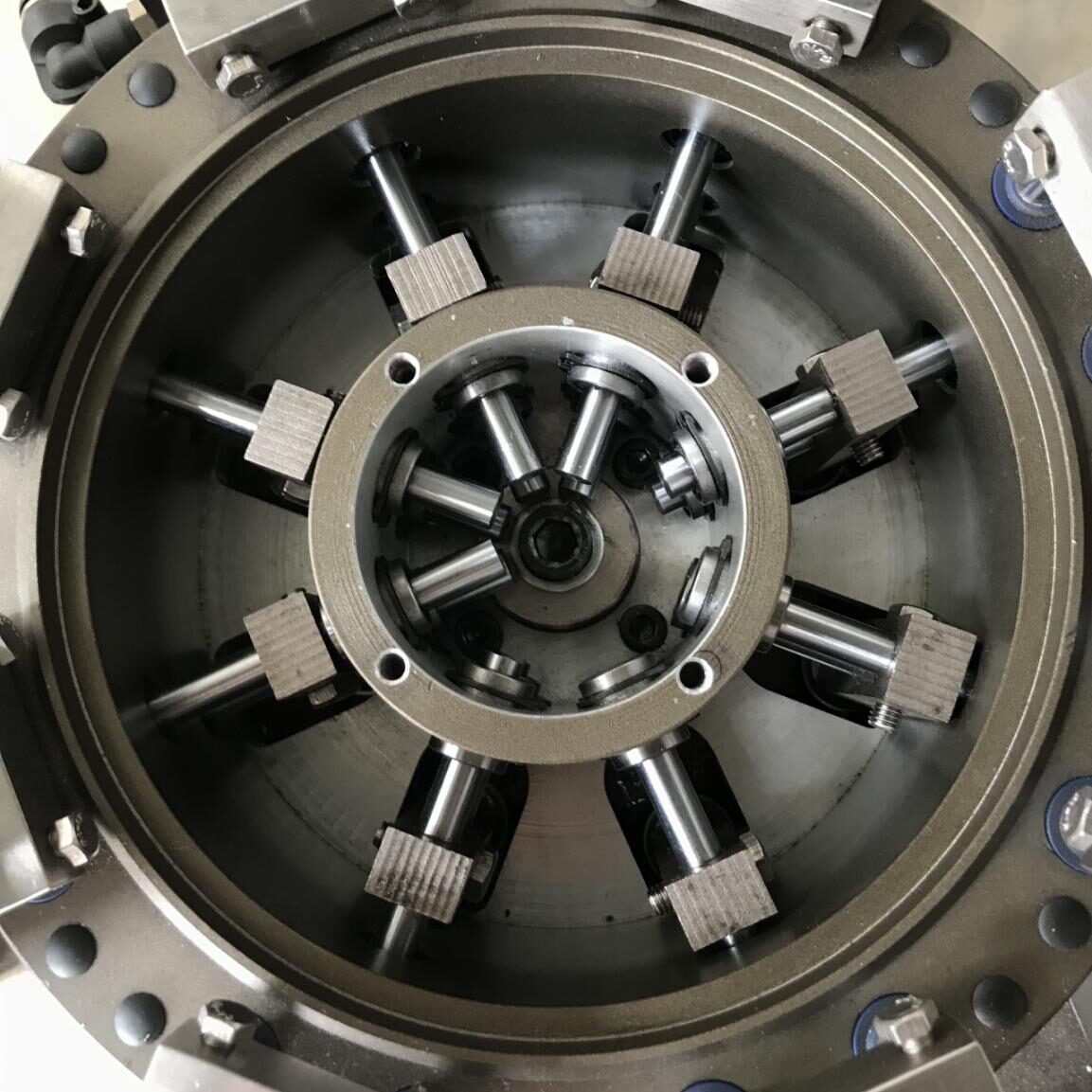

Its new rotary table is designed fully enclosed and with concept of modularization. Its super low station designed, equipped with imported Silicone ring, provides a very good anti-dust effect. It can prevent drug powder from entering the rotary table’s inner cavity, ensuring maintenance-free and lubrication charging-free for the inside part. It operates with high stability and accuracy, and meets the requirements of two-in-one filling process.

Modular design and positioning by pins for clamper of filling allow adjusting the filling dosage without need to stop the machine. The filling pipe of different size can be changed conveniently and rapidly.

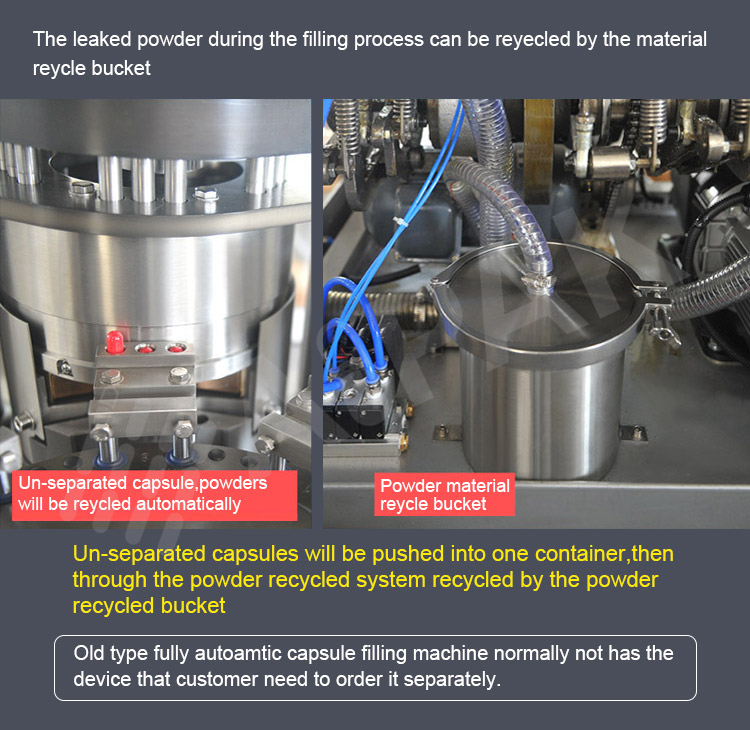

Its base of filling station is designed with negative pressure room, which is connected to the powder recycler. During the operation, any powder entering into the base will be inhaled into the powder recycler device by the negative pressure. The powder recycled will be used again after being filtered, preventing drug powder wasting and losing.

When the abnormal capsules are failed to be separated properly, powder entering the lower holes of filling station will be absorbed into powder aspirator by recycling device, completely stopping the powder from scattering onto the platform, avoiding drug powder wasting and losing.

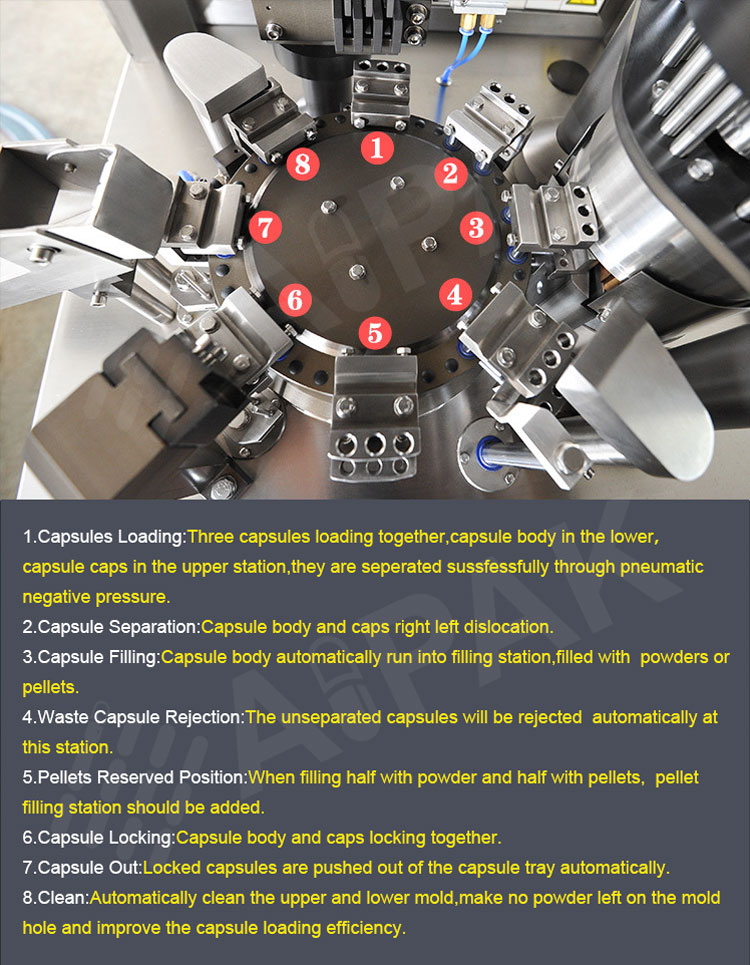

1.Automatic Capsule Filling Machine Working Principle

2.Automatic Capsule Filling Station

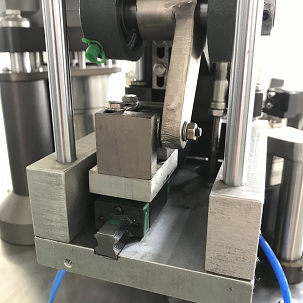

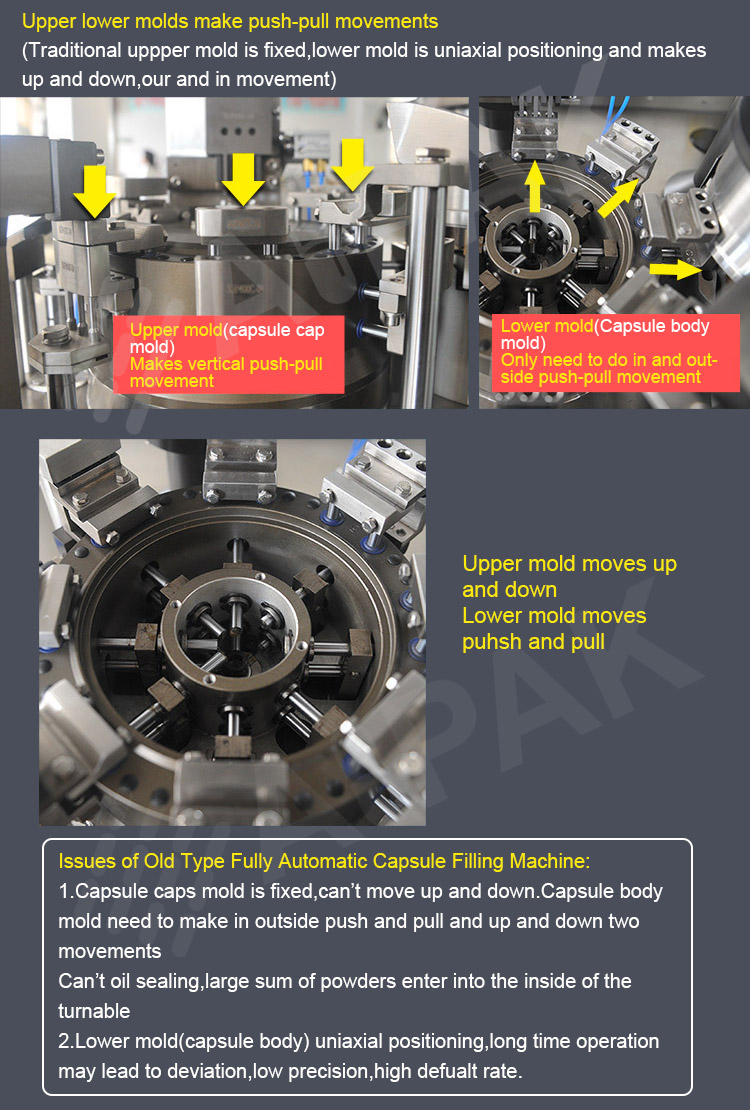

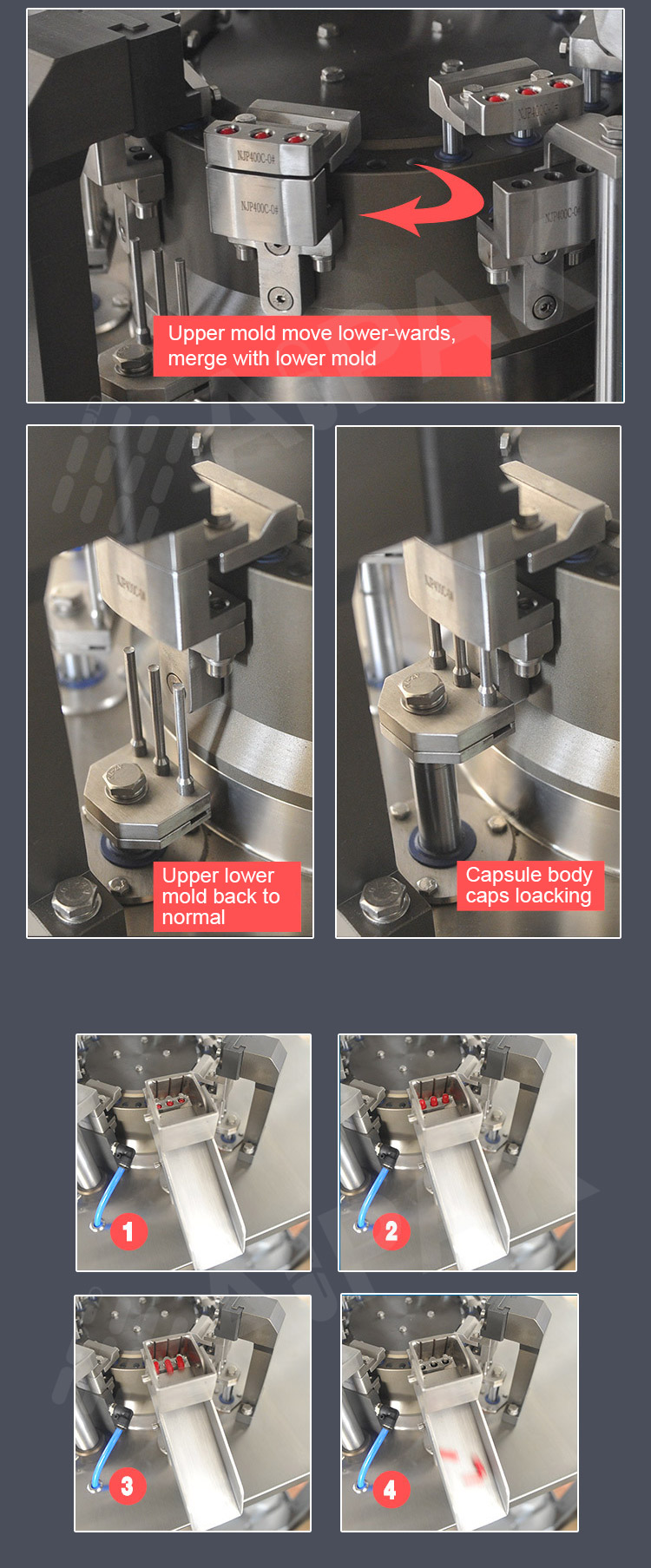

3.Upper Mold Movement

4.Double Shaft Double Oil Sealing

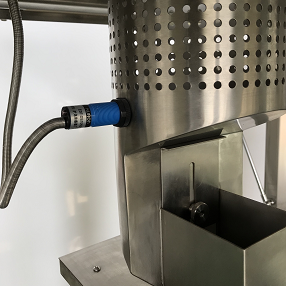

5.Loading Valve

6.Aviation Material

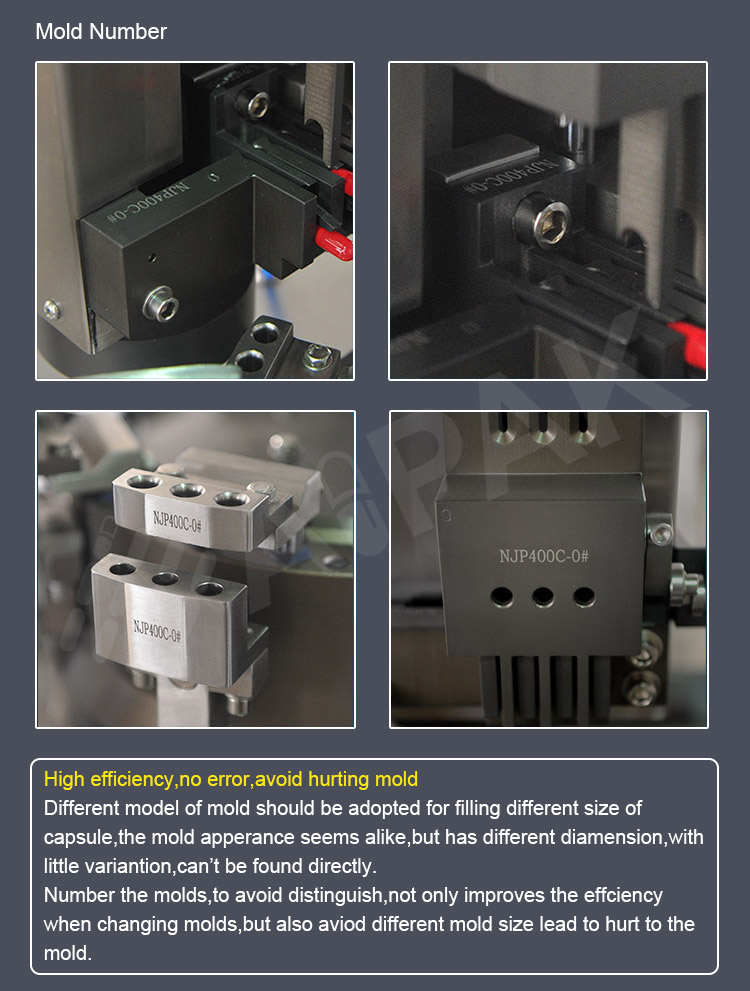

7.Mold No.

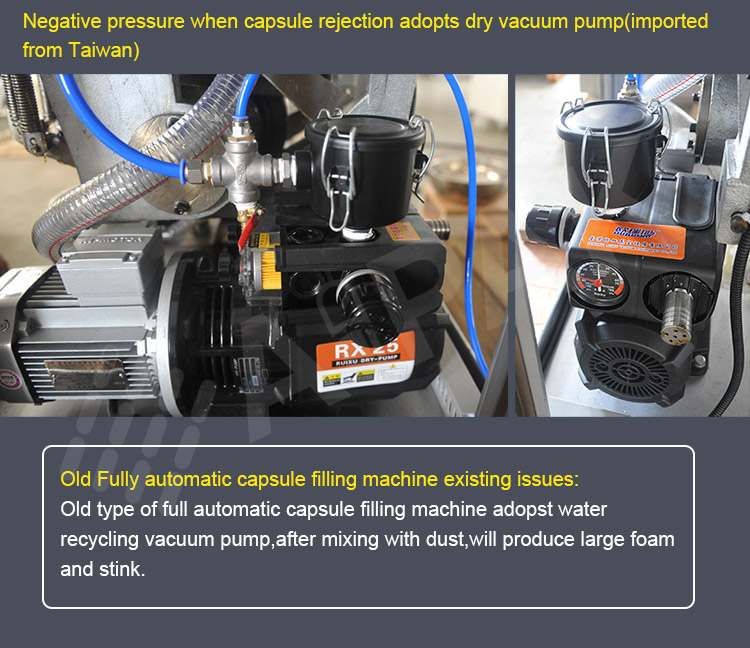

8.Dry Vacuum Pump

9.Safety

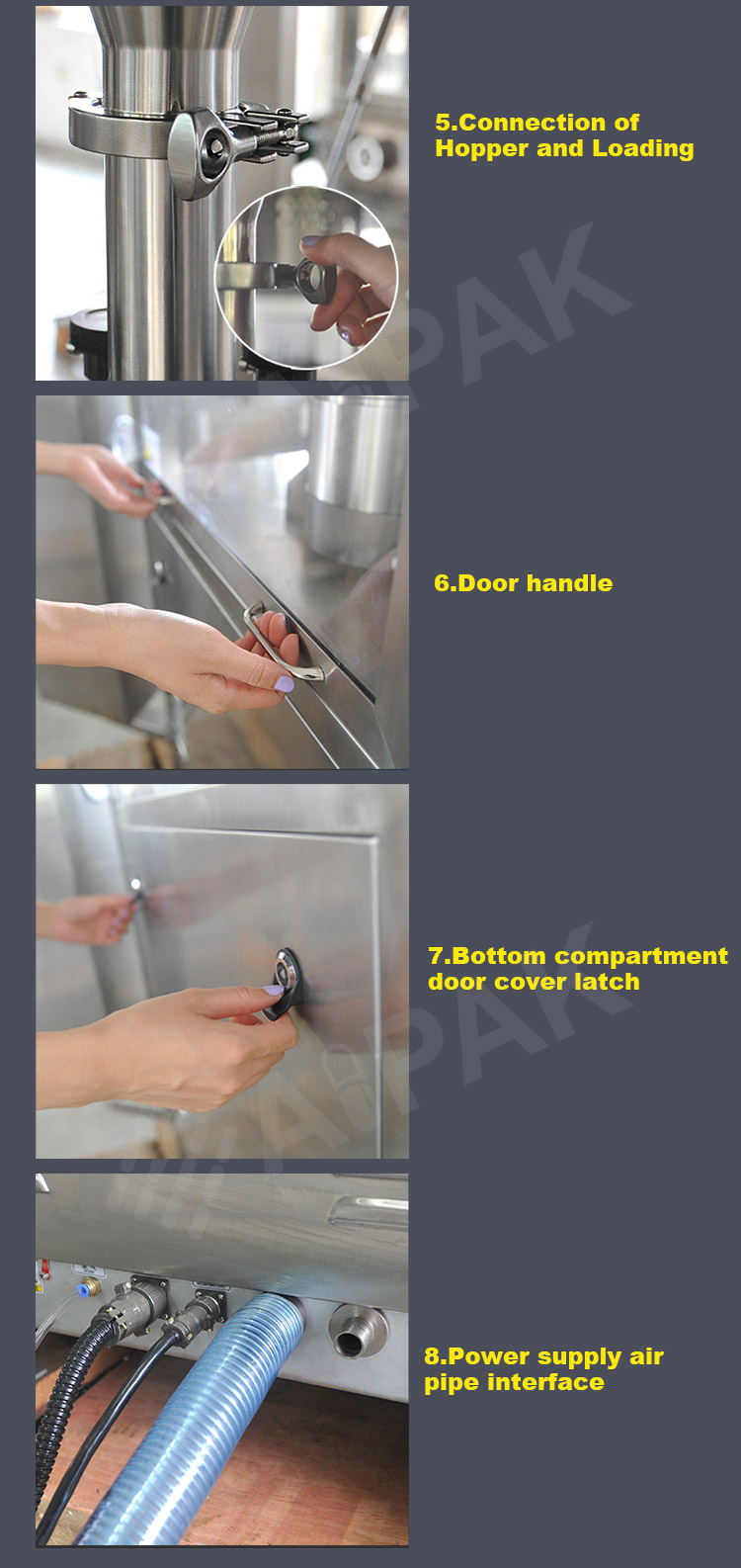

10.Specific Details

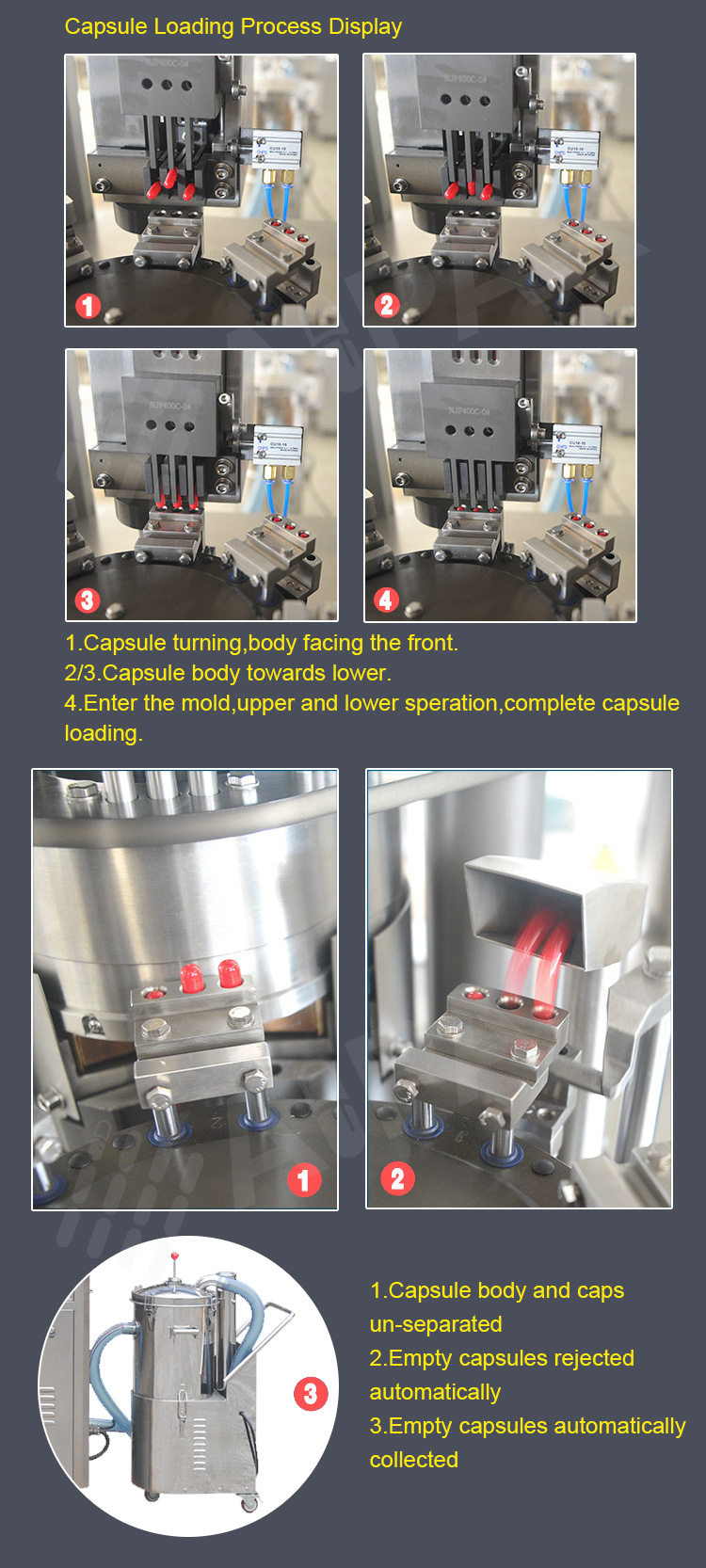

11.Capsule Filling Complete Process

12.Pellet Filling

13.What AIPAK Automatic Capsule Filling Machine Can

FEATURE

- Small in size, light in weight, energy savings, easy to operate and clean.

- Opening and locking of capsule can be controlled automatically which is safe and convenient.

- Equipped with inching control system, which makes it easy and convenient for cleaning, loading and unloading of upper and lower dies.

- Equipped with gate control security system and mechanical failure security system, which provides functions of automatic alarm and shutdown.

- Automatic alarm and shutdown will be activated when lacks empty capsule or powder.

- Rich functions designed on the HMI, including counting and displaying functions during the production, and it is able to link with printer, if needed, for printing information including date of production, lot number, quantity, etc.

- The plane cams are running in the mode of double rails, where the two axes run out separately. It can improve the operation accuracy and meanwhile eliminate the possibility of collision between the lower die and the dosage disc.

- The high precision cam splitter uses optical dividing head of German Zeiss. The dividing spindle is machined in the CNC all at once, which has ensured accuracy dividing of the turntable and dosage disc while the machine runs fast, thus ensuring the precision of filling. Higher precision of cam splitter also provides the machine longer service life.

- The operating cams are all processed with 20crmoti carburizing and quenching treatment, and then machined in CNC grinding machine all at once, which has ensured the accuracy and unity of the cams and provided a longer service life.

DATA SHEET

|

Model |

NJP-400C |

|

Filling capacity |

24000pcs per hour |

|

Weight |

600Kg |

|

Dimension |

1000×710×1900mm |

|

Power supply |

380/220V 50Hz |

|

Total power |

3KW |

|

Segment bores |

3 holes |

|

Vacuum |

20m3/h-0.04-0.08Mpa |

|

Dust collector |

17.6Kpa 180m3/h |

|

Air compression |

Air consumption 4m3/h Pressure 5-7Kg |

|

Operating noise |

<75DB(A) |

|

Filling percentage |

Empty capsule 99.9% filled capsule 99.8% |

|

Capsule size |

00,0,1,2,3,4,5# safety capsule A-E |

|

Filling accuracy |

Western medicine ±3% Chinese medicine ±4% |

|

Suitable for |

Powder, Granule, Pellet, Tablet. |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586